Patents

Literature

251results about How to "Reduce investment risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for transferring patterns on fiber fabric

InactiveCN102797172AReduce investment riskLess investmentTransfer printing processDyeing processTextile printerFiber

The invention relates to a printing method of fabrics, and in particular relates to a method for transferring patterns on a fiber fabric. The method comprises the steps of (1) coating a transfer layer: coating a prepared coating adhesive on a film or paper by a photogravure press or a coating machine so as to form the transfer layer on the surface of the film or the paper, drying, and then printing the surface of the transfer layer by utilizing dye base ink to prepare a transfer printing film or transfer printing paper; (2) starching the fiber fabric: coating fixation slurry for transfer printing on the surface of the fiber fabric; (3) transferring the patterns; and (4) evaporating and fixing: after the transfer, stripping the transfer printing film or the transfer printing paper, drying, evaporating and fixing the fiber fabric. According to the method, the difficulties that the dye base ink can not be directly printed on the film, and the transfer rate of the dye on the paper is not high can be solved, and also the transfer layer, the dye, the film and the paper with an isolation layer are not compatible, so that more than 98% of dye can be transferred, and the transfer rate and the color rate of the printing are improved greatly.

Owner:沈翰宇

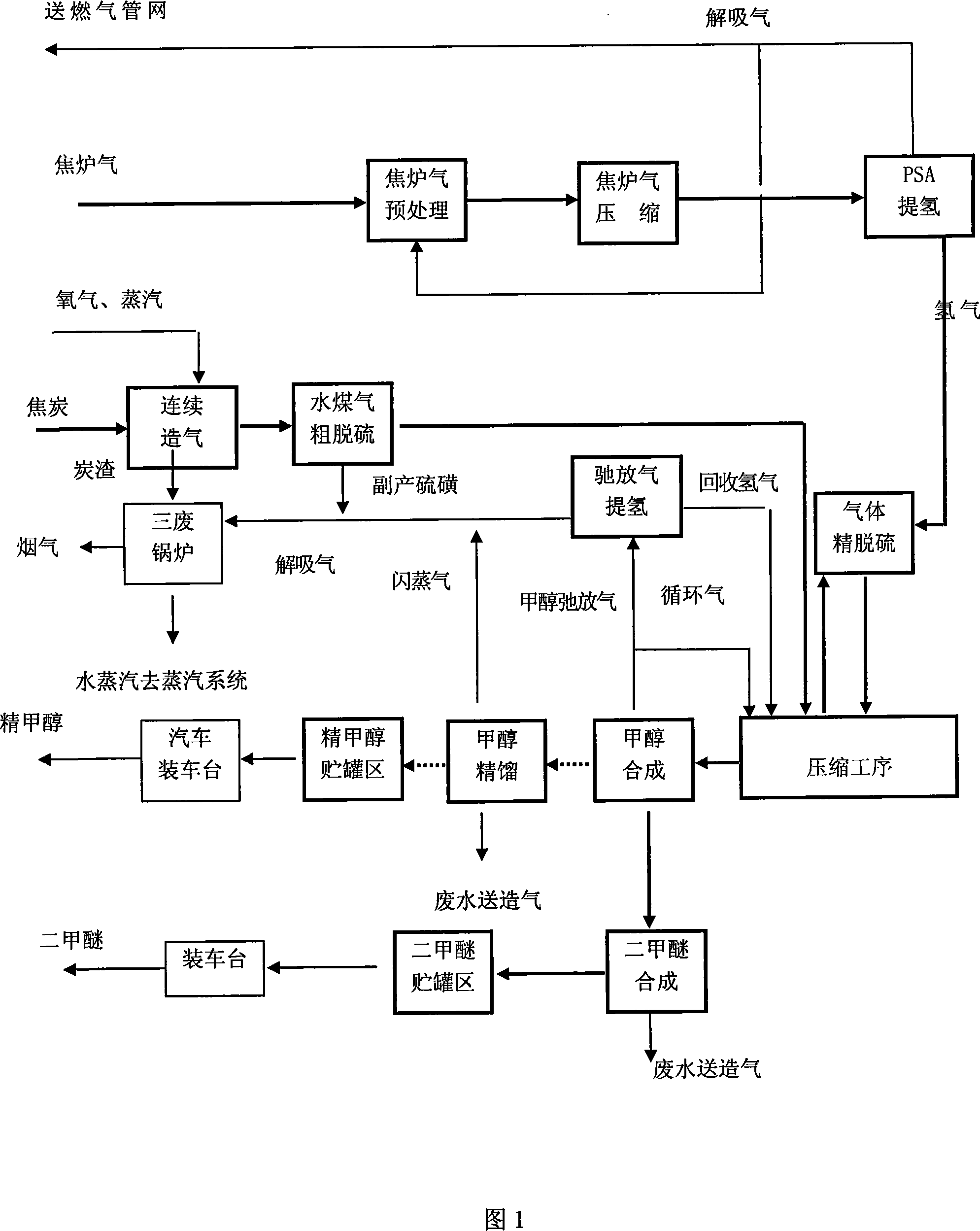

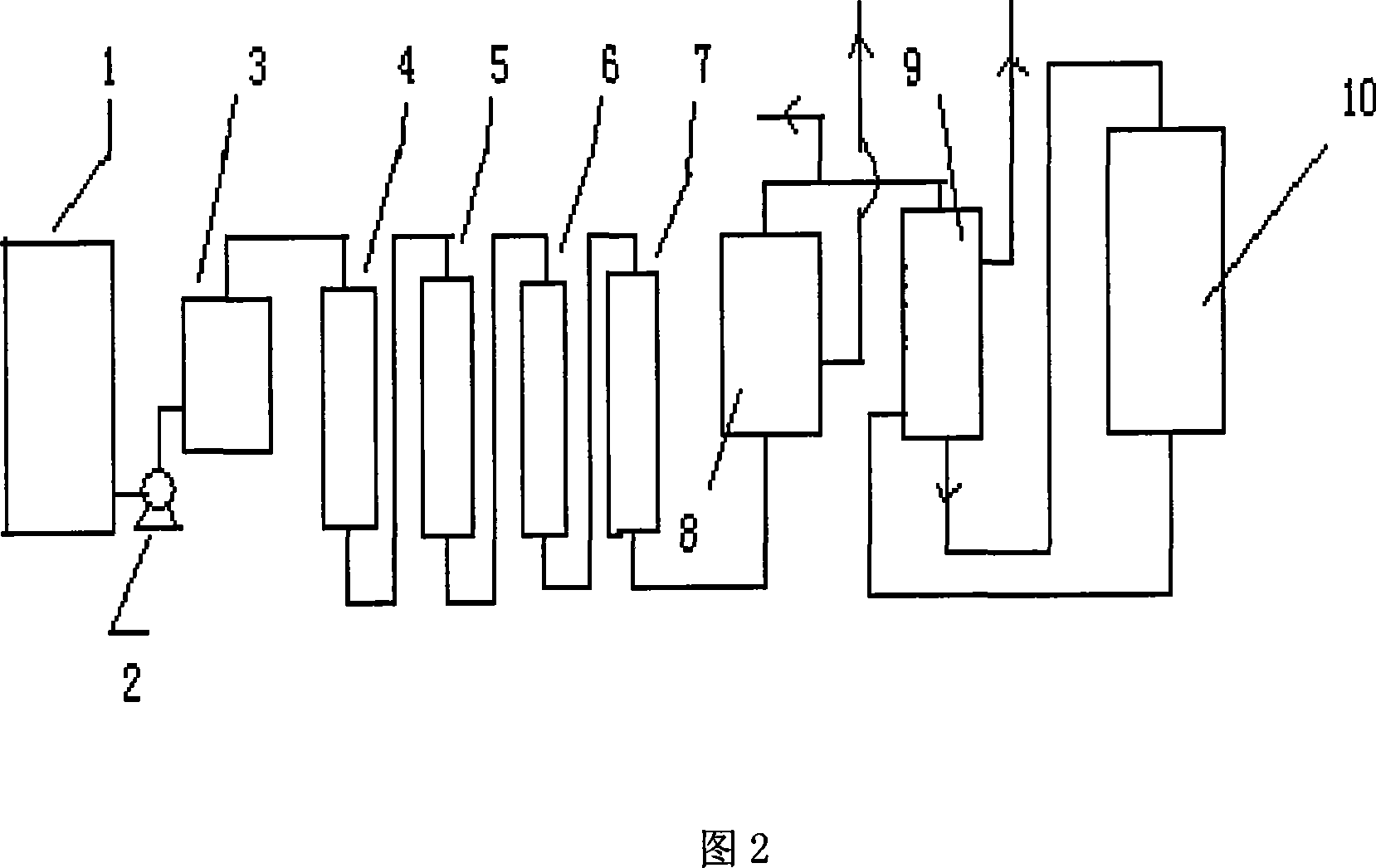

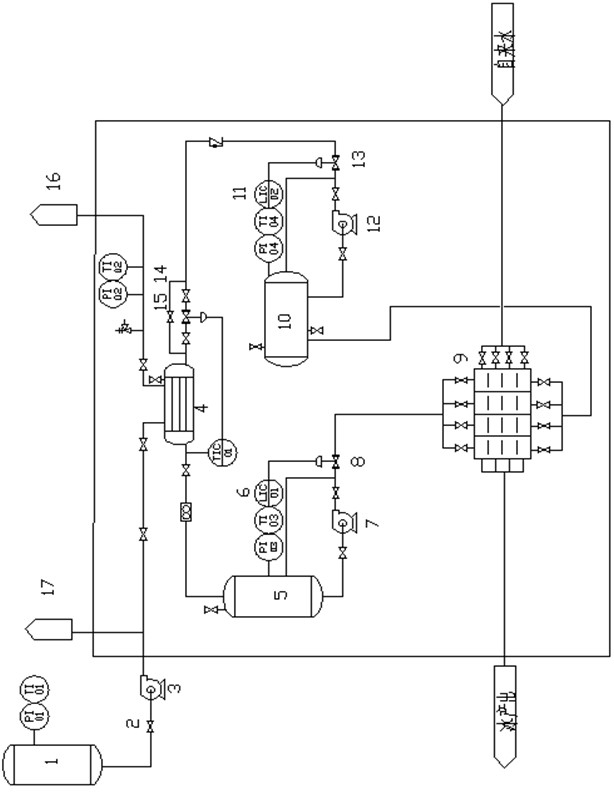

Method for producing alcohol ether fuel from hydrogen prepared from coke oven gas and synthesis gas prepared from scorched particles

InactiveCN101125796AReduce pollution and waste of resourcesReduce equipment investment and operational riskOrganic compound preparationHydroxy compound preparationChemistryEther

The invention discloses a manufacturing method of alcohol ether fuel which is produced by synthesis gas while the synthesis gas is produced by hydrogen and scorched particles collaboratively, and the hydrogen and scorched particles are made by coke-oven gas. The method comprises the processes of gas making, rough decoking, fine decoking, pretreatment of coke-oven gas, adsorption and extraction of hydrogen through transformation, methyl alcohol synthesis and methyl alcohol rectification, the alcohol ether fuel is made after the processes. The invention makes use of abandoned scorched particles to prepare water gas and takes advantage of PSA technique to extract hydrogen in coke-oven gas, and alcohol ether fuel is synthesized after adding water gas. Furthermore, the rest materials with higher thermal value are returned to a coke oven to be used as fuel, thus, coke-oven gas firstly is avoided to be blown down and environment pollution and resource waste are reduced; secondly, a single transforming process for preparing methyl alcohol by coke-oven gas, equipment investment and operation risk are avoided; thirdly, the processes of carbon monoxide conversion and decarburization are reduced so as to ensure the integrative use of carbon resources in the system, pyrogenic gas is used rationally and effectively and cost and operation difficulty of methyl alcohol is reduced so as to guarantee the continuous and steady run of system and realizing a plurality of advantages of environmental improvement, rational use of resources, reduction of cost, reduction of working procedure.

