Decompressing injection-augmenting strengthening waterflooding anti-swelling swelling-reducing drag-reducing active agent

An active agent, expansion and shrinkage technology, applied in the field of cationic surfactants, can solve the problems of low permeability reservoirs with strong heterogeneity, low displacement efficiency, low single well production, etc., to protect the water flooding of oil and gas layers The effect of development, reducing injection water resistance and improving formation permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

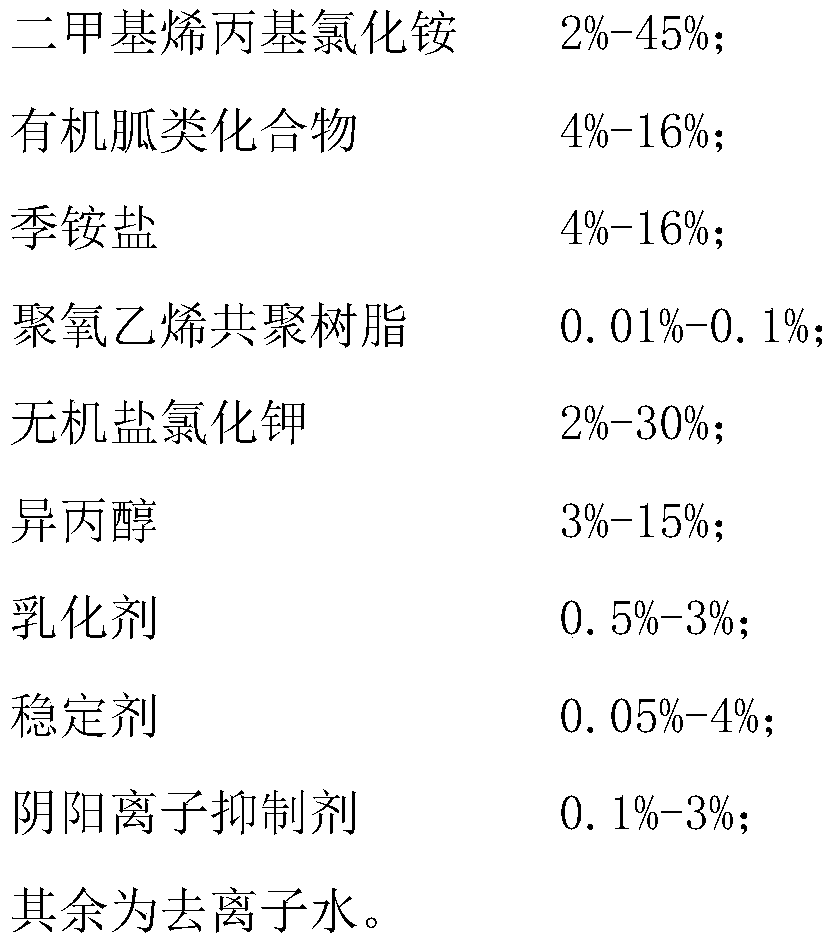

Image

Examples

Embodiment 1

[0032] A pressure-reducing and increasing-injection enhanced water flooding anti-swelling and shrinkage-reducing active agent, comprising 10% of dimethyl allyl ammonium chloride; 6% of organic guanidine compounds, and the organic guanidine compounds are 4% % of guanidine nitrate and 8% of guanidine acetate, the ratio of the two combinations is 1:3.5; the molecular weight is 4 million macromolecular quaternary ammonium salt 7%; the average molecular weight is 0.02% of polyoxyethylene copolymer resin with an average molecular weight of 500,000; inorganic Salt potassium chloride 8%; isopropanol 6%; emulsifier 1%; stabilizer 1%; anion and cation inhibitor 0.8%; the rest is deionized water.

[0033] Its preparation method is as follows, (1) add deionized water in the reaction kettle, start stirring, the rotation speed is 105 rpm, slowly add polyoxyethylene copolymer resin under stirring, and stir for two hours until it is fully dissolved; (2) the reaction kettle The internal temper...

Embodiment 2

[0035] A pressure-reducing and increasing-injection enhanced water flooding anti-swelling and shrinkage-reducing active agent, comprising 25% of dimethyl allyl ammonium chloride; 10% of organic guanidine compounds, and the organic guanidine compounds are 10% The mixture of guanidine nitrate and 12% guanidine acetate, the ratio of the two combinations is 1:4.5; the molecular weight is 6 million macromolecule quaternary ammonium salt 10%; the average molecular weight is 0.05% of polyoxyethylene copolymer resin of 2 million; Inorganic salt potassium chloride 15%; isopropanol 10%; emulsifier 1.8%; stabilizer 2%; anion and cation inhibitor 1.8%; the rest is deionized water.

[0036] Its preparation method is as follows, (1) add deionized water in the reaction kettle, start stirring, the rotation speed is 105 rpm, slowly add polyoxyethylene copolymer resin under stirring, and stir for two hours until it is fully dissolved; (2) the reaction kettle The internal temperature was raised ...

Embodiment 3

[0038] A pressure-reducing and increasing-injection enhanced water flooding anti-swelling, swelling and drag-reducing active agent, comprising 40% of dimethyl allyl ammonium chloride; 15% of organic guanidine compounds, and the organic guanidine compounds are 16% The mixture of guanidine nitrate and 15% guanidine acetate, the ratio of the two combinations is 2.2:2.45; the molecular weight is 8 million macromolecular quaternary ammonium salt 14%; the average molecular weight is 4 million polyoxyethylene copolymer resin 0.08%; inorganic Salt potassium chloride 25%; isopropanol 14%; emulsifier 2.8%; stabilizer 3.5%; anion and cation inhibitor 2.8%; the rest is deionized water.

[0039]Its preparation method is as follows, (1) add deionized water in the reaction kettle, start stirring, the rotation speed is 105 rpm, slowly add polyoxyethylene copolymer resin under stirring, and stir for two hours until it is fully dissolved; (2) the reaction kettle The internal temperature is rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com