Fireplace firewood retainer assembly with air deflector, fireplace incorporating the same and method of reducing particulate emissions in a wood burning fireplace

a technology of air deflector and firewood retainer, which is applied in the field of fireplace firewood retainer assembly with air deflector, which can solve the problems of high particulate emissions, inefficient use of air, and high particulate combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

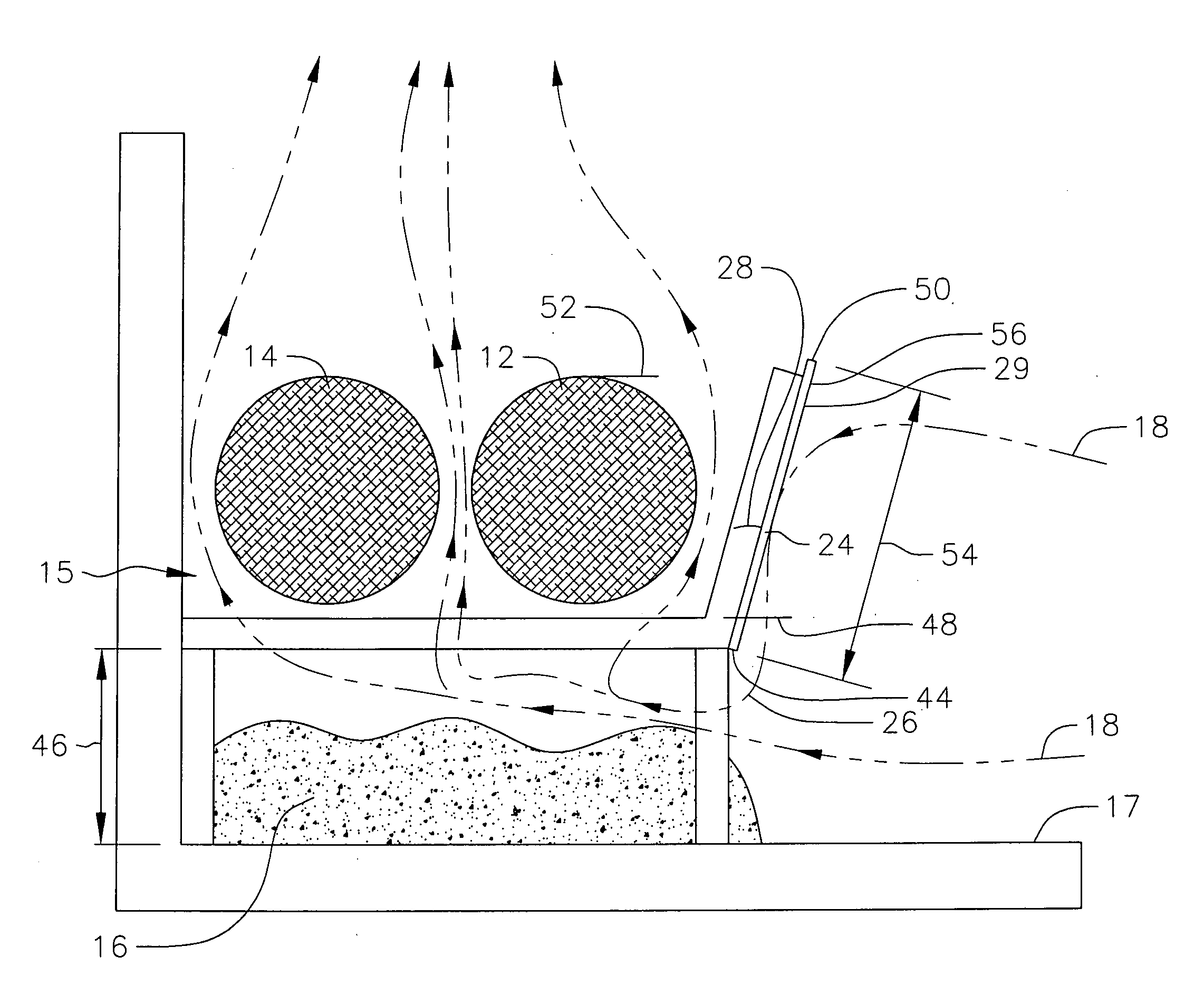

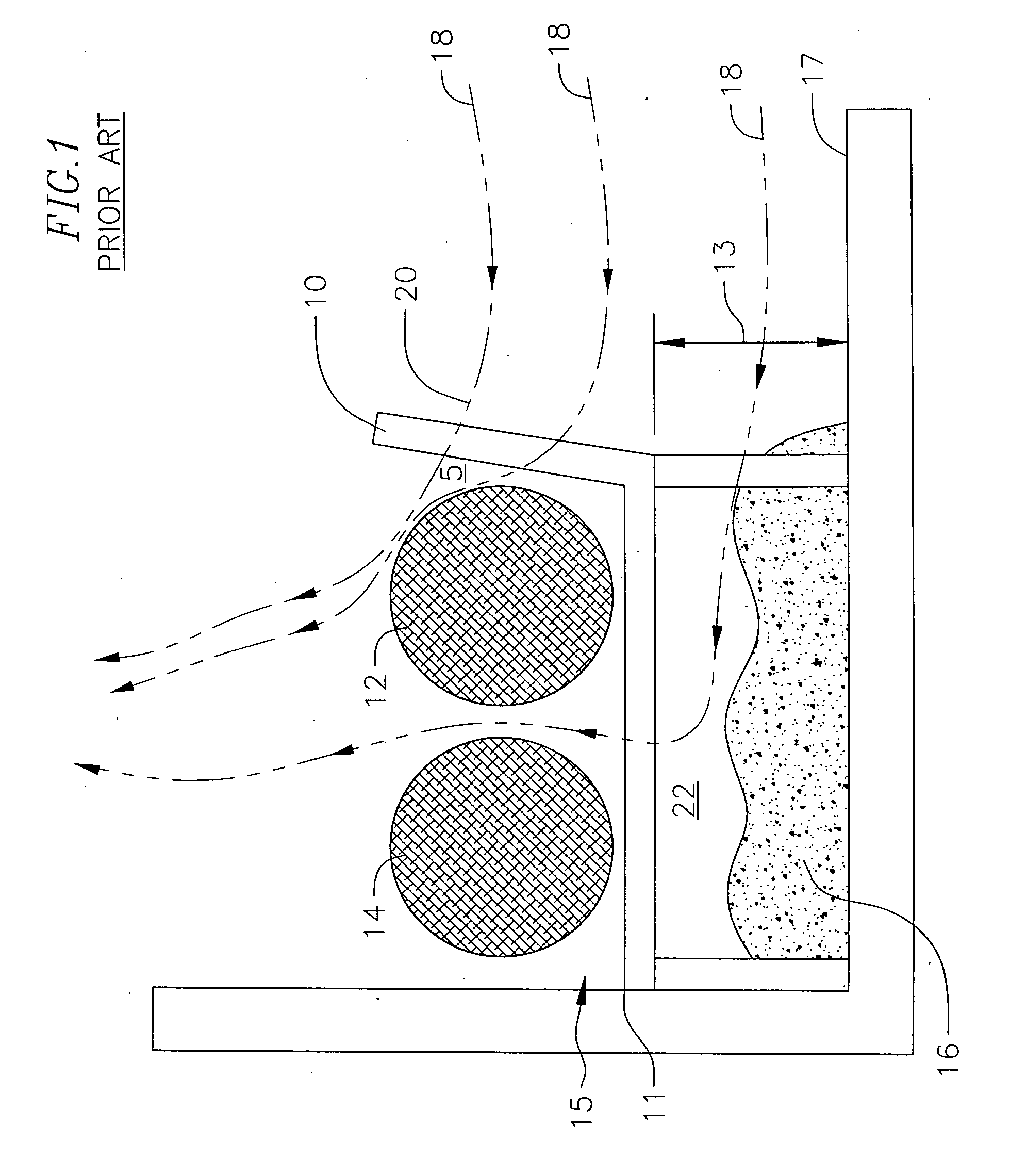

