A wind-swept dynamic and static combined high-efficiency dust separator

A dust separator, dynamic and static combination technology, used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Problems such as poor classification accuracy, to achieve the effect of improving work efficiency, improving uniformity, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

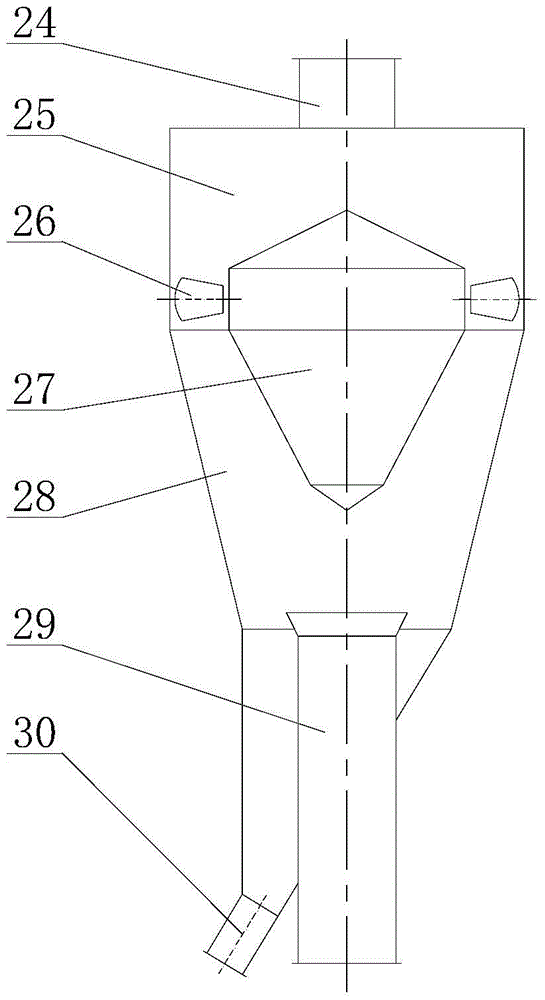

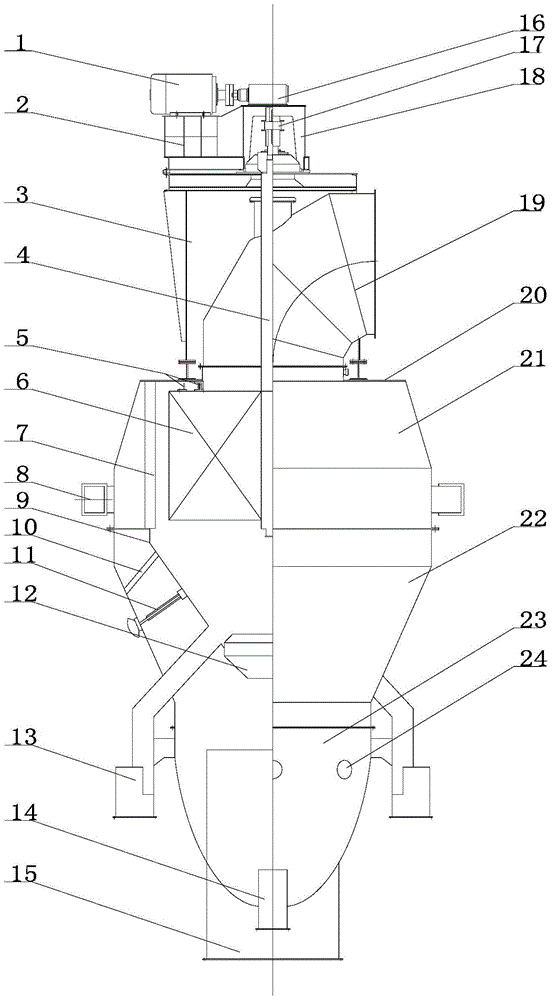

[0024] Such as figure 1 and 2 As shown, a wind-swept dynamic and static combined high-efficiency separator, the motor 1 and the reducer 16 are respectively fixed on the upper part of the transmission bracket 3 through the motor base 2 and the reducer frame 18, and the lower part of the reducer 16 is provided with a shaft coupling 17, which is connected with the transmission The shaft constitutes the transmission part; the transmission is realized by the motor 1 and the reducer 16; the transmission bracket 3 and the air outlet pipe 19 are fixed on the upper part of the upper cover 20; the upper cover 20 is welded to the upper part of the upper cylinder 21 and the upper cylinder 21, the middle cylinder Body 22 and lower cylinder 23 form the shell part of the air-swept dynamic and static combined high-efficiency separator. The upper cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com