A kind of oxidation adjustment equipment for oxidizing pu(iii) to pu(iv)

A technology of equipment and oxidation tower, which is applied in the field of oxidation price adjustment equipment, can solve the problems of unfavorable post-treatment process, increase the burden of tail gas disposal, and reduce the utilization rate of NOx, so as to reduce the disposal burden, respond quickly, and increase the treatment scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

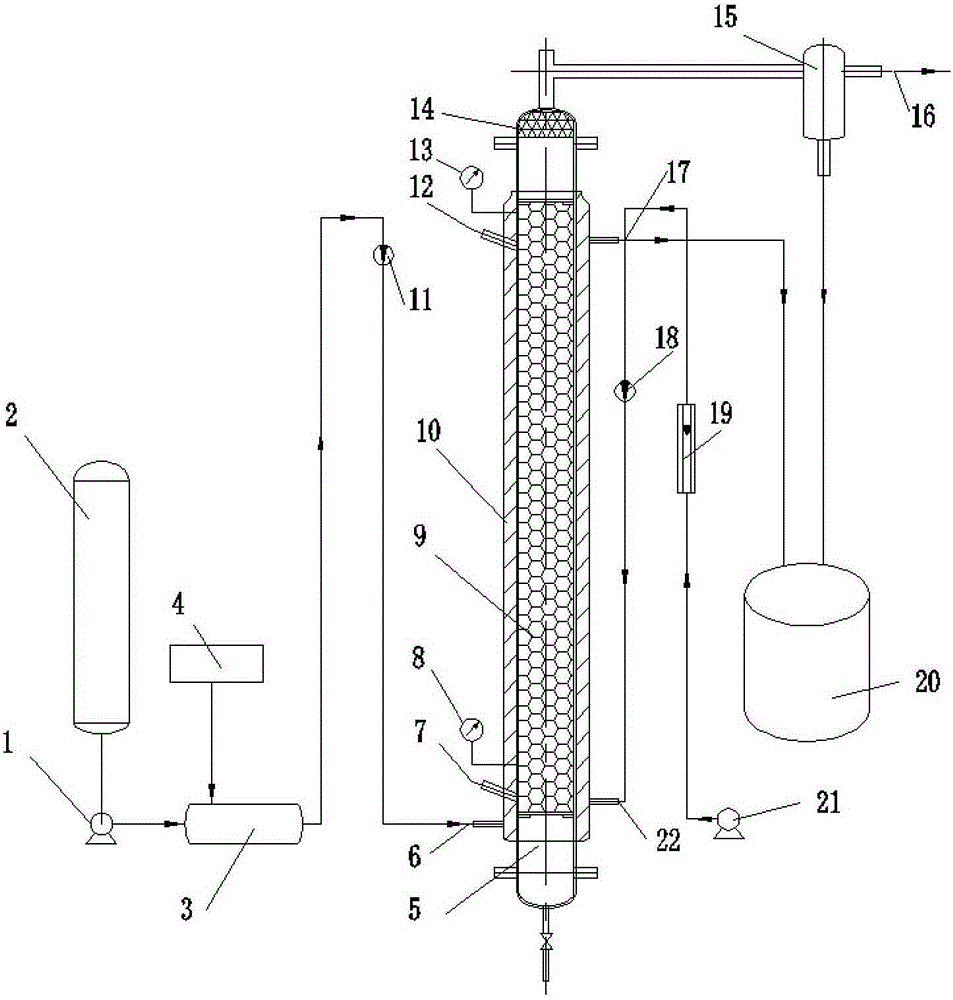

[0031] A kind of oxidation adjustment device that Pu(III) is oxidized to Pu(IV), such as figure 1 As shown, the equipment mainly includes oxidation tower 5, feed liquid receiving tank 20 and NO X Storage tank 2, wherein the upper end of oxidation tower 5 is provided with feed liquid outlet 17, and the lower end is provided with Pu(III) feed liquid inlet 22 and NO X Feed inlet 6, feed liquid receiving tank 20 and feed liquid outlet 17 on the top of oxidation tower 5 are connected by pipelines; wherein the main body of oxidation tower 5 and the packing in the tower are all radiation-resistant and nitric acid corrosion-resistant stainless steel west tower rings; An electric heating plate 10 is set on the outer wall of the tower 5, so that the temperature of the liquid in the tower is 40°C; a neutron-absorbing material is set in the middle of the oxidation tower 5 10 B 4 c. A demister 14 is installed on the top of the oxidation tower 5 to separate the feed liquid entrained by t...

Embodiment 2

[0041] The difference from Example 1 is that one or more sieve plates are arranged inside the oxidation tower 5 to separate the packing; the heating method of the gasification tank 3 is water bath heating, and the heating temperature is 90 ° C; the heating method of the oxidation tower 5 In order to wind a layer of heating water jacket on the outer wall of the tower, the temperature of the liquid in the tower is 50°C; the neutron-absorbing material placed on the wall of the oxidation tower 5 is 6 LiF; NO X The highest point of the inverted U-shaped tube through which the gas enters the oxidation tower body is 300mm higher than the outlet of the feed liquid.

Embodiment 3

[0043] The difference from Example 1 is that the heating method of the oxidation tower 5 is to wrap a layer of electric heating tape on the outer wall of the tower, so that the temperature of the feed liquid in the tower is 40 ° C; NO X is NO, NO and oxygen are jointly formed by NO X The feed inlet enters the tower, where the oxygen content is twice that of NO; NO X The highest point of the inverted U-shaped tube through which the gas enters the oxidation tower body is 400mm higher than the outlet of the feed liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com