Low permeable oil deposit virtual horizontal well development method

A horizontal well and low-permeability technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as poor economic benefits, low oil displacement efficiency, production shutdown or semi-stop production, etc., and achieve strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

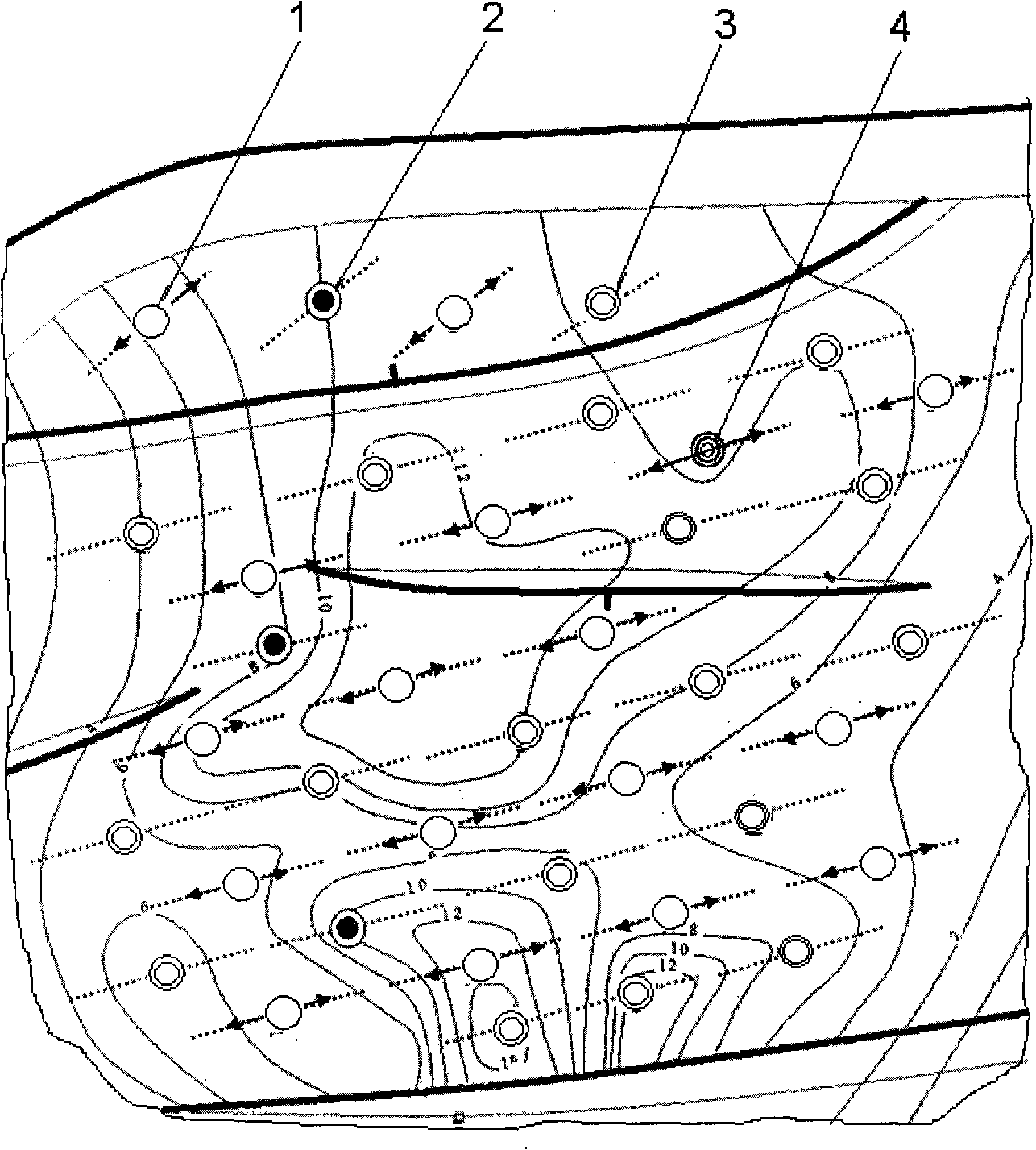

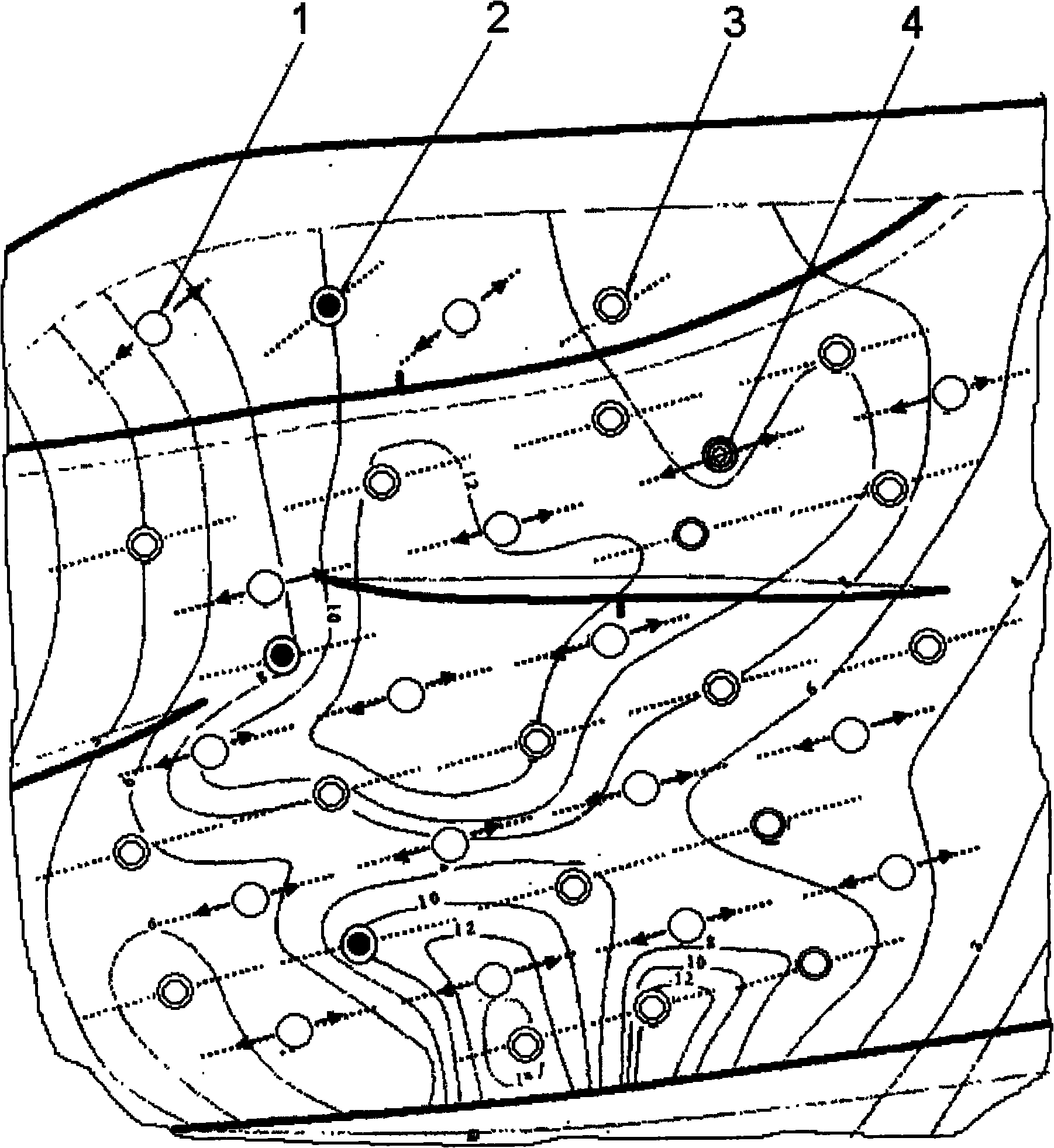

[0015] Referring to the accompanying drawings, a method for imitating horizontal well development in low-permeability reservoirs includes the following technologies: well pattern deployment for development, early water injection under near-high pressure conditions, optimization of perforation well sections and perforation methods, development technology design and deployment, and Ultra-large-scale fracturing technology to create long fractures, fracturing adopts measures such as large-displacement construction, small particle slugs, high-quality fracturing fluid selection, and fracture monitoring. The developed well pattern deployment is to design and deploy the well pattern in the area above the oil layer thickness of 4m. The well pattern is oil-water drainage spacing 490m-520m, which is 500m in the figure, and injection-production drainage spacing is 170m-200m, which is 180m in the figure. Five-point square well pattern, the direction of oil well row and water well row is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com