Crawler travelling stacker

A crawler-type and feeding device technology, applied in the field of stacking devices, can solve the problems of lack of flexibility in movement and steering, inability to adapt to dusty materials, and low stacking height, so as to improve operating capabilities, move and turn flexibly, and strong The effect of gradeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

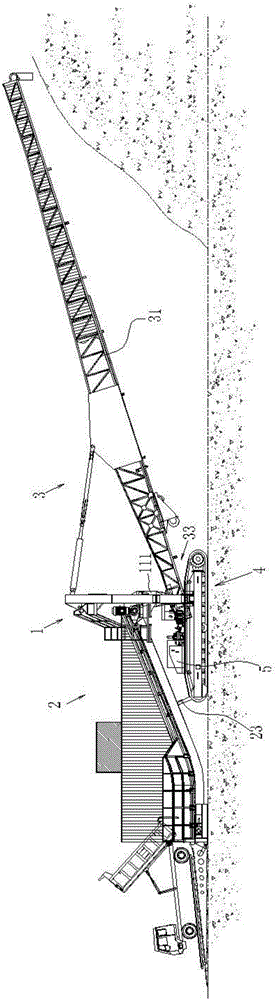

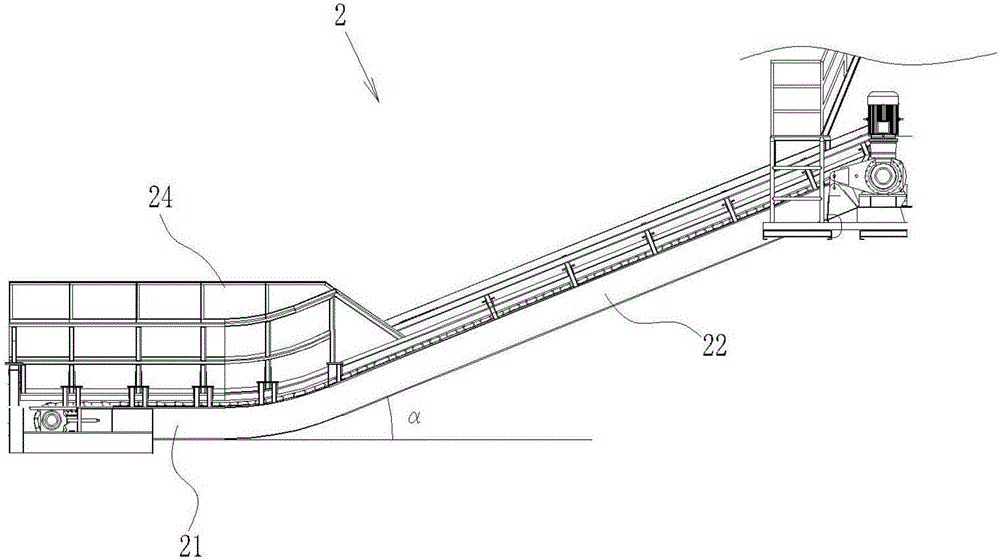

[0036] figure 1 to Figure 6 Schematically shows the first embodiment according to the present invention A crawler-type mobile stacking device , suitable for all kinds of bulk, granular and other loose material storage yards. Including the frame 1 and the feeding device 2, the discharging device 3, and the control system 5 located on the frame 1, the feeding device 2 is connected with the discharging device 3, and the control system 5 controls the operation of the feeding device 2 and the discharging device 3 .

