Turbulence resonance fluid sounder

A sounder and fluid technology, applied in the field of turbulent resonance fluid sounder, can solve the problems of difficulty in further improving cavitation strength, difficulty in application of reed reed engineering, and difficulty in finding nodes for reeds, so as to improve wastewater treatment effect and strengthen wastewater. Processing effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

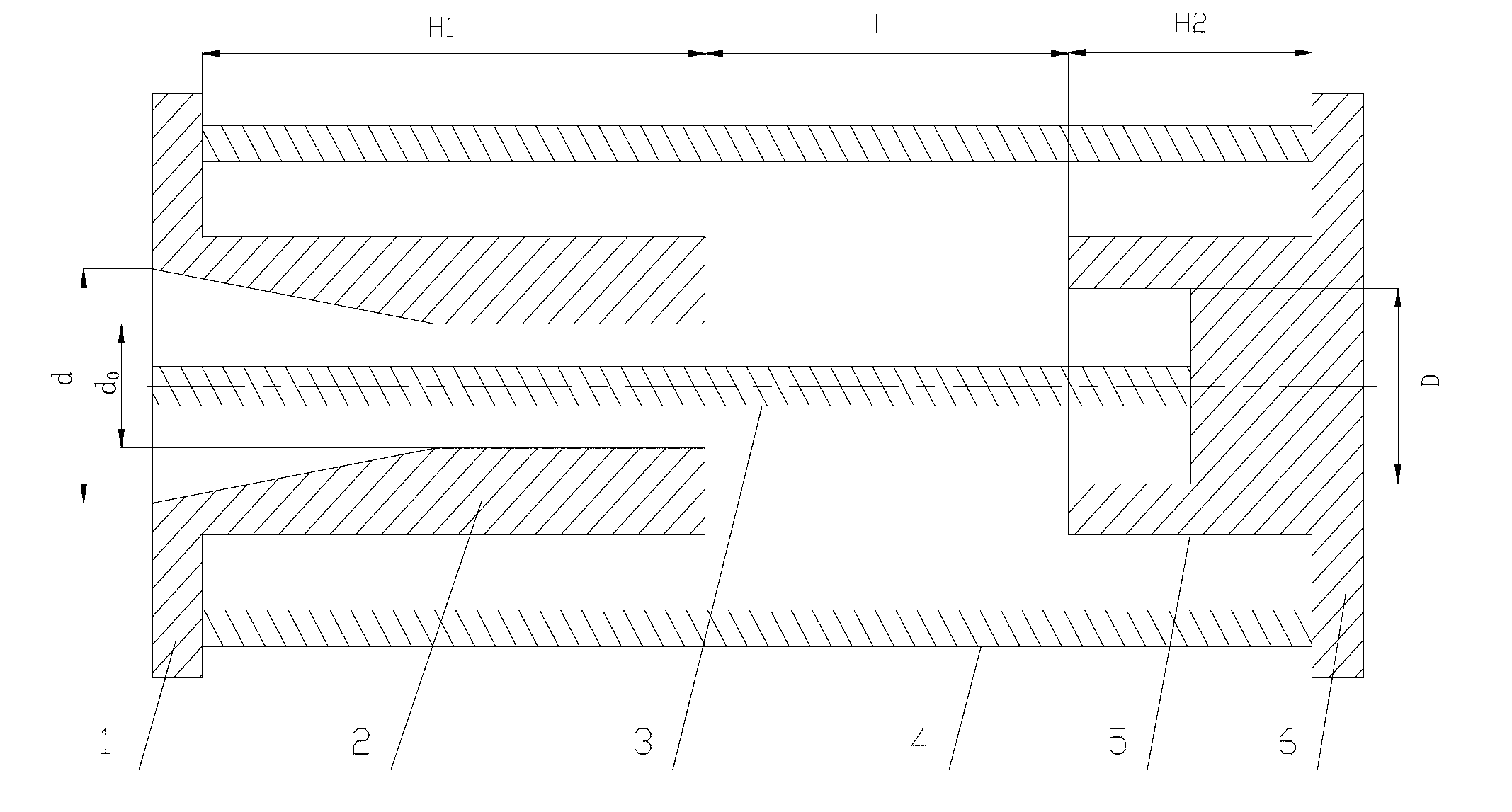

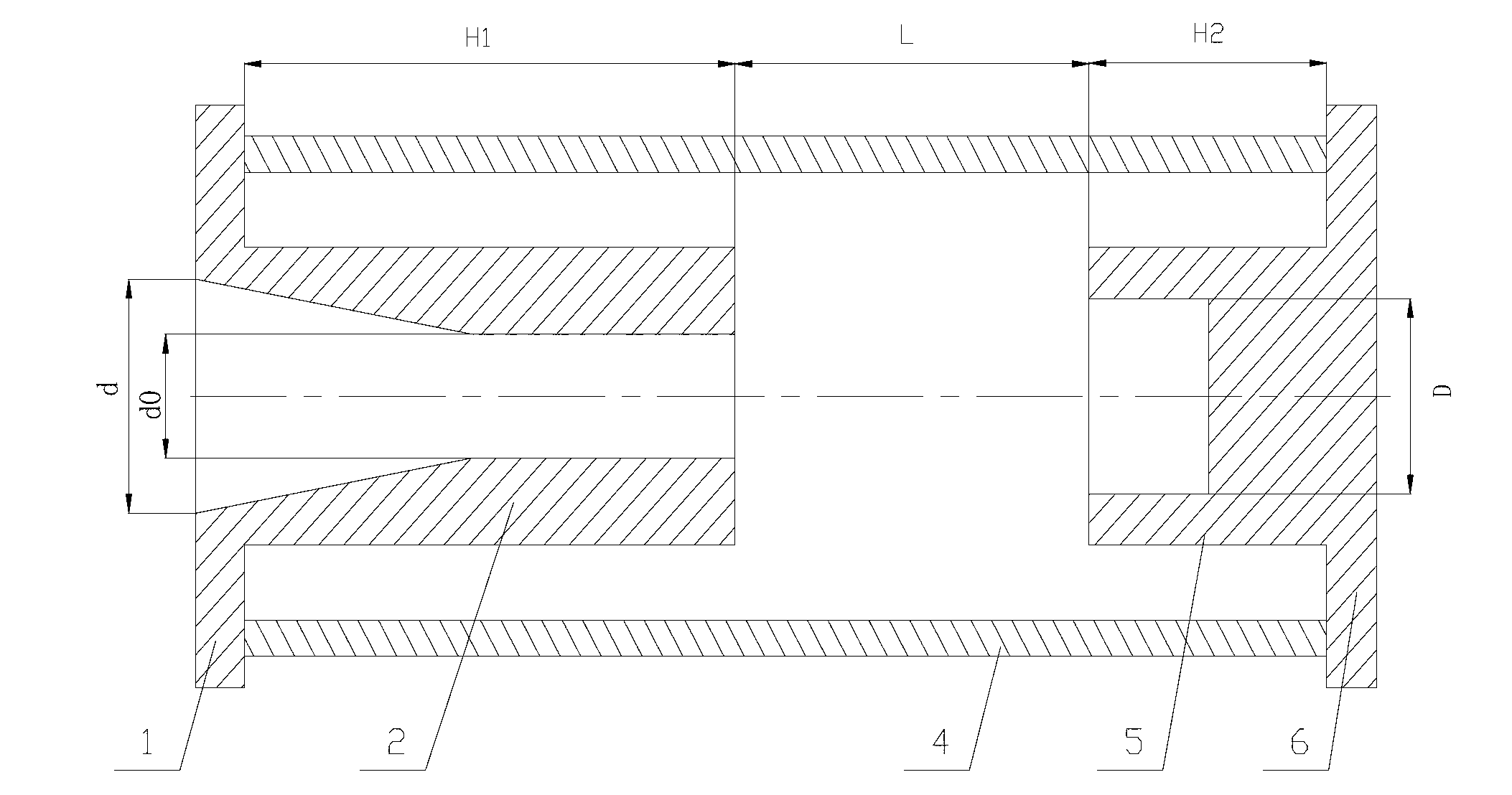

[0014] by figure 1 It can be seen that the turbulent resonant fluid sound generator of this embodiment is composed of an inlet disk 1, a nozzle 2, a center rod 3, a resonance rod 4, a barrier 5, and a chassis 6 connected together.

[0015] The inlet disc 1 of this embodiment is a circular plate made of stainless steel. An inlet with a diameter of 20mm is machined in the middle of the inlet disc 1. The inlet extends inward to form a large to small convergent nozzle 2. Nozzle 2 The depth H 1 48mm, the outlet diameter is 10mm, that is, the inlet diameter d and the outlet diameter d of the nozzle 2 0 The ratio is 1:0.5. A circular stainless steel chassis 6 is installed under the inlet disk 1, and a barrier 5 is provided coaxially with the nozzle 2 in the middle of the chassis 6, and the barrier 5 is a cavity with grooves on the top. Structure, the periphery of the barrier body 5 is the same diameter as the periphery of the nozzle 2, and the opening diameter D of the groove is the outl...

Embodiment 2

