Light hydrocarbon separation device and method for liquefied natural gas

A technology of liquefied natural gas and separation device, applied in the field of light hydrocarbon recovery, can solve the problems of high equipment cost, high pressure, unfavorable storage and transportation, and substandard product concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

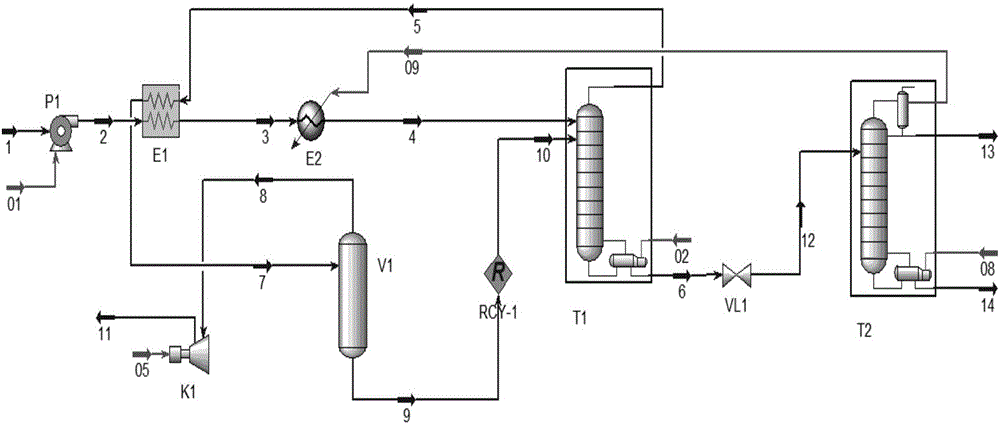

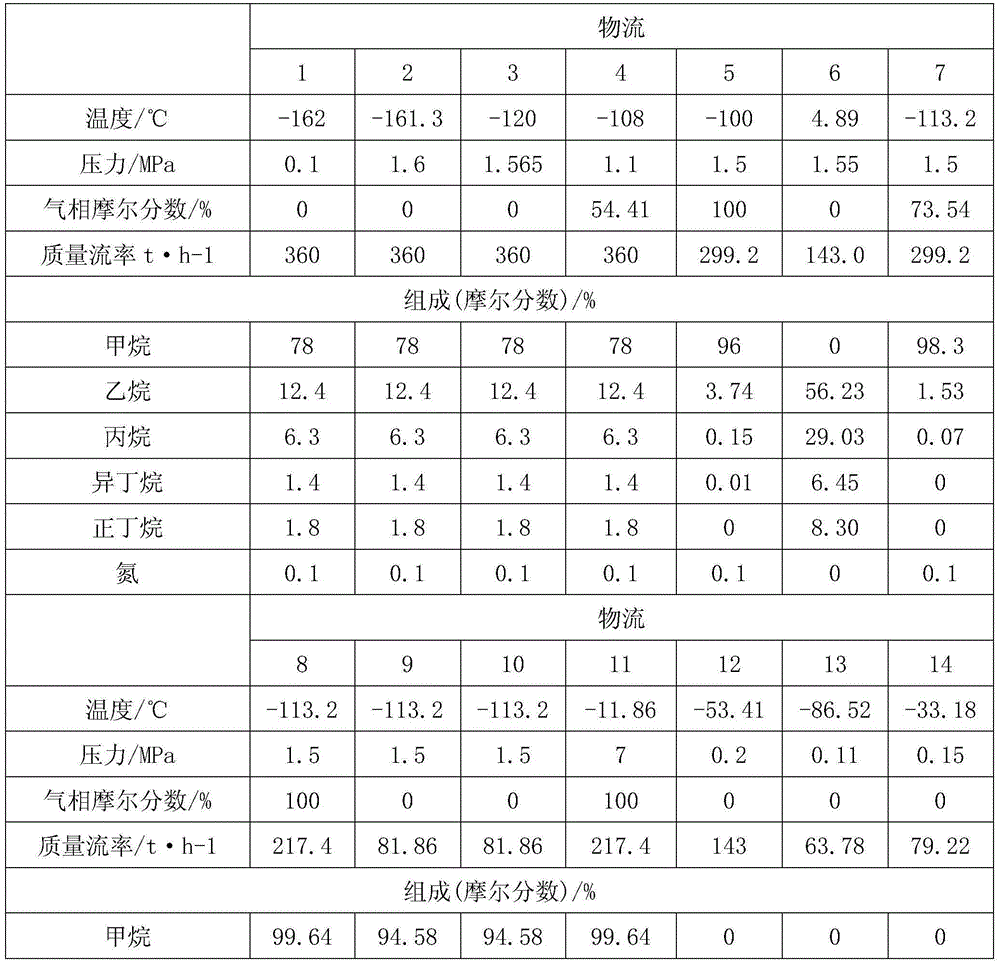

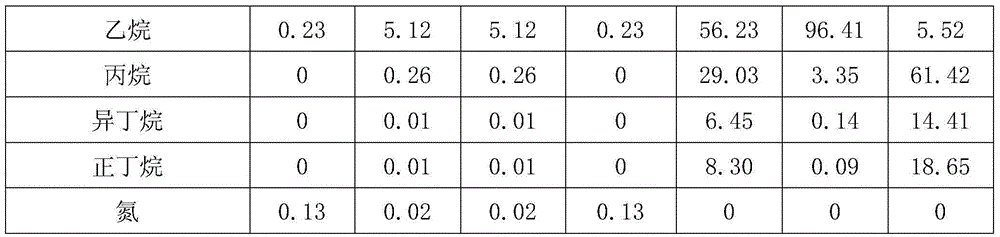

[0048] The processing capacity is 360t / h, the LNG temperature is -162°C, normal pressure, and the molar content is: methane 78%, ethane 12.4%, propane 6.3%, isobutane 1.4%, n-butane 1.8%, nitrogen 0.1%.

[0049] Atmospheric LNG raw material is first boosted to 1.6MPa by pump P1, and then flows through heat exchangers E1 and E2 for heating twice. The heated LNG raw material is partially gasified, and its gas phase mole fraction is about 50%. The partially vaporized LNG enters the demethanizer T1, which operates at a pressure of 1.5 MPa. Methane-enriched natural gas with a methane mole fraction of 98.3% is obtained at the top of the column by separation, and this stream enters the flash tower V1 for further separation after heat exchange with the LNG feed in the heat exchanger E1. Liquid phase C is obtained at the bottom of the demethanizer 2 + Light hydrocarbons, of which the molar content of ethane is about 56%, and the remainder is C 3 + light hydrocarbons. The stream is...

Embodiment 2

[0059] The processing capacity of the device is 1 million tons per year, the LNG pressure is 0.8MPa, the temperature is -158°C, and the molar composition is as follows: methane 86.78%, ethane 8.13%, propane 3.67%, isobutane 0.55%, n-butane 0.55%, 0.05% isopentane, 0.05% n-pentane, 0.01% n-hexane, 0.22% nitrogen.