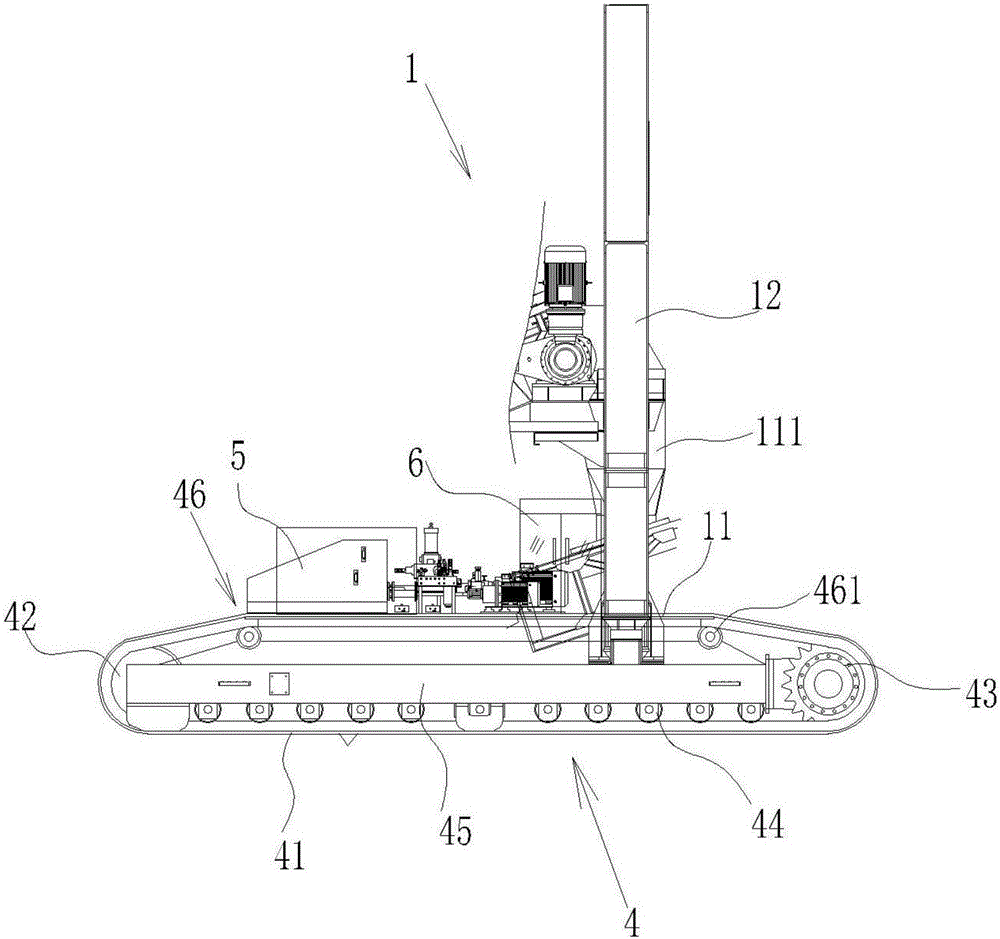

[0037] Such as figure 1 and figure 2 As shown, a traveling mechanism 4 is arranged at the bottom of the frame 1, and the traveling mechanism 4 adopts a crawler traveling mechanism, including a motor, a crawler belt 41, a guide wheel 42, a tow chain wheel 43, several supporting wheels 44, a traveling frame 45 and a tensioning device 46 , Such as figure 2 As shown, the guide wheel 42 and the tow chain wheel 43 are respectively located at the front a...

Embodiment 2

[0050] Example 2 provided A crawler-type mobile stacking device The structure is basically the same as that of Embodiment 1, the difference is that the feeding lifting mechanism and the cantilever pitching mechanism 32 are hoisting mechanisms, and the feeding device 2 and the discharging device 3 are controlled by the hoisting mechanism. The hoisting mechanism includes a stay rope, two Pulley and hoist, the hoist is located on the crawler chassis 11, two pulleys are located on both sides of the upper end of the support 12, and the ends of the stay rope are respectively connected to the middle position of the feeding transmission mechanism 22 and the connecting seat 321 in the middle of the feeding arm frame 311 , the stay rope is wound on the winch on the crawler chassis 11 after the pulley on the upper end of the support 12, and the winch is controlled by the control system 5.

[0051] provided by the invention A crawler-type mobile stacking device , The stacking device mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com