Owner:TOWN STAR IND +1

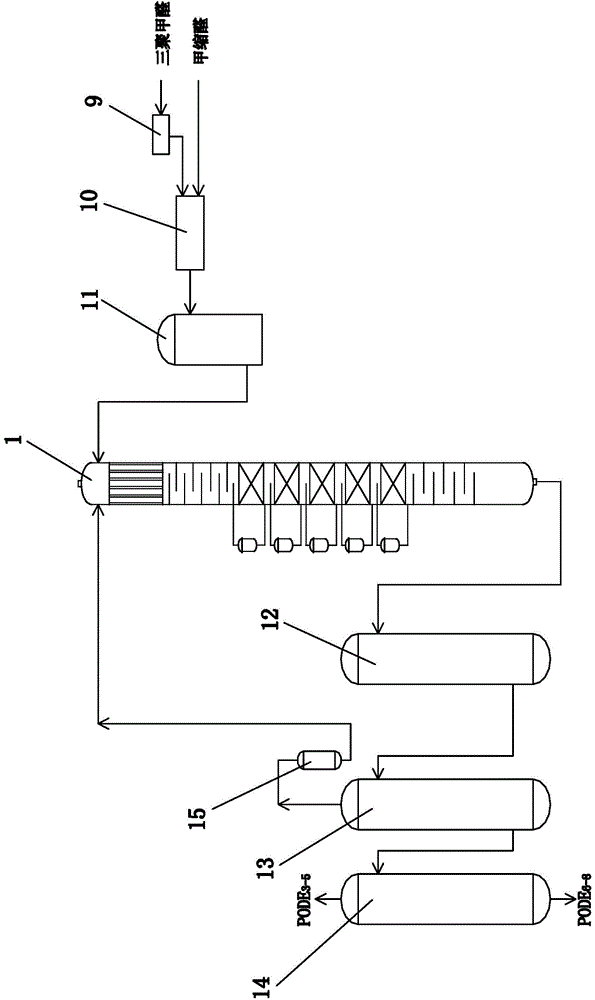

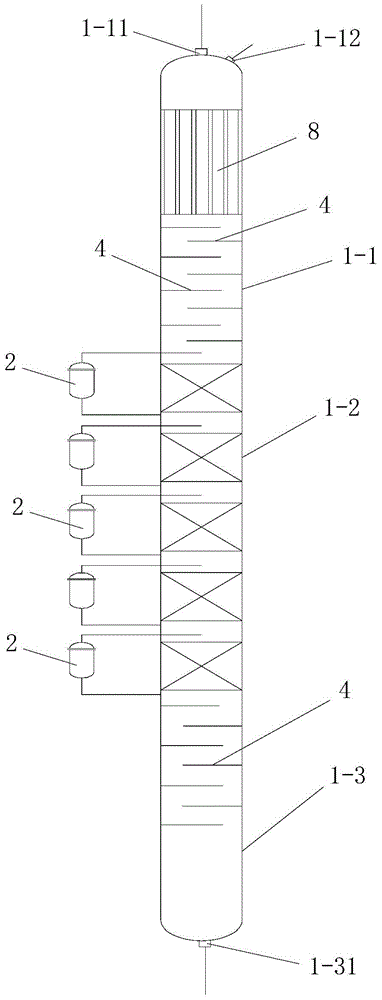

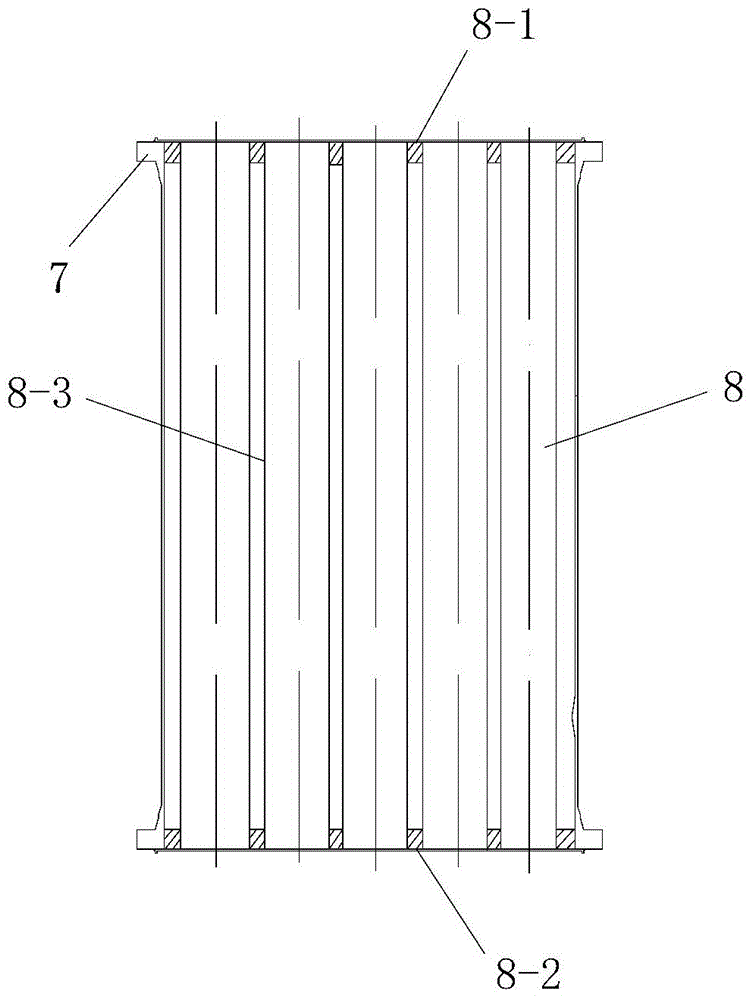

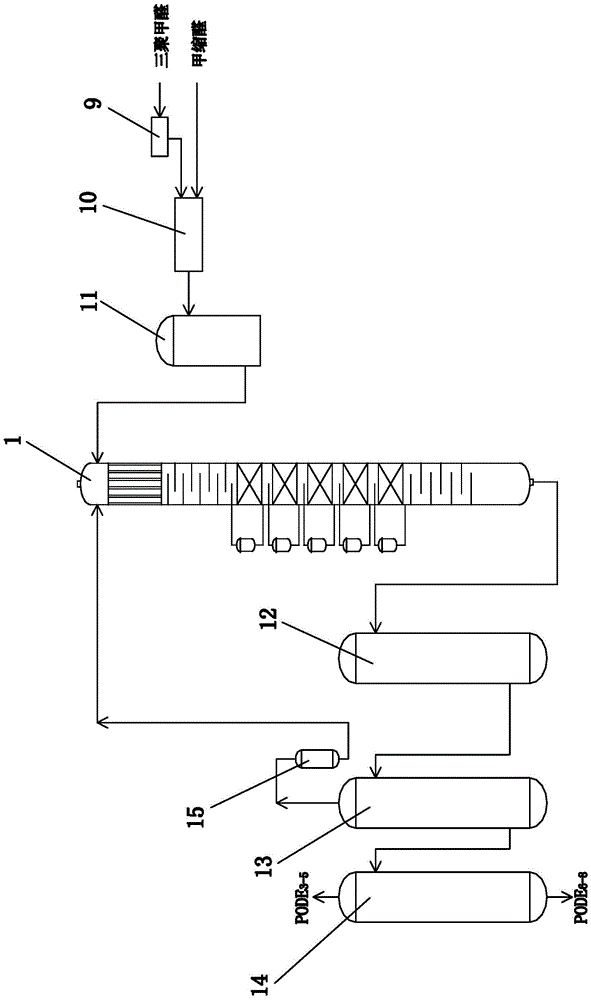

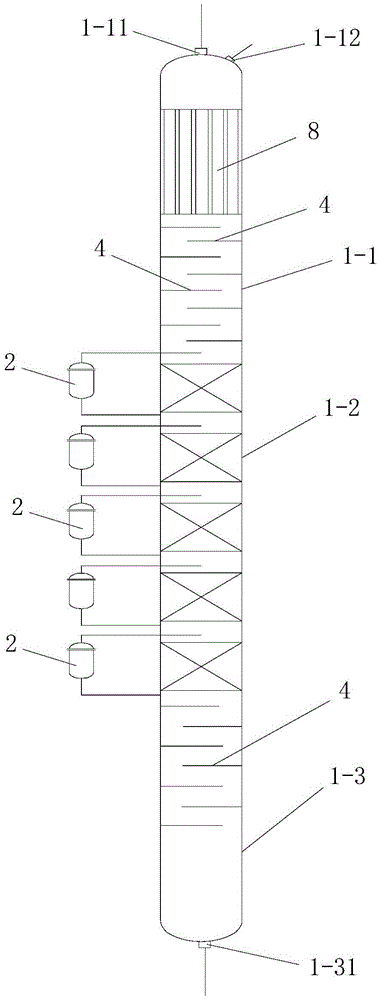

Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

ActiveCN104355973AHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveTower

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

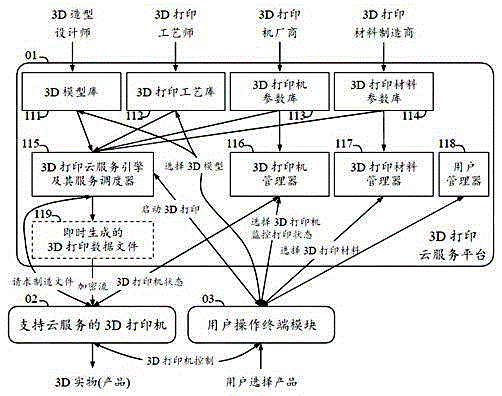

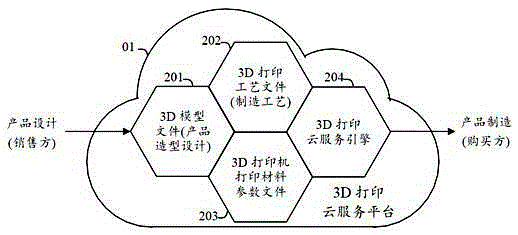

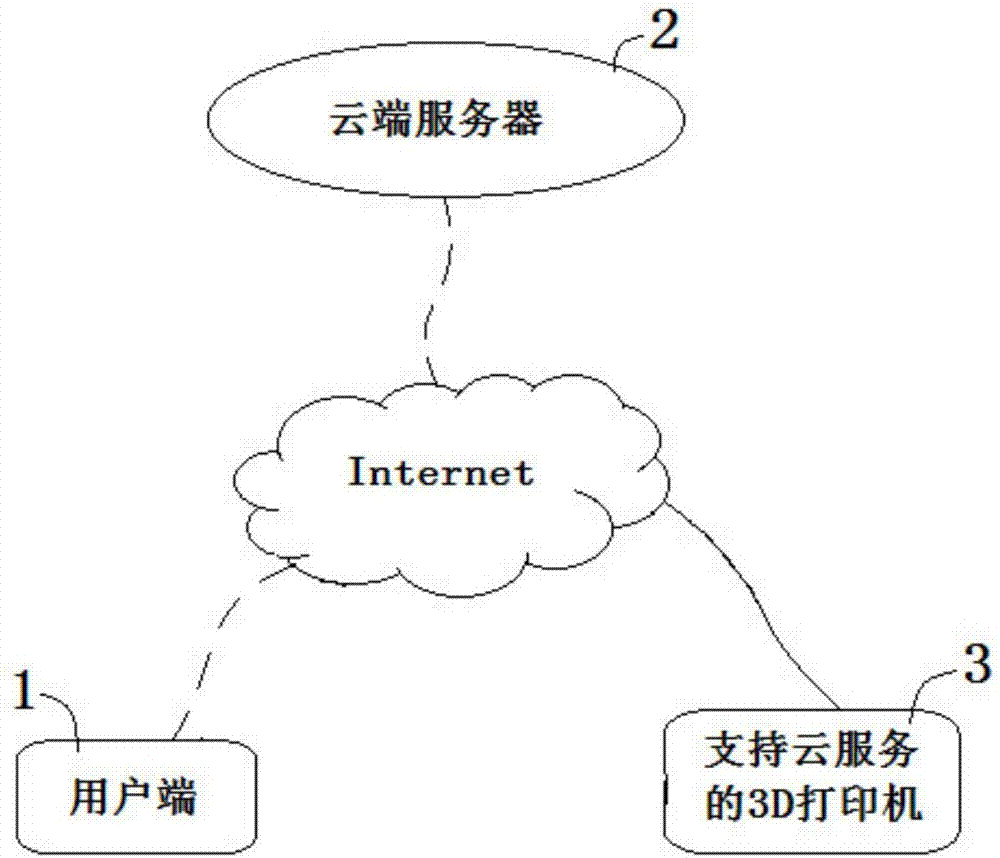

3D printing system supporting cloud service

ActiveCN105291440AReduce difficulty of useFast design iterationAdditive manufacturing apparatusOriginal equipment manufacturerComputer terminal

The invention discloses a 3D printing system supporting cloud service. The 3D printing system comprises a cloud service platform, a 3D printer supporting cloud service and a user operation terminal module, wherein the cloud service platform comprises a model library, a printing process library, a printer parameter library, a printing material parameter library, a 3D printing cloud service engine and a service scheduler thereof; the 3D printing cloud service engine and the service scheduler thereof comprise a printing model hierarchical processing algorithm engine. When a user chooses to print certain model in a 3D model library, the 3D printing cloud service engine and the service scheduler thereof locate a corresponding printing resource file and generate a 3D printing file according to a printer and a printing material used by the user. Through the 3D printing system supporting cloud service, the using difficulty of the 3D printer can be reduced; the user is more likely to obtain professional-class-quality works; the product trading manner is characterized by selling design, buying design and self producing or producing by original equipment manufacturer; the investment risk of the product designer can be reduced; the waste of social resources can be reduced.

Owner:ZHEJIANG UNIV OF TECH

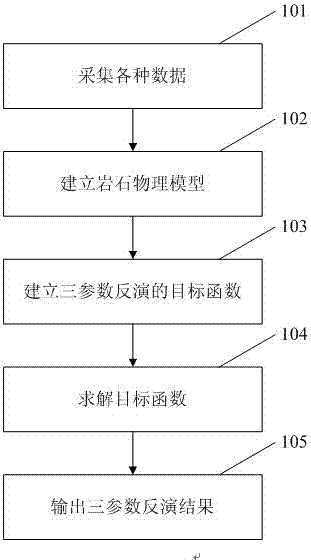

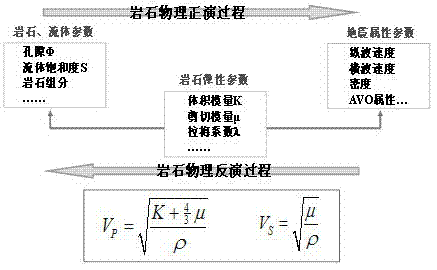

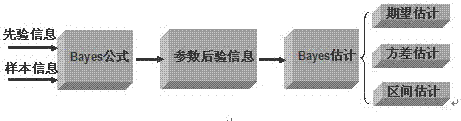

New method for simultaneous inversion of reservoir porosity, water saturation and shale content parameters

ActiveCN107290782AImprove objectivityImprove accuracySeismic signal processingStatistical analysisData information

The invention provides a new method for simultaneous inversion of reservoir porosity, water saturation and shale content parameters. The method comprises steps: 1, elastic parameters, logging data and core data information are acquired; 2, rock elastic parameters and reservoir physical parameters are combined, and a rock physical model is built; 3, an objective function for inversion of the reservoir porosity, the water saturation and the shale content is built, and the objective function is solved; and 4, through solving the objective function, an inversion result for the reservoir porosity parameter, the water saturation parameter and the shale content parameter is outputted. The method combines rock physics and geostatistical analysis, research on a new method for reservoir physical recognition is developed, physical parameters such as the porosity and the saturation of the reservoir are obtained, the objectivity and the accuracy of reservoir physical estimation result are improved, and important economic and social significance is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat transfer digital printing method for natural fibers and regenerated cellulose fibers

InactiveCN102677492ALess investmentReduce investment riskDyeing processDigital printingNatural fiber

The invention relates to a printing method for textiles, in particular to a heat transfer digital printing method for natural fibers and regenerated cellulose fibers. The heat transfer digital printing method comprises the following steps of: spreading and printing a film or a composite film which is subjected to coating treatment and textiles subjected to sizing by using an ironing press at the temperature of between 40 and 100 DEG C for 30 to 90 seconds; stripping the film or the composite film; and drying the textiles subjected to printing, and ageing for color fixing. By the heat transfer digital printing method, the problem that a digital printing machine and a computer photogravure press cannot perform jet printing on the film directly is solved, and the obtained printing textiles have the characteristics of high resolution ratio of printing patterns and distinct gradation of flower types and can achieve a photo effect; and a process is easy to operate and low in production cost.

Owner:沈翰宇

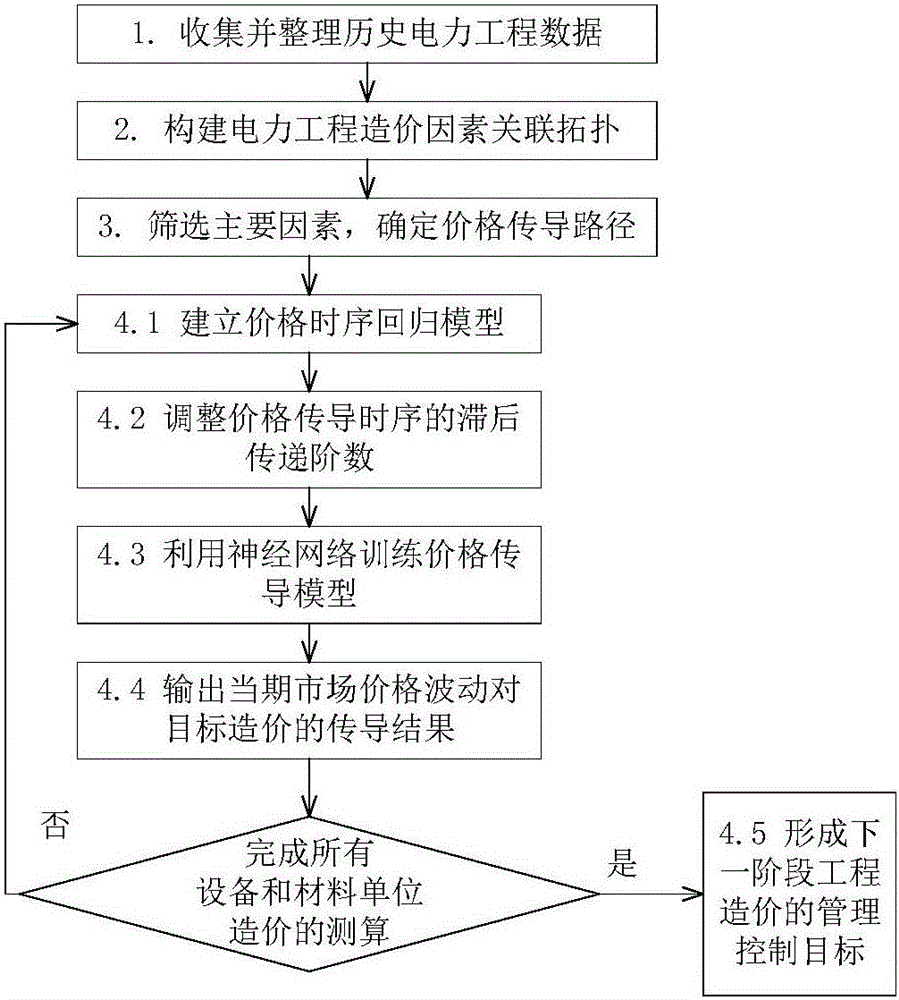

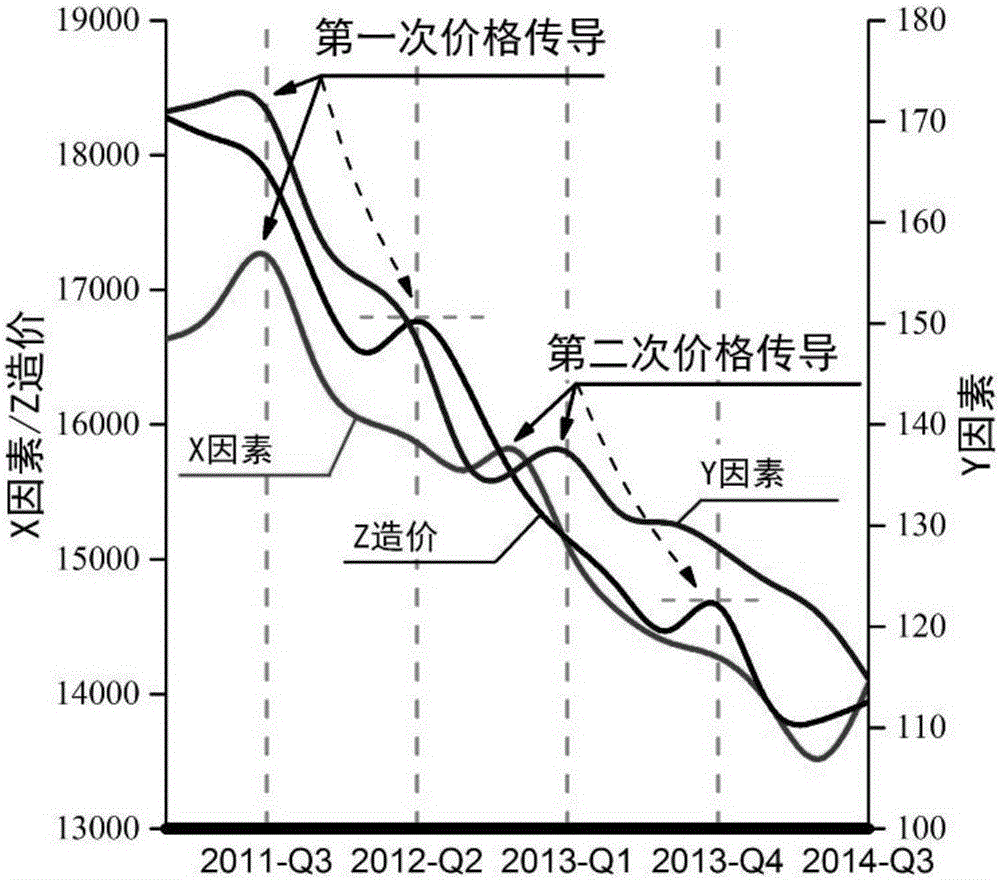

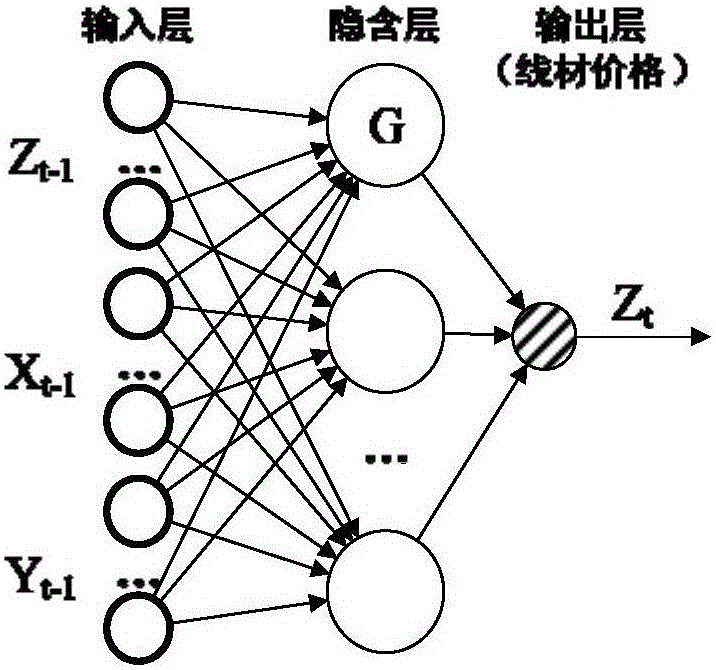

Electric power engineering cost management method

InactiveCN105930931AReduce investment riskImprove the dynamic management and control systemFinanceForecastingEngineering sampleChanging trend

The invention discloses an electric power engineering cost management method, comprising: 1) collecting and organizing historical electric power engineering data and establishing an engineering sample database; 2) digging out influence factors that affect electric power engineering cost, and constructing a cost factor association topology; 3) determining a price transmission path; 4) according to factor distribution of the price transmission path, establishing an electric power engineering cost change trend model, training the model with the combination of the historical data, and solving a price change trend set about devices and materials that are required by current engineering. By the invention, overall consideration is given to the price transmission effect of market price fluctuation on devices and materials that are required by current engineering, so that a corresponding management control scheme of the engineering cost of the next stage is proposed in a relatively clear and targeted manner, cost deviation is further reduced, the investment risk of the electric power engineering is decreased, and an electric power engineering dynamic control system is improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY ECONOMIC TECHN INST +2

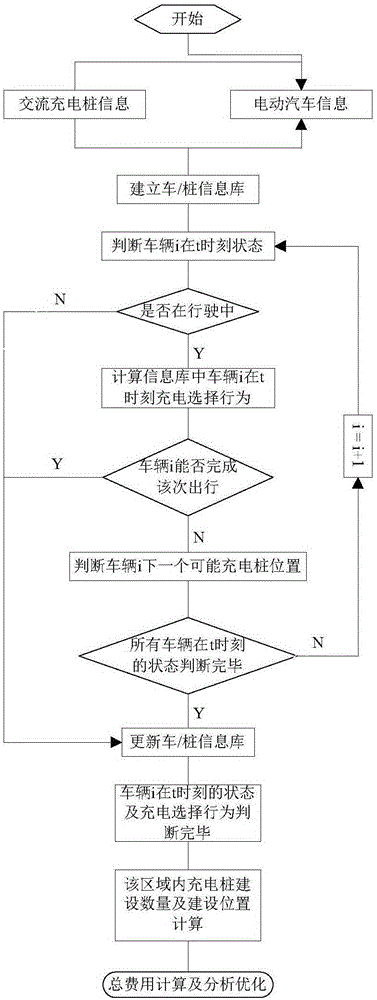

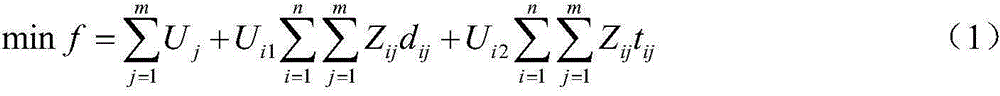

Electric automobile charging pile optimization layout method

InactiveCN105160449AThe overall cost of charging is smallReduce investment riskResourcesDesign objectsDistribution characteristic

The invention provides an electric automobile charging pile optimization layout method. The electric automobile charging pile optimization layout method comprises three parts of electric automobile pile information base establishment and update, electric automobile charging pile quantity and position calculation and electric automobile charging pile layout optimization. Electric automobile pile information base establishment relates to charging pile quantity, position and vehicle distribution characteristics in an object region, through vehicle behavior simulation, charging pile and vehicle information in the region are updated. Based on the charging pile information, the quantity and positions of the charging piles in the region are calculated, total cost of the charging piles in the region is calculated and optimized through a total cost object function and constraint conditions, and optimum configuration of the charging piles in the region can be figured out.

Owner:STATE GRID CORP OF CHINA +3

Bletilla striata large-scale high-yield cultivation method

InactiveCN104380994APromote growthPromote photosynthesisPlant cultivationCultivating equipmentsBletilla striataEffective microorganism

The invention discloses a bletilla striata large-scale high-yield cultivation method. The method includes the steps of seed breeding, hardening, transplanting to a field, growth management, second year growth management and harvesting. The bletilla striata large-scale high-yield cultivation method has the advantages that the microbial technology and the ecological cultivation technology are combined, EM (Effective Microorganisms) is used for quickly accelerating the plant growth and decomposing residual farm chemical for further greatly shortening the planting period and improving the yield of bletilla striata. Compared with traditional cultivation methods, the planting period of bletilla striata is shortened for1 to 2 years and can be harvested in 3 years, the harvested bletilla striata is big in root and bright in color, and the yield per mu (one mu equals about 1.667square meters) of the bletilla striata is two to three times of that in traditional root cultivation, so that the risk of investment is greatly reduced, the early planting investment cost is low, the high economic benefit is achieved quickly, the non-polluting effect is obtained, and the conditions of industrialized and large-scale bletilla striata planting are met. The bletilla striata large-scale high-yield cultivation method is easy to popularize and apply.

Owner:SHIZONG KANGDA ECOLOGICAL AGRI

Longan planting method

InactiveCN105248222AImprove survival ratePreventing Pests and DiseasesBiocidePlant growth regulatorsPruningThinning

The invention belongs to the technical field of plant cultivation, and particularly relates to a longan planting method. The method comprises such steps as planting land selection, seedling selection, field planting pit preparation, field planting, fertilization management, training and pruning, and disease and pest control. The method is simple and easy to popularize, and can effectively improve the survival rate of longan seedlings; through adoption of a disease and pest control management measure, diseases and pests can be prevented, and thus longan trees have low probability of suffering from various diseases in the planting process; through reasonable fertilization, the longan trees can grow healthily; when the longan trees grow to bloom and yield fruits, flower and fruit thinning is reasonably performed for the longan trees, so as to improve the fruit setting rate and the fruit quality of the longan trees; according to the method, the longan growth can be obviously promoted, the longan yield can be improved, and not only can the economic benefit of a planter be guaranteed, but also the healthy development of the longan planting industry can be promoted. Therefore, the method is relatively high in economic benefit and social benefit.

