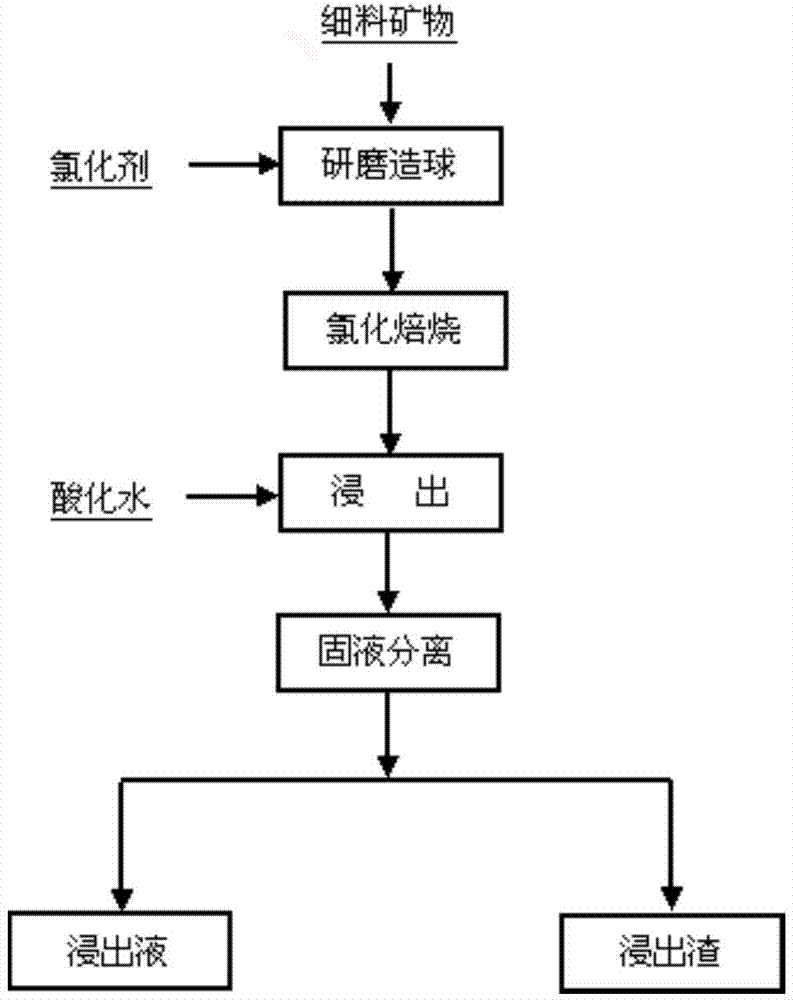

Method for extracting nickel and cobalt from nickel laterite by chloride roasting

A laterite nickel ore and roasting technology, which is applied to the field of nickel and cobalt extraction by chloride salt roasting of laterite nickel ore, can solve the problems of complex treatment process, large nickel loss, large impurity iron content in leaching solution, etc., and achieves simple operation process, less environmental impact, The effect of strong adaptation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 50g of lateritic nickel ore with a particle size of 0.074-0.15mm and 10g of NaCl:MgCl 2 : CaCl 2 (0.1:0.3:0.6) chlorination agent is ground evenly and placed in a porcelain crucible, add water and mix evenly to form pellets (diameter 4cm), cover the porcelain crucible cover and place the crucible in a muffle furnace heated to 800°C for roasting After taking it out for 2h, leaching with pH=4.5 acidified water at 80°C for 20min, and then measuring the leaching rate of Ni, Co, Mn, Fe and Ni / Fe, Ni / Mg ratio in the leaching solution. Through the control of the above conditions, the leaching rate of nickel in low-grade laterite nickel ore reaches 86%, and the leaching rate of cobalt reaches 67%. The nickel-iron ratio increased from 0.0581 in the raw ore to 1.544, and the Ni / Mg ratio increased from 0.0123 in the raw ore to 0.487, which increased by 30 times and 40 times respectively, which significantly reduced the treatment capacity of the subsequent purification and imp...

Embodiment 2

[0023] Mix 50g of lateritic nickel ore with a particle size of 0.074-0.15mm and 8g of NaCl:MgCl 2 : CaCl 2 (0.2:0.5:0.3) chlorination agent is ground evenly and placed in a porcelain crucible, mixed with water to form pellets (diameter 3cm), covered with a porcelain crucible lid, and placed in a muffle furnace heated to 700°C for roasting After taking it out for 2.5h, leaching with pH=3.2 acidified water at 60°C for 40min, and then measuring the leaching rate of Ni, Co, Mn, Fe and Ni / Fe, Ni / Mg ratio in the leaching solution. Through the control of the above conditions, the leaching rate of nickel in low-grade laterite nickel ore reaches 83%, and the leaching rate of cobalt reaches 65%. The nickel-iron ratio rose from 0.0581 in the ore to 1.144, and the Ni / Mg ratio rose from 0.0123 in the ore to 0.387. Significantly reduces the processing capacity of the subsequent purification and impurity removal process.

Embodiment 3

[0025] Mix 50g of lateritic nickel ore with a particle size of 0.074-0.15mm and 9g of NaCl:MgCl 2 : CaCl 2 (0.3:0.1:0.6) The compound chlorinating agent is ground together evenly and placed in a porcelain crucible, add water and mix evenly to make pellets (diameter 2cm), cover the porcelain crucible and place the crucible in a muffle furnace raised to 600°C Internal roasting for 3 hours, after taking out, leaching with pH=2 acidified water at 50°C for 30 minutes, and then measuring Ni, Co, Mn, Fe leaching rate and Ni / Fe, Ni / Mg ratio in the leaching solution. Through the control of the above conditions, the leaching rate of nickel in low-grade laterite nickel ore reaches 85%, and the leaching rate of cobalt reaches 64%. The nickel-iron ratio rose from 0.0581 in the ore to 1.344, and the Ni / Mg ratio rose from 0.0123 in the ore to 0.417. Significantly reduces the processing capacity of the subsequent purification and impurity removal process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com