Corrosion-resistant break-resistant steel rail or steel wheel of train

A fracture-resistant and corrosion-resistant technology, applied in the direction of wheels, rails, and wheels featuring rail running parts, etc., can solve problems such as interference with railway signals, difficult cathodic protection of rails, hydrogen embrittlement fracture, etc., to reduce investment risks and production. Efficient and easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

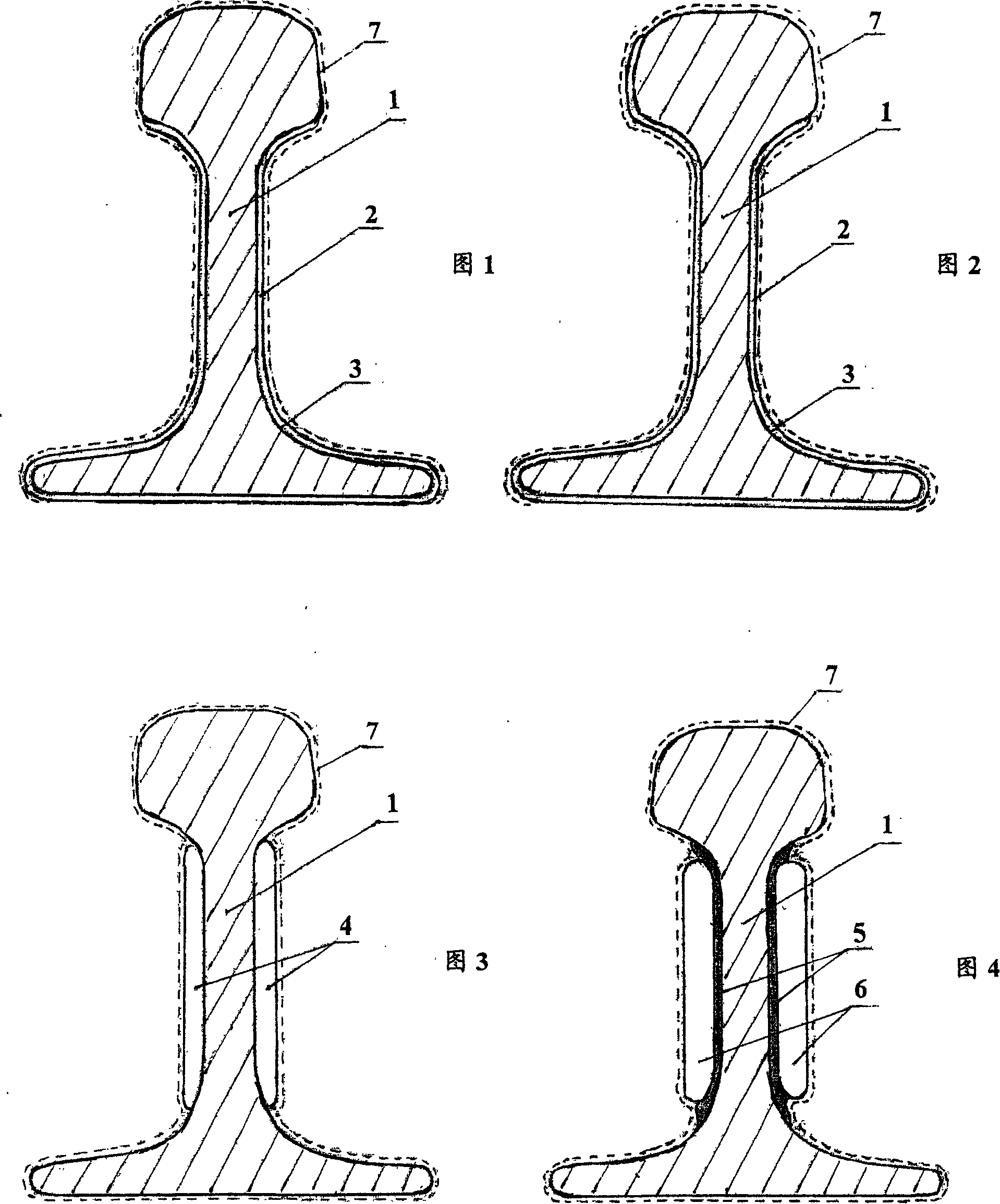

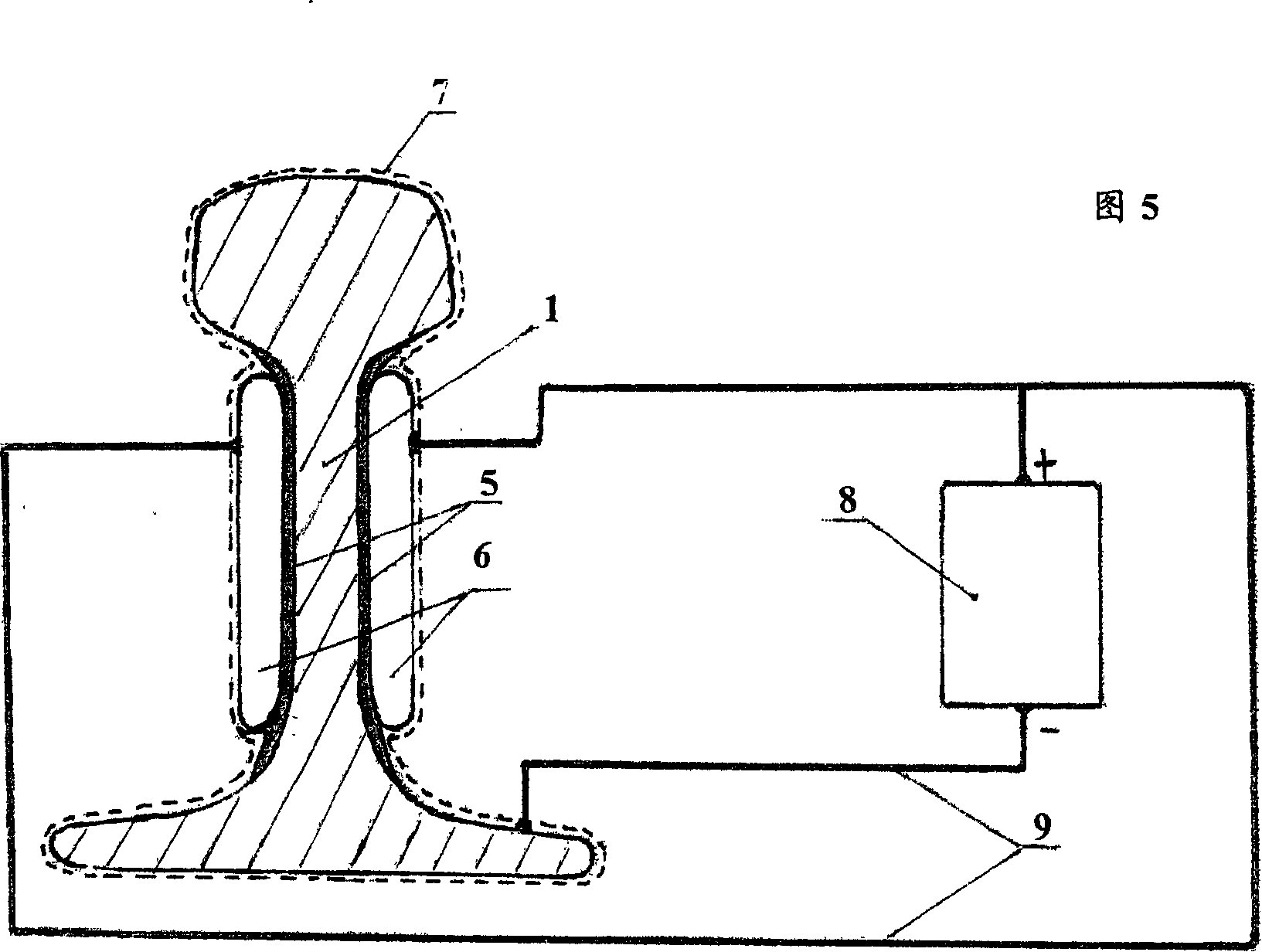

Embodiment 1

[0057] Use aluminum alloy containing 3% Zn, 0.025% In, 0.1% Si, 0.3% Zr, and the balance is Al to make a thin plate with a thickness of 0.2 ~ 0.3mm in an annealed state, and go through matting treatment and coat the inner surface with a layer in advance A linear epoxy resin with a huge molecular weight, and the aluminum alloy sheet treated in this way is used as a sacrificial anode plate for standby. Attach the inner surface of the above-mentioned anode plate to the rail waist and rail bottom of the rail (see Figure 1), and use high frequency or intermediate frequency or other surface (instantaneous) heating methods to make the anode plate firmly adhere to the rail under pressure surface. During the railway transportation, use the existing oil coating device to recoat the alkaline corrosion inhibition layer, and apply it every 1 to 4 days. The formula of the alkaline corrosion inhibition layer is as follows:

[0059] Low molecular weight polyamide ...

Embodiment 2

[0066] The scope of bonding the anode plate, except the surface of the rail waist and the rail bottom according to the first embodiment, also includes the outer side of the rail head, and the others are exactly the same as the first embodiment, see Figure 2.

Embodiment 3

[0068] A zinc alloy containing 0.1-0.5% Al, 0.025-0.15% Cd, and the rest Zn is used as a sacrificial anode, and the anode is fixed on both sides of the rail through mechanical connection. Others are the same as in Embodiment 1, see FIG. 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com