Owner:DAXIN PRODIVITY PROMOTING CENT

Method for developing heavy oil reservoir of horizontal well by combining staged volume fracturing and fracturing filling

ActiveCN105422068AReduce heat lossImprove seepage propertiesFluid removalSealing/packingPorosityGeomorphology

The invention provides a method for developing a heavy oil reservoir of a horizontal well by combining staged volume fracturing and fracturing filling. According to the method, firstly, a steam injection well is deployed at the bottom of the oil reservoir; a production well is deployed at the middle upper part of the oil reservoir; then, the volume fracturing or fracturing filling operation is performed according to the porosity degree and seepage rate distribution condition of the two horizontal wells; then, the two wells form heat communication in a steam throughput mode; next, the two wells transfer to continuous steam injection production; and the production is stopped when the oil-steam ratio is lowered to 0.1. According to the invention, a fracture net system is formed in a compact region by the volume fracturing, so that the seepage capability of the oil reservoir is improved; the fracturing filling process is used in a high-porosity and high-permeability region for performing compaction so as to reduce a formation sand production phenomenon; the seepage mode of a low-permeability region oil reservoir is converted from the single seepage to the sewage and fracture laminar flow; meanwhile, a high-permeability region is filled with small-grain-size sand for filling loose reservoir sandstone particle pores, so that the permeability near the production well is reduced,the oil reservoir anisotropy is reduced and the whole oil reservoir can be uniformly used and developed.

Owner:PETROCHINA CO LTD

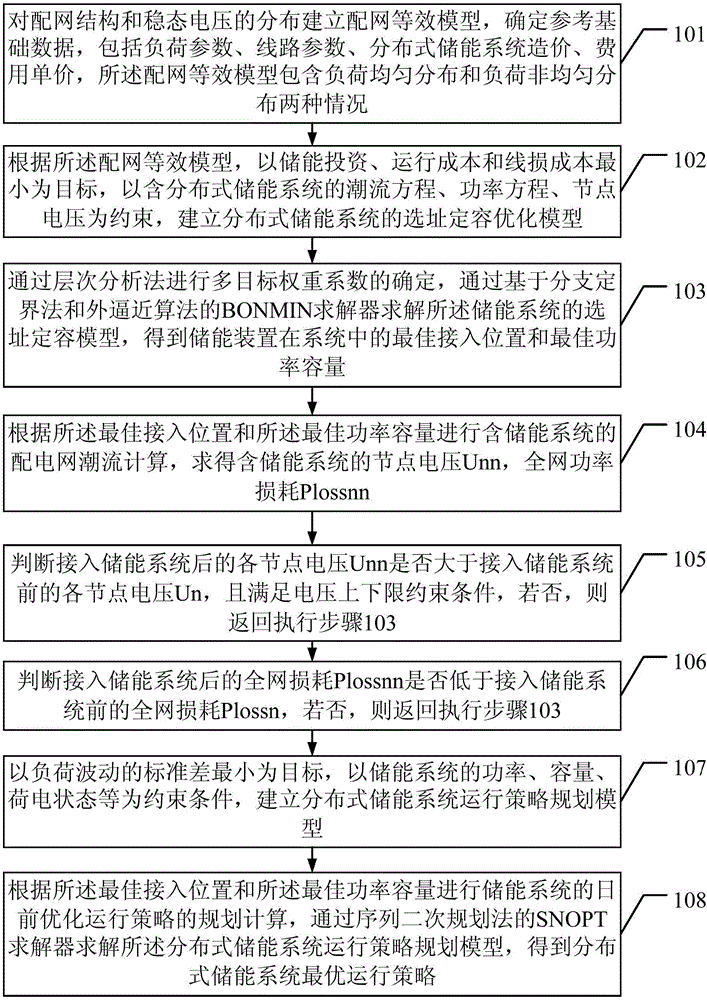

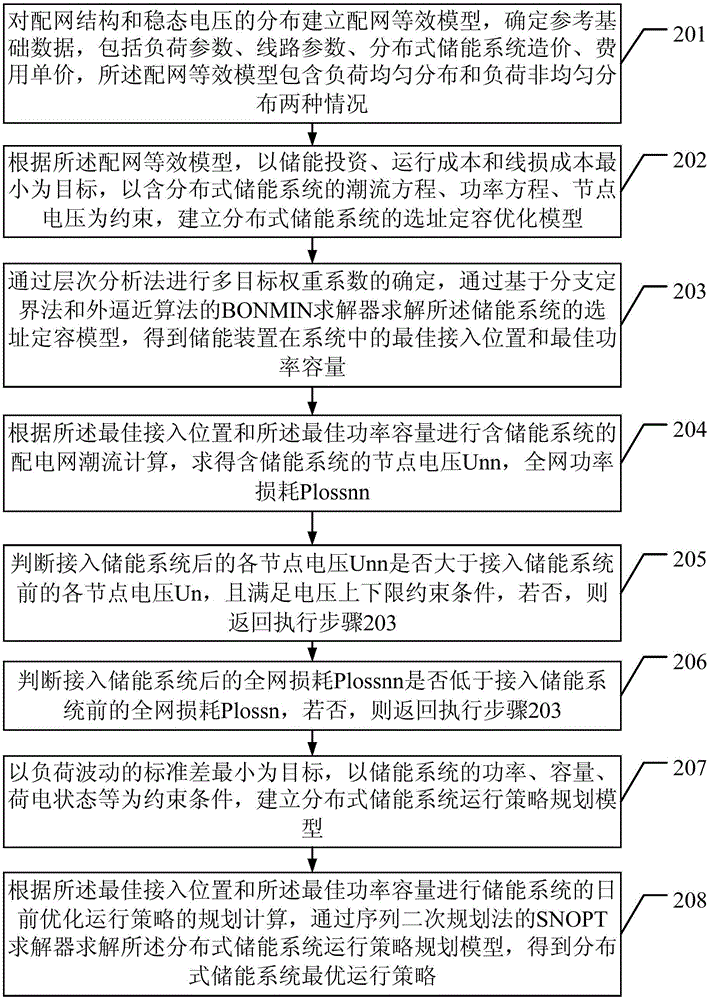

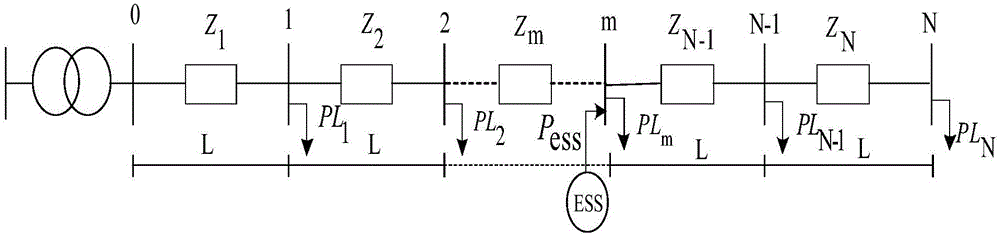

Electric energy quality improvement method of low voltage distribution network distributed energy storage system

InactiveCN106803157AImprove power qualityConsider economyResourcesSystems intergating technologiesPower qualityLow voltage

The embodiment of the invention is to provide an electric energy quality improvement method of a low voltage distribution network distributed energy storage system. A distribution network equivalent model and a locating and sizing optimization model of the distributed energy storage system are established, and a multi-target weight coefficient is determined through an analytic hierarchy process so as to convert the multi-target optimization problem into the single target problem. The optimal access position and the optimal power capacity of the energy storage device in the system are calculated, and finally the optimal operation strategy of the distributed energy storage system is accordingly solved by combining the operation strategy planning model of the distributed energy storage system so that the electric energy quality of the low voltage distribution network can be improved, the economic performance of energy storage investment can also be considered, the risk of investment can be reduced and the utilization rate of equipment can be enhanced. According to the distributed energy storage system planning method, the defects of the existing method are compensated so that the electric energy quality of the low voltage distribution network can be effectively improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

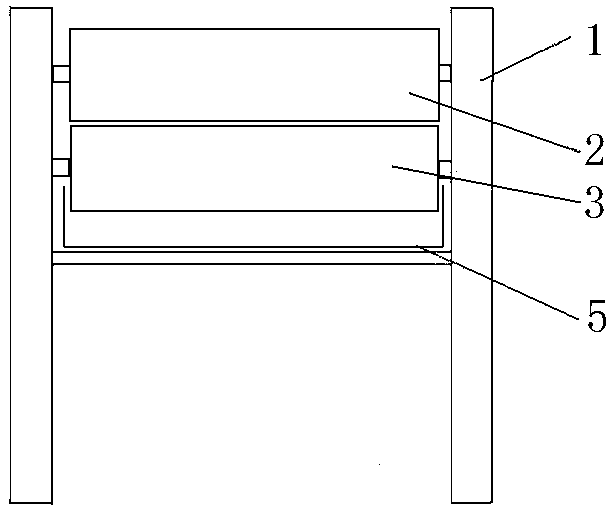

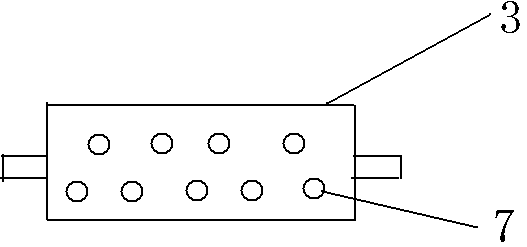

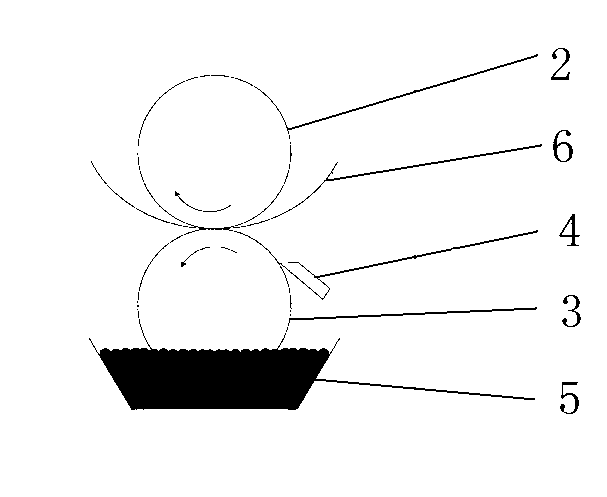

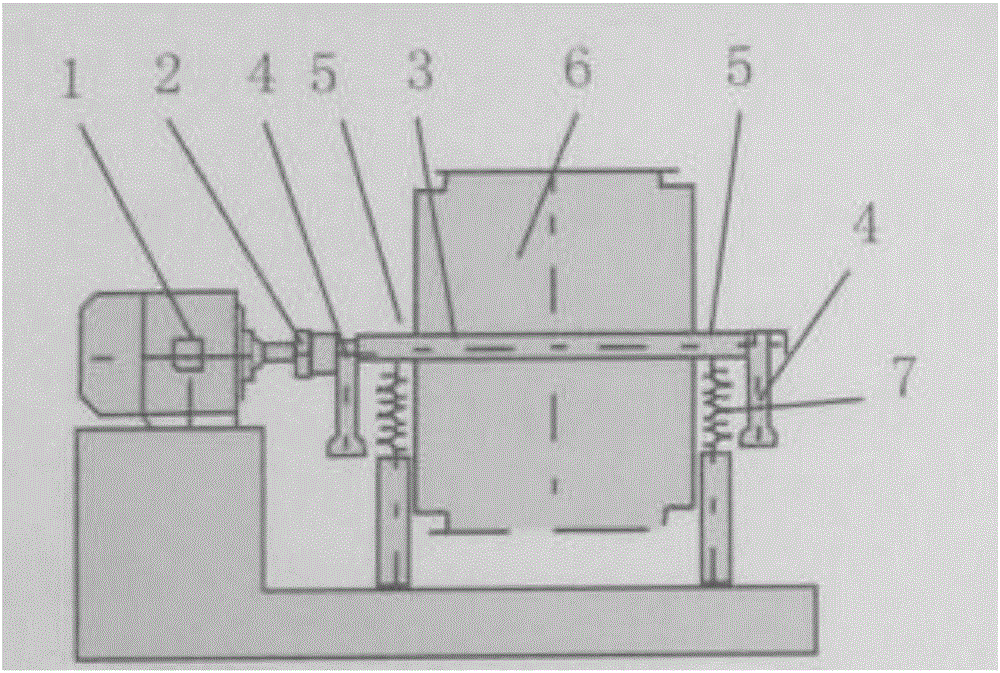

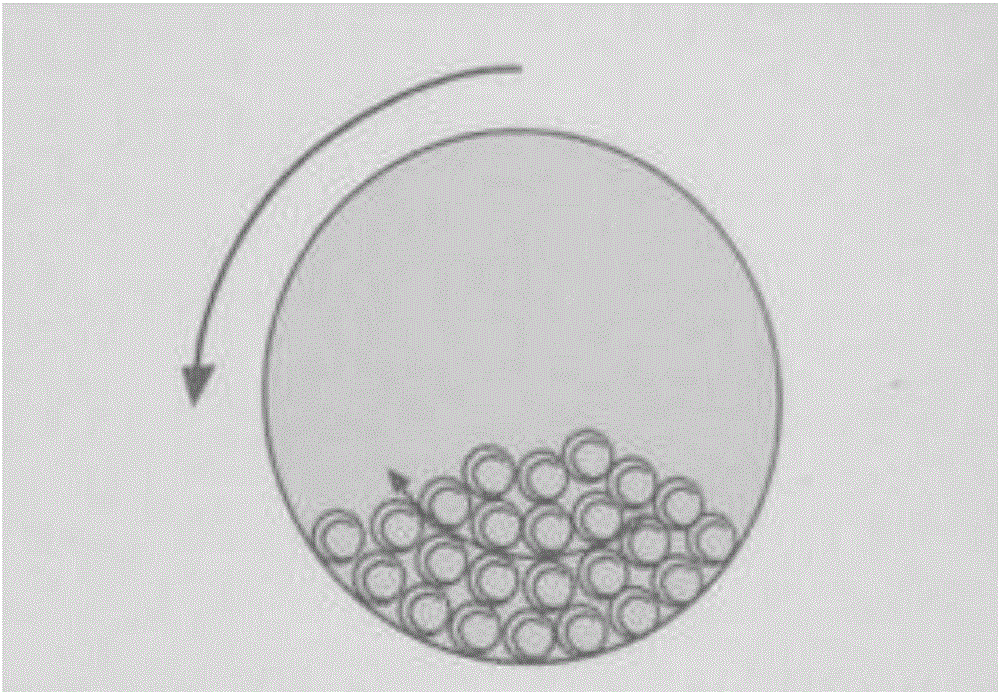

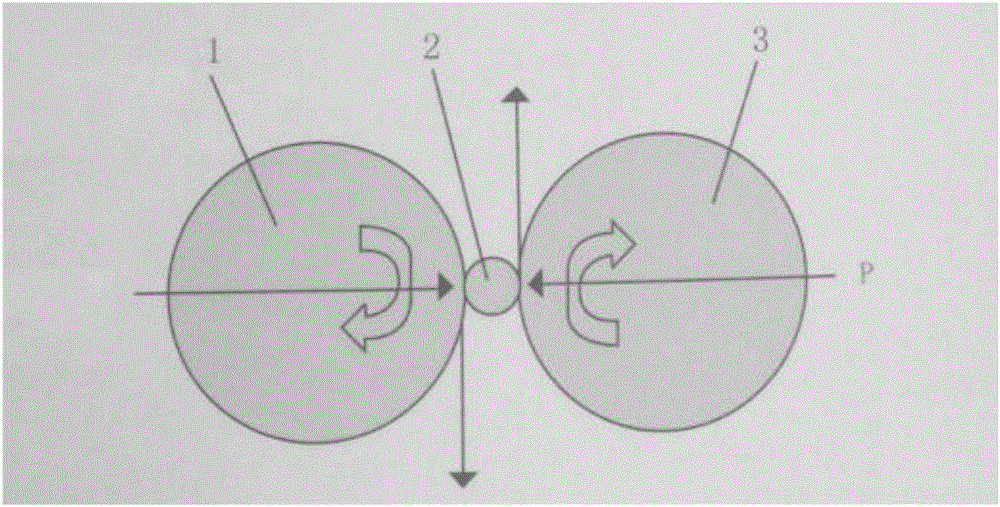

Wall-breaking and superfine grinding process and device for better ground traditional Chinese medicine decoction piece

ActiveCN105344428AImprove qualityStable and controllable qualityGrain treatmentsLiquid-crystal displayMedicine

The invention belongs to the field of medicinal material grinding and smashing equipment and method, and particularly relates to a wall-breaking and superfine vibration grinder for a better ground traditional Chinese medicine decoction piece, a traditional Chinese medicine decoction piece preparation method adopting the grinder, and the better ground traditional Chinese medicine decoction piece. The grinder comprises a motor (1), a coupler (2), a rotating spindle (3), a bearing pedestal (4), a drum holder (5), a drum (6), a supporting spring (7), a base, an excitation vibration absorber, a controller, a timer, a liquid crystal display operating panel, a central processing unit and a silencing case. By means of the specific rotating speed and the specific motion trace of the motor of the grinder, the grinder achieves the advantages of energy conservation, high efficiency and smaller sizes of smashed grains.

Owner:SHAANXI NIANQINGBAO PHARMA CO LTD

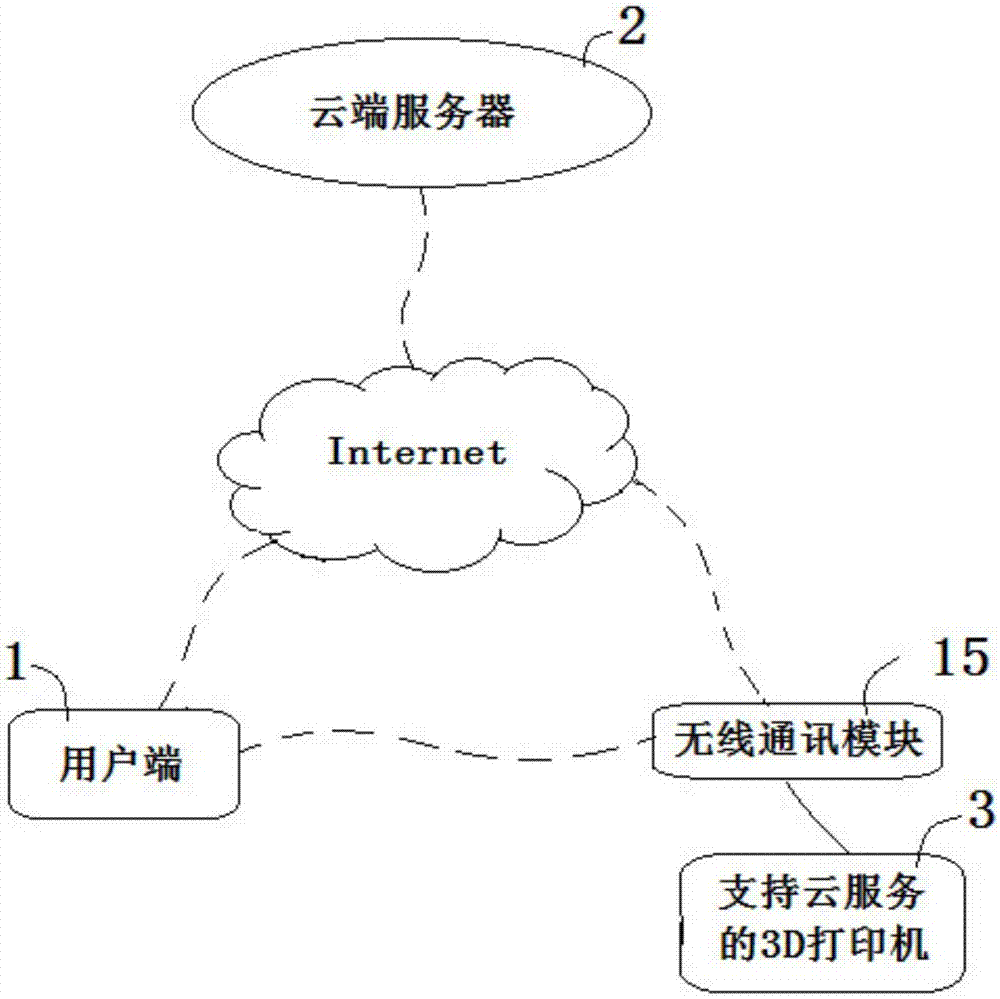

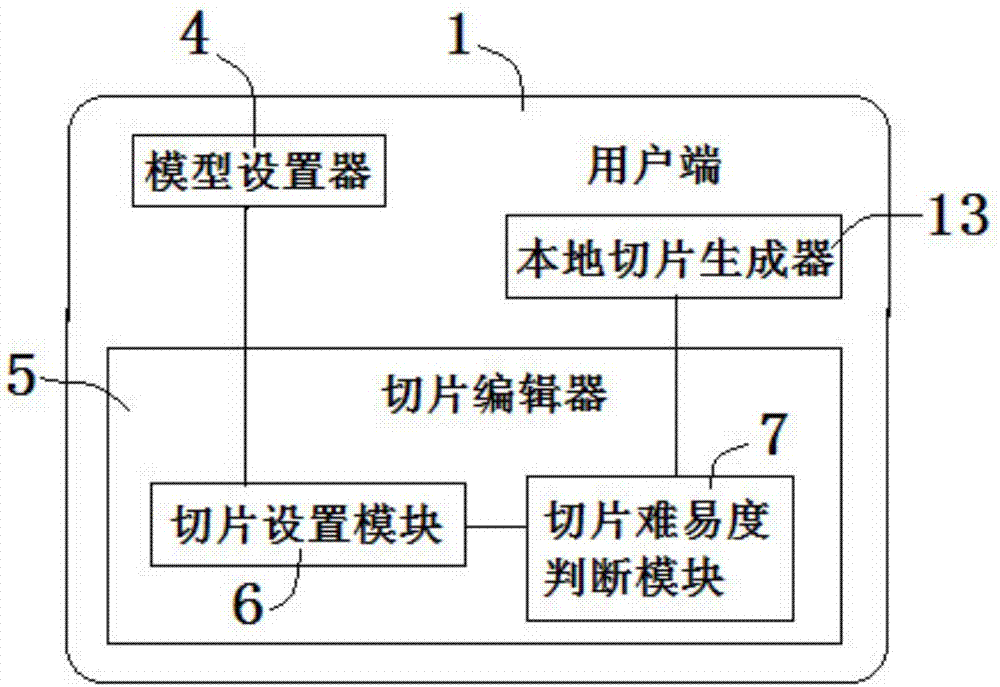

3D printer control system for supporting user side

ActiveCN107368268ASolve the problem that cannot be controlled remotelySolve adaptation problemsAdditive manufacturing apparatusManufacturing data aquisition/processingControl systemThe Internet

