Coal bunker

A technology of coal bunkers and connecting pipes, which is applied in the direction of combustion methods, block/powder supply/distribution, containers, etc., which can solve the problems of continuous supply of coal, easy blockage of boilers, and influence on boiler combustion, so as to save manpower, The effect of reducing work intensity and stabilizing combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

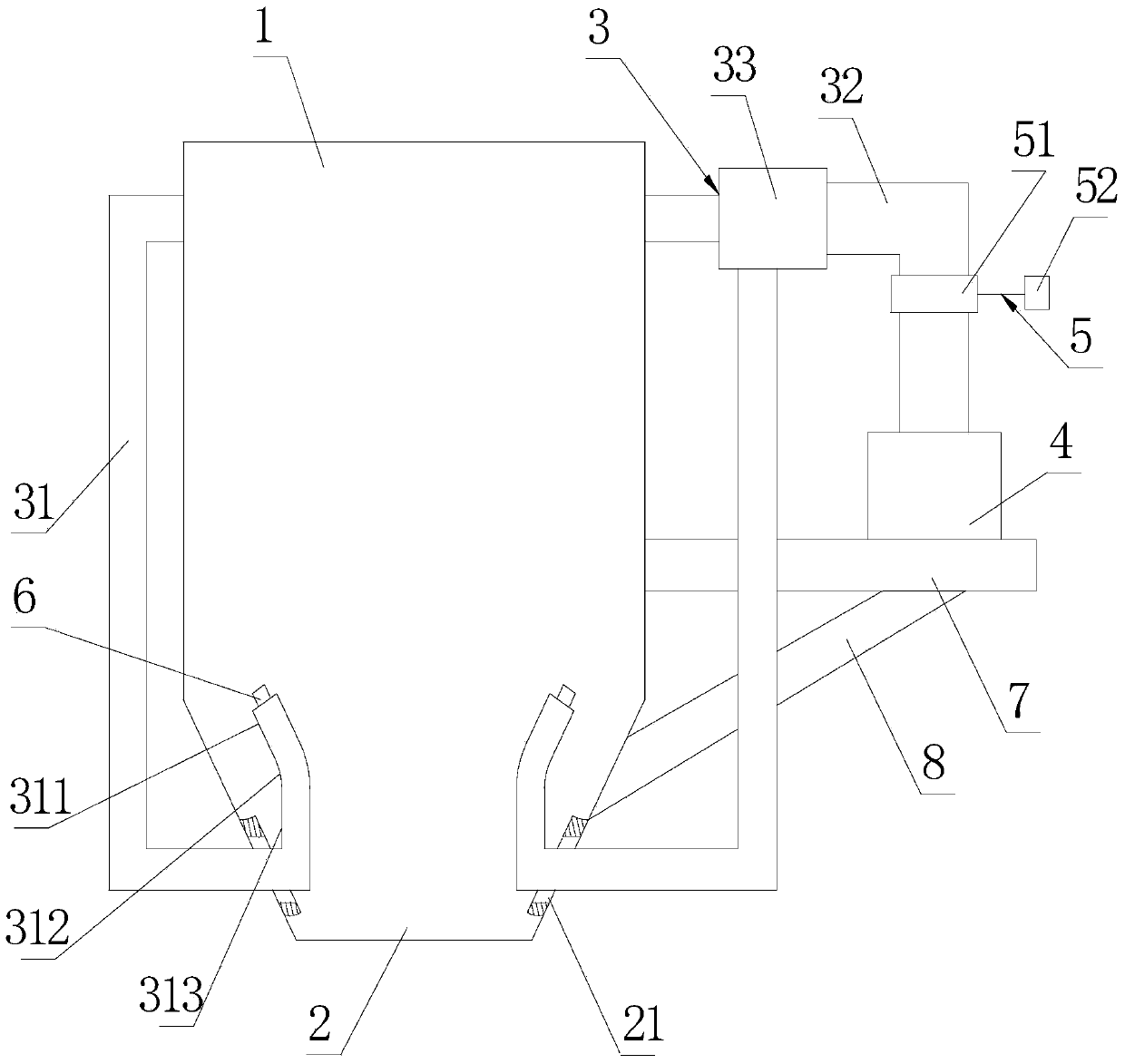

[0018] Like the coal bunker described in Embodiment 1, this embodiment has the following differences: the two first connecting pipes 31 are installed on the discharge port of the lower coal bunker 2, the structure is simple, the installation is convenient, the use effect is good, and it is convenient Lower coal bunker 2 lower coal.

[0019] When in use, when there is coal blockage in the lower coal bunker 2, the solenoid valve 51 is opened by the control switch 52, so that the air in the air supply device 4 enters the lower coal bunker 2 through the air duct 3, which is beneficial to the kinetic energy generated by the air to make the original blockage If the coal is loosened, the coal can be discharged smoothly, which can effectively avoid coal clogging and is conducive to production.

[0020] The air in the air supply device is controlled by the control device to enter the lower coal bunker through the air duct, and the kinetic energy generated by the air from bottom to top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com