[0060] Atmospheric LNG raw material is first boosted to 3.8MPa by pump P1, and then heated twice through heat exchangers E1 and E2. The heated LNG raw material is partially gasified, and its gas phase mole fraction is about 20%. The partially vaporized LNG enters the demethanizer T1, which operates at a pressure of 3.6MPa. Methane-enriched natural gas with a methane mole fraction of 98% is obtained at the top of the tower by separation, and this stream enters the flash tower V1 for further separation after heat exchange with the LNG feed in the heat exchanger E1. Obtain the liquid phase C in the demethanizer tower kettle 2 + Light hydrocarbons, in which the molar ...

Embodiment 3

[0069] The processing capacity of the device is 1 million tons per year, the LNG pressure is 0.8MPa, the temperature is -158°C, and the molar composition is as follows: methane 91.15%, ethane 5.91%, propane 0.15%, isobutane 0.33%, n-butane 0.33%, Isopentane 0.01%, n-pentane 0.01%, n-hexane 0.01%, nitrogen 0.75%.

[0070] Atmospheric pressure LNG raw material is first boosted to 3.8MPa by pump P1, then flows through heat exchangers E1 and E2 for two heat exchanges and is partially gasified, and its gas phase mole fraction is about 6%. The partially vaporized LNG enters the demethanizer T1, which operates at a pressure of 3.6MPa. Methane-enriched natural gas with a methane mole fraction of 98% is obtained at the top of the tower by separation, and this stream enters the flash tower V1 for further separation after heat exchange with the LNG feed in the heat exchanger E1. The liquid phase C2+ light hydrocarbons are obtained in the bottom of the demethanizer, in which the molar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com