The invention relates to a 3D printer control system for supporting a user side. The system comprises the user side, a cloud side server and a 3D printer for supporting cloud service, the user side, the cloud side server and the 3D printer interact with one another through the Internet, the user side comprises a model setter, a slice editor and a local slice generator, the model setter selects a to-be-printed 3D model, and the slice editor sets a slice strategy, and calculates the number of nodes and sections, and if the number of the nodes or the sections is lower than a set numerical value, the local slice generator generates a local 3D print text and a slice preview; the cloud side server comprises a 3D model library and a cloud side slice generator, if the number of the nodes or the sections is higher than the set numerical value, the user side uploads the slice strategy, the cloud side slice generator generates a cloud side 3D print text according to the slice strategy, and the user side downloads the cloud side 3D print text and afterwards generates a slice preview; the 3D printer receives the 3D print texts and afterwards conducts 3D printing work. According to the 3D printer control system for supporting the user side, remote manipulation of the 3D printer is achieved, and the system is adaptive to 3D printers of various types.

Owner:BEIJING JUZHENKONGJIAN TECH CO LTD

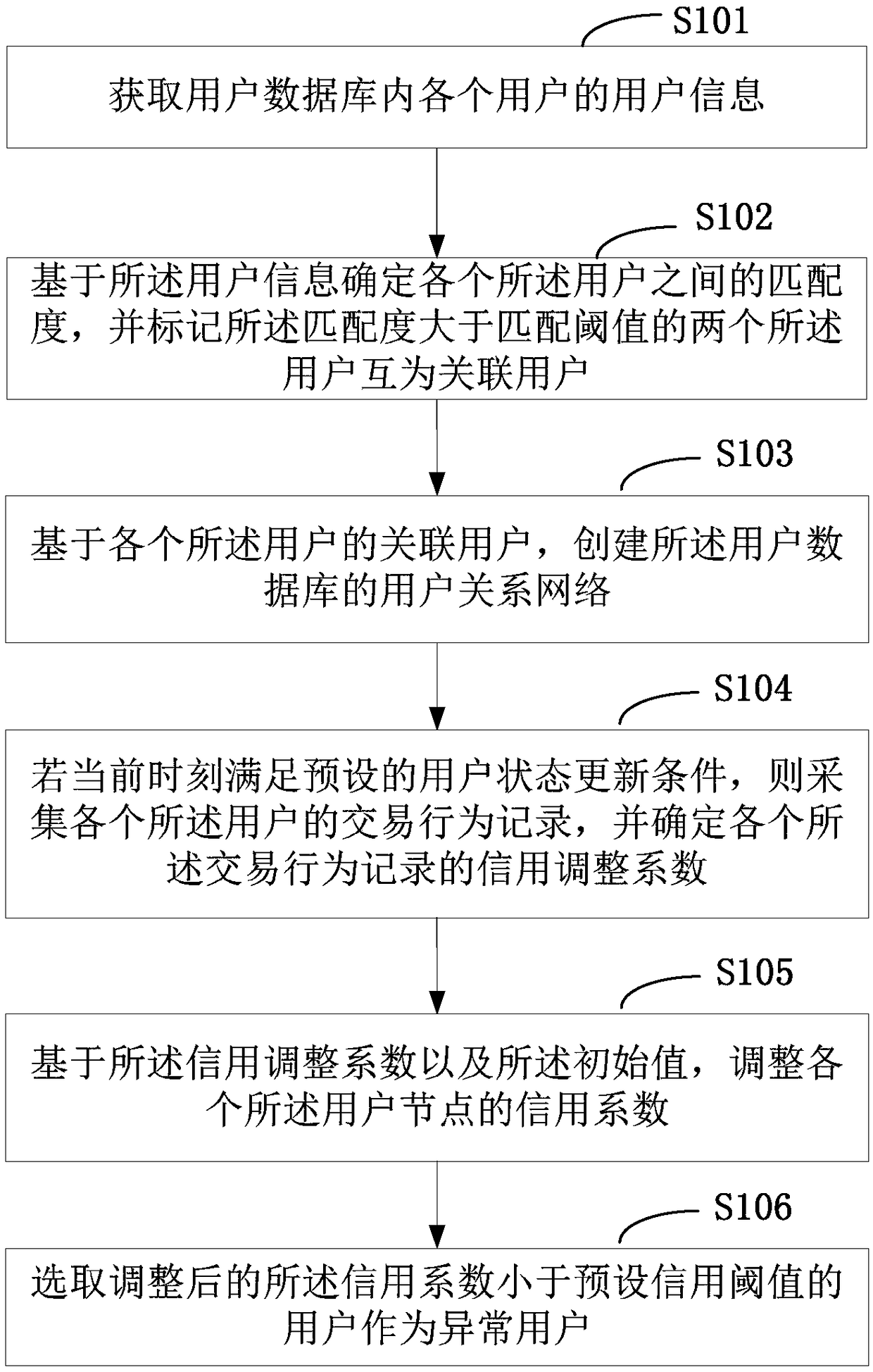

Abnormal user identification method and equipment

PendingCN108615119AReduce investment riskEffective protectionFinanceResourcesInformation processingEngineering

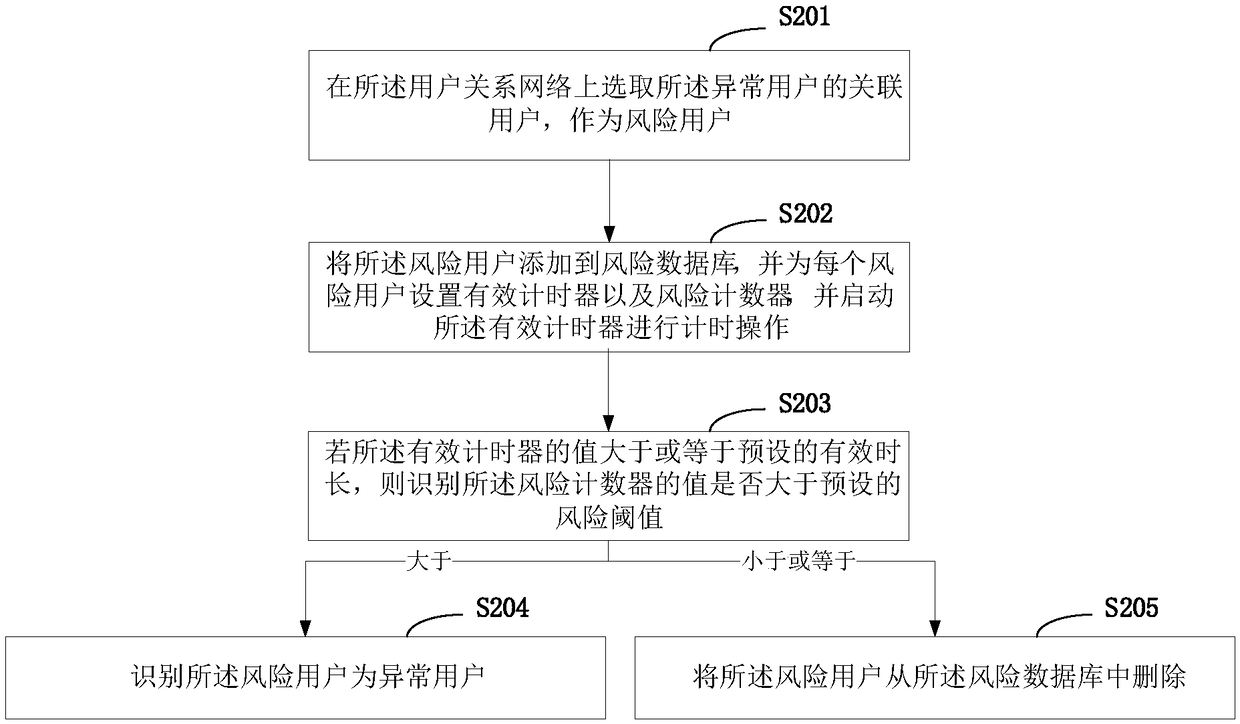

The invention relates to the information processing technical field, and provides an abnormal user identification method and equipment; the method comprises the following steps: obtaining user information of each user in a user database; determining a matching rate between the users according to the user information, and tagging two users with the matching rate greater than a matching threshold asassociated users; creating a user relation network according to associated users of each user; gathering transaction behavior records of each user if the present moment satisfies preset user state updating conditions, and determining a credit adjusting coefficient of each transaction behavior record; adjusting the credit coefficient of each user node according to the credit adjusting coefficientand an initial value; selecting users with the credit coefficient smaller than the credit threshold as abnormal users. The method can identify finance frauds in a grouping mode; once certain member inthe group conducts an illegal deal, the method can immediately determine other criminal members in the group, thus effectively protecting funds of the financial mechanism.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

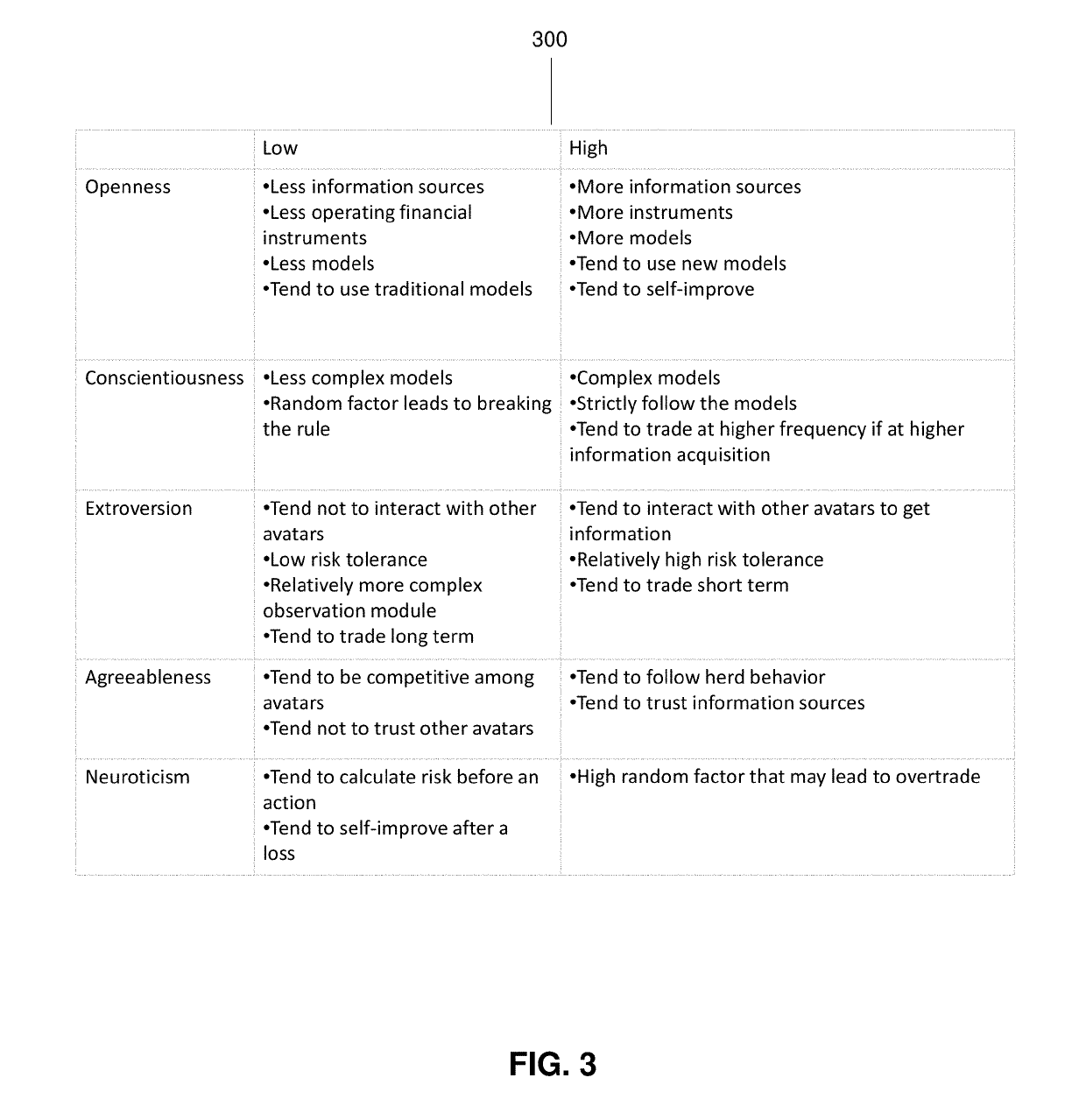

Persona-driven and artificially-intelligent avatar

ActiveUS20190205727A1Improve performanceExtension of timeFinanceCharacter and pattern recognitionHuman–computer interactionControl parameters

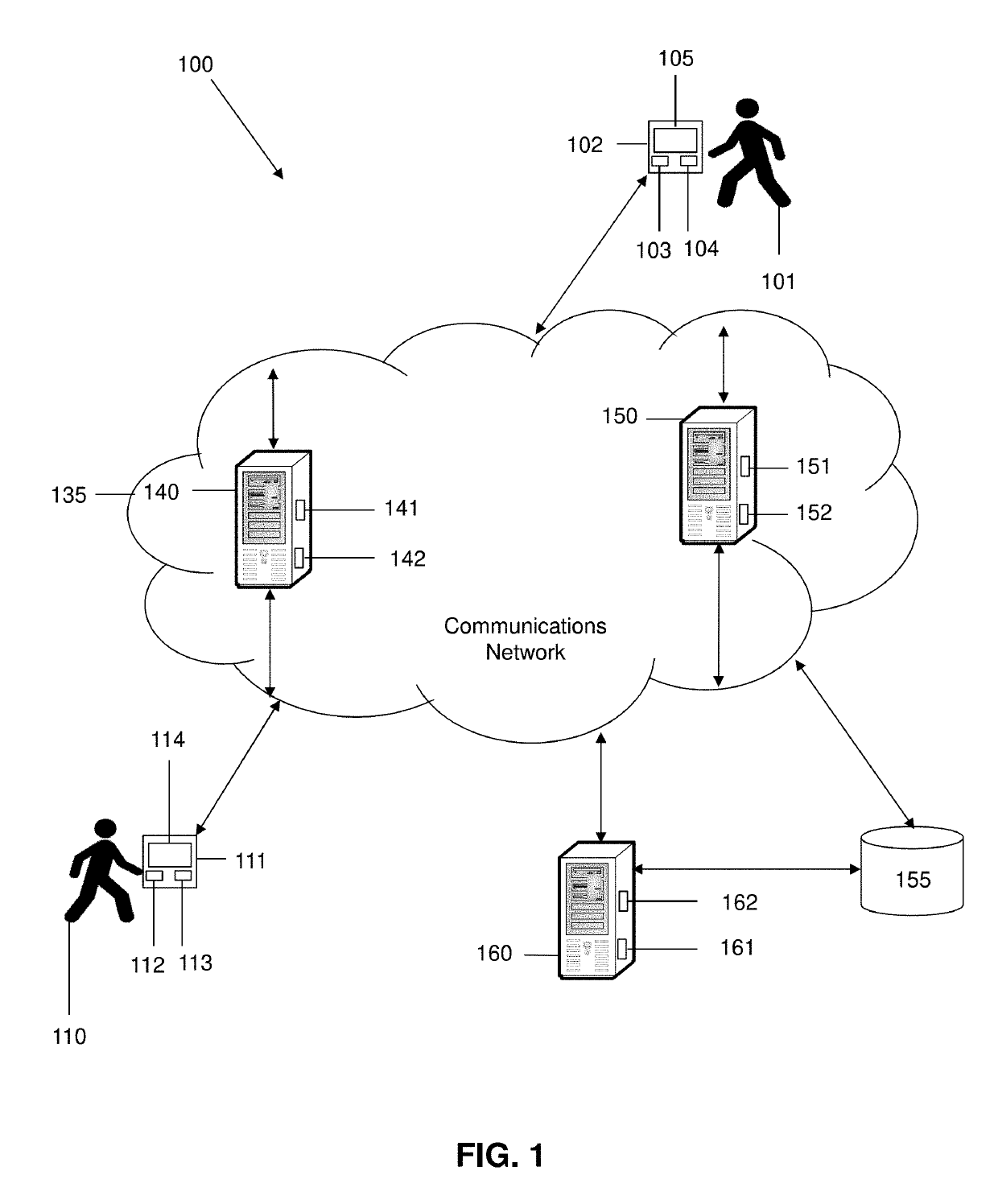

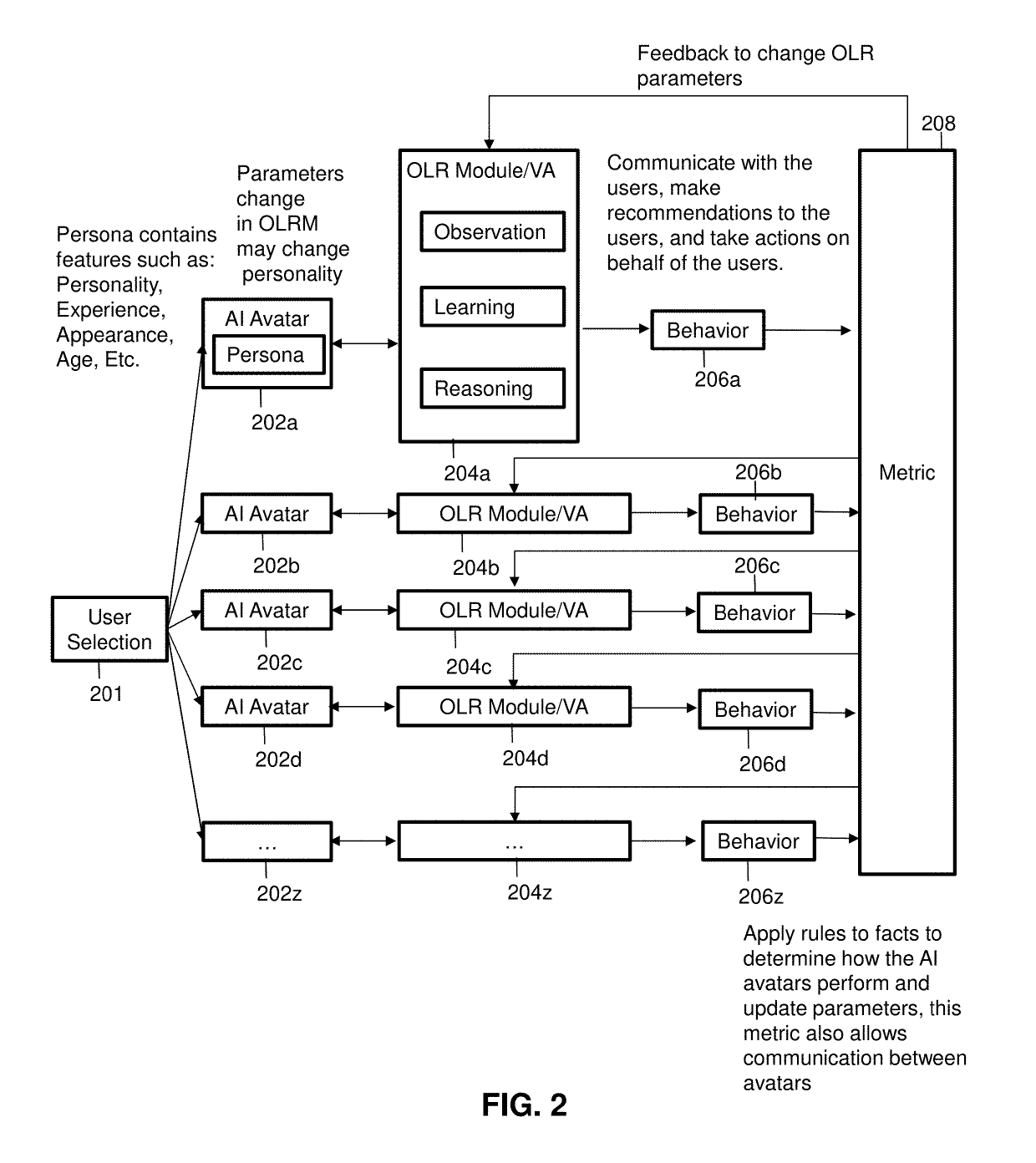

A system for providing a persona-driven and artificially-intelligent avatar is disclosed. The avatar may be utilized to represent an artificially-intelligent virtual assistant that may perform actions on behalf of a user, such as actions related to an investment strategy for the user. Notably, the avatar may influence artificial intelligence algorithms supporting the functionality of the virtual assistant via quantifiable traits of a persona of the avatar. In particular, the quantifiable traits of the persona of the avatar may be utilized to range bound the controlling parameters of the algorithms such that the virtual assistant represented by the avatar performs actions that conform to the ranged-bounded controlling parameters. Metrics corresponding to the performance of the virtual assistant may be tracked, and the system may modify parameters of the virtual assistant based on the metrics so as to adjust future actions performed by the virtual assistant for the user.

