Reciprocating grate furnace with two-section-reverse-acting and one-section-forward-acting grate

A grate furnace, push forward technology, applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of incomplete stirring and breaking up, easy to agglomerate, insufficient drying, etc., to reduce the cost of incineration , Stable combustion conditions and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

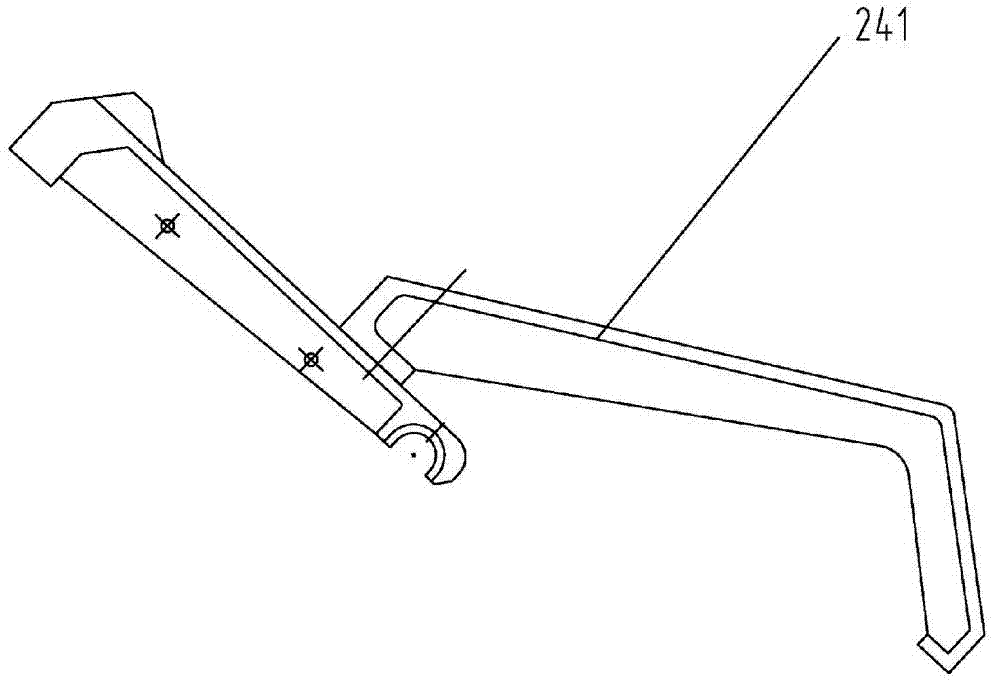

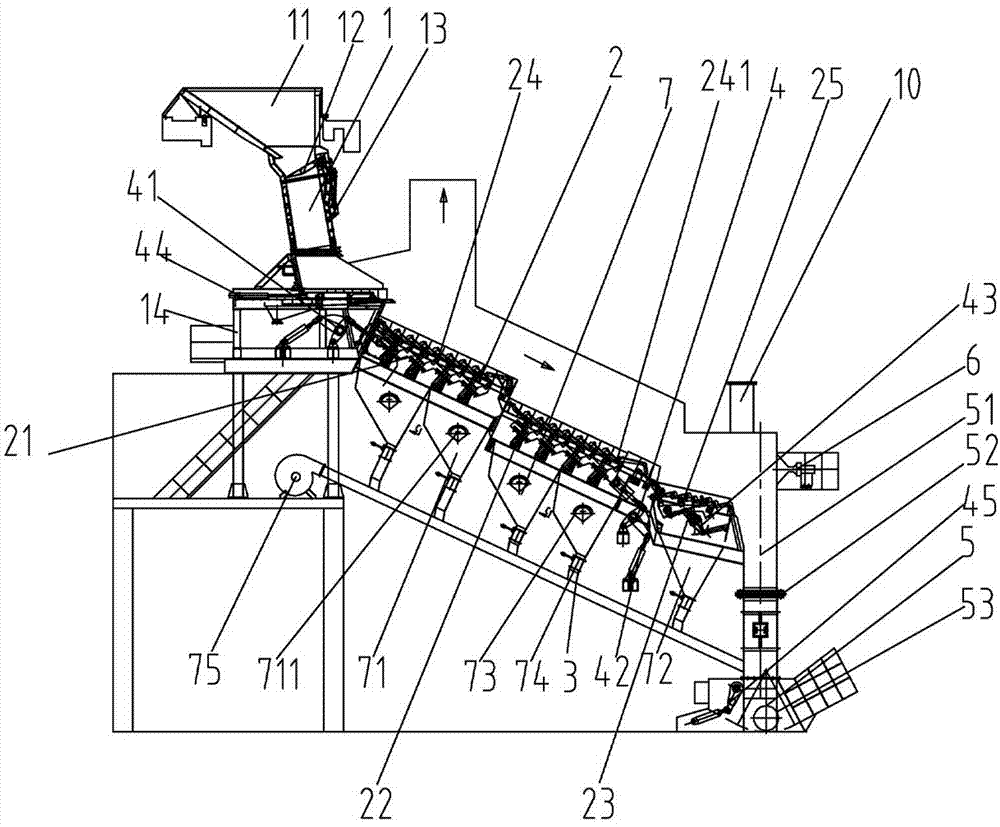

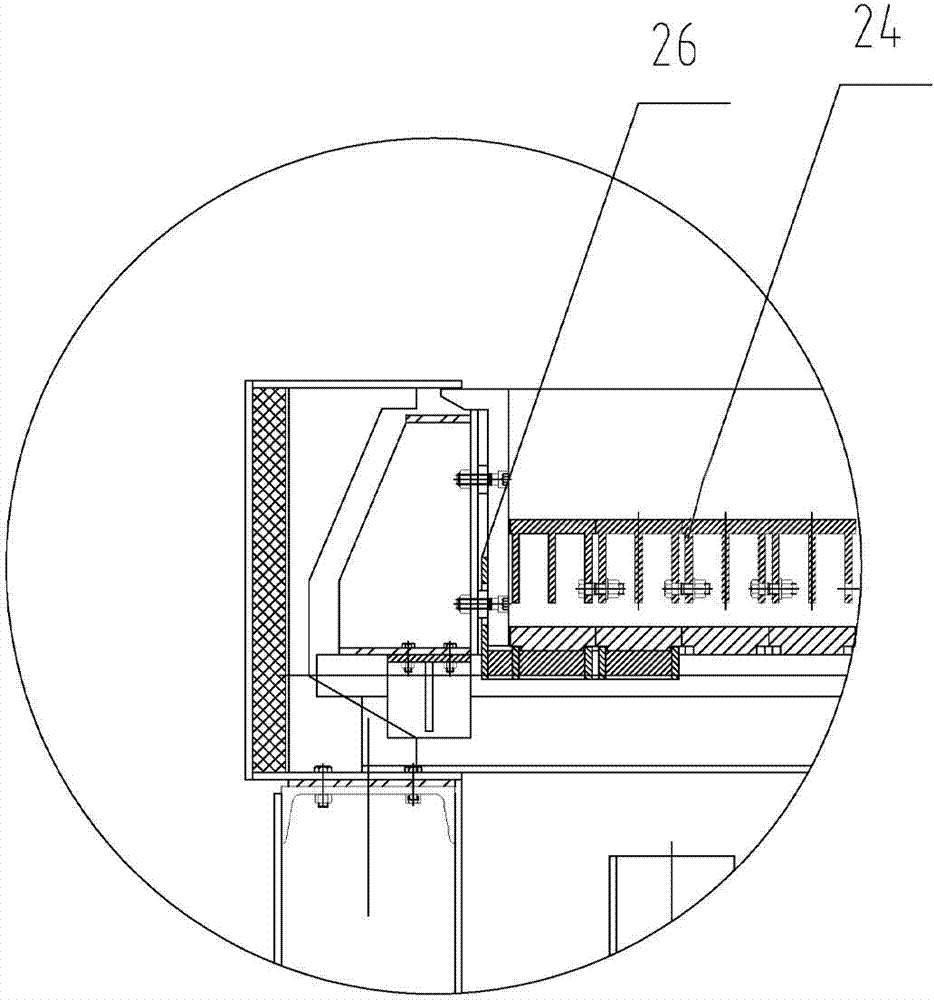

[0021] Combine now figure 1 -3 Further describe in detail a preferred embodiment of a reciprocating grate furnace with two sections of reverse push type and one section of forward push type grate according to the present invention: a two-stage reverse push type plus one section of forward push type fire grate The reciprocating grate furnace includes feeding system 1, grate 2, ash discharge channel 3, electro-hydraulic control system 4, slag discharge device 5, automatic grate control system 6, and air chamber 7. From the bottom to the bottom, it is divided into: drying section 21, burning section 22 and burning section 23. There is a height difference between each section. The drying section 21 and burning section 22 are reverse-push grate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com