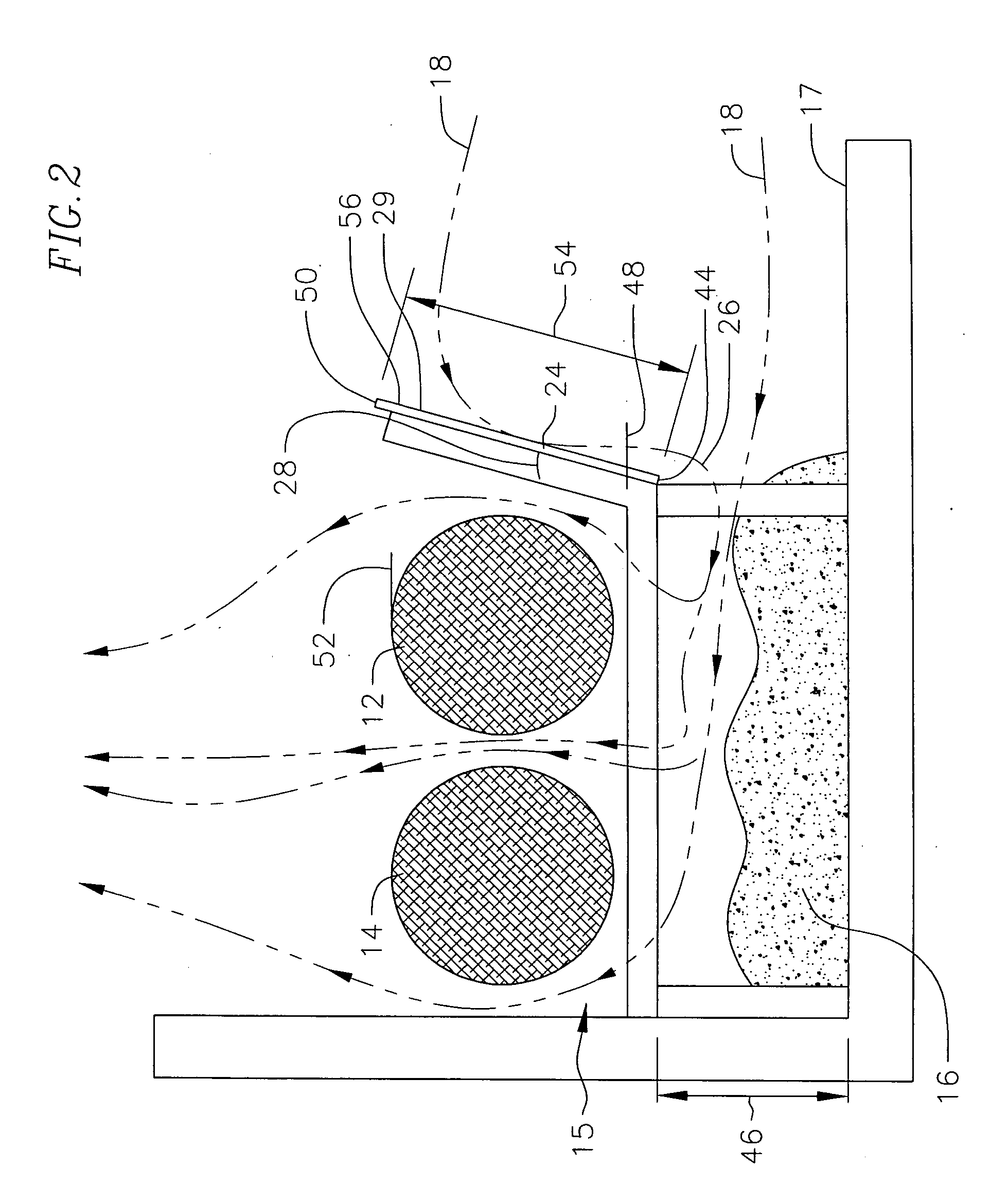

[0009]Applicant has discovered that a way to improve the burning efficiency and to reduce particulate emissions of a wood burning fireplace is to have the air entering the combustion chamber that is used for combustion be pre-heated. Applicant has discovered that this can be achieved by guiding the air entering the combustion chamber 15 beneath the firewood, e.g., the logs 12, 14 in a space 22 between the logs and the heated embers 16, as for example shown in FIG. 2. As the air moves past the heated embers, it is heated and then rises to aid in the combustion of the logs 12, 14. To achieve this effect, a baffle or deflector 24 such as for example a deflector plate is positioned in front of the grate so that air 18a entering the combustion chamber strikes the deflector 24 and is deflected downward towards the embers, as for example along a path 26. In an exemplary embodiment, the deflector is a plate angled from the vertical plane along an angle 28. In an exemplary embodiment, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com