Automatic Waste Feed Control System

A feed control and waste technology, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of affecting the judgment of feeding, high degree of manual dependence, and affecting the operator's judgment of on-site conditions, etc. The effect of reducing the workload and pressure, and stabilizing the combustion conditions of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

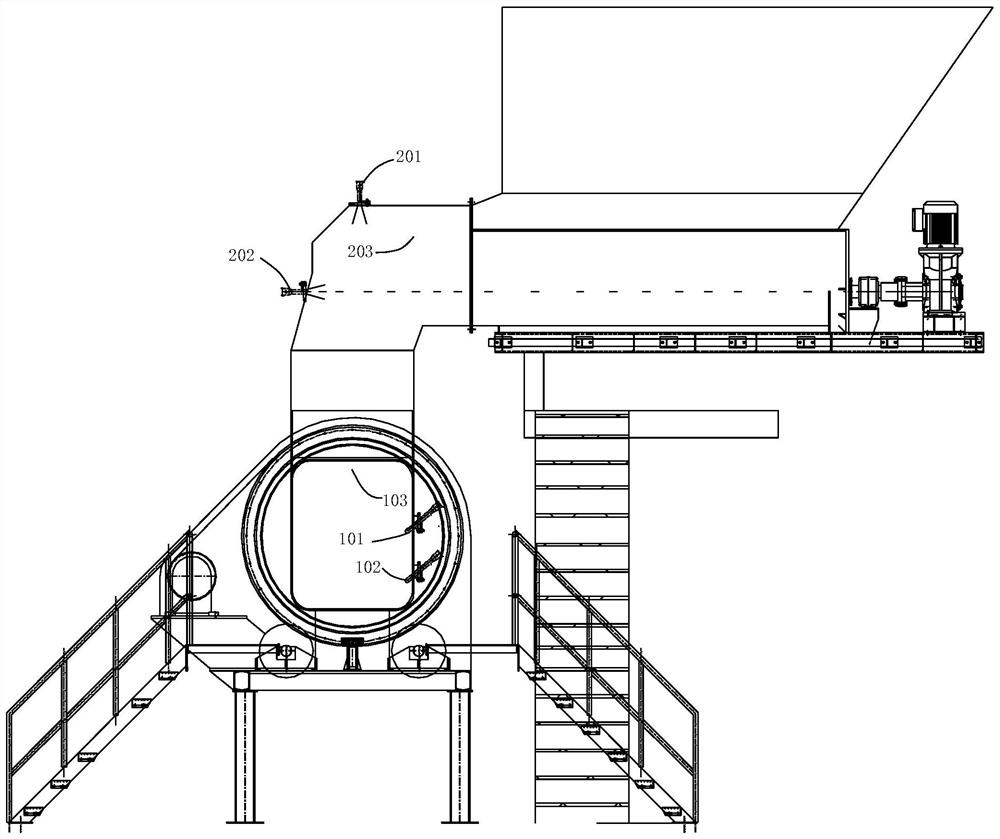

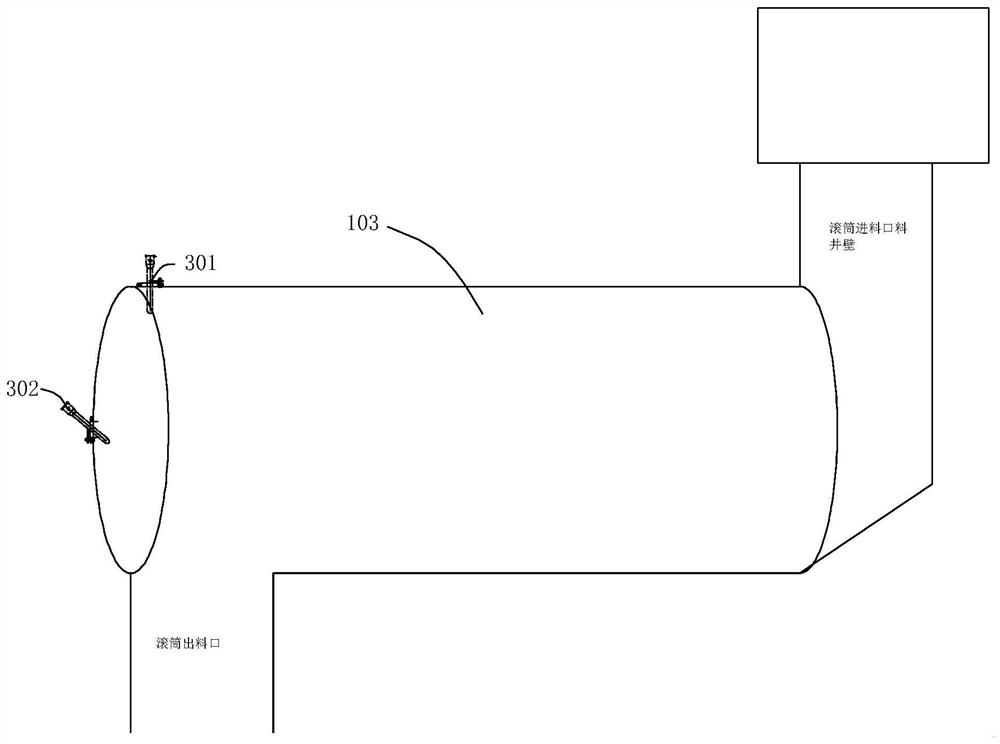

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0023] Figure 1-4 Among them, an automatic garbage feeding system includes a first radio frequency admittance level switch, at least one second radio frequency admittance level switch, and an ultrasonic sensor.

