Fire cover for gas stove

A gas stove and fire cover technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of small heat load, incomplete gas, heat increase, etc., and achieve the effect of stable combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

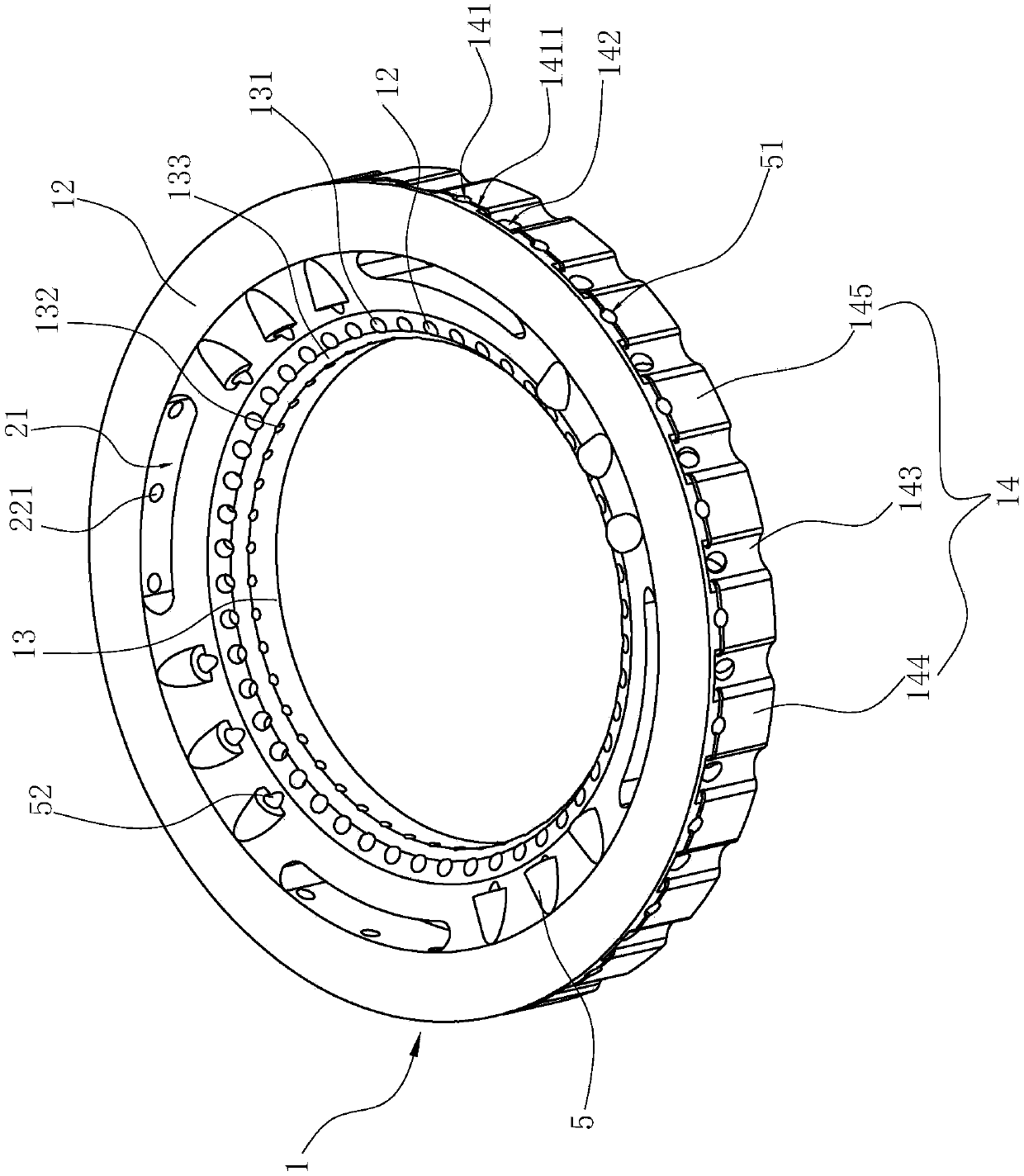

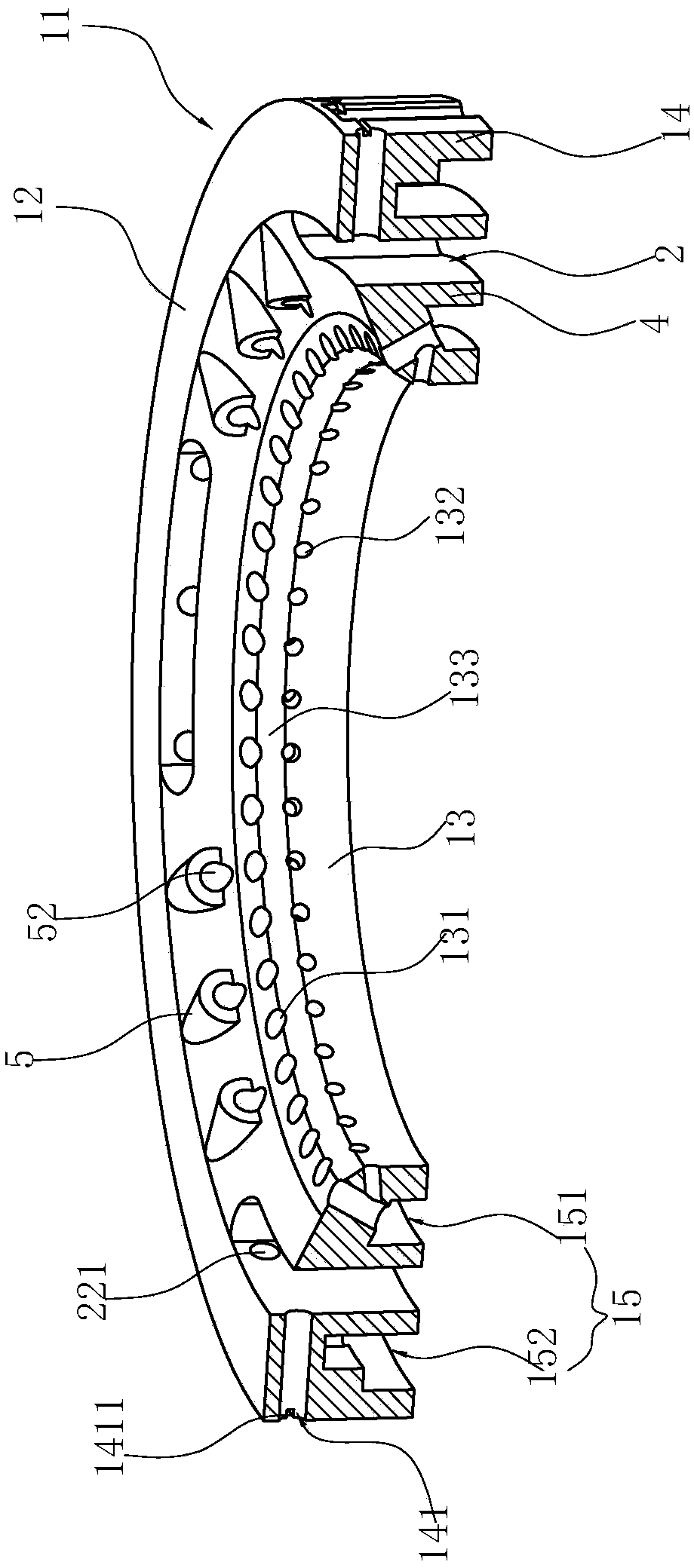

[0027] like Figure 1~4 Shown is the best embodiment of the present invention. The fire cover 1 for the gas stove of the present embodiment includes a fire cover 1, and the fire cover 1 includes a ring-shaped body 11, and the ring-shaped top wall 12 of the body 11 is connected with the inner edge of the ring-shaped top wall 12, An air mixing chamber 15 is formed between the inner ring wall 13 and the outer ring wall 14 extending vertically or obliquely downward at the outer edge, and there is a relatively isolated air supplementary chamber 2 in the air mixing chamber 15, and at least one of the air supplementary chambers 2 The wall is provided with an air inlet 21 in fluid communication with the outside air, and the outer ring wall 14 is provided with a first air outlet 141 in fluid communication with the air supplementary chamber 2 at a position corresponding to the air supplementary chamber 2. The ring wall 14 is provided with at least one main fire hole 142 communicating w...

Embodiment 2

[0031] The structure is basically the same as that of Embodiment 1, the difference is that the air supplementary chamber 2 includes a top wall and a side wall extending downward from the top wall, and an air inlet 21 is opened on the side wall, and of course the air inlet 21 is opened on the side wall Some connecting channels such as tubular pipes can pass through the upper part.

