Finishing method for simulated mink cashmere fabric

A fabric and mink fleece technology, applied in the processing of textile materials, continuous processing of textile materials, liquid-repellent fibers, etc., can solve the problems of detergent influence, ordinary cleaning agent cleaning, time-consuming and labor-intensive, etc., to reduce pollution And the waste of resources, the effect of reducing the number of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The titanium dioxide finishing agent is prepared by the following steps:

[0030] A chelating agent is mixed with tetrabutyl titanate to carry out a chelating reaction to obtain a chelating reaction liquid; the chelating agent is acetic acid;

[0031] The chelating reaction solution is mixed with a catalyst for hydrolysis reaction to obtain a titanium dioxide finishing agent; the catalyst is an aqueous solution of acetic acid.

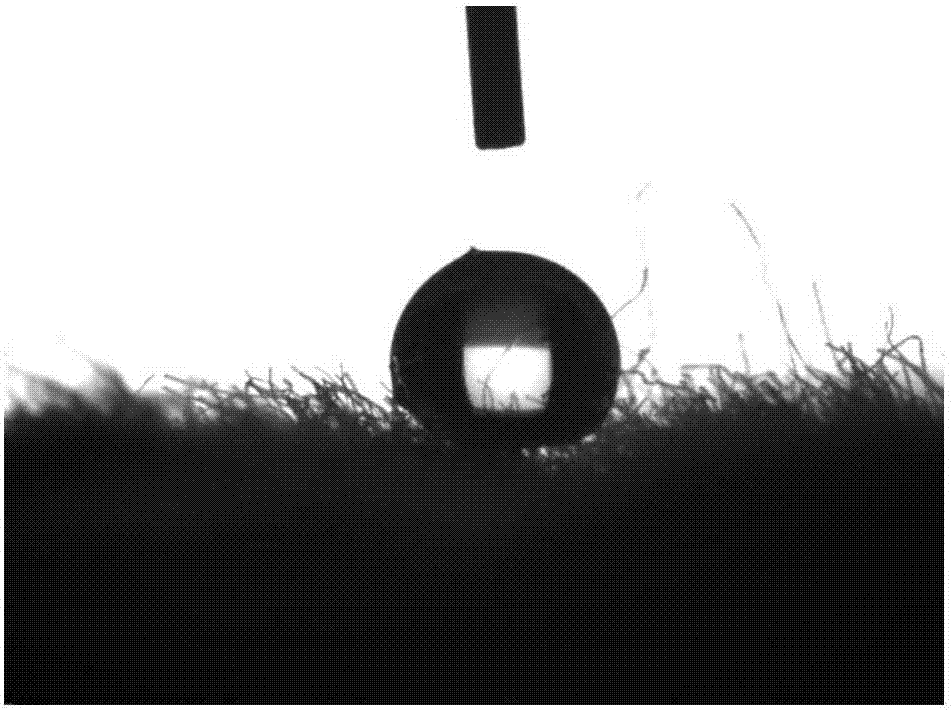

[0032] The invention soaks the simulated mink velvet fabric in the titanium dioxide finishing agent to obtain the soaked simulated mink velvet fabric. In the present invention, the material of the simulated mink velvet fabric is preferably the simulated mink velvet fabric blended with polyester, acrylic fiber and PTT; the grammage of the simulated mink velvet fabric is preferably 700~900g / m 2 , more preferably 750-850g / m 2 , most preferably 800g / m 2 The fluff thickness of the simulated mink fleece fabric is preferably 5-10 mm, more preferably...

Embodiment 1

[0049] (1) Preparation of titanium dioxide finishing agent

[0050] Pour tetrabutyl titanate into a beaker at room temperature as a precursor, and pour acetic acid as a chelating agent into a beaker to mix with tetrabutyl titanate. The molar ratio of acetic acid to tetrabutyl titanate is 1:0.5; The mixed solution with tetrabutyl titanate was stirred for 30 min to obtain a transparent mixed solution.

[0051] Add 6.4mol / L acetic acid aqueous solution dropwise to the transparent mixed solution at a rate of 40 drops / min. The volume ratio of acetic acid aqueous solution to the transparent mixed solution is 0.6:1; after the addition, continue to react for 5 minutes to obtain a colorless and transparent solution titanium dioxide finishing agent.

[0052] (2) Finishing of artificial mink cashmere fabric by prepared titanium dioxide finishing agent

[0053] Put the polyester imitation mink fabric into the titanium dioxide finishing agent prepared in (1) and soak for 10min;

[0054]...

Embodiment 2

[0063] (1) Preparation of titanium dioxide finishing agent

[0064] Pour tetrabutyl titanate into a beaker at room temperature as a precursor, and pour acetic acid as a chelating agent into the beaker to mix with tetrabutyl titanate. The molar ratio of acetic acid to tetrabutyl titanate is 1:1.5; The mixed solution with tetrabutyl titanate was stirred for 30 min to obtain a transparent mixed solution.

[0065] Add 6.5 mol / L acetic acid aqueous solution dropwise to the transparent mixed solution at a rate of 35 drops / min. The volume ratio of acetic acid aqueous solution to the transparent mixed solution is 0.8:1; continue to react for 5 minutes after the addition is completed, and a colorless and transparent solution is obtained. titanium dioxide finishing agent.

[0066] (3) Finishing of artificial mink cashmere fabric by prepared titanium dioxide finishing agent

[0067] Put polyester imitation velvet into the titanium dioxide finishing agent prepared in (1) and soak for 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com