Natural gas liquefaction system and method

A technology of natural gas and circulation system, applied in the field of natural gas liquefaction, can solve the problems of increasing operating costs, occupying process space, and wasting limited space resources, etc., and achieves the effect of improving the utilization rate of cold energy, simplifying the process, and improving the value of promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0032] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

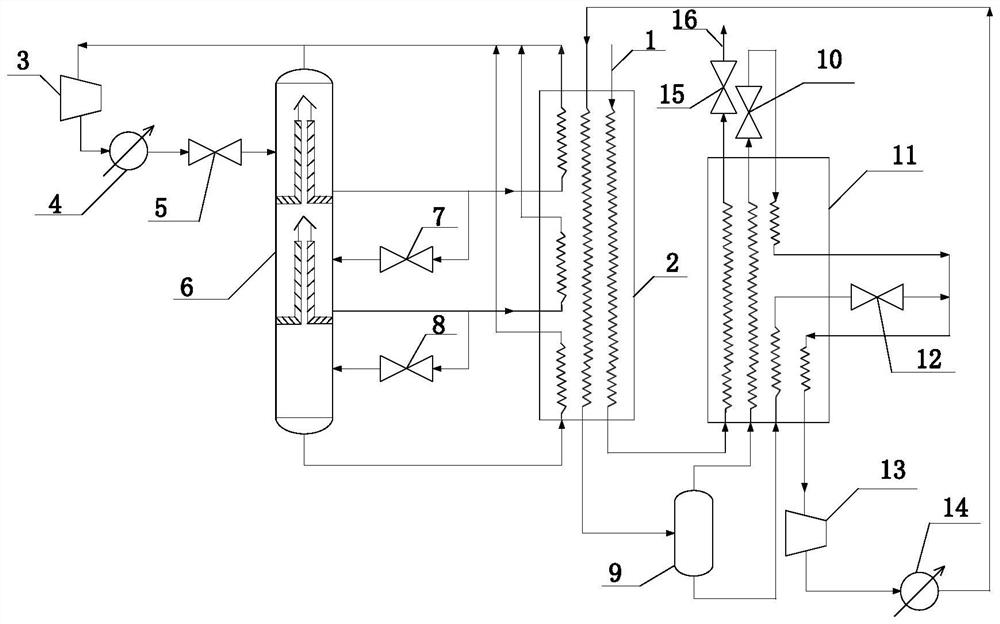

[0033] Such as figure 1 Shown, be the natural gas liquefaction system of the present invention, structure is as follows:

[0034] The natural gas liquefaction system includes a first liquefaction cold box 2 and a second liquefaction cold box 11, the inlet end of the primary pre-cooling section in the first liquefaction cold box 2 is connected with the natural gas inlet pipeline 1, and the first liquefaction cold box 2 The outlet port of the third-stage precooling section is connected with the inlet port of the first-stage cryogenic section in the second liquefaction cold box 11, and the outlet of the second-stage cryogenic section in the second liquefaction cold box 11 is connected with the sixth throttle valve 15 , connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com