Hydraulic multi-frequency ultrasonic generator

A sound generator and ultrasonic technology, applied in the field of hydraulic multi-frequency ultrasonic sound generator, can solve the problems of difficulty in sound pressure amplitude, difficulty in further improving cavitation strength, and difficulty in application of reed whistle engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

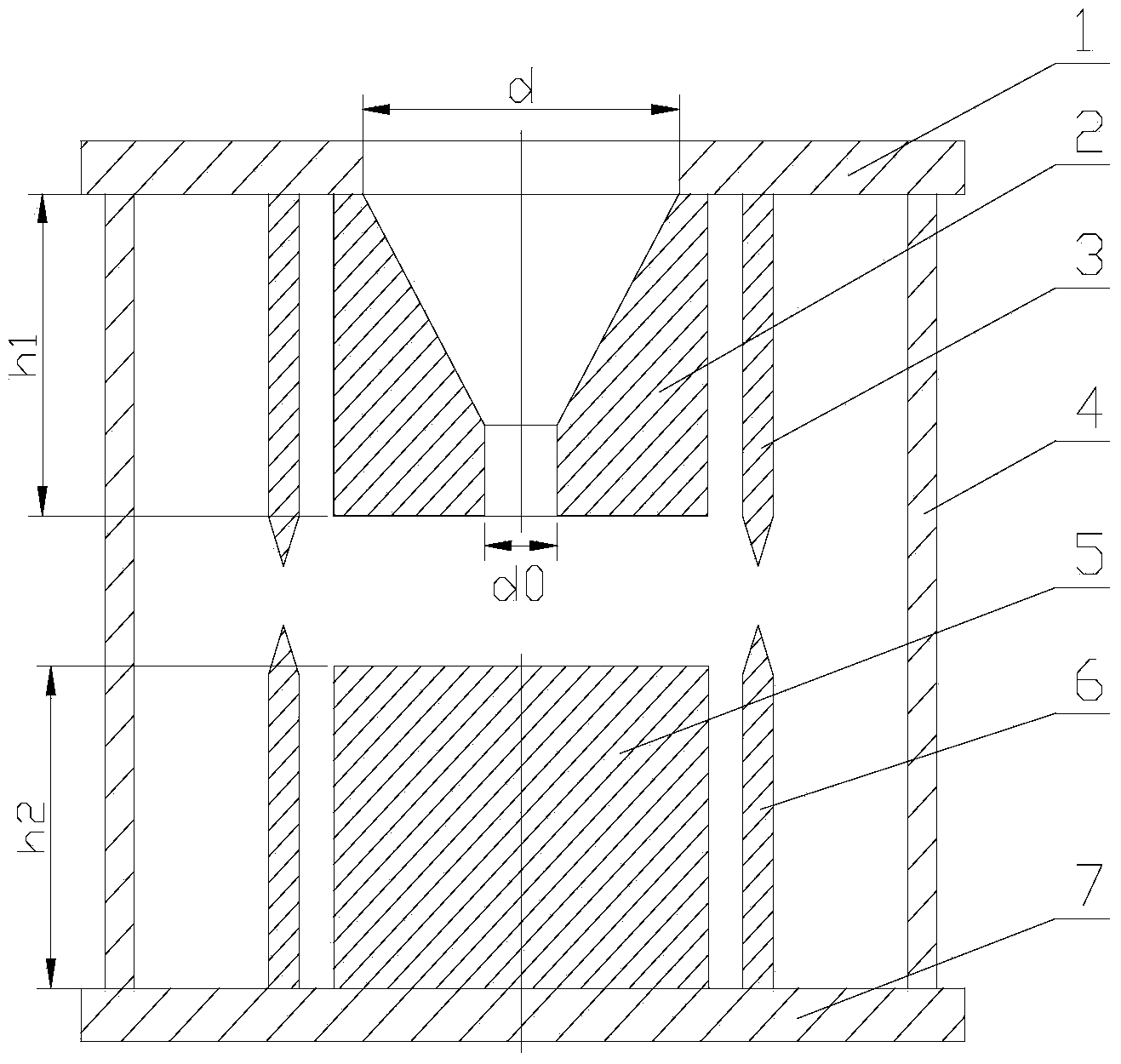

[0013] Depend on figure 1 It can be seen that the hydraulic multi-frequency ultrasonic sounder of this embodiment is composed of the inlet plate 1 , the nozzle 2 , the inlet reed 3 , the connecting rod 4 , the barrier body 5 , the bottom reed 6 and the chassis 7 .

[0014] The inlet plate 1 and the chassis 7 of the present embodiment are circular plates made of stainless steel, and the inlet plate 1 and the chassis 7 are connected by four connecting rods 4 evenly distributed on the same circumference. A fluid inlet is processed in the center of the fluid inlet, and a converging nozzle 2 extending inward is installed on the fluid inlet. The inlet diameter d of the nozzle 2 is 8mm, and the outlet diameter d 0 is 4mm, and the length h1 is 30mm, that is, the inlet diameter d and the outlet diameter d 0 The ratio is 1:0.5, 6 inlet reeds 3 are installed on the outside of the nozzle 2 at a position 2mm away from the outer wall of the nozzle 2, and the 6 inlet reeds 3 are symmetrical...

Embodiment 2

[0017] In this embodiment, the inlet plate 1 and the chassis 7 are connected by two connecting rods 4 evenly distributed on the same circumference. A fluid inlet is processed in the center of the inlet plate 1, and a fluid inlet extending inward is installed on the fluid inlet. Convergent nozzle 2, the inlet diameter d of nozzle 2 is 8mm, and the outlet diameter d 0 is 3.2mm, and the length h1 is 30mm, that is, the inlet diameter d and the outlet diameter d 0 The ratio is 1:0.4. Eight inlet reeds 3 are installed on the outside of the nozzle 2 at a position 3mm away from the outer wall of the nozzle 2. The eight inlet reeds 3 are symmetrically distributed on the same circumference with respect to the center line of the nozzle 2. Each The entrance reed 3 has a length of 31mm and a thickness of 3mm, and its end is pointed, and the size of the pointed angle is 10°, and the generated ultrasonic frequency is 2.554kHz. A barrier body 5 is installed at the position facing the outlet ...

Embodiment 3

[0020] In this embodiment, the inlet plate 1 and the chassis 7 are connected by 8 connecting rods 4 evenly distributed on the same circumference. A fluid inlet is processed in the center of the inlet plate 1, and a fluid inlet extending inward is installed on the fluid inlet. Convergent nozzle 2, the inlet diameter d of nozzle 2 is 8mm, and the outlet diameter d 0 is 5.6mm, and the length h1 is 10mm, that is, the inlet diameter d and the outlet diameter d 0 The ratio is 1:0.7. Two inlet reeds 3 are installed on the outside of the nozzle 2 at a position 2mm away from the outer wall of the nozzle 2. The two inlet reeds 3 are symmetrically distributed on the same circumference with respect to the center line of the nozzle 2. Each The entrance reed 3 has a length of 11 mm and a thickness of 2 mm. Its end is pointed, and the size of the pointed angle is 15°. The generated ultrasonic frequency is 13.522 kHz. A barrier body 5 is installed at the position facing the outlet end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com