Owner:GRAPHEN INC

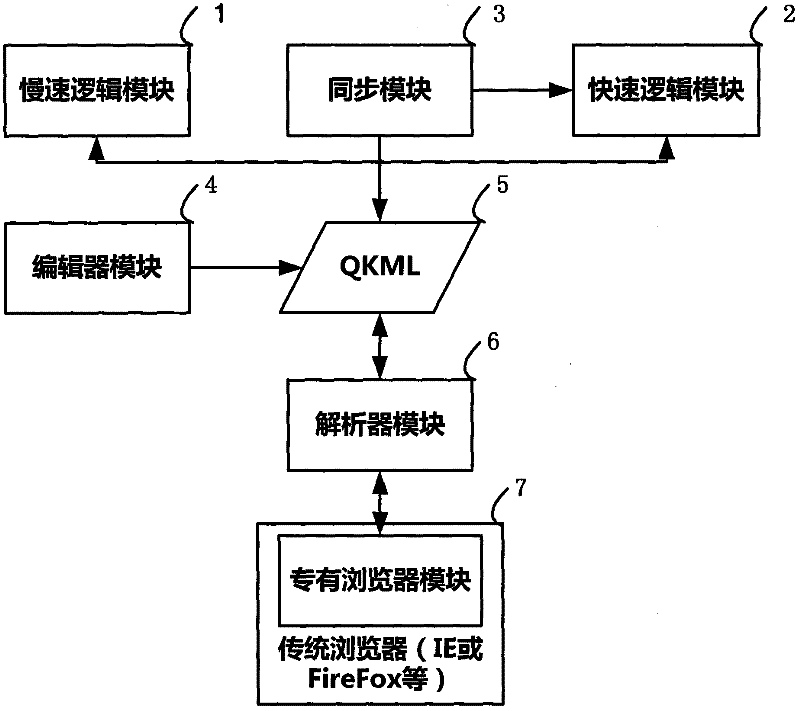

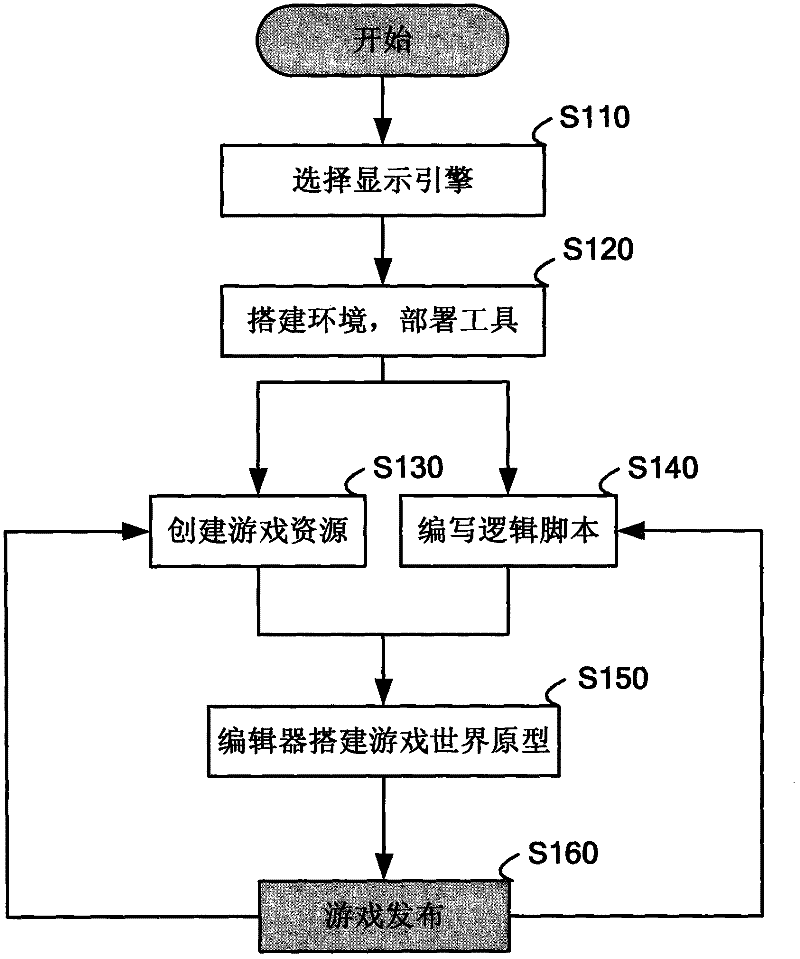

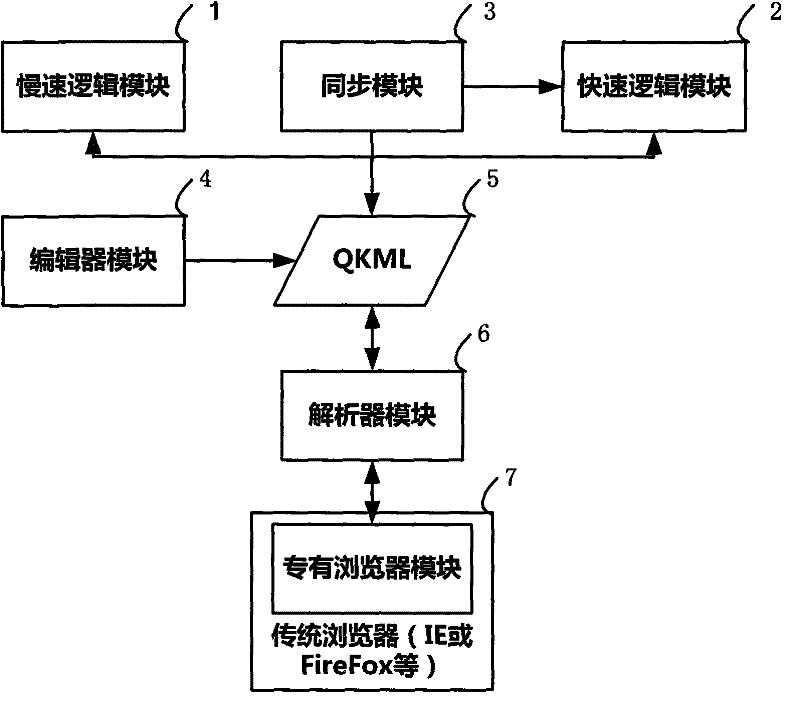

Computer network game development system and method based on Internet b/s structure

InactiveCN102262534AReduce labor costsReduce riskTransmissionSpecific program execution arrangementsLow speedThe Internet

The invention discloses a system and a method for developing computer online games based on an Internet browser / server (B / S) structure. By using the system, the online game development is established on the basis of the standard internet browser / server (B / S) structure. By using the system, a marking language for the online game development is established, and the data interaction between a service end and a client end and between low speed logic and high speed logic of the service end are realized by using a marking language resolving module. The marking language resolving module realizes thedata interaction with any third party 3D or 2D render engine by calling a standard 3D or 2D interface. The system fully supports version control and multi-person cooperation, and provides visualized product designs and implementation. Besides, the system supports multiplatform release, and widens the game terminal field. By using the system, the requirement on developers is greatly reduced, the developers of general websites can be employed, and a development company can realize the vision of developing large-scale online games on the premise of minimum human input and minimum investment risk.

Owner:北京一骑当千网络科技股份有限公司

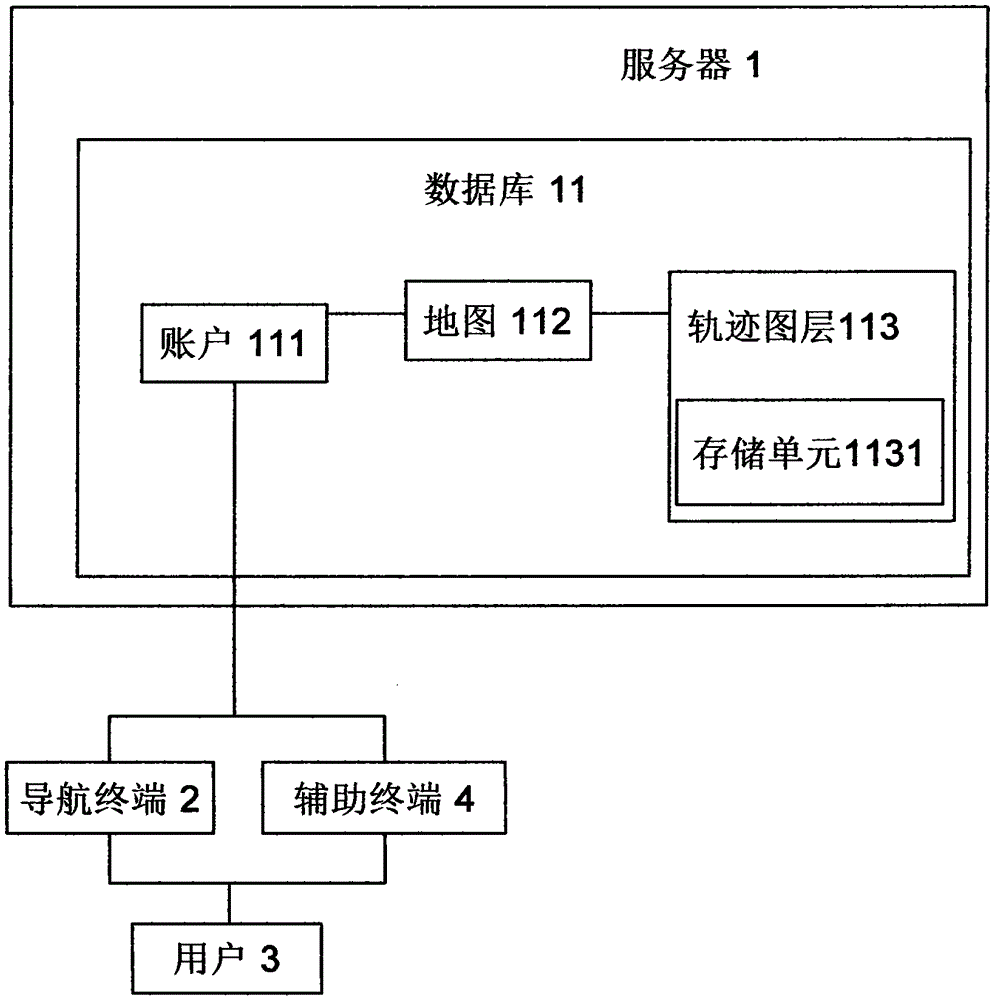

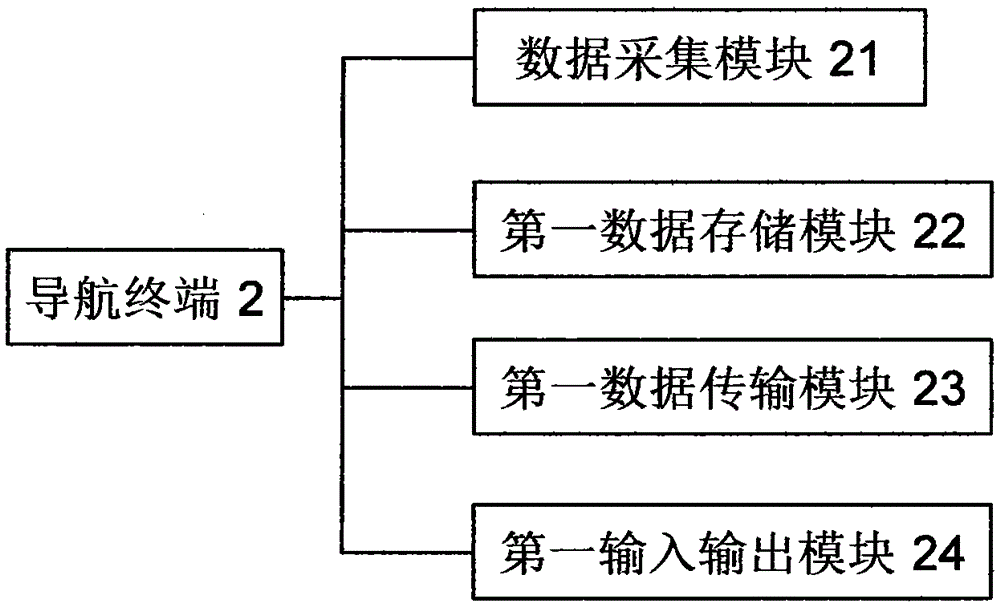

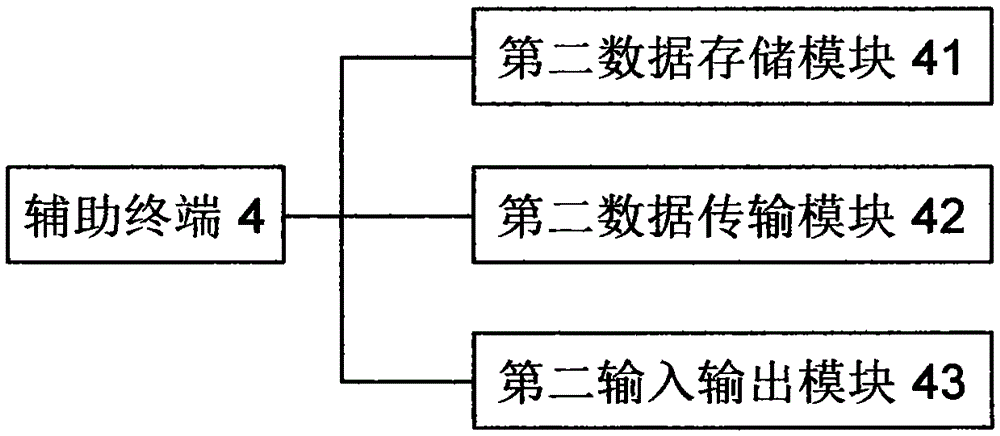

A navigation advertisement pushing system based on geographic positions

ActiveCN105594235AReduce computing loadAchieve playbackNavigation instrumentsSatellite radio beaconingUser inputGeolocation

A navigation advertisement pushing system based on geographic positions is disclosed and includes a server, a plurality of navigation terminals and a plurality of corresponding users, wherein the server comprises a database, a map and a track map layer corresponding to the map are stored in the database, and the track map layer is divided into memory units so that each of the memory units is corresponding to a geographic zone in the map. The servicer receives positioning data sent by the navigation terminals and corresponding times in real time, determines the memory units corresponding to the geographic positions of the navigation terminals on the map, and stores user names corresponding to the navigation terminals and the times into the memory units. The users input a pushing zone through the navigation terminals to generate a navigation advertisement. The server receives the navigation advertisement, calculates according to a user track in the memory unit corresponding to the pushing zone to screen affiliated persons, and sends the navigation advertisement to the affiliated persons.

Owner:薛俊华

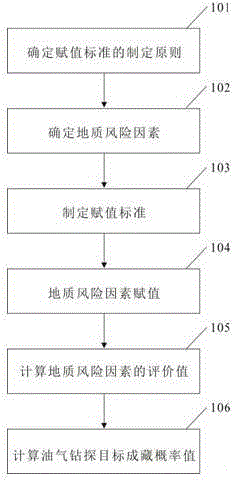

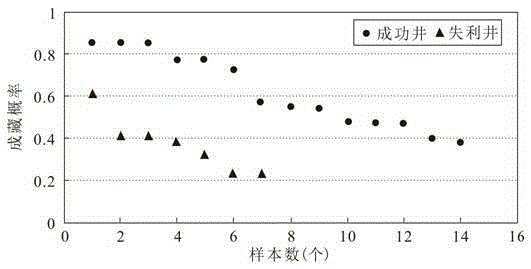

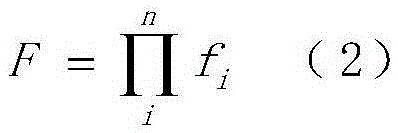

Method for quantitative evaluation of geological risk of oil gas drilling target

ActiveCN106501854ASolve problems that are difficult to quantifyImprove the success rate of explorationSeismic signal processingRisk evaluationPetroleum engineering

The invention provides a method for quantitative evaluation of geological risk of an oil gas drilling target. The method comprises the following steps: determining an establishing principle of a geological risk assignment standard, determining geological risk factors, determining a main control factor and a correction factor in each geological risk factor, creating a geological risk factor assignment standard, assigning a geological risk factor of the oil gas drilling target, calculating the evaluation values of respective geological risk factors, and calculating the probability of oil and gas accumulation of the oil gas drilling target. The method for quantitative evaluation of geological risk of the oil gas drilling target establishes a geological risk evaluation program and standard of the oil and gas drilling target, achieves quantitative evaluation of geologic risks before drilling the oil gas drilling target, and improves a pre-drilling risk evaluation ability and the success rate of oil and gas exploration.

