Method and device for making ice by using liquefied natural gas cold energy

A technology for liquefied natural gas and cold energy, applied in ice making, ice making, application, etc., can solve the problems of insufficient utilization of LNG cold energy, low energy utilization efficiency, complex equipment and process, etc., to achieve easy operation and maintenance, high efficiency The effect of energy saving and cooling energy utilization rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

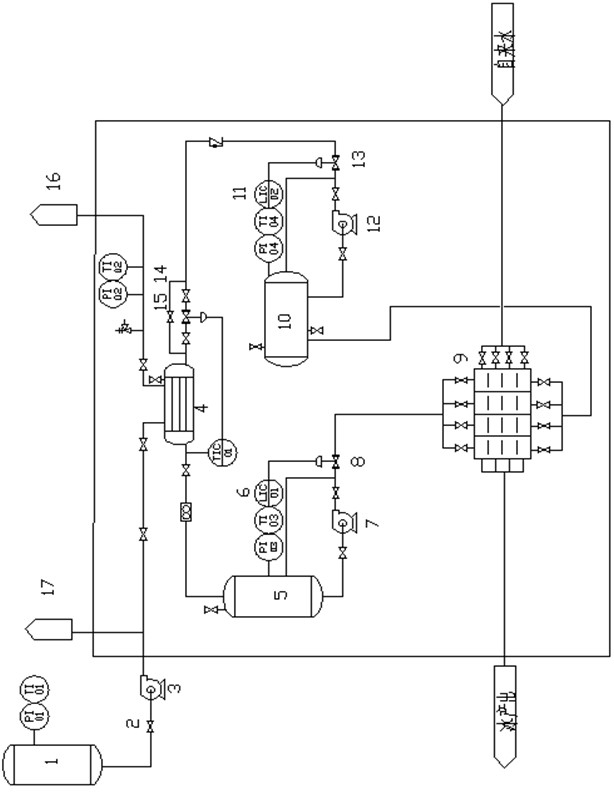

[0027] A method for using liquefied natural gas cold energy to make ice, comprising the following steps:

[0028] (1) After heat exchange between liquefied natural gas at 0.3-0.5MPa, -162°C and ethylene glycol aqueous solution with a concentration of 50%wt at 1°C, the temperature is 15°C, the pressure is 0.3-0.5MPa, and then gasified to 0.3-0.5 Natural gas at MPa and 25°C enters the natural gas pipeline network;

[0029] (2) After heat exchange, the temperature of the ethylene glycol aqueous solution drops to -35°C, pressurize to 0.3-0.5MPa, exchange heat with water, the water condenses into ice, and scrape off the ice;

[0030] (3) The ethylene glycol aqueous solution after heat exchange with water is returned to the ethylene glycol normal temperature storage tank, and the ethylene glycol aqueous solution in the normal temperature storage tank is raised to 1°C for recycling.

[0031] The LNG storage tank 1 is connected to the cold flow inlet of the LNG vaporizer 4 through an...

Embodiment 2

[0045] The low-temperature and low-pressure LNG coming out from the LNG storage tank 1 is pressurized to 0.3-0.5MPa through the first centrifugal pump 3, and the LNG after pressurization flows into the LNG vaporizer 4, and the ethyl alcohol after the pressurization from the normal temperature storage tank 10 of ethylene glycol aqueous solution The aqueous glycol solution exchanges heat in the vaporizer 4 . Referring to the pressure sensor 15 and temperature sensor 14 of the LNG pipeline, adjust the flow rate of LNG to ensure that the flow rate is 0.15kg / s, the flow rate of ethylene glycol solution is 1kg / s, the LNG outlet temperature is 17°C, and the pressure is 0.3-0.5MPa , regasified into natural gas at 0.3-0.5MPa and 25°C and enters the natural gas pipeline network, the cooled ethylene glycol aqueous solution flows into the ethylene glycol aqueous solution cold storage tank 5, and passes through the second centrifugal pump 7 with a flow rate of 1kg / s. The pressure rises to ...

Embodiment 3

[0047] The low-temperature and low-pressure LNG coming out from the LNG storage tank 1 is pressurized to 0.3-0.4MPa through the first centrifugal pump 3, and the LNG after pressurization flows into the LNG vaporizer 4, and the ethylene glycol after the normal temperature storage tank 10 pressurization from the aqueous solution of ethylene glycol. The aqueous glycol solution exchanges heat in the vaporizer 4 . Referring to the pressure sensor 15 and temperature sensor 14 of the LNG pipeline, adjust the LNG flow rate to ensure that the flow rate is 0.1kg / s, the flow rate of the ethylene glycol aqueous solution is 0.7 kg / s, the LNG outlet temperature is 20°C, and the pressure is 0.3-0.5MPa , regasified into natural gas at 0.3-0.5MPa and 25°C and then enters the natural gas pipeline network, the cooled ethylene glycol aqueous solution flows into the cold storage tank 5, passes through the second centrifugal pump 7, the flow rate is 0.7Kg / s, and the pressure rises To 0.3-0.5MPa, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com