Crucible for manufacturing optical glass

A technology of optical glass and crucible, which is applied in the direction of manufacturing tools, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of difficult control of the homogenization effect of optical glass and serious loss of platinum crucible, so as to speed up the aging rate, slow down the melting speed, The effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

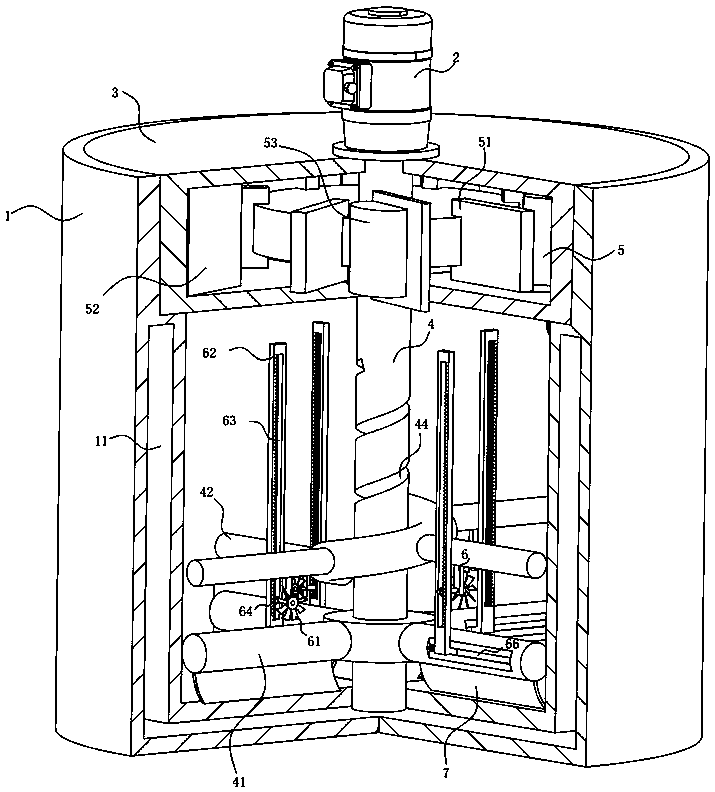

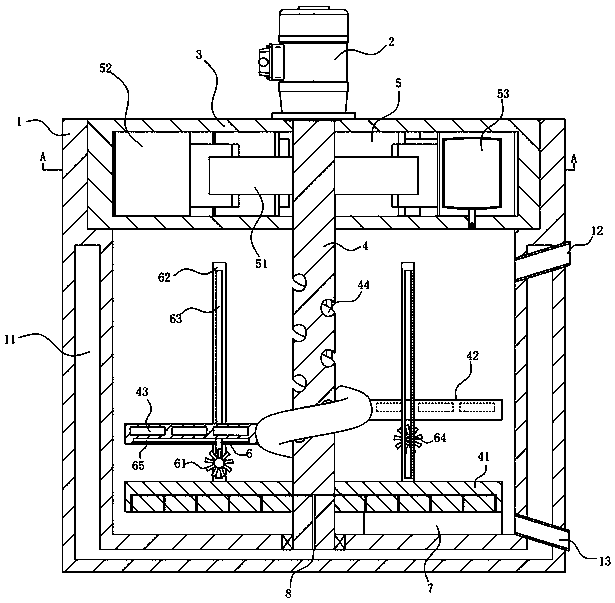

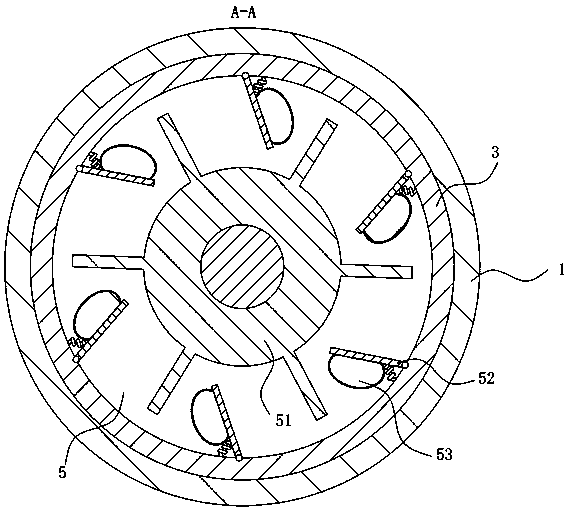

[0025] As an embodiment of the present invention, the lower surface of the heating rod 42 is fixedly connected with a guide rod 6; the end of the guide rod 6 away from the heating rod 42 is rotatably connected with a rotating wheel 61; one side of the stirring rod 41 is fixedly connected The limit plate 62; the limit plate 62 is provided with a through groove 63 and the side wall of the through groove 63 is designed in a rack shape; the rotating shaft of the rotating wheel 61 extends into the limit plate 62 through the groove 63; The rotating shaft of the rotating wheel 61 is located in the inner part of the through groove 63 and is fixedly connected with a gear 64, and the gear 64 meshes with the rack-shaped inner wall of the through groove 63; when working, the motor 2 drives the stirring shaft 4 to rotate, thereby driving the heating rod 42 to go up and down. Movement, the guide rod 6 fixed on the lower surface of the heating rod 42 drives the rotating wheel 61 to move up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com