Centralized aerobic mud pulling sedimentation tank

A centralized, sedimentation tank technology, applied in aerobic process treatment, flocculation/sedimentation water/sewage treatment, oxidized water/sewage treatment, etc., can solve uneven water discharge, low surface load rate, increase treatment scale, etc. problems, to achieve the effect of strengthening biological action, realizing sludge return and automatic sludge discharge, and strengthening physical flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

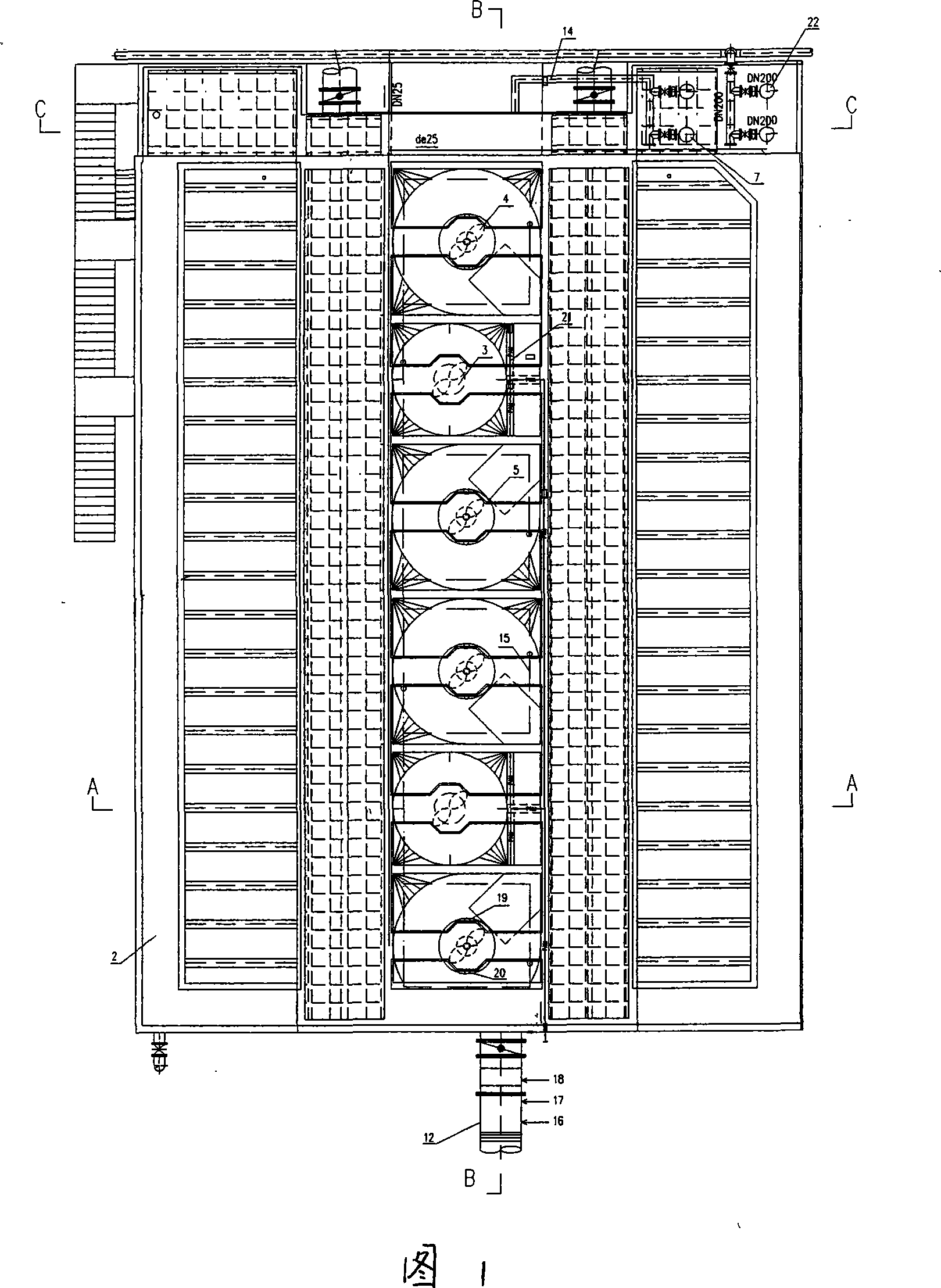

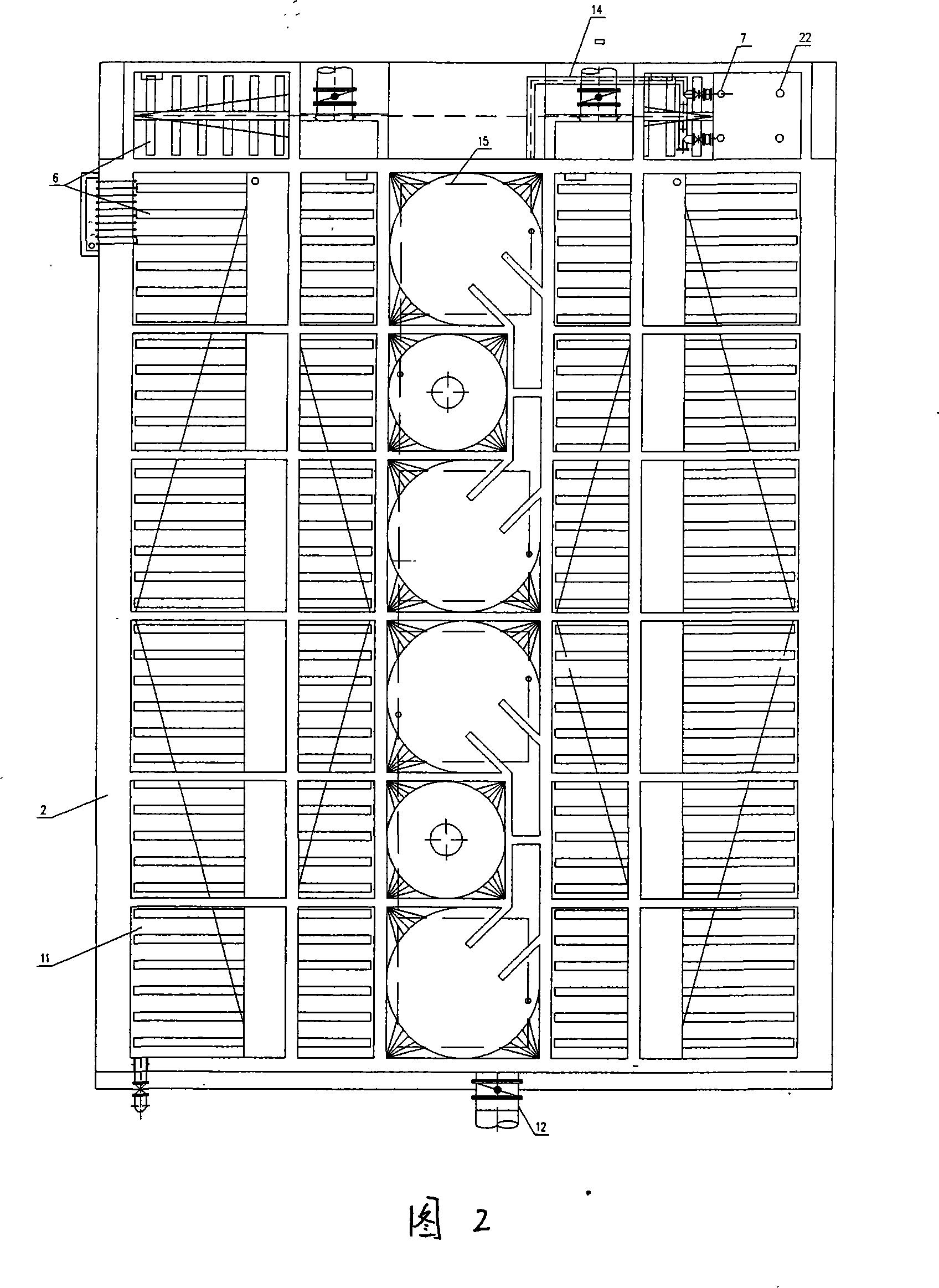

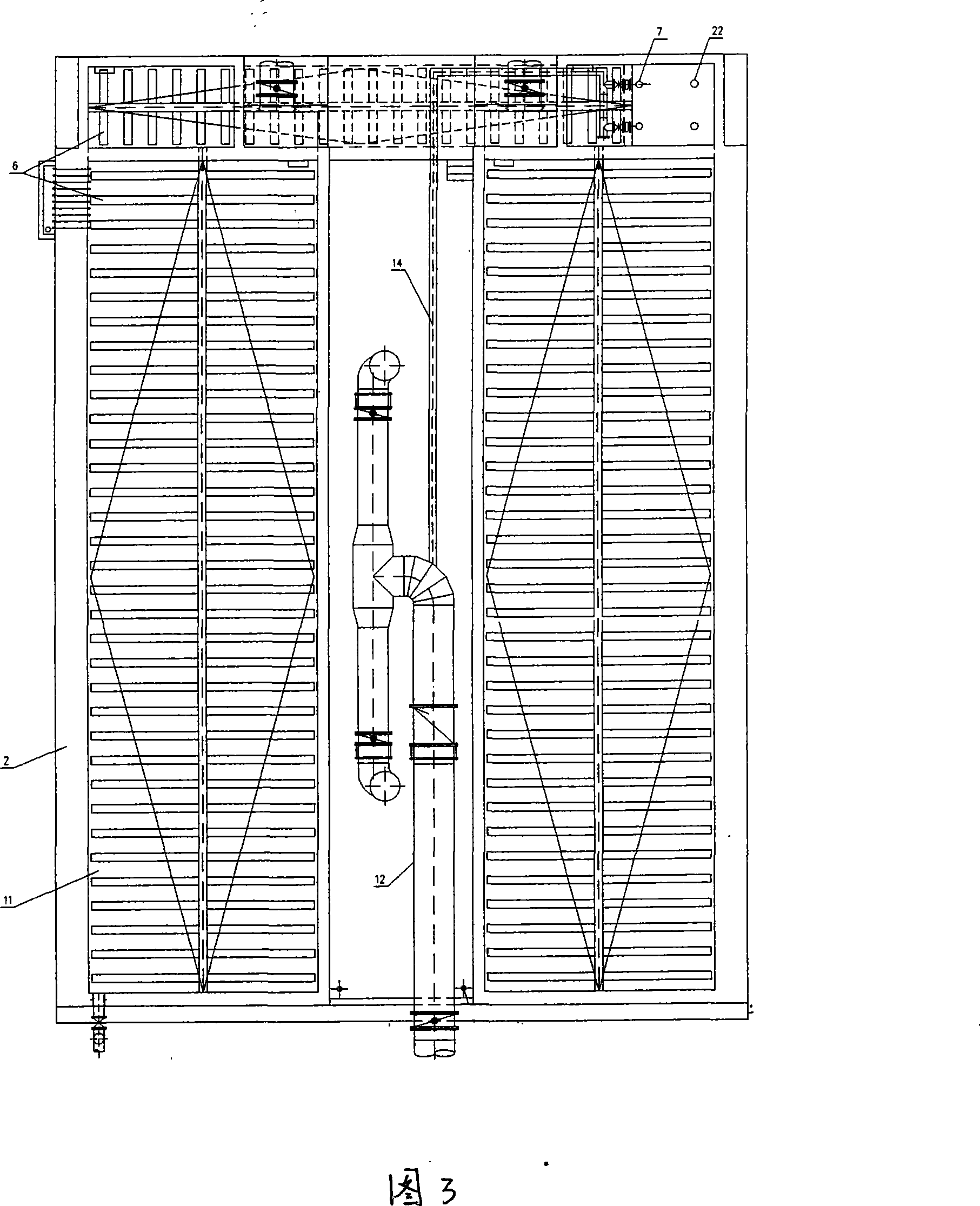

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The present invention is a centralized aerobic mud pushing sedimentation tank 1, as shown in Figure 1, the sedimentation tank mainly includes a mixing zone and a lifting mixing zone arranged in the main tank body 2, and a mixing mixer is arranged in the mixing zone 3. The lifting mixer 4 and the stainless steel cylinder 5 attached to the lifting mixer 4 are installed in the lifting mixing zone, the aeration pipeline 15 in the mixing mixing zone and the lifting mixing zone, and the concentrated sludge discharge zone 11 is set at the bottom of the main pool body 2 to concentrate A concentrated mud pusher 6 is provided in the mud discharge area 11, a water distribution weir and a baffle system 10 are provided on the upper part of the concentrated mud discharge area 11, and a plastic inclined pipe area 8 and a stainless steel outlet rectangular tank 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com