Owner:CHINA PETROLEUM & CHEM CORP +1

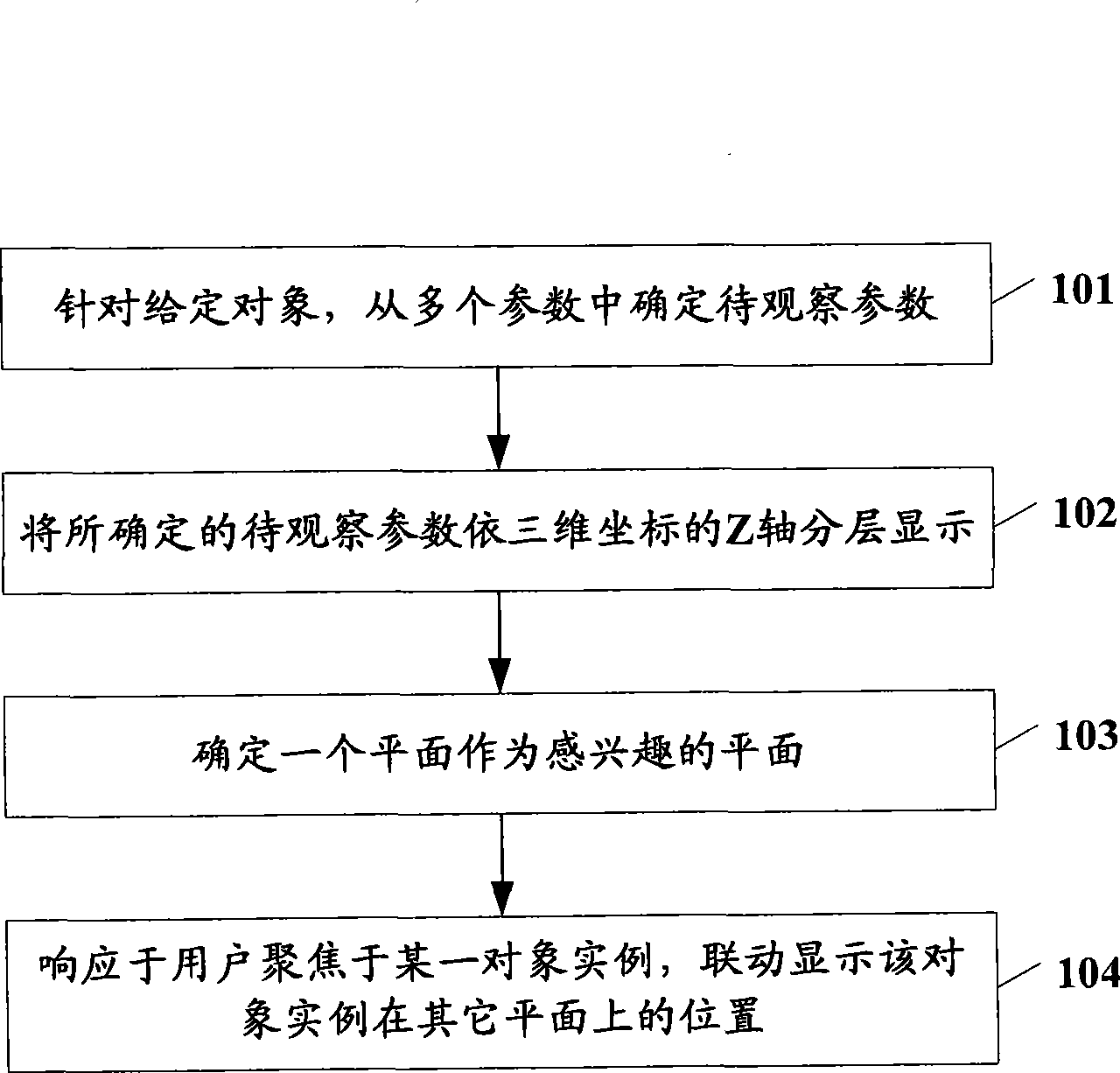

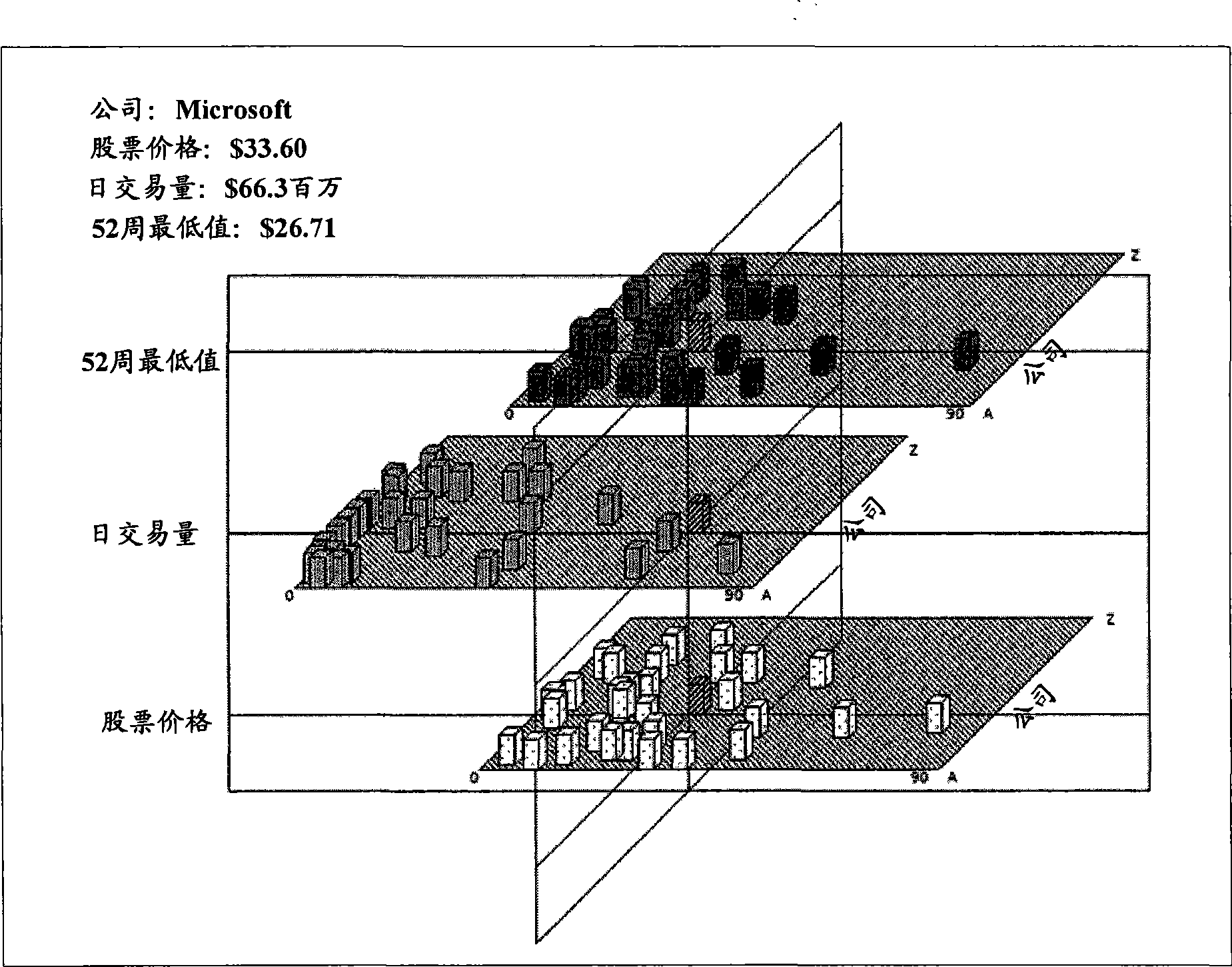

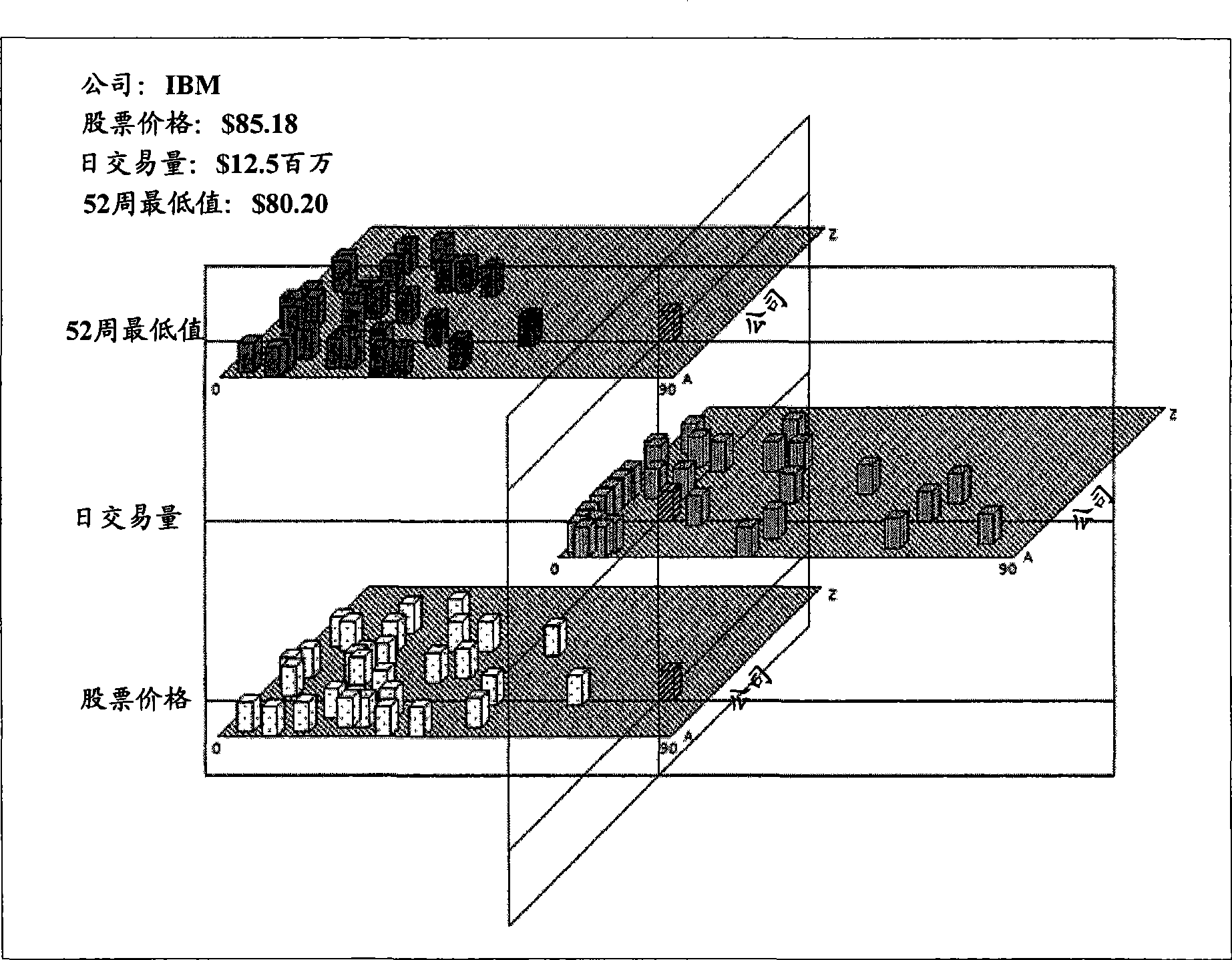

Visualization method and apparatus for multidimensional data

InactiveCN101510291AReduce investment riskEfficient use ofDrawing from basic elementsFinanceMultidimensional dataVisualization methods

The invention provides a visual method of multidimensional data and a visual device of the multidimensional data. According to one aspect of the invention, the visual method of the multidimensional data is provided, wherein the multidimensional data comprises a plurality of parameters relevant to a given object; the method comprises the steps as follows: the parameters to be observed of the given object are displayed by layers along the Z axis of a three-dimensional coordinate, wherein each parameter is respectively displayed on a two-dimensional surface; one surface is determined as an interesting surface; and one object instance is focused in response to users, and the positions of the object instance on other surfaces are displayed in a linked way. By the visual method of the multidimensional data and the visual device, the multidimensional data can be displayed on one window by layers or a screen and displayed in a linked way, thereby being capable of intuitively displaying the relationship between different parameters of the multidimensional data to the users, and leading the users to utilize and analyze various information exactly and effectively.

Owner:INT BUSINESS MASCH CORP

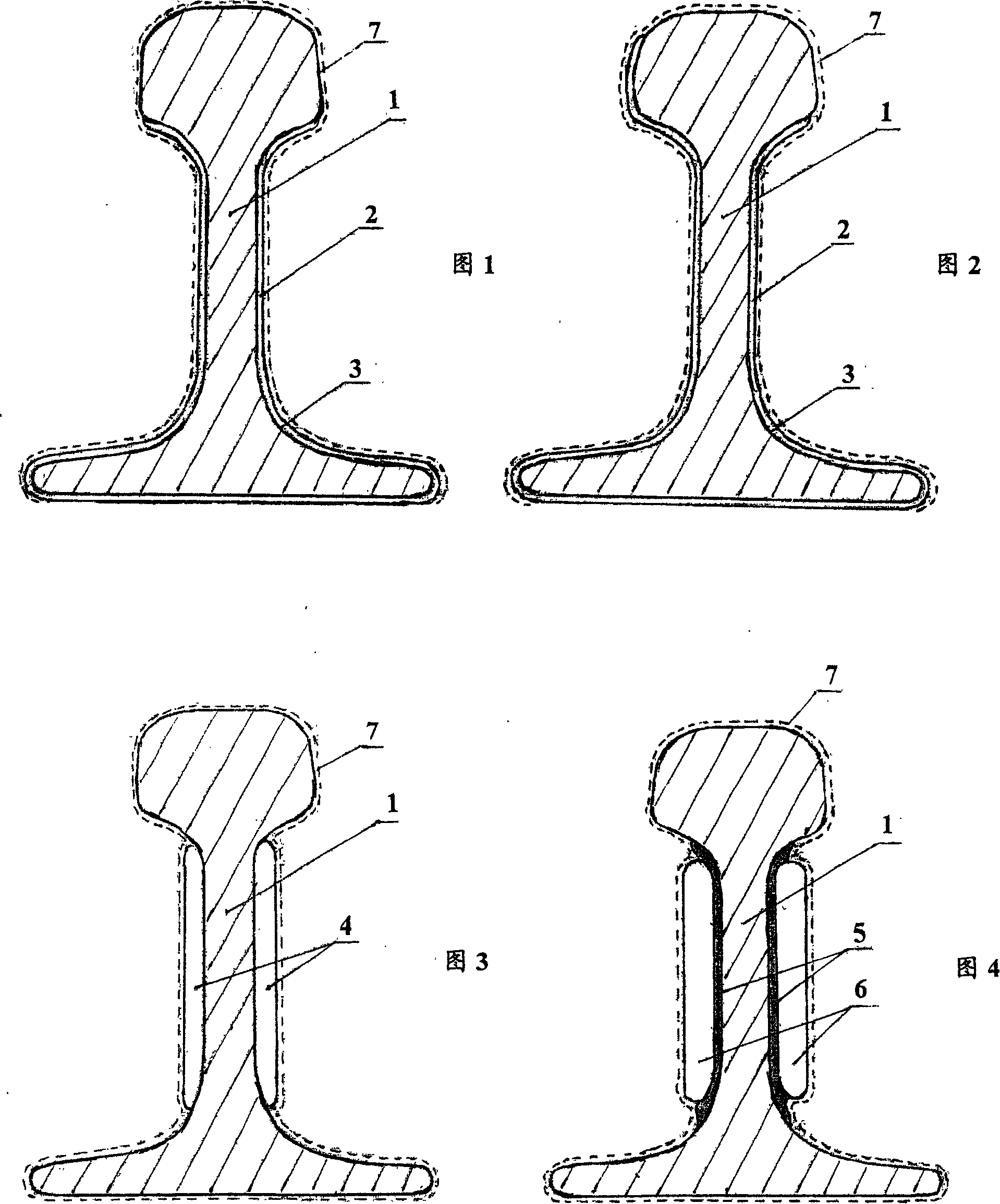

Corrosion-resistant break-resistant steel rail or steel wheel of train

InactiveCN101153398AAutomatic adjustment of cathodic polarization valuePlay a role in monitoring and finding broken railsRailsRail-engaging wheelsCrack resistanceWear resistant

The invention relates to a corrosion- and fracture-resistant rail or train rail, which aims to eliminate various failures caused by corrosion, the crack or fracture phenomenon of wear resistant rail-wheel (or ordinary rail-wheel) caused by stress corrosion or corrosion fatigue and the contradiction between wear resistance and crack resistance of rail (or wheel). Concretely, an anode is directly arranged on the non-working face of a rail or a wheel; moreover, the surface of the rail or the wheel is coated with a corrosion inhibition layer with ionic conduction and corrosion inhibition functions. Through sacrificing anode or external connection with a controllable DC source, the invention realizes the novel electrochemical protection which combines cathodic protection with corrosion inhibitor; therefore, the service life of the rail, the wheel and rail fittings are prolonged times to meet the pressing requirements of speed increase and increasing heavy load of railway transportation.

Owner:赵全玺

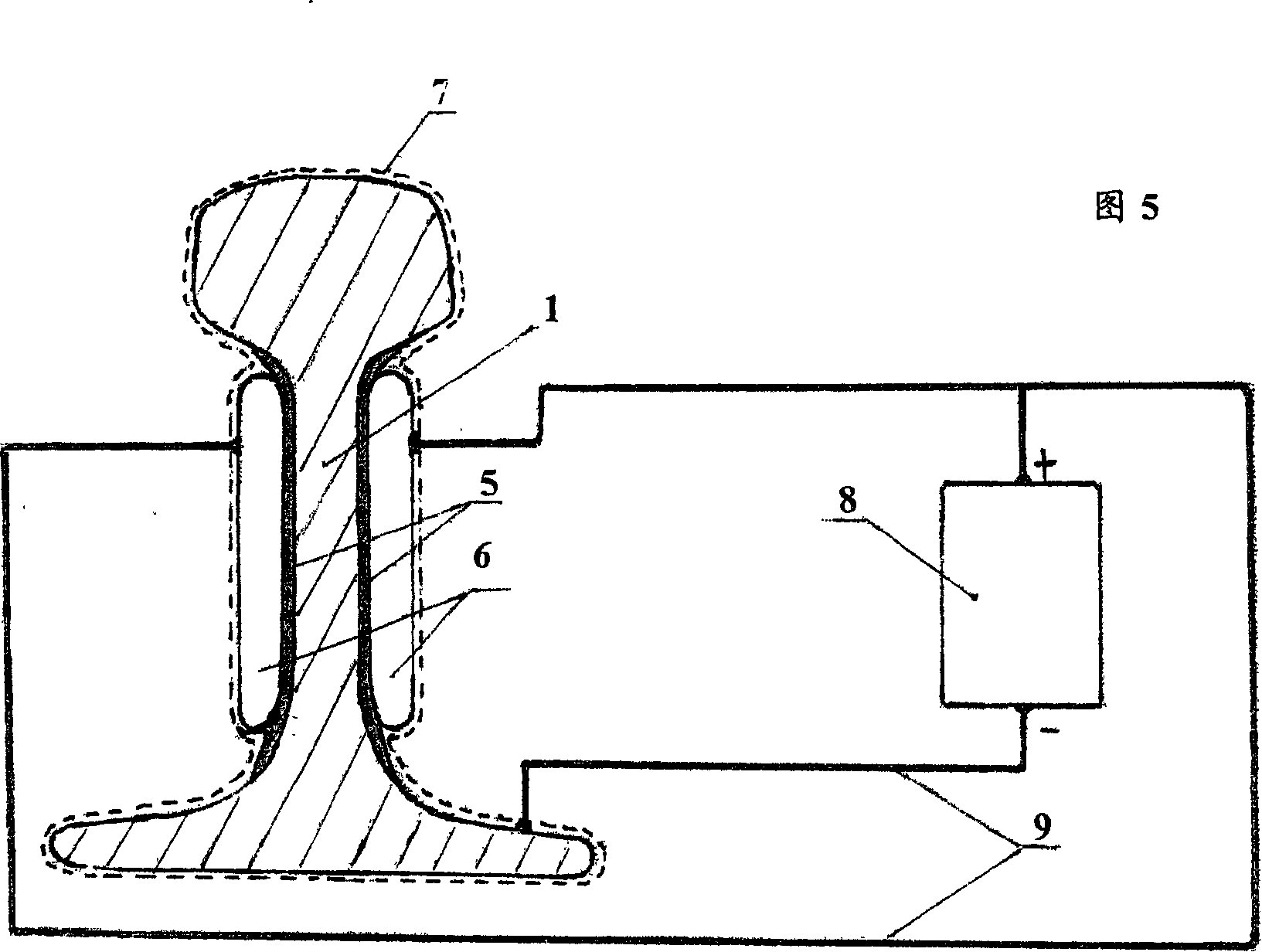

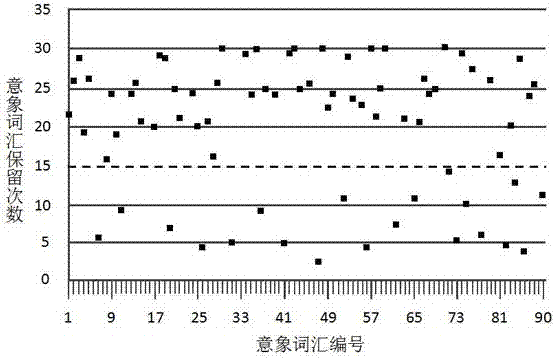

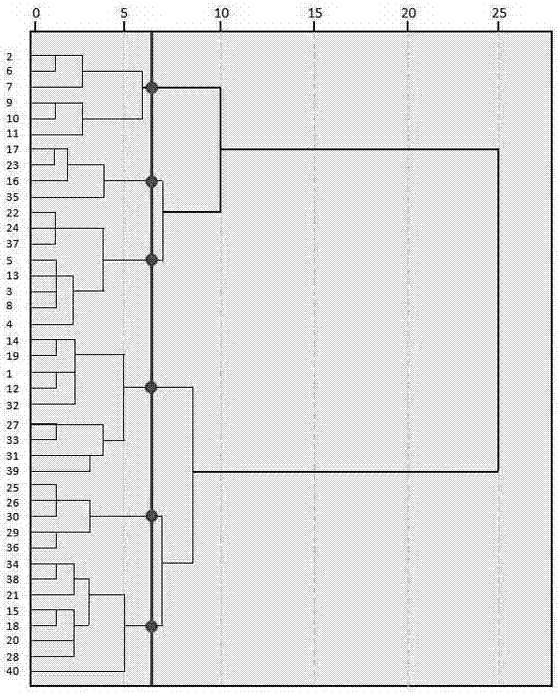

Multidimensional image-based product design scheme evaluation method

InactiveCN107067182AAvoid influenceReduce subjectivityResourcesManufacturing computing systemsMultidimensional scalingAlgorithm

The invention discloses a multidimensional image-based product design scheme evaluation method. The method includes the following steps that: (1) a k-mean clustering analysis method and factor analysis method are utilized to obtain a typical sample and typical perceptual image which accord with the perceptual cognition of a user, and then, a user-image initial evaluation value is obtained through using a semantic differential method; and (2) a gray correlation analysis and technique for order preference by similarity to an ideal solution (TOPSIS)-combined method is used to realize order optimization of alternative design schemes under the specific requirements of the multidimensional image of the user, and this process includes determining an alternative design scheme set, generating an original evaluation matrix, calculating the weights of evaluation indexes through using information entropies, constructing a normalized evaluation matrix, calculating distances, calculating relative proximities and sequencing the schemes. With the method of the invention adopted, the subjectivity of the perceptual image acquisition of the user can be balanced, and the validity of data can be ensured.