[0018] The inlet disc 1 of this embodiment is a circular plate made of stainless steel. An inlet with a diameter of 20mm is machined in the middle of the inlet disc 1, and the inlet extends inward to form a convergent nozzle 2. The depth of the nozzle 2 is H 1 48mm, the outlet diameter is 6mm, that is, the inlet diameter d and the outlet diameter d of the nozzle 2 0 The ratio is 1:0.3. A circular stainless steel chassis 6 is installed under the inlet plate 1. A barrier 5 is provided coaxially with the nozzle 2 in the middle of the chassis 6, and the barrier 5 is a cavity with grooves on the top. Structure, the periphery of the barrier body 5 and the periphery of the nozzle 2 have the same diameter, the opening diameter D of the groove and the nozzle 2 exit diameter d 0 Equal, ie 6mm, depth H 2 The distance L between the top of the barrier 5 and the nozzle 2 exit is 1.2mm, which is 0.2 times the diameter D of the groove opening. In order to increase the pressure field intensity in ...

Embodiment 3

[0021] The inlet disc 1 of this embodiment is a circular plate made of stainless steel. An inlet with a diameter of 20mm is machined in the middle of the inlet disc 1, and the inlet extends inward to form a convergent nozzle 2. The depth of the nozzle 2 is H 1 48mm, the outlet diameter is 12mm, that is, the inlet diameter d and the outlet diameter d of the nozzle 2 0 The ratio is 1:0.6. A circular stainless steel chassis 6 is installed under the inlet plate 1, and a barrier 5 is provided coaxially with the nozzle 2 in the middle of the chassis 6, and the barrier 5 is a cavity with grooves on the top. Structure, the periphery of the barrier body 5 is the same diameter as the periphery of the nozzle 2, and the opening diameter D of the groove is the outlet diameter d of the nozzle 2. 0 1.17 times that of 14.04mm, depth H 2 The distance L between the top of the barrier 5 and the nozzle 2 exit is 8.424mm, which is 0.6 times the diameter D of the groove opening. In order to increase th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com