Gas stove and gas stove control method

A control method and technology for gas stoves, which are applied in the field of household kitchen utensils, can solve problems such as the inability to automatically adjust the damper structure of gas stoves, and achieve the effects of stabilizing combustion conditions, reducing emissions, and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

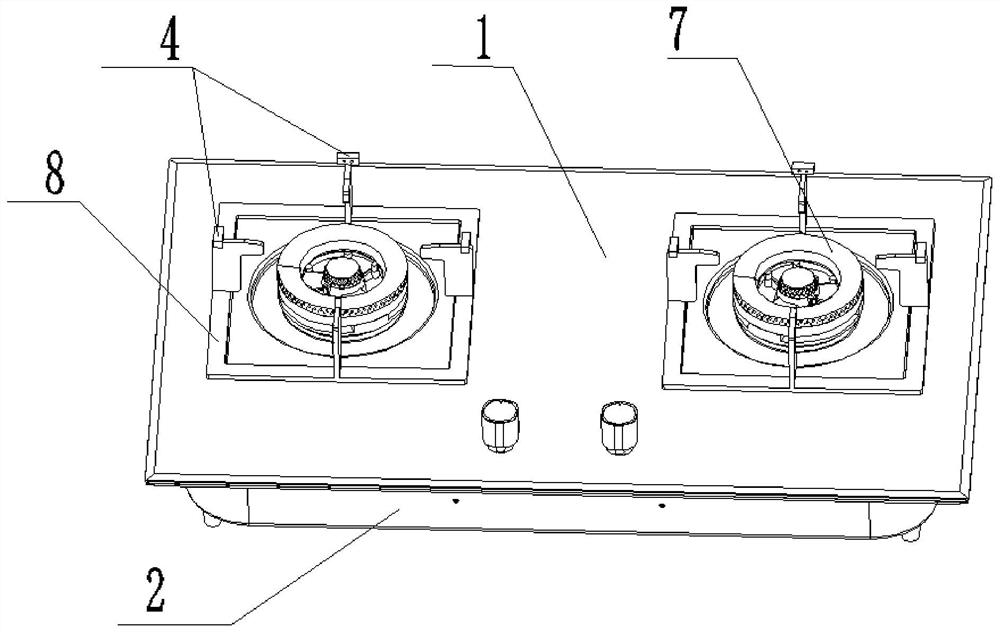

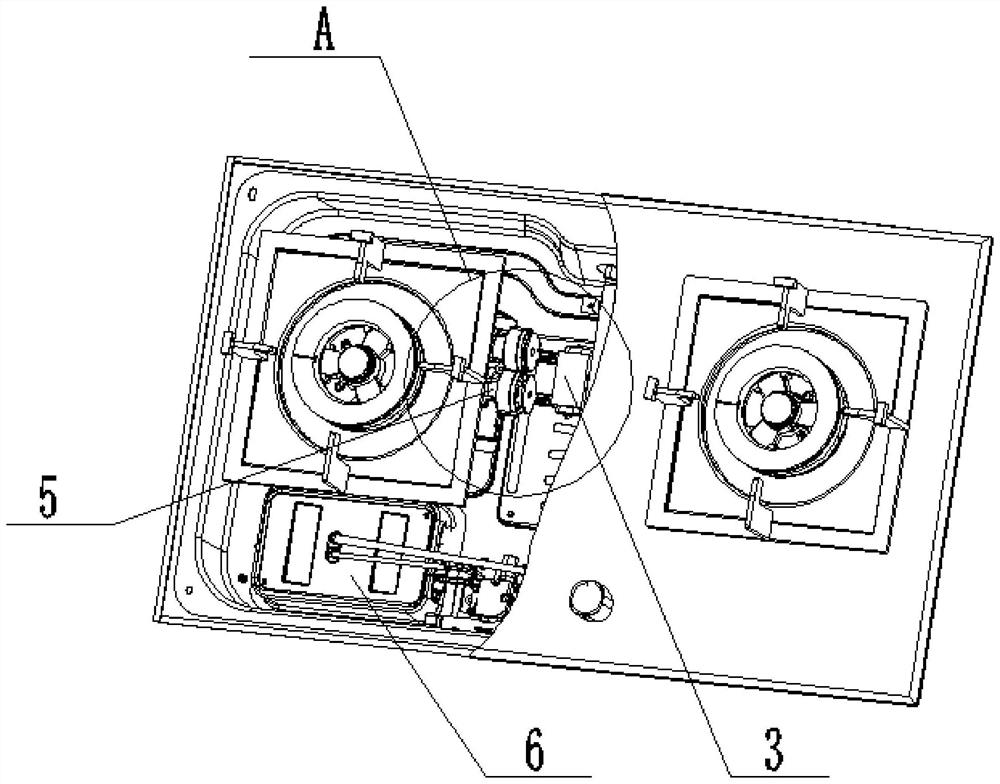

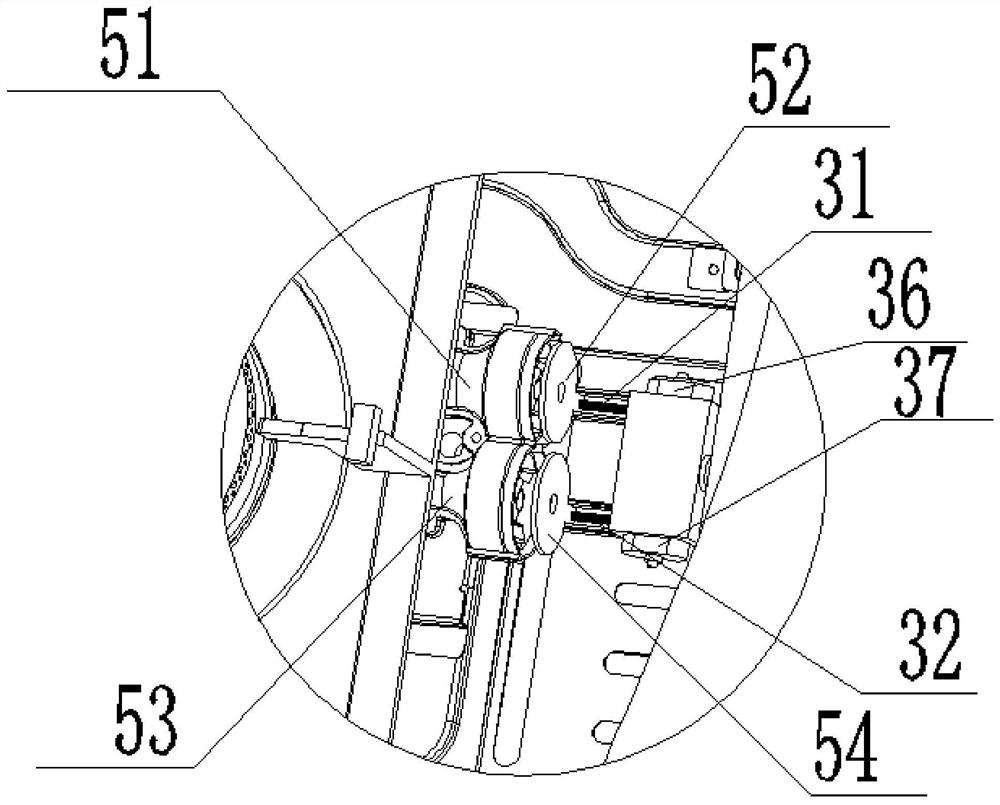

[0055] like figure 1 - Figure 5 , the present embodiment provides a gas stove, including a panel 1 and a bottom case 2, the panel 1 is provided with two burners 7 and a switch knob, and a support structure 8 for carrying pots is arranged along the circumference of the burner 7, The bottom shell 2 is also provided with a damper structure 5, the damper structure 5 includes an ejector tube, one end of the ejector tube is connected to the burner 7, and the other end is provided with a flange annular port, and the port is provided with a damper sheet structure correspondingly. In addition, the gas stove also includes: a damper adjustment device 3 , a gas detection device 4 and a controller 6 .

[0056] The damper adjusting device 3 is arranged adjacent to the burner 7 inside the bottom casing 2, and is movably connected with the damper structure 5, and can adjust the ventilation volume of the damper structure 5;

[0057] The gas detection device 4 is arranged on the panel 1, and...

Embodiment 2

[0074] This embodiment provides a gas stove control method, such as Image 6 As shown, the gas stove includes a damper structure 5 and an ejector tube structure, including the following steps:

[0075] S1. Obtain the volume fraction of carbon monoxide;

[0076] In this embodiment, the volume fraction of carbon monoxide indicates the ratio between the volume Vco of carbon monoxide entering the inside of the gas stove and the total gas Vgas entering the inside of the gas stove. Vgas includes not only the volume of carbon monoxide, but also oxygen, nitrogen and air. other trace gases, etc. Specifically, the volume fraction of carbon monoxide is defined as: Vco / Vgas.

[0077] S2. Determine whether the volume fraction of carbon monoxide falls within the preset range;

[0078] In this embodiment, the set interval value is [0.02-0.03].

[0079] S3. Control the damper structure 5 to approach or move away from the ejection tube structure according to whether it falls within a prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com