Method for transferring patterns on fiber fabric

A fiber fabric and pattern technology, applied in the field of textile printing, can solve the problems of protein fiber embrittlement, complex process, high investment, etc., achieve high resolution, simple process operation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for pattern transfer to fiber fabrics is carried out as follows:

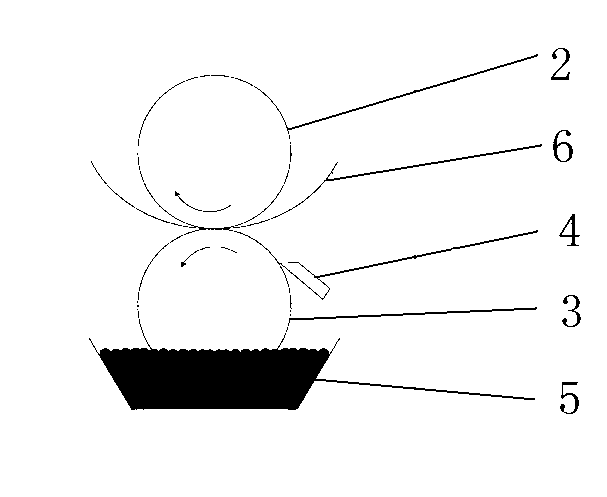

[0038] 1. Paper coating and isolation layer: prepare white kraft paper with a weight of 80g and a width of 1.8m and put it on the laminating machine, heat the solid PE to 140°C, and then pour it on the white kraft paper through the die of the extruder. The coating thickness is 15g / ㎡.

[0039] 2. Preparation of coating glue: Mix the components according to the weight ratio shown in Table 1, and stir with a mixer to form a colloidal coating glue. After the preparation is completed, place it at room temperature for more than 12 hours for later use.

[0040]

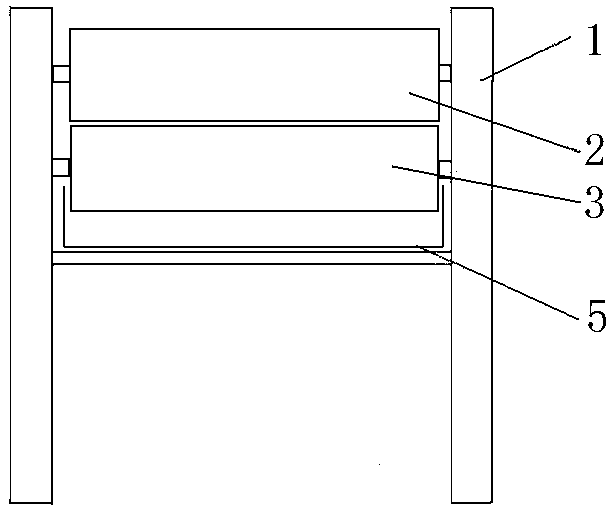

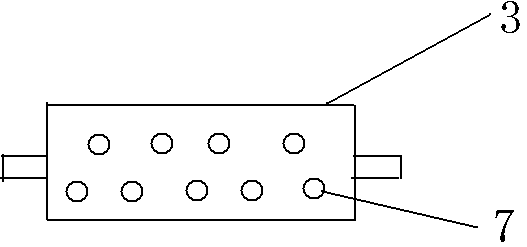

[0041] 3. Coating glue for paper coating: use the coating machine to coat the prepared coating glue and the paper with a width of 1.8m and a PE isolation layer on the surface. The coating should be applied on the On the isolation layer, the coating should be uniform. At this time, a transfer layer with a thickness of about 10 μm is formed...

Embodiment 2

[0050] A method for pattern transfer to fiber fabrics is carried out as follows:

[0051] 1. Preparation of coating glue: Mix the components according to the weight ratio shown in Table 1, and stir with a mixer to form a colloidal coating glue. After the preparation is completed, place it at room temperature for more than 12 hours for later use.

[0052] 2. Film coating and printing coating glue: use the coating machine to coat the prepared coating glue and the film with a width of 1.8m. The coating should be uniform. At this time, the surface of the film forms a thickness Transfer layer around 10 μm.

[0053] 3. Printing on the film: put the paper coated with the transfer layer colloid on the digital inkjet printer, and print the designed pattern with reactive dye ink.

[0054] 4. Same as step 5 of embodiment 1, and the wool fabric in embodiment 1 is replaced by cashmere fabric.

[0055] 5. Same as step 6 of embodiment 1.

[0056] 6. Same as Step 7 of Example 1.

[0057]...

Embodiment 3

[0061] A kind of pattern is transferred to the method for fibrous fabric, concrete steps are the same as embodiment 2, difference only lies in the composition of coating glue.

[0062] In this embodiment, the dye transfer rate is over 98%, the pattern resolution is very high, the pattern layers are clear, there is little floating color in the washing process, the color fastness is above grade 4, and the printing effect reaches the level of imported digital printing machines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com