Method for preparing firewood sticks by waste cassava residues and application on charcoal preparation

A technology of cassava and waste residue, applied in the direction of waste fuel, special dry distillation, solid fuel, etc., can solve the problems such as the difficulty of fully dehydrating the enlarged potato residue, the inability to continue drying, and the difficulty of solid-liquid separation, so as to avoid the fugitive discharge of materials and process leakage, prolonging the hot air utilization time, and obvious direct economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The method for making fuel sticks from cassava residues of the present invention and its application in charcoal production will be further described below in conjunction with the accompanying drawings and examples.

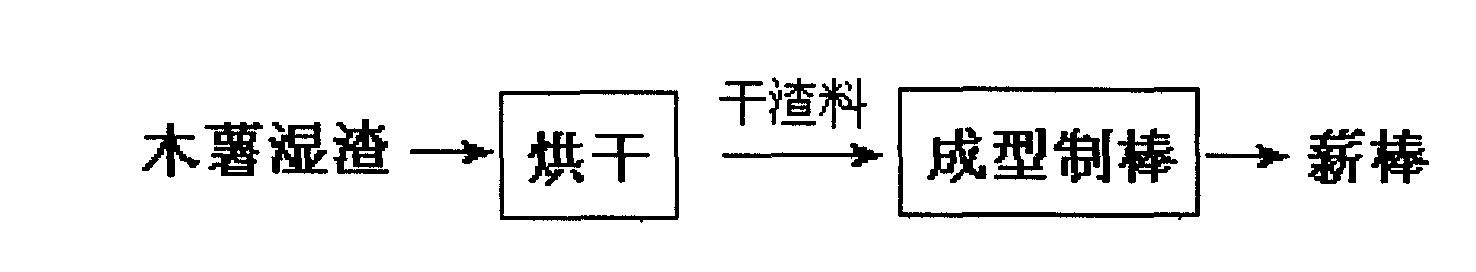

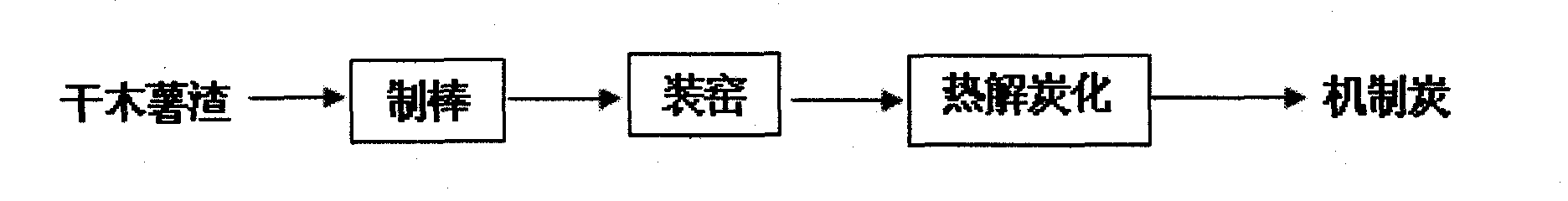

[0057] 1. Making cassava waste residue into salary sticks

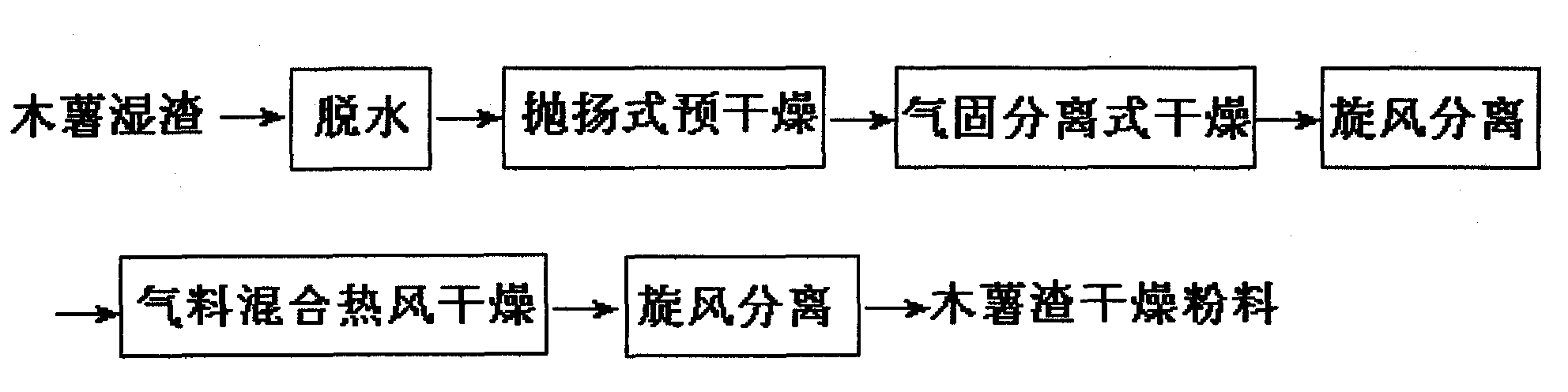

[0058] figure 1 It is a process flow diagram of an embodiment of the present invention using cassava waste residues to make fuel rods. figure 2 is a schematic flow chart of an embodiment of the drying process therein. The specific method is as follows: using cassava wet residue produced in the production process of cassava starch as the initial raw material,

[0059] 1) Dehydration until the moisture content of the cassava residue wet material is ≤71%;

[0060] 2) The obtained wet material is sent to the throwing type pre-drying section for preheating and breaking up into powdery wet material;

[0061] 3) The powdery wet material enters the inner cavity of the interlayer drier for pre-stage g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com