Owner:GUIZHOU UNIV

Method and device for making ice by using liquefied natural gas cold energy

InactiveCN102331127AImprove cold energy utilizationReduce energy consumptionLighting and heating apparatusIce productionAqueous solutionThermal water

The invention discloses a method and device for making ice by using liquefied natural gas cold energy. The method comprises the following steps that: (1) the liquefied natural gas with pressure of 0.3-0.5 MPa and temperature of -162 DEG C is kept at a temperature of 15-20 DEG C and a pressure of 0.3-0.5 MPa after exchanging heat with glycol aqueous solution, and then is gasified into the natural gas with pressure of 0.3-0.5 MPa and temperature of 25 DEG C; and the natural gas with pressure of 0.3-0.5 MPa and temperature of 25 DEG C enters a natural gas pipe network; (2) the glycol aqueous solution after heat exchange is cooled to -34 to -36 DEG C and supercharged to 0.3-0.5 MPa; and then the glycol aqueous solution exchanges heat with water; the water is condensed into ice; and the ice is scraped off; and (3) the glycol aqueous solution after exchanging heat with water returns to a room temperature glycol storage tank; the glycol aqueous solution in the room temperature storage tank is heated to 1-2 DEG C to be recycled. The method for making the ice by using the liquefied natural gas cold energy, disclosed by the invention, has the advantages of high LNG (Liquefied Natural Gas) cold energy utilization rate, no need of additional refrigeration power source during making ice and energy consumption conservation.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing active aluminum oxide utilizing industrial sludge of aluminium section bar plant

InactiveCN1557714AIncrease surface areaHigh activitySolid waste disposalSludge treatment by pyrolysisLiquid wastePorosity

The present invention belongs to the field of the comprehensive utilization of waste solid, and is especially to biological environment material technology. The production process of active alumina with industrial sludge from aluminum section factory includes depositing waste liquid to obtain sludge as solid waste with main components of gamma-AlOOH and Al(OH)3 and amorphous structure; and mixing dilute nitric acid with dry sludge to form plastic mud and to obtain active alumina with crystal phase gamma-Al2O3. The prepared active alumina is white or grey sphere, column or other grain, and has great specific surface area and great porosity.

Owner:FUZHOU UNIV

High-yield cultivation method of annual Angelica sinensis

InactiveCN103875393AReduce planting costsReduce incidenceHorticultureBiotechnologyAngelica Sinensis Root

The invention discloses a high-yield cultivation method of annual Angelica sinensis. The method comprises the steps of seedbed settling, sowing and seedling raising, seedling raising management, temporary planting seedling discharging, field transplanting, field management and harvesting and processing. When the cultivation method is used for planting Angelica sinensis, planting cost is low, investment risks are small, after transplanting, survival rate is high, the growth vigor of plants is strong, a planting cycle is short, technology practicability is high, the method is suitable for large-area promotion planting, meanwhile, compared with the prior art, under the situation that quality and pesticide effect are not changed, yield and quality are obviously improved, the occurring rate of plant diseases and insect pests is low, pesticide residual quantity is small, pollution is small, a good foundation is laid for improving manual large-scale planting of Angelica sinensis and enhancing the product competitiveness of Angelica sinensis, and great economic benefit, social benefit and ecological benefit are achieved.

Owner:XUANWEI HUIHONG AGRI TECH DEV CO LTD

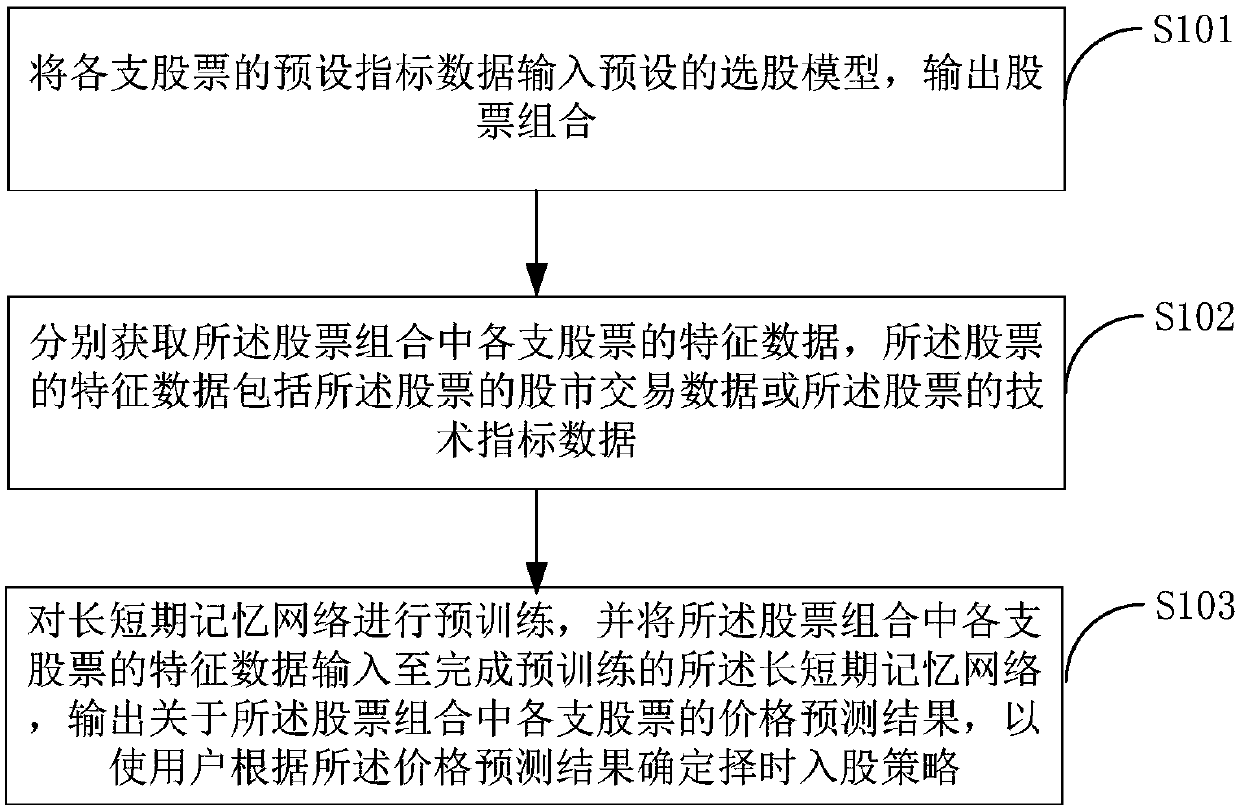

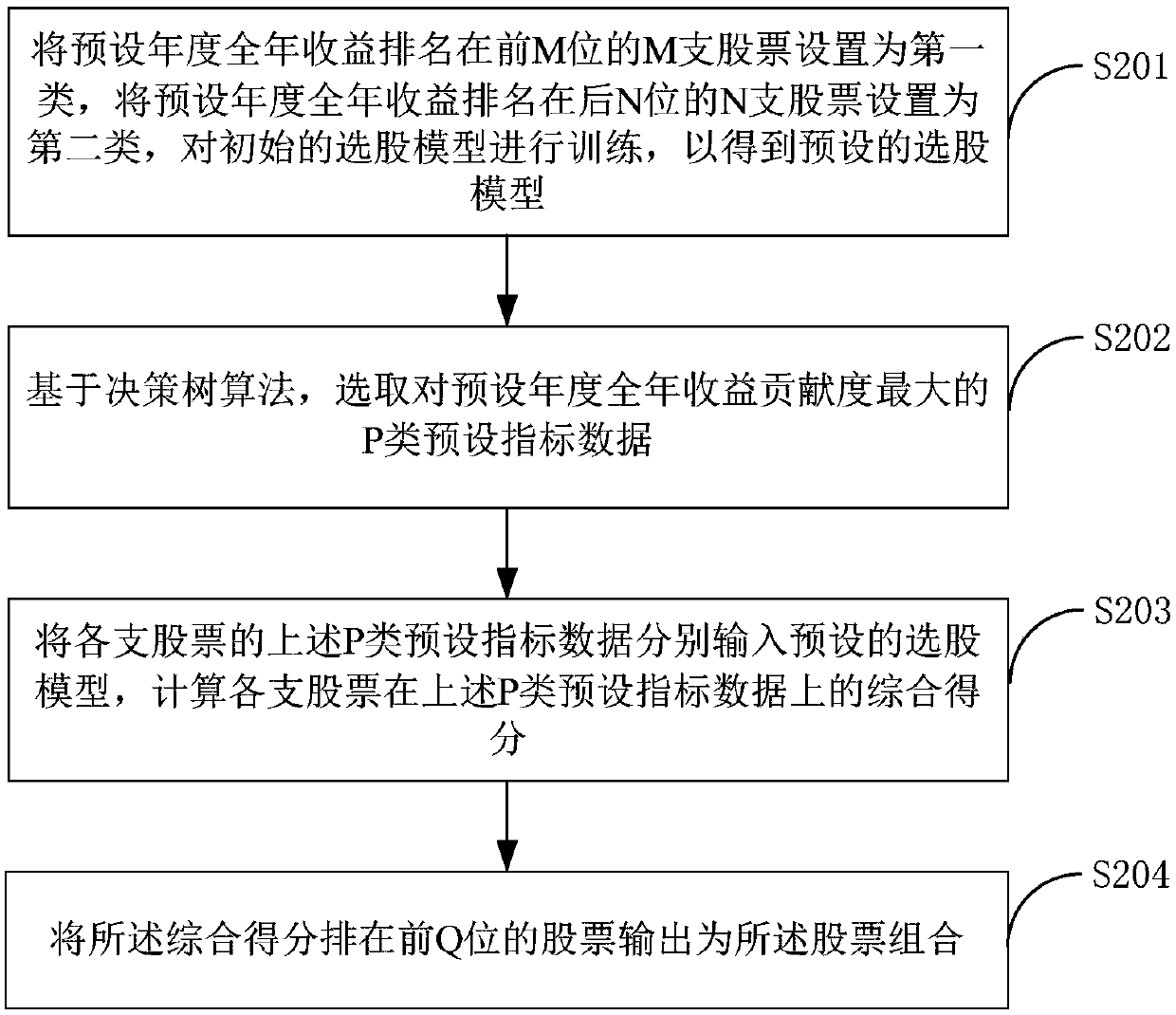

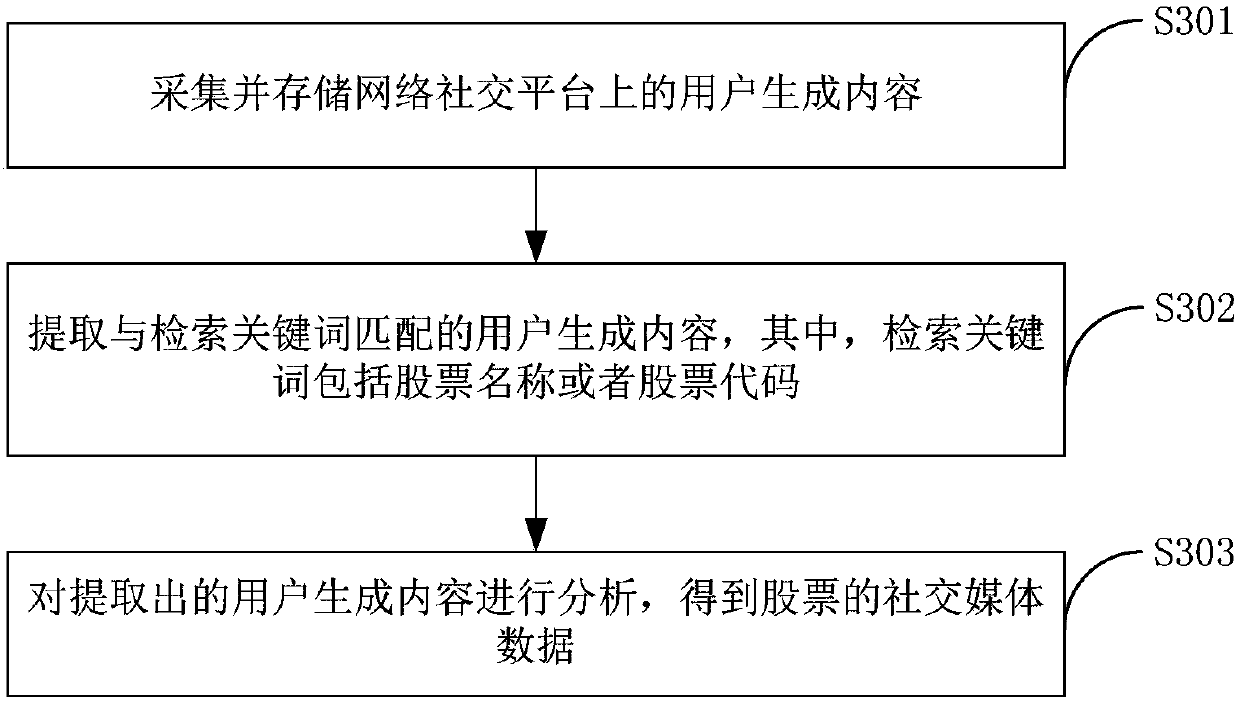

Time selection admission method based on machine learning, and terminal equipment

The invention is suitable for the technical field of computers, and provides a time selection admission method based on machine learning, and terminal equipment. The method comprises the following steps that: inputting the preset index data of each stock into a preset stock picking model, and outputting a stock combination; independently obtaining the feature data of each stock in the stock combination, wherein the feature data of the stock comprises the stock market transaction data of the stock or the technical index data of the stock; and inputting the feature data of each stock in the stock combination into a long short-term memory which finished being pre-trained, and outputting a price prediction result about each stock in the stock combination. By use of the method, the whole prediction process fully considers the behavior characteristics of a financial market, a deviation between the prediction result and the subsequent practical price tendency of the stock is effectively reduced, a user can more reasonably carry out the investment behaviors of stock selection and time selection admission on the basis of the predict prediction result, and the investment risk of the user iseffectively lowered.

Owner:PING AN TECH (SHENZHEN) CO LTD

A kind of method for preparing polyoxymethylene dimethyl ether by fixed-bed reactive distillation

