Apparatus for removing nitrous acid in reprocessing feed solution

A nitrous acid and feed liquid technology, which is applied in nuclear engineering, radioactive purification, steam distillation, etc., can solve the problems of inappropriate large-scale removal of nitrous acid, and achieve the effect of continuous operation processing capacity, high speed and improving processing scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

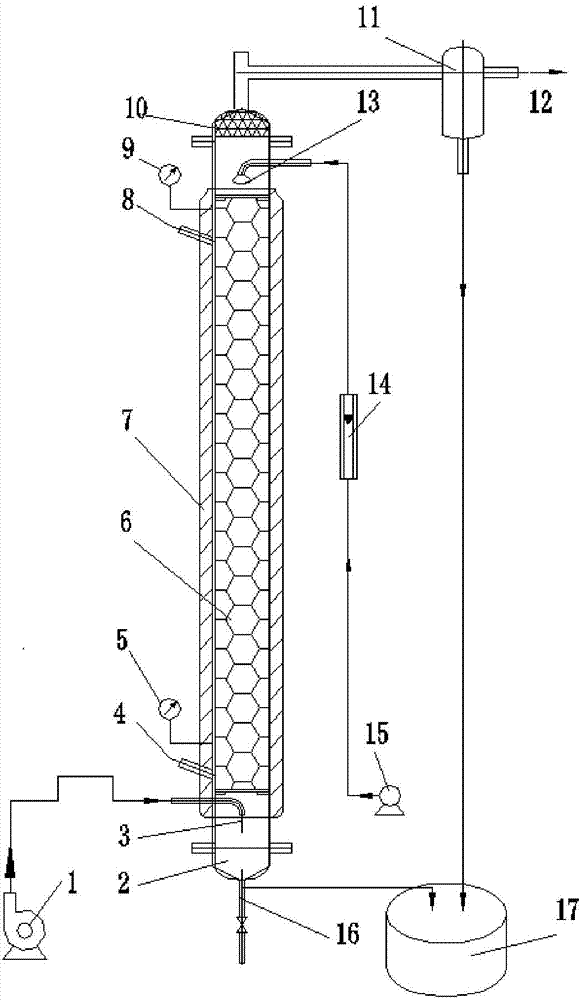

[0030] A device for removing nitrous acid in post-treatment feed liquid, such as figure 1 As shown, the equipment includes a removal tower 2 (the effective height is 2350 mm, and the diameter is 273 mm), an air generating device 1 and a feed liquid receiving tank 17, wherein the upper end of the removal tower 2 is provided with a feed liquid inlet 13, and the lower end is provided with an air inlet 3. There is a feed liquid outlet 16 at the bottom, and a packing 6 is arranged inside, and an electric heating plate 7 is installed on the outer wall of the removal tower 2, so that the temperature of the feed liquid in the tower is 30°C; the feed liquid to be treated is transported by the feed liquid The pump 15 enters the feed liquid inlet 13 through the feed liquid input pipe, and is in countercurrent contact with the air entering from the air inlet 3, wherein a check valve is installed on the feed liquid input pipe. The feed liquid receiving tank 17 is connected with the feed li...

Embodiment 2

[0034] The difference from Example 1 is that one or more sieve plates are built in the removal tower 2 to separate the packing, and the middle part of the removal tower 2 is equipped with neutron absorbing materials. 10 B 4 c. The heating device arranged on the outer tower wall of the removal tower 2 is an electric heating belt wound on the tower wall, so that the temperature of the feed liquid in the tower is 50°C. A demister 10 is arranged on the top of the demister 2 , and a cyclone separator 11 is arranged at the rear end of the demister 10 . The volume flow ratio of the air fed from the air inlet to the feed liquid fed from the feed liquid inlet is 200. The air generating device is an air compressor.

[0035] Adopt the equipment described in embodiment 1, carry out the removal of nitrous acid to post-treatment feed liquid, processing capacity is 100L / h, and wherein feed liquid consists of: nitric acid concentration: 2.1mol / L, U (VI) concentration: 2g / h L, Fe(III) conc...

Embodiment 3

[0037] Different from Example 1, one or more sieve trays are built in the removal tower 2 to separate the packing, and the wall of the removal tower 2 is equipped with neutron absorbing materials. 6 LiF. The heating device arranged on the outer tower wall of the removal tower 2 is a heating water jacket wound on the tower wall, so that the temperature of the feed liquid in the tower is 40°C. The volume flow ratio of the air fed from the air inlet to the feed liquid fed from the feed liquid inlet is 350. The air generating device is an air compressor.

[0038] Adopt the equipment described in embodiment 1, carry out the removal of nitrous acid to aftertