A low temperature liquid nitrogen heat exchanger with adjustable temperature difference

A low-temperature liquid nitrogen, adjustable technology, applied in direct contact heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problem of increased liquid nitrogen consumption, insufficient use of cold energy, and heat transfer temperature differences Large and other problems, to achieve the effect of improving the utilization rate of cold energy, compact structure, and strong self-shrinking ability at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

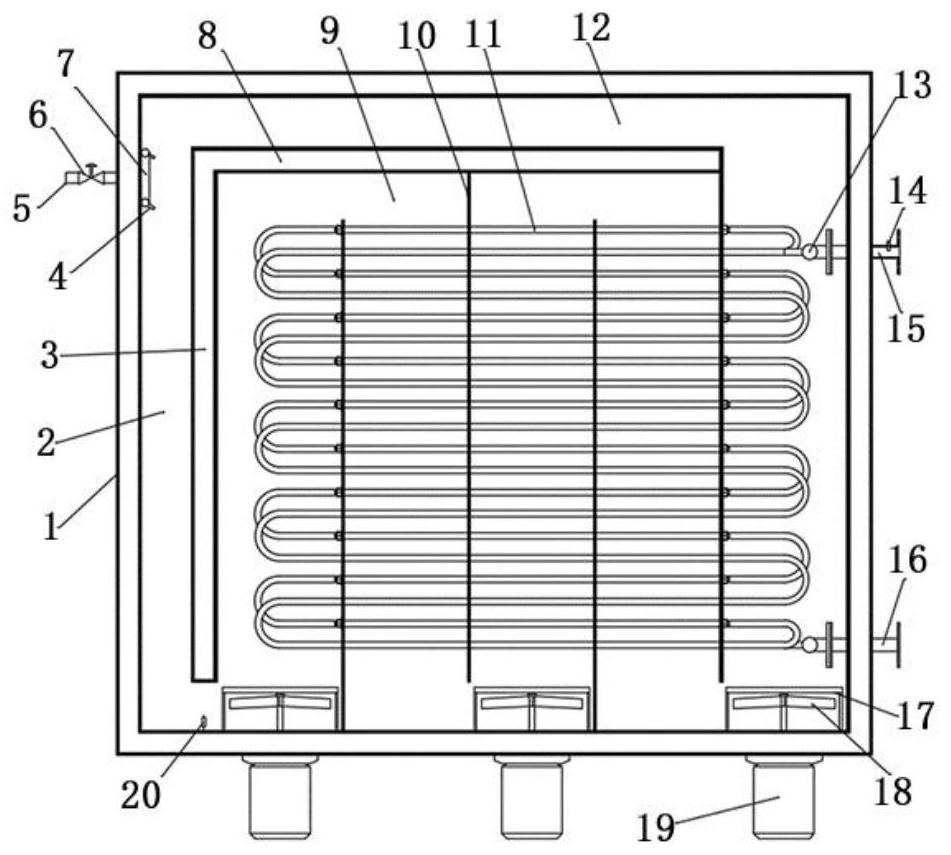

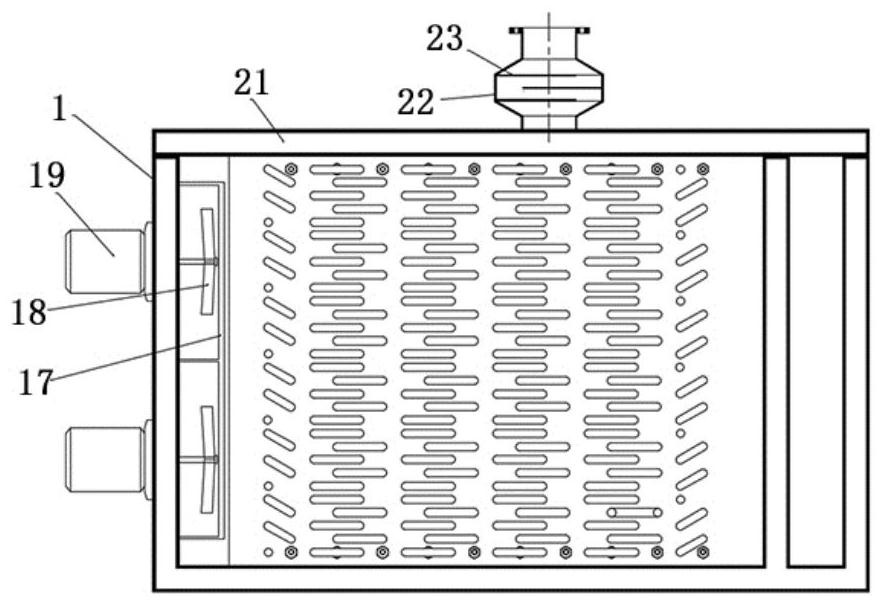

[0020] Below in conjunction with accompanying drawing, the embodiment of technical scheme of the present invention is described in detail:

[0021] Such as figure 1 As shown, a low-temperature liquid nitrogen heat exchanger with adjustable temperature difference includes a shell 1, a heat exchange tube 11, a baffle plate 10, a fan and a temperature measuring device. Two partitions are arranged inside the shell 1, and the The interior of the shell 1 is divided into a liquid nitrogen evaporation zone 2, a heat exchange zone 9 and a return channel 12, wherein the shell 1 and the partition are all heat-insulated; the number of the heat exchange tubes 11 is several, and in this embodiment, the There are six groups, which are layered and arranged in the heat exchange area 9 from top to bottom. The number of the baffles 10 is four, and they are arranged in the heat exchange area 9 in the shell 1. There are regular triangular rows on the baffles 10. At the same time, the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com