Embodiment 3

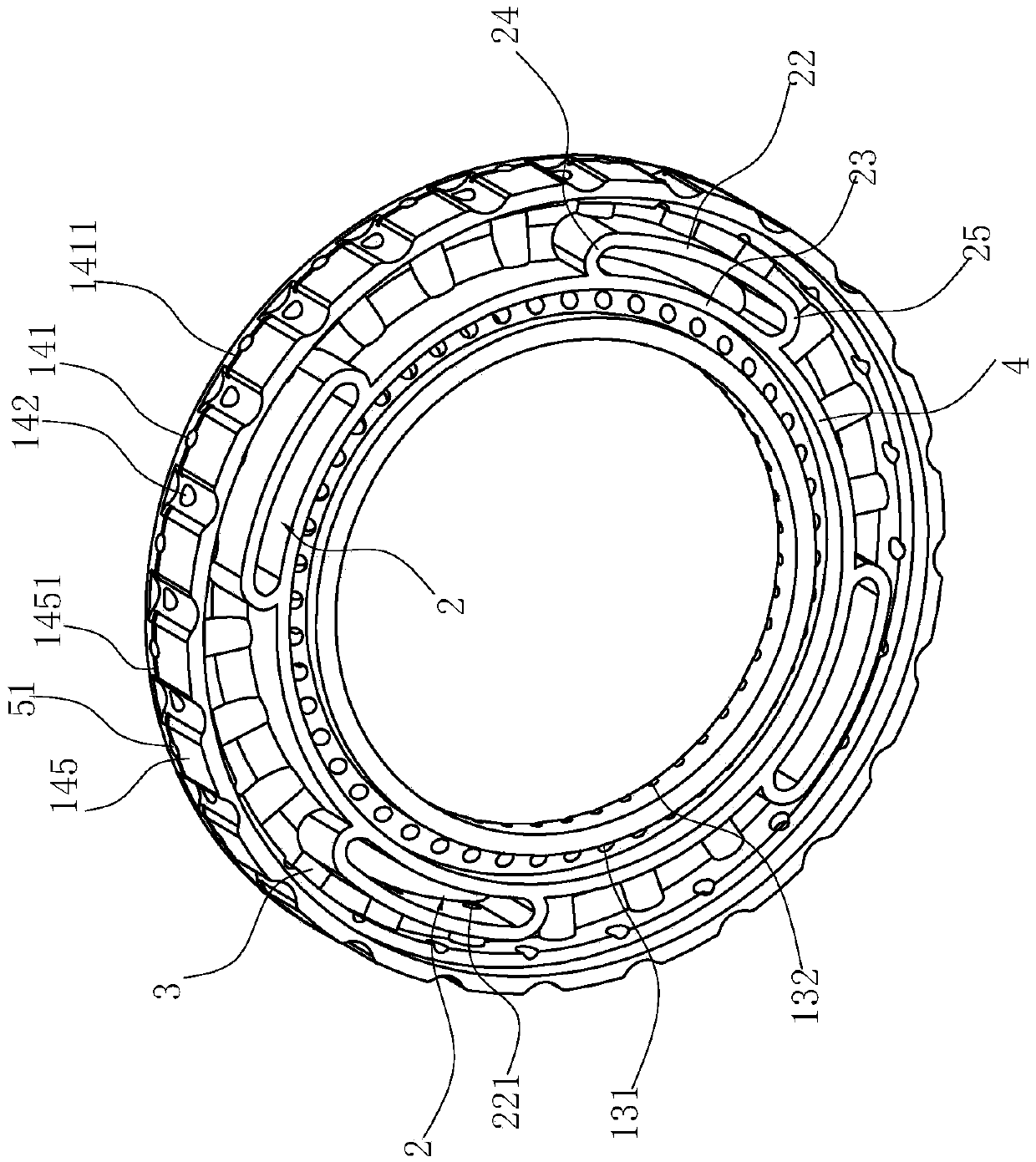

[0033] The structure is basically the same as that of Embodiment 1, the difference is that the part of the outer ring wall 14 with the first air outlet 141 is directly used as the outer wall of the air supplementary chamber 2, and there are three side walls of the air supplementary chamber 2: the one opposite to the outer wall The first side wall 23 connects the outer side wall with the second side wall 24 and the third side wall 25 of the first side wall 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com