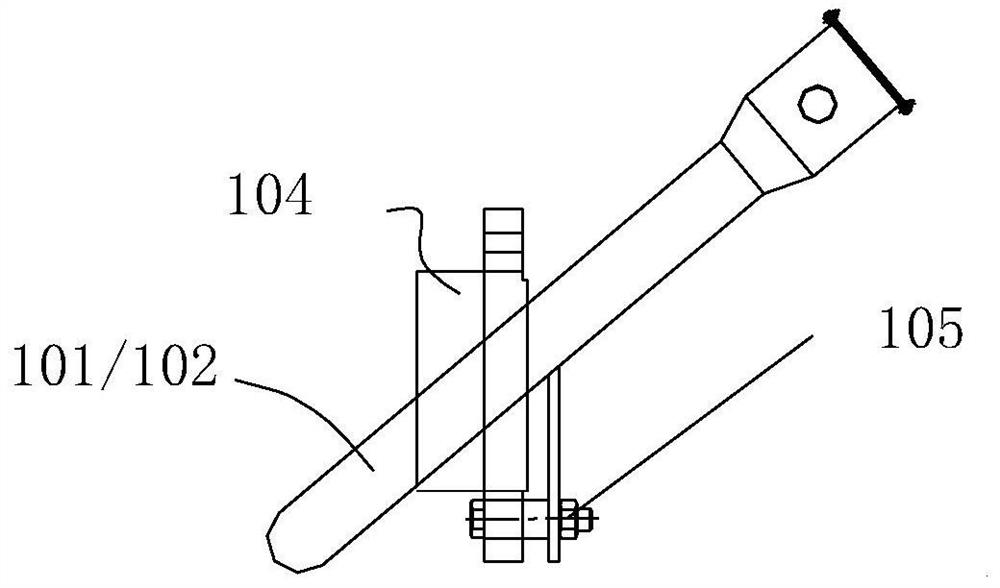

[0024] The first radio frequency admittance material level switch is provided with a low material level switch and a high material level switch, and the low material level switch and the high material level switch are installed on the material well wall of the drum feeding port from bottom to top (the material level switch is installed The specific position of the high and low limit detection is provided by the boiler operator according to the actual material level of production); the installation position of the first radio frequency admittance material level switch is equipped with a flange casing, and the flange casing is inclined at an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com