Tunnel diffusion draught fan

A technology of ejector fan and wind tunnel, which is applied in the direction of wind engine, wind engine consistent with the wind direction, wind engine control, etc. It can solve the problems of increased average output time of the fan at high speed, inconvenient installation and maintenance, and large resource loss. , to achieve the effect of increasing the average flow velocity, reducing the cost of the tower, and reducing the proportion of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

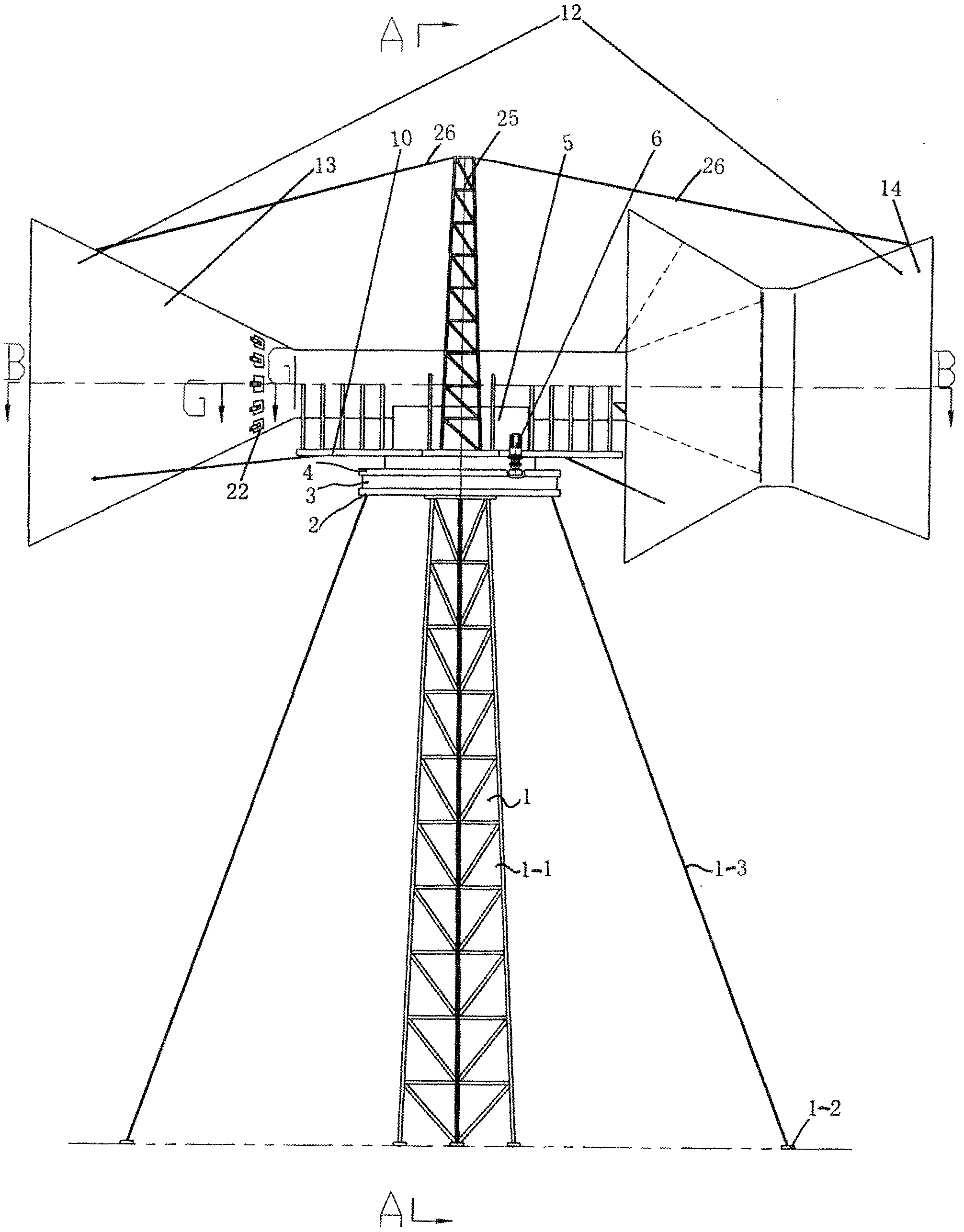

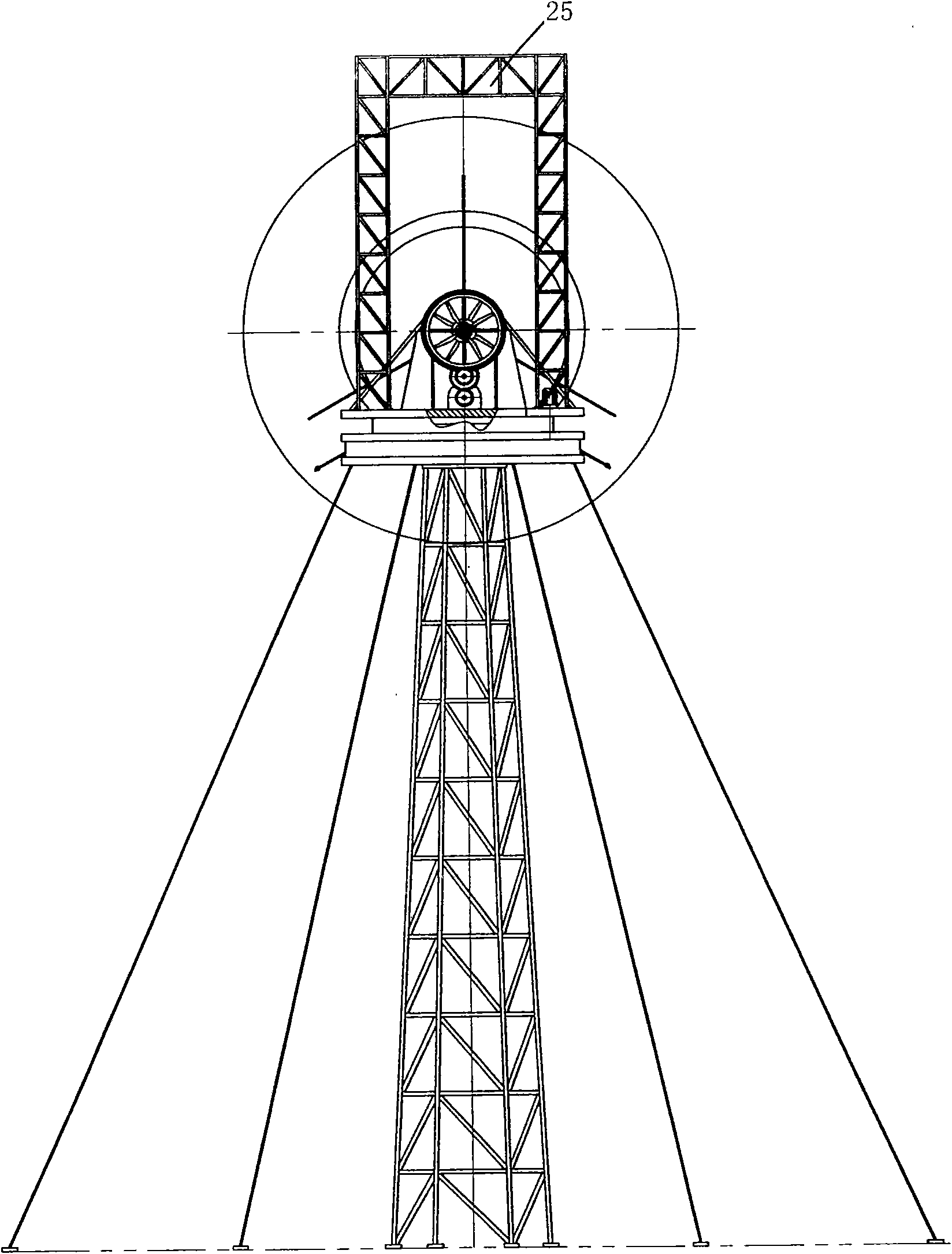

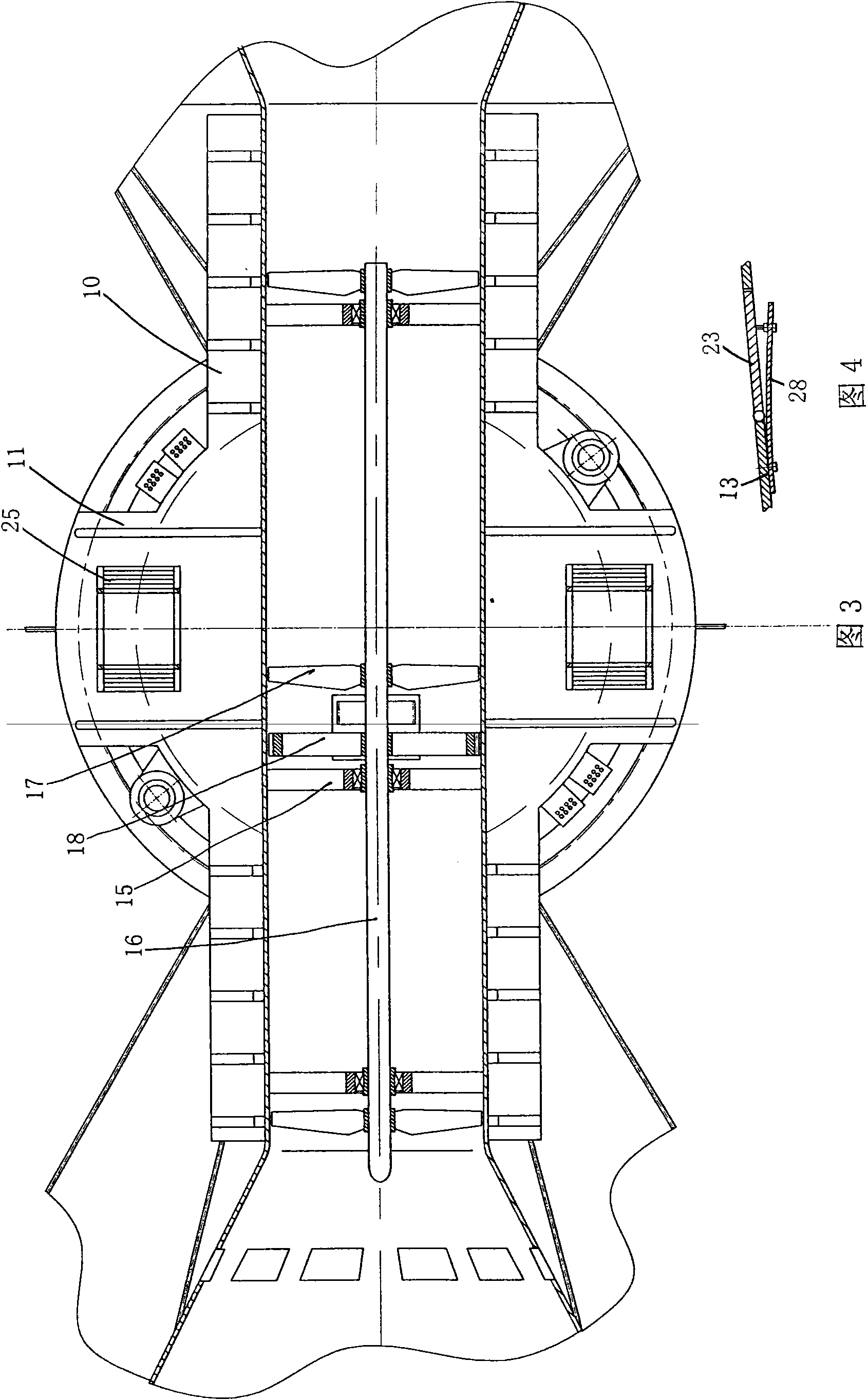

[0050] Figure 1 to Figure 10 Figure 1 of this embodiment is given. see Figure 1 to Figure 10 , the wind tunnel type diffuser and ejection fan in this embodiment includes a tower 1, a circular working platform 2 mounted on the top of the