Oil extraction method

A technology for oil reservoirs and crude oil, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., which can solve problems such as fast advance, difficult on-site control, and high risk of fire lines breaking into horizontal wellbore, so as to expand the affected area and reduce the The risk of capital investment and the effect of wide application range of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

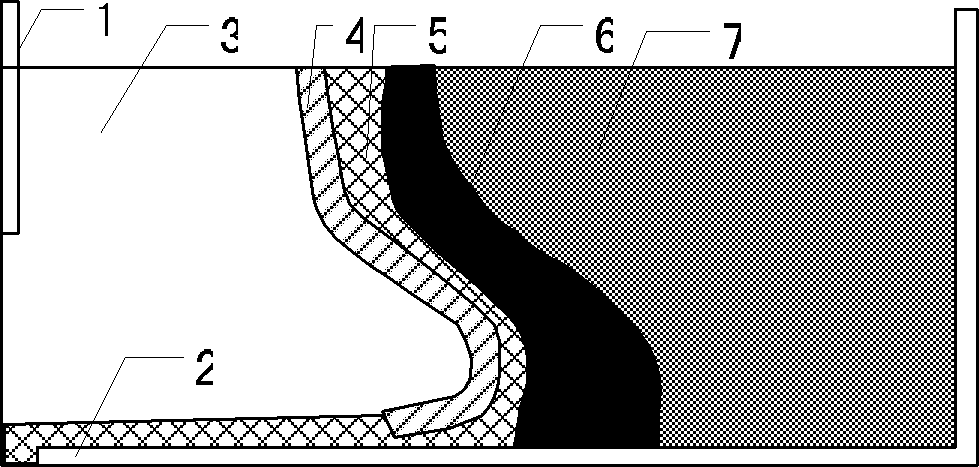

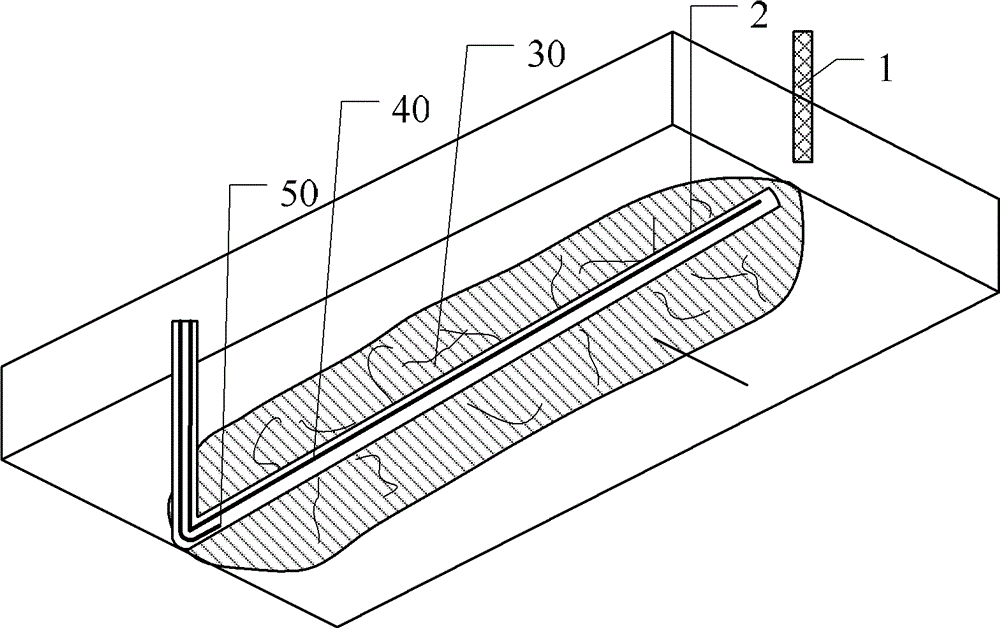

[0043] In the numerical simulation study of oilfield blocks, the model made a comparison between those without horizontal fractures and those with horizontal fractures. Basic reservoir parameters: porosity 30%, oil saturation 75%, permeability 2000md, oil layer thickness 10m, crude oil degassing viscosity at reservoir temperature 500000mPa.s. Injection-production parameters in preheating stage: bottom hole dryness 75%, maximum steam injection pressure 4.0MPa. Gas injection parameters in the ignition stage: the bottom hole injection air temperature is 480°C, and the daily air injection is 5,000 cubic meters.

[0044] Basic parameters of well pattern: horizontal well length 200m, horizontal well spacing 100m.

[0045] Basic parameters of fractures: Research shows that the permeability of fractures is generally several hundred to several thousand darcies, and the fracture width is generally 4-10mm. Considering that the minimum grid of the numerical simulation model is 0.2m, the ...

example 2

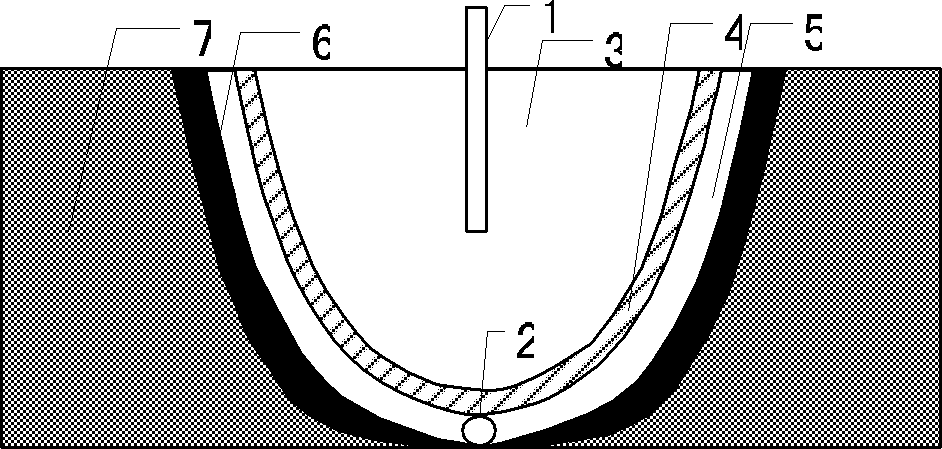

[0049] The depth of a certain reservoir is 200m, the thickness of the oil layer is 10m, the horizontal permeability of the oil layer is 2000md, and the temperature of the oil layer is 18°C; the degassed viscosity of crude oil at the reservoir temperature is 500000mPa.s, the oil saturation is 75%, and the dip angle of the oil layer is 6°. Injection-production parameters in preheating stage: bottom hole dryness 75%, steam injection pressure 3-4MPa, daily steam injection 70-80 tons per day. Gas injection parameters in the ignition stage: the temperature of the air injected at the bottom of the well is above 480°C after being heated by an electric igniter, and the daily air injection is 3000-4000 cubic meters.

[0050] Basic parameters of the fracture: the width of the fracture is 4-10mm, and the maximum fracture radius is 40-50m.

[0051] 1) Screening according to the characteristics of the reservoir, in line with the screening criteria for fracturing single horizontal well fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com