Acoustically Variable Burner System

a burner system and acoustically variable technology, applied in the direction of gaseous heating fuel, stoves or ranges, lighting and heating apparatus, etc., can solve the problems of system dynamic and burner shape failure to produce realistic flame patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

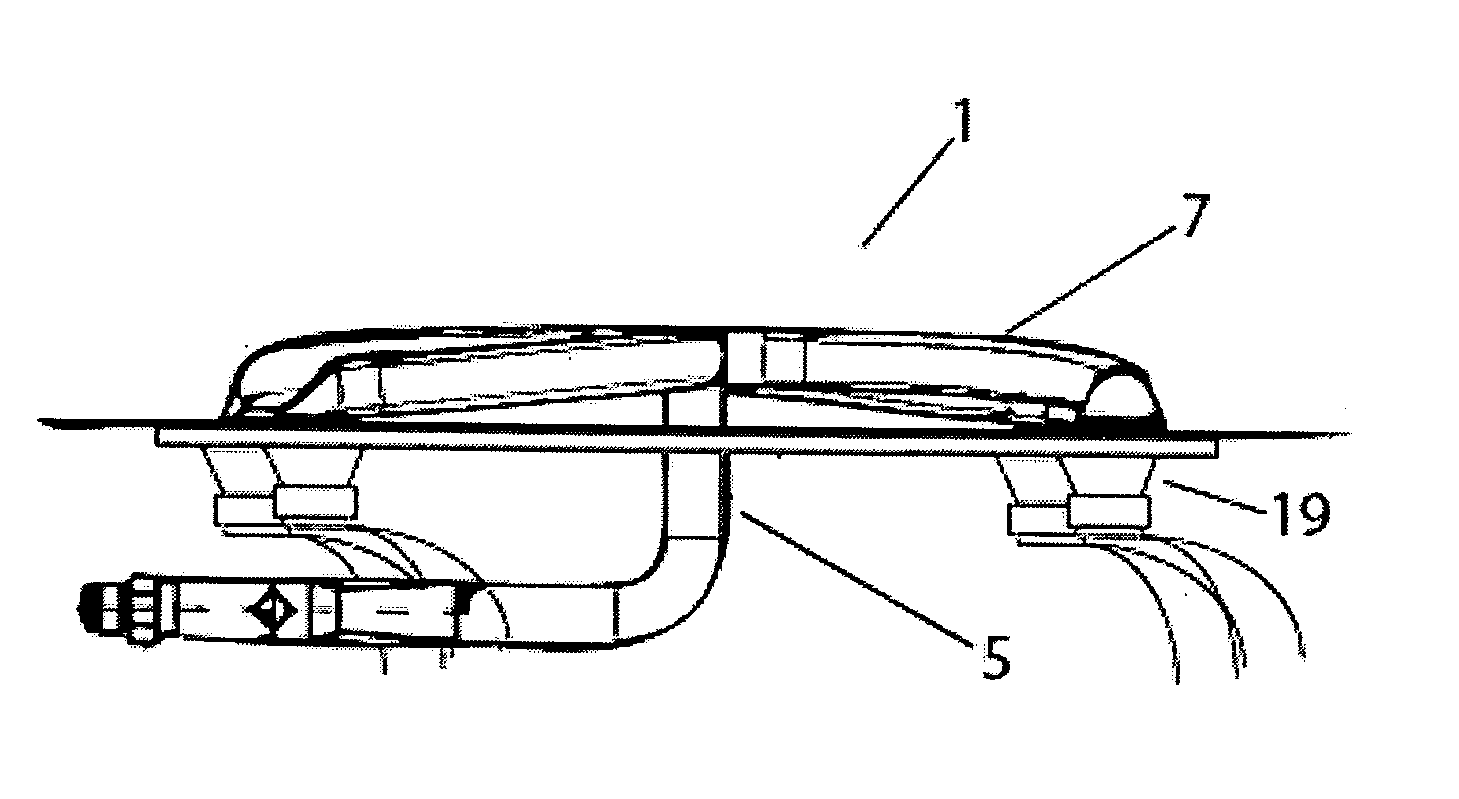

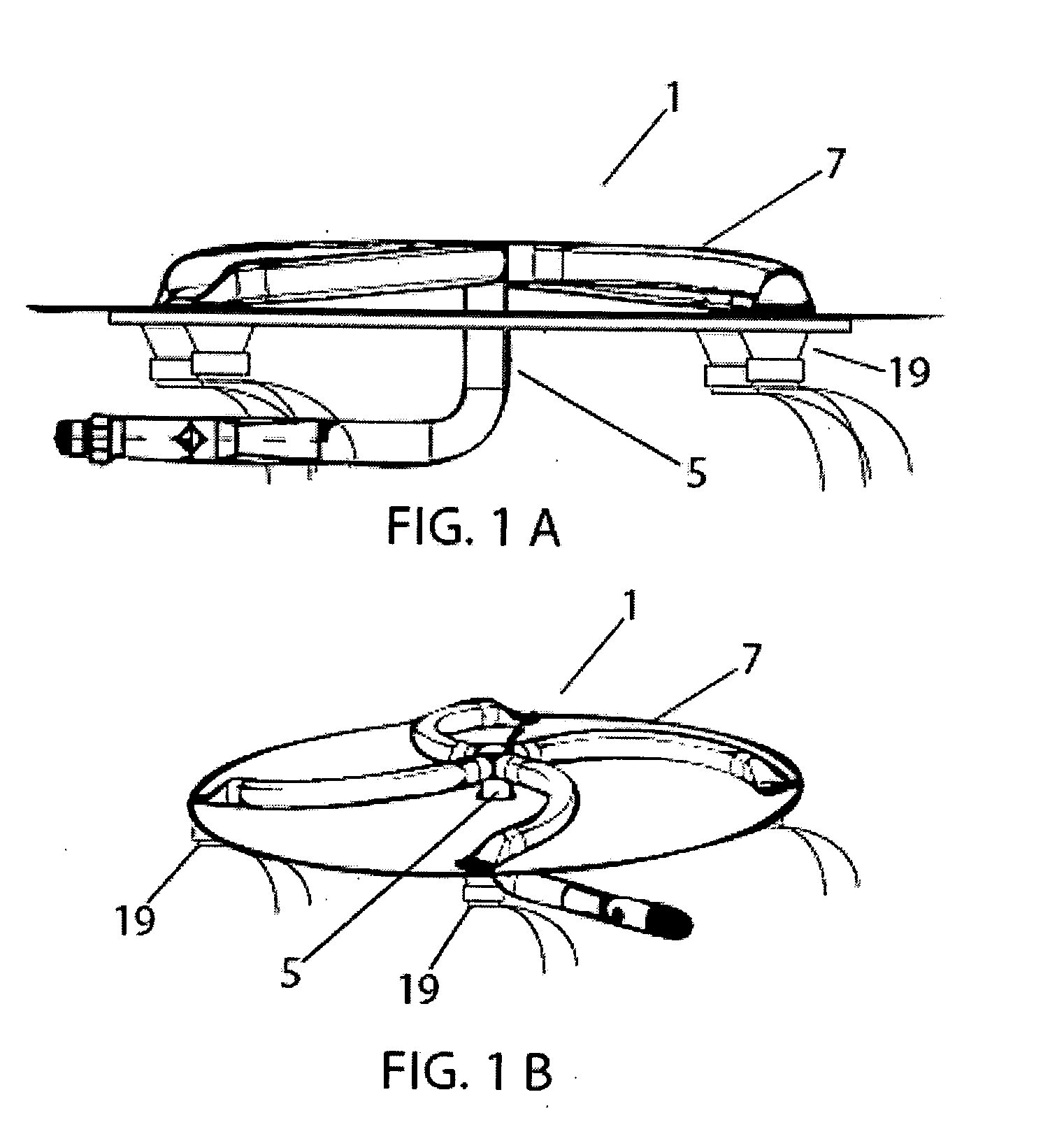

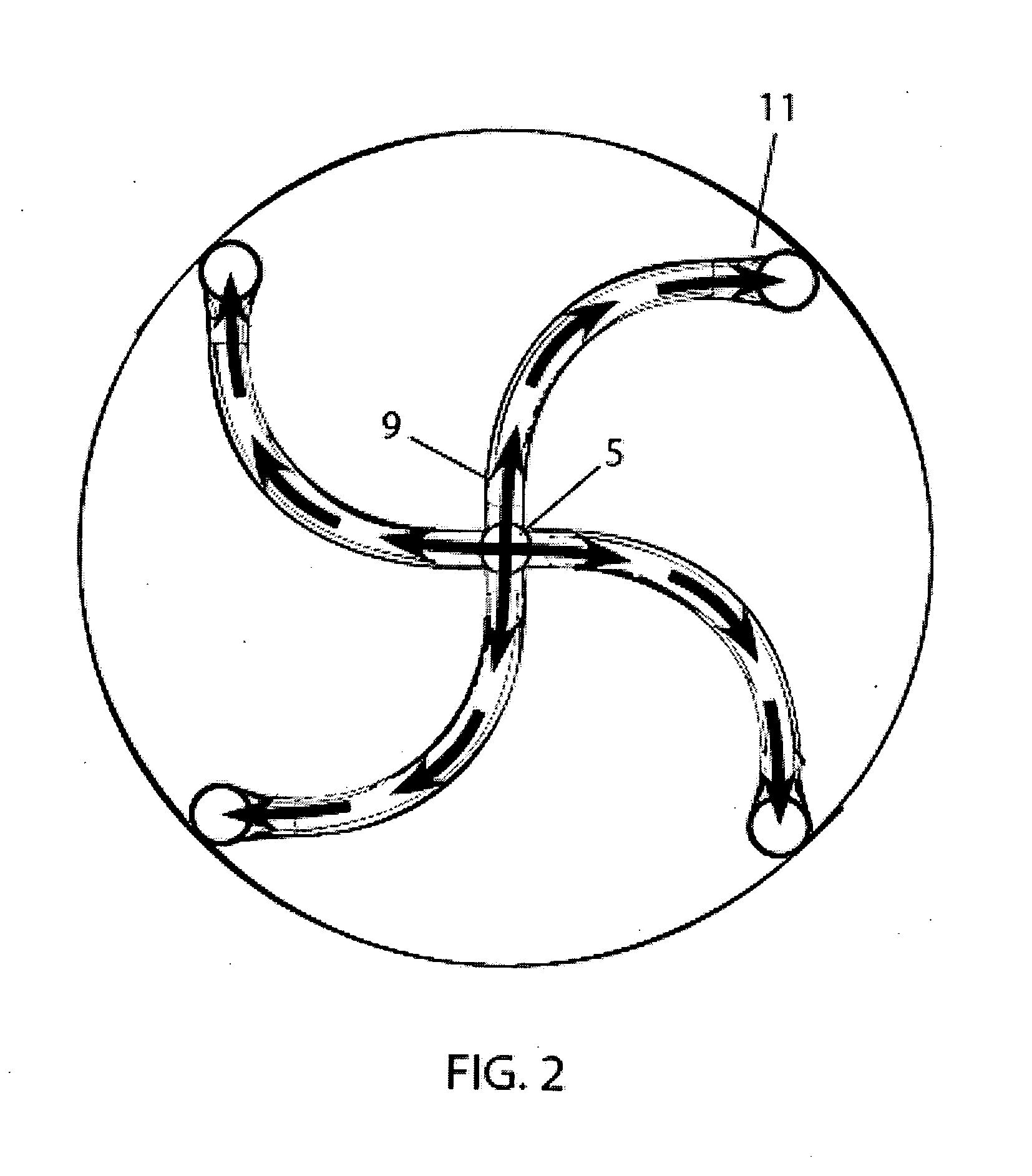

[0037]As illustrated in FIG. 1A-5, in a preferred embodiment, the present invention provides an acoustically variable burner system 1 comprised generally of a burner 3, one or more electroacoustic transducers 19 in communication with the burner 3, and a controller interface 21. As shown in FIGS. 1B and 2, the burner 3, which is configured to produce a wood burning-like flame, is comprised of a central gas chamber 5 in communication with a plurality of burner tubes 7. The burner tubes 7 are in communication with the central gas chamber 5 at a first end 9 of the burner tube 7, and a second end 11 of the burner tube 7 is disposed opposite the first end 9. The burner tubes may be linear or non-linear in shape. In a preferred embodiment, the burner 3 comprises a plurality of burner tubes 7, each burner tube having an arc-shape configuration.

[0038]The electroacoustic transducers 19 may be disposed adjacent the second ends 11 of the burner tubes 7, as illustrated in FIGS. 1A-3. Alternative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com