tower, a lower bearing plate 3 installed on the circular working platform, and a lower bearing plate located on the lower bearing plate. The upper bearing plate 4, the nacelle 5 installed on the upper bearing plate, the four yaw motor output shafts in the yaw device 6 installed on the upper bearing plate and the yaw teeth on the lower bearing plate Ring 7 meshes so as to drive the nacelle and the driving gear 8 that the upper load-bearing coil rotates around the yaw ring gear, and a plurality of yaw brakes 9 are arranged on the upper and lower load-bearing discs (see Figure 9 , Figure 10 ). A support bracket 10 is housed on the upper force plate. The support bracket is a rectangular frame with wings 11 on both sides (see Figure 8 ). ...

Embodiment 2

[0067] figure 2 Figure 2 of this embodiment is given. Embodiment 2 is basically the same as Embodiment 1. The difference is that there is no ejector.

[0068] The shape, structure, size, proportion, and material of the diffuser and ejector of the present invention must be determined, and in special cases or fan fluid passages are directly built on canyons, hillsides, special-shaped landforms, or other building objects without towers, etc. Circumstances can be adjusted accordingly. But as long as the diffuser or other artificial flow fields can achieve the technical and economic effect of increasing the speed of airflow diffusion.

[0069] In the present invention, the number of stages of impellers installed in the fluid channel can be determined according to actual needs. As long as it can achieve the effect of intensively capturing kinetic energy through the artificial flow field.

[0070] The number, orientation, and form of the constant-pressure hatches at the three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com