ActiveCN104355973BHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

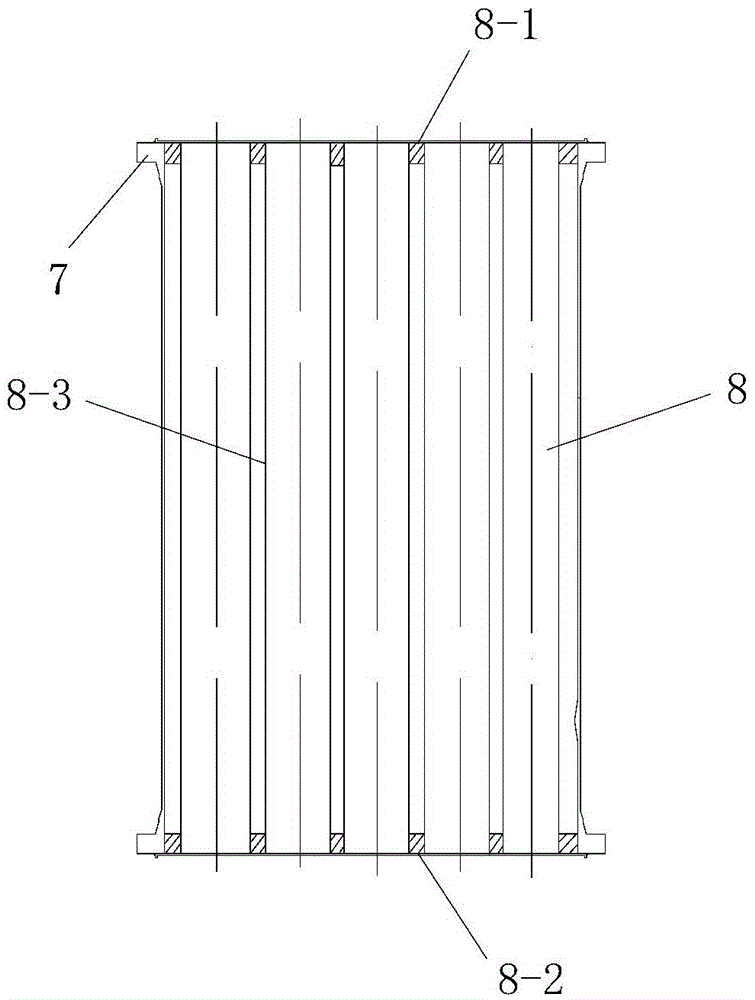

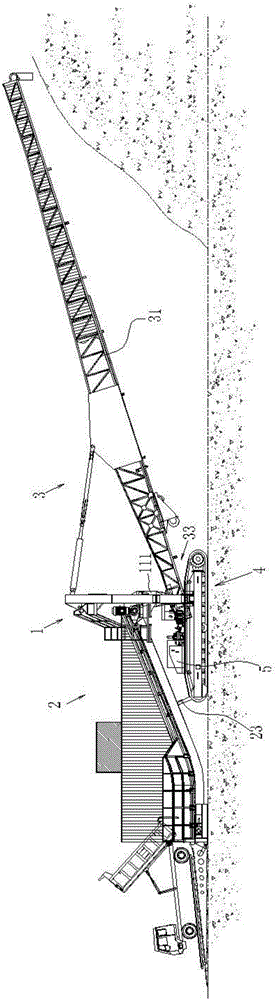

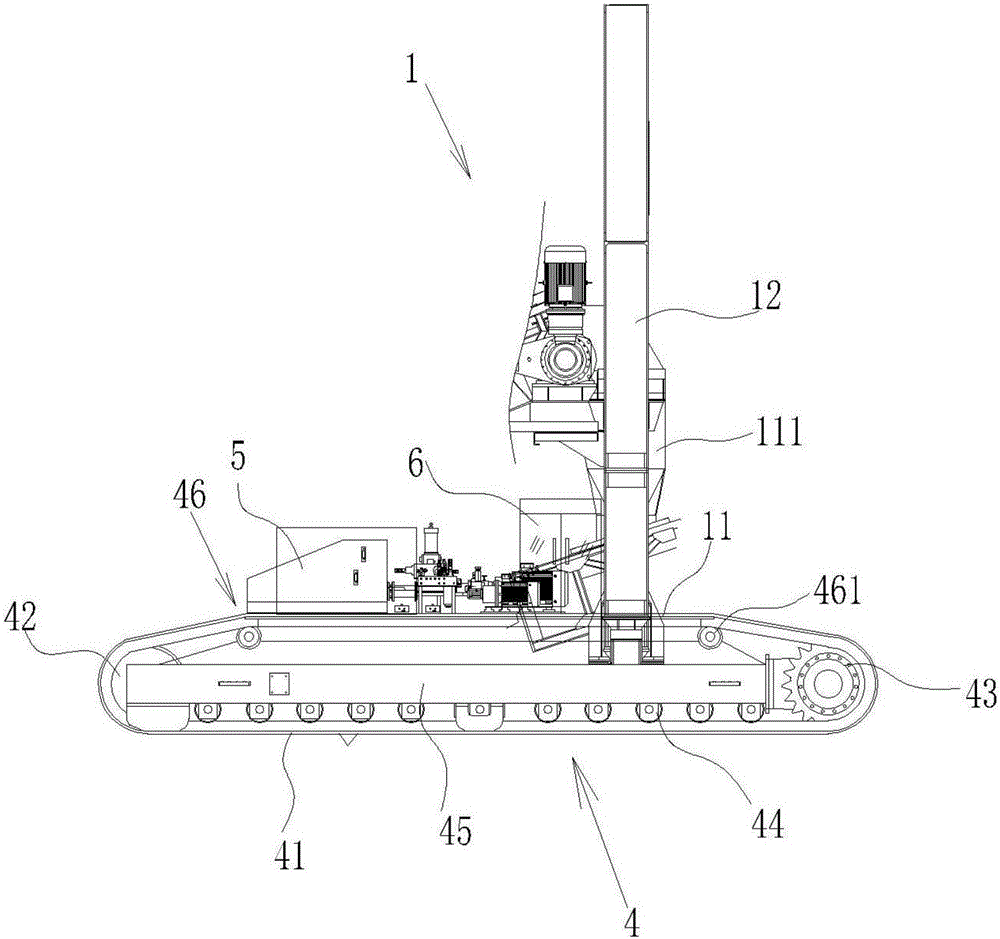

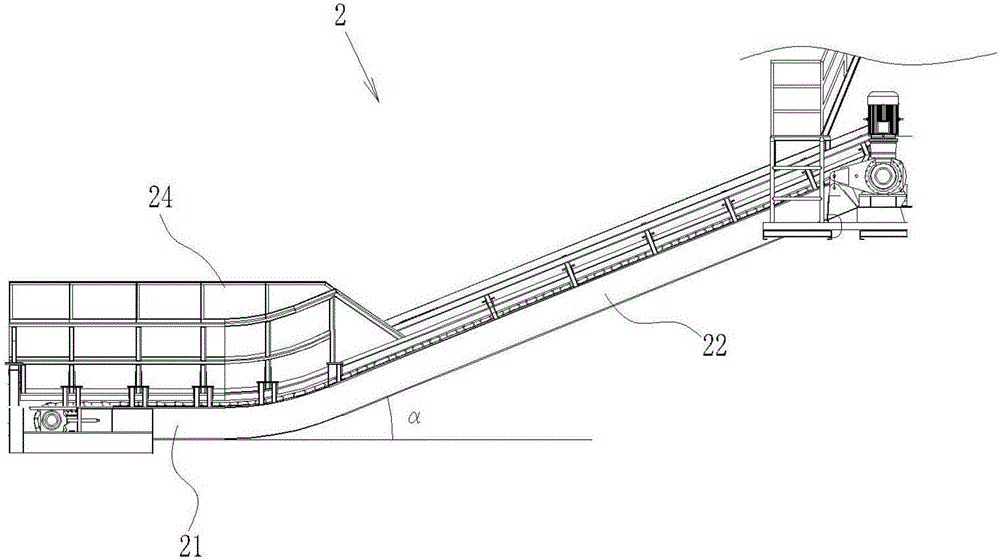

Crawler travelling stacker

The invention provides a crawler travelling stacker. The crawler travelling stacker comprises a rack as well as a feeding device, a discharging device and a control system which are arranged on the rack. The crawler travelling stacker is characterized in that the feeding device and the discharging device are connected through a slip material transition bin; the slip material transition bin is arranged on the rack; a travelling mechanism is arranged at the bottom of the rack and served as a crawler travelling mechanism; the feeding mechanism comprises a fed material lifting mechanism; the discharging mechanism comprises a cantilever pitching mechanism and a cantilever slewing mechanism; and the control system is used for controlling the travelling mechanism, the fed material lifting mechanism, the cantilever pitching mechanism and the cantilever slewing mechanism. The crawler travelling stacker provided by the invention can directly receive materials from a high-capacity dump truck, so as to improve the operational capability; by adoption of the crawler travelling mechanism, the crawler travelling stacker can move and change directions flexibly and stack the materials at any position of a site, and thus the utilized space of the site is enlarged; and the crawler travelling stacker can adapt to stacking sites with relatively complex working conditions, can pass through a place where bulk materials are stacked, is relatively strong in climbing capability, and can adapt to various working conditions of the stacking sites.

Owner:JIANGSU WANBAO MACHINERY

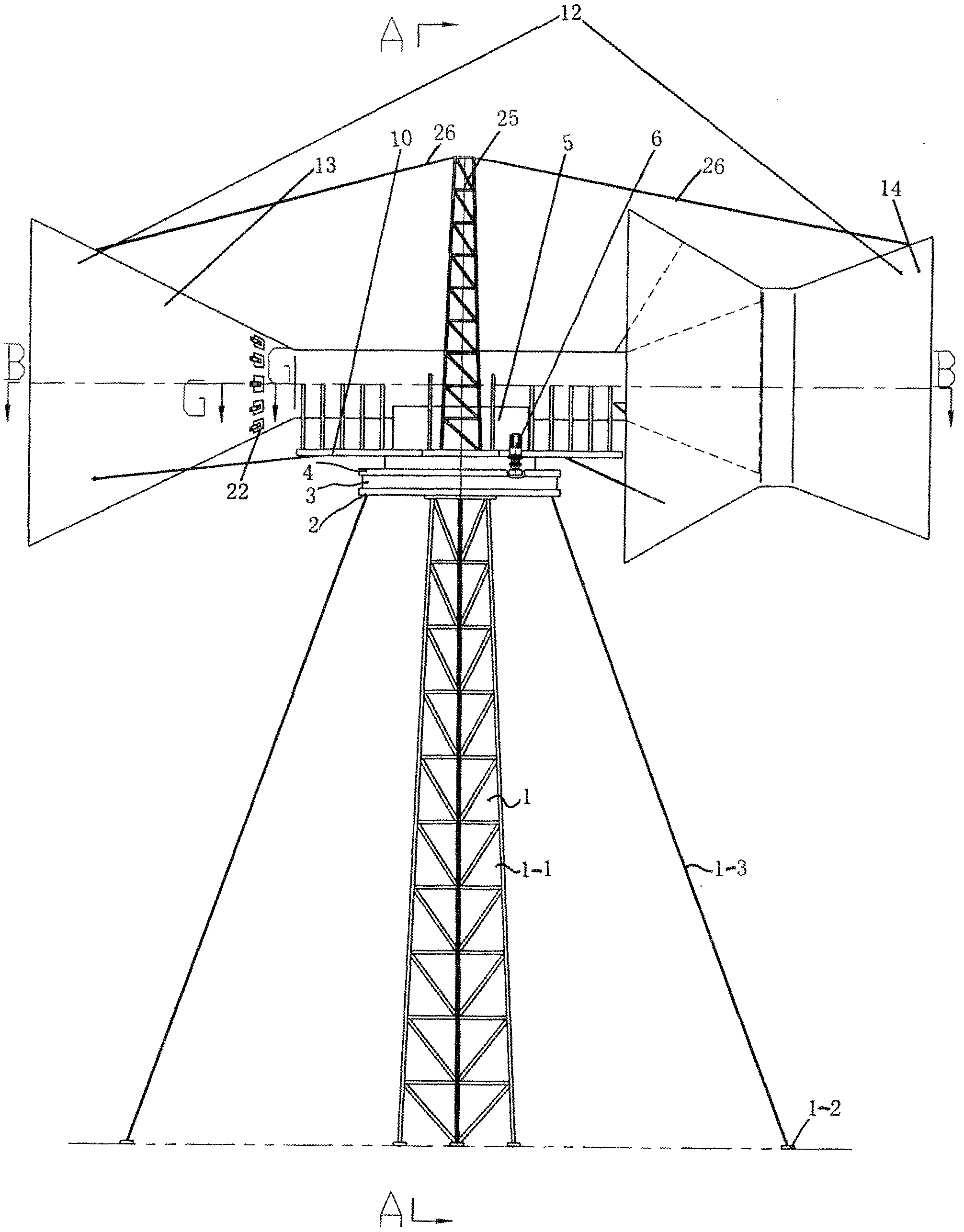

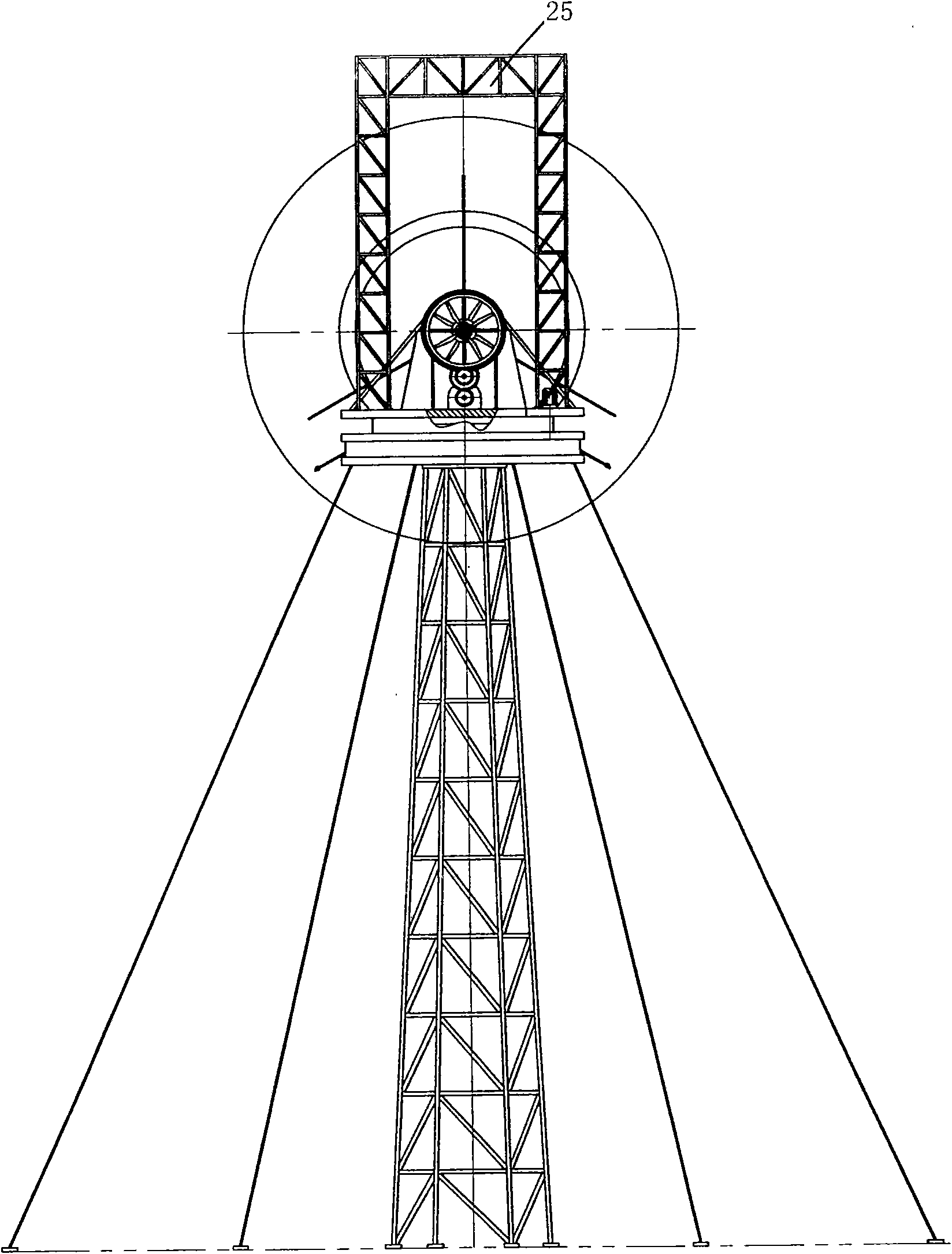

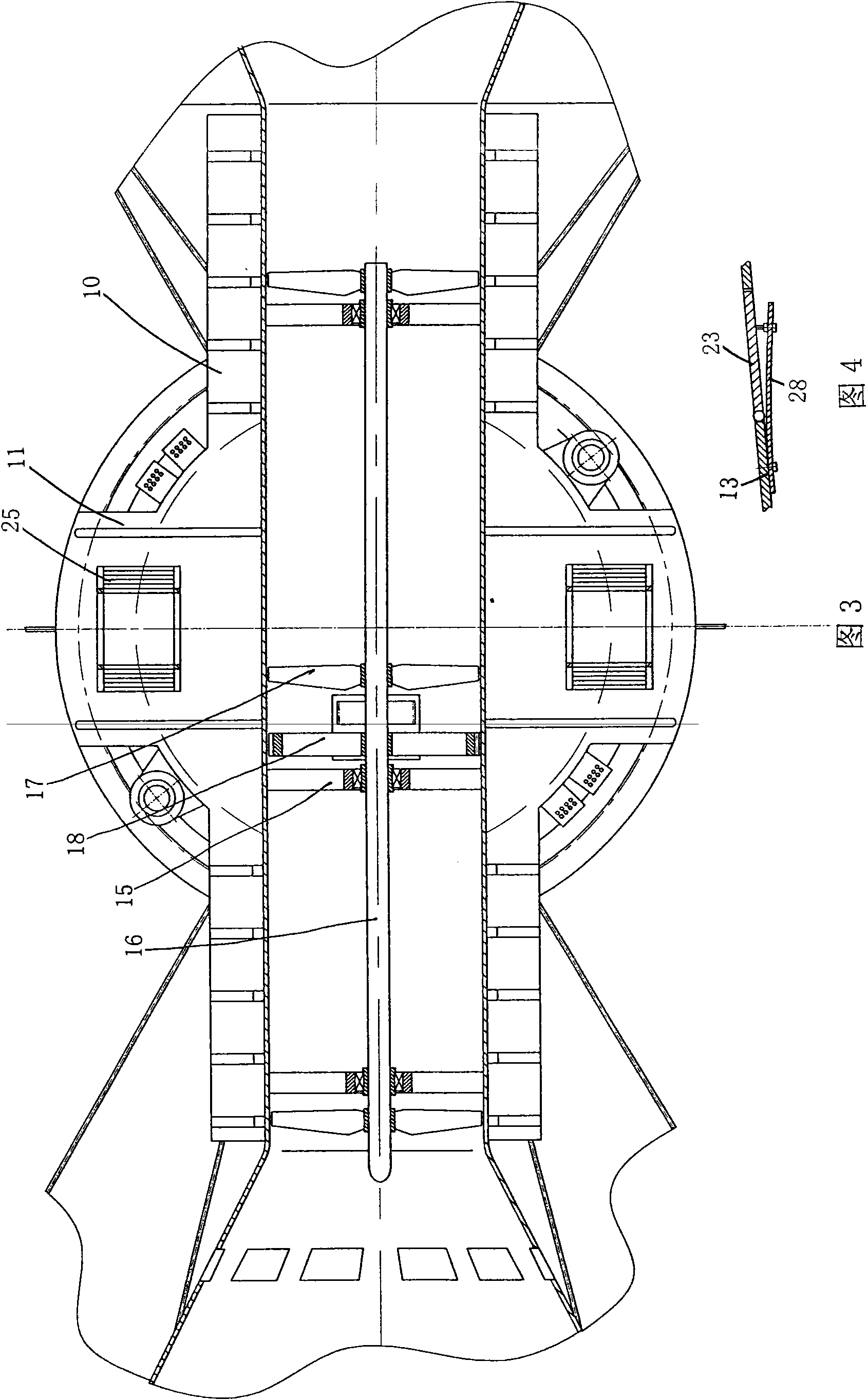

Tunnel diffusion draught fan

InactiveCN101949353AVelocity increasesImprove economyWind motor controlFinal product manufactureImpellerNacelle

The invention discloses a tunnel diffusion draught fan, which comprises a tower, a worktable arranged on the top of the tower, a lower bearing disk arranged on the worktable, an upper bearing disk positioned on the lower bearing disk and a cabin arranged on the upper bearing disk, wherein the upper bearing disk is provided with a supporting bracket which is provided with a tunnel diffusion draught fluid channel with a round cross section; a diffuser is arranged in the tunnel diffusion draught fluid channel; a front diffusion and acceleration section three-dimensional channel, a three-dimensional fluid acting channel and a rear post-action air flow three-dimensional fluid channel, which are communicated in turn, are arranged in the diffuser; and the three-dimensional fluid acting channel is provided with at least two impellers along the axial direction of the fan, and a working machine positioned in the cabin is connected with the impellers through a transmission mechanism. The tunnel diffusion draught fan has high kinetic energy utilization rate and reduced cost and is convenient and safe in manufacturing, transportation, installation and maintenance.

Owner:李平

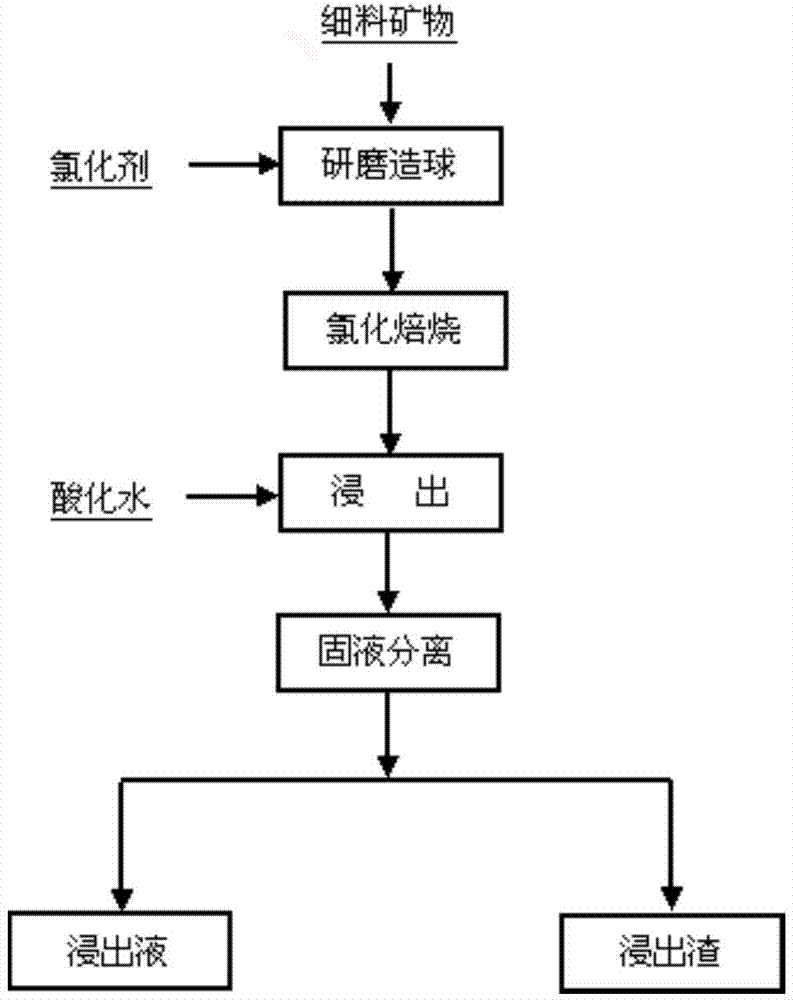

Method for extracting nickel and cobalt from nickel laterite by chloride roasting

The invention relates to the pyrometallurgical and hydrometallurgical field of non-ferrous metals, in particular to a method for extracting nickel and cobalt from nickel laterite by chloride roasting. The method provided by the invention comprises the following steps: grinding a chlorinating agent and ore material together and uniformly pelletizing, wherein the amount of the chlorinating agent accounts for 15-20wt% of the ore material; loading an ore sample which is well ground into a porcelain crucible, covering a cover, and placing into a tube furnace for roasting, wherein the roasting temperature is 600-800 DEG C and the roasting time is 2-3 hours; leaching the ore sample after roasting with acidified water with the pH value of 2-4.5 at the temperature of 50-80 DEG C for 20-40 minutes, then performing solid-liquid separation, and performing vacuum suction filtration to obtain nickel and cobalt filtrate. According to the method provided by the invention, the laterite with low nickel content is treated by a chloride roasting technology, and the selective chlorination of the nickel, the cobalt and other valuable metals, as well as iron and magnesium is realized; by using the acidified water method to leach the valuable metals, namely the nickel and the cobalt, the hydrolysis of ferric chloride is simultaneously inhibited, the loss of the nickel and the cobalt caused by precipitation is prevented, and the high leaching rate of above 85% of the nickel and high leaching rate of above 70% of the cobalt are simultaneously ensured.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com