High-temperature thermal storage type combined oven arch embedded second rotational flow overfire air burning inferior fuel

A technology of inferior fuel and secondary air, applied in the field of boilers, can solve the problems of low thermal efficiency, black smoke, poor fuel adaptability, etc., and achieve the effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

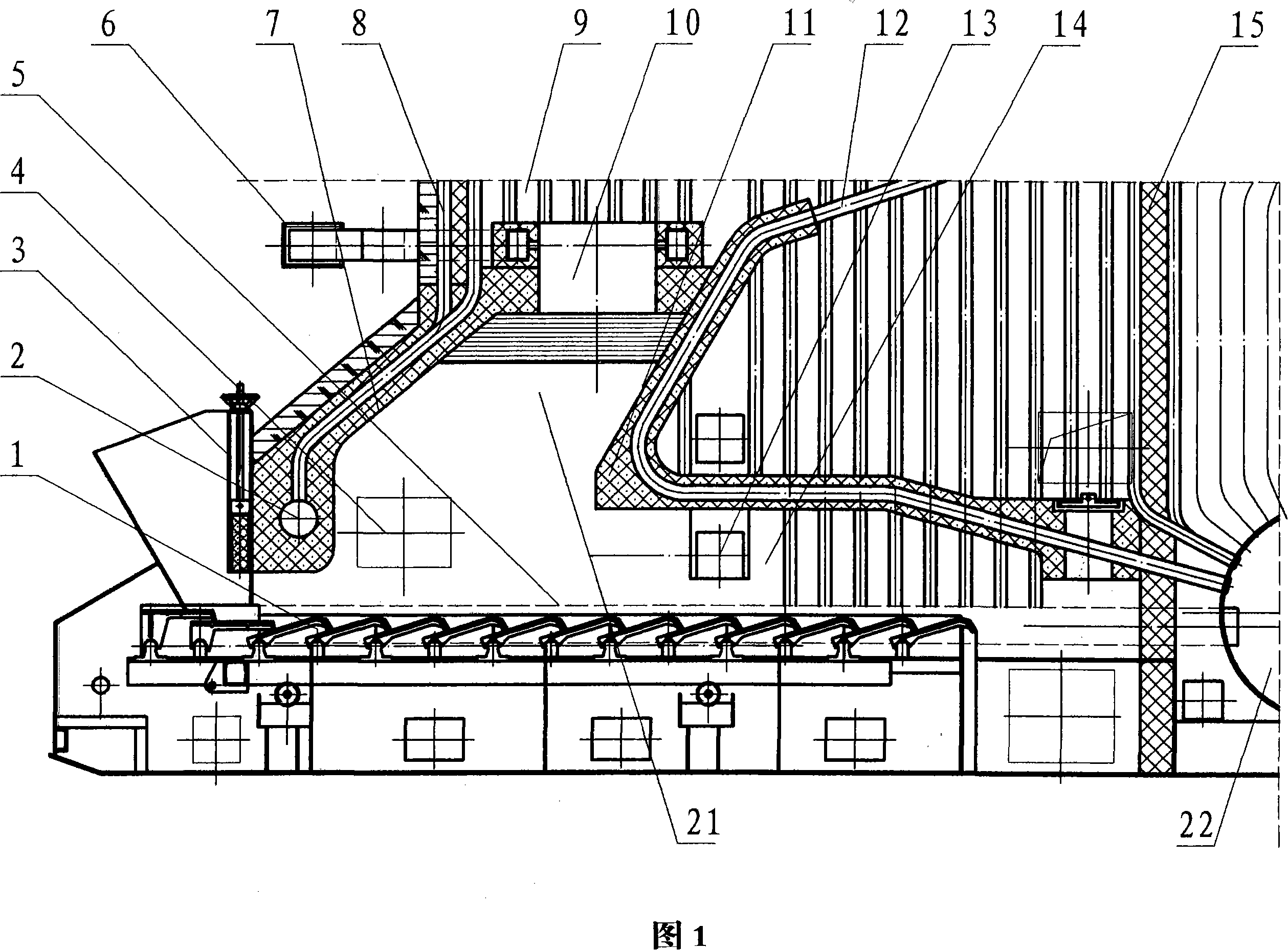

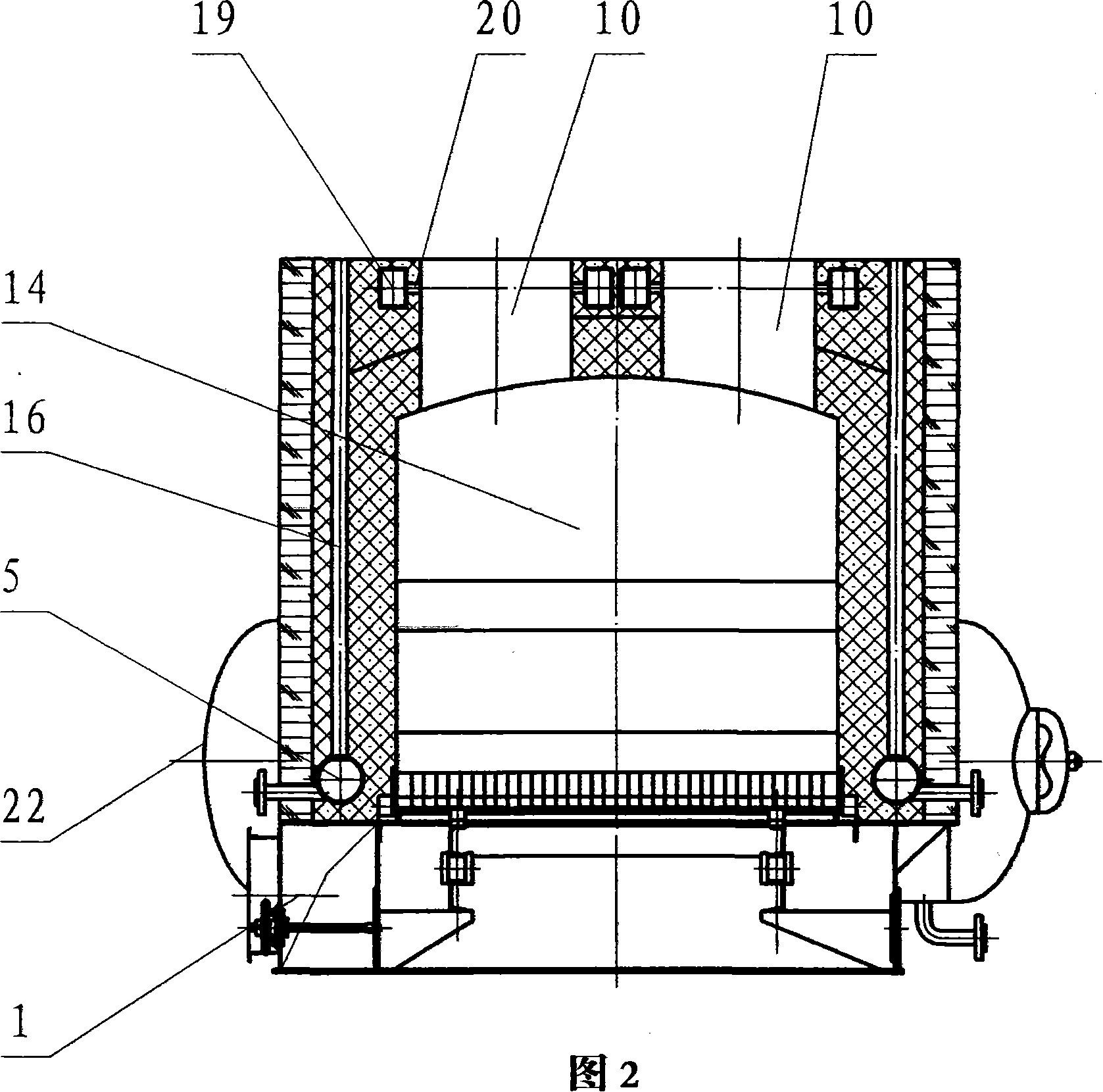

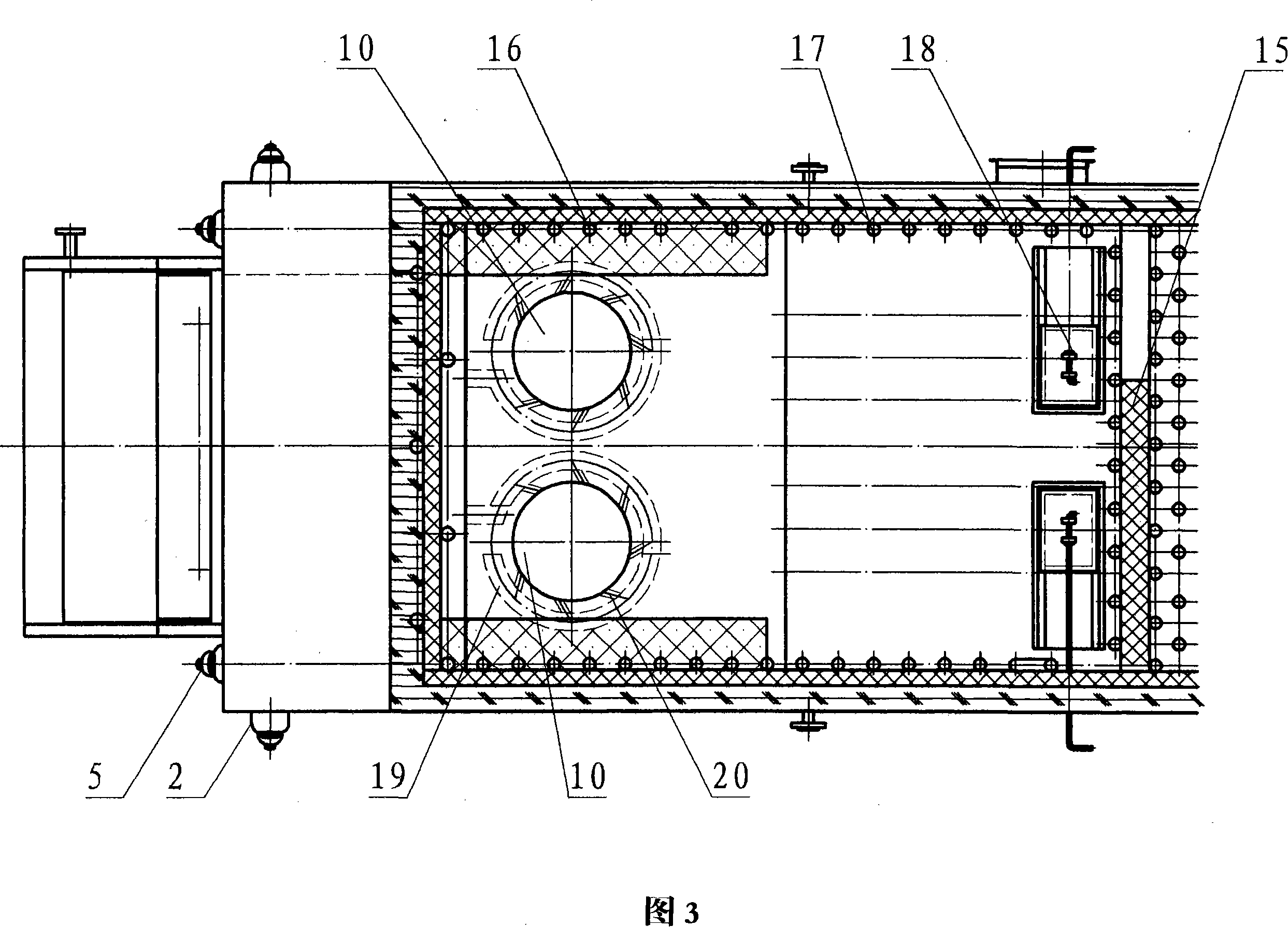

[0021] Further illustrate the present invention below in conjunction with accompanying drawing:

[0022] Including the front arch 7 located at the front of the boiler, the front arch tube 8 is connected with the front arch header 2, and the front arch header 2 is connected with the coal hopper 3 through refractory concrete; the front arch header 2 is located behind the coal hopper 3 , above the grate 1. The front arch 7 is composed of the front arch pipe 8, the front arch header 2, and refractory concrete; the lower end of the rear arch pipe 12 is connected with the lower drum 22, and the upper end of the rear arch pipe 12 is connected with the upper drum. The refractory concrete is hung on the rear arch tube 12. The rear arch 11 is located on the middle rear part of the fire grate 1;

[0023] Its characteristics are: between the front arch 7 and the rear arch 11, and above the middle front of the grate 1, there are two high-temperature regenerative cylindrical swirling middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com