Method for producing alcohol ether fuel from hydrogen prepared from coke oven gas and synthesis gas prepared from scorched particles

A coke oven gas and synthesis gas technology, applied in the direction of fuel, liquid carbon-containing fuel, chemical instruments and methods, etc., can solve the problems of wasting resources, polluting the environment, etc., and achieve the effects of ensuring comprehensive utilization, efficient operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

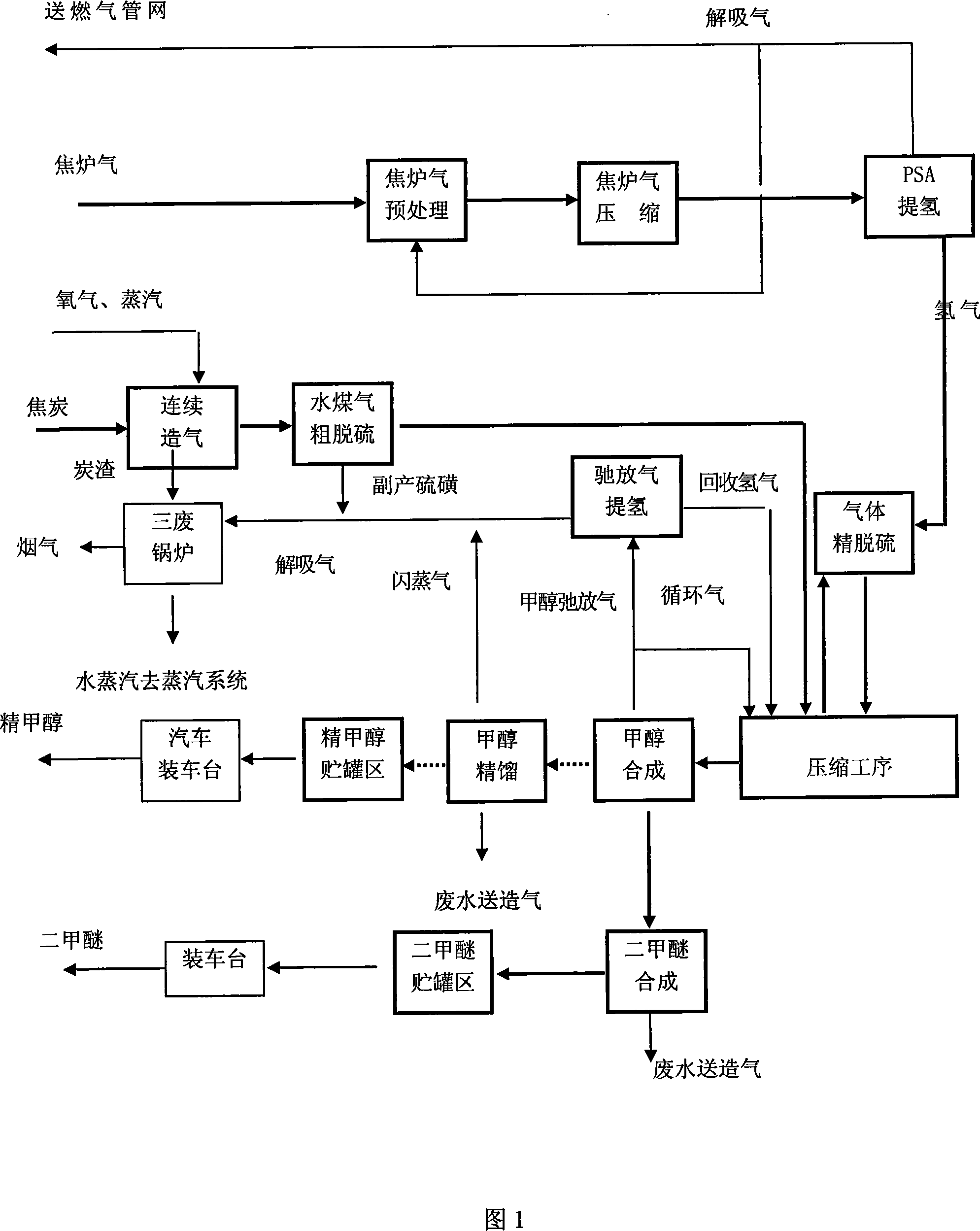

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail with embodiment, and its concrete process step is carried out in the following order:

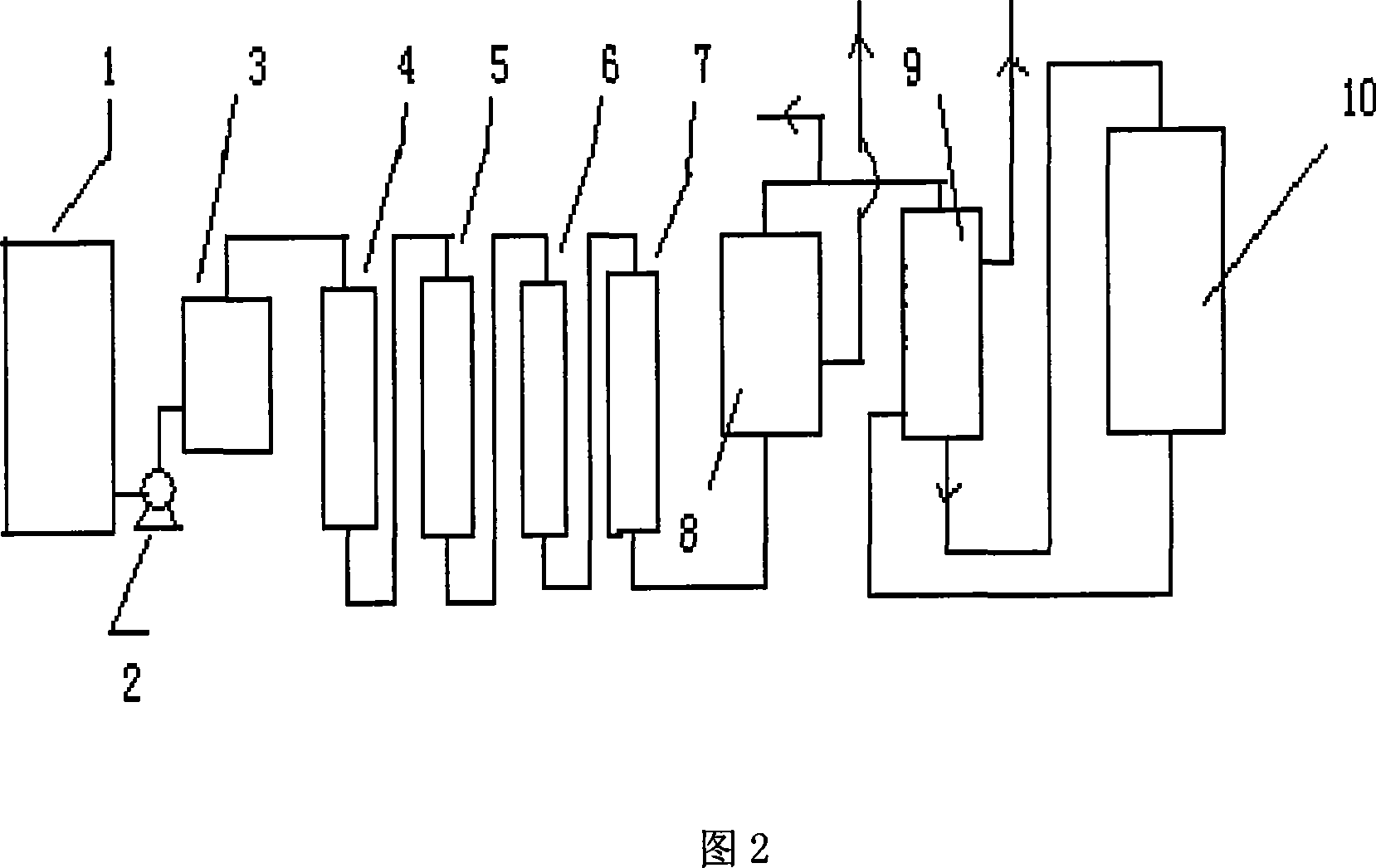

[0026] The first step is to make gas: the coke is sent to each furnace silo by the conveyor belt, and is added to the gasifier by the automatic coke charging machine for gasification reaction, and the coke charging is completed in the down blowing stage. The gasification process includes six stages: blowing, steam blowing, up blowing gas, down blowing gas, secondary steam blowing up and air blowing. The blowing gas in the gasification process is sent to the three-waste boiler to recover heat after being dedusted by the cyclone dust collector; the produced water gas passes through the gas dust collector, then enters the heat pipe waste heat boiler to recover waste heat, and then enters the scrubber for washing and dust removal, and then sends it to To the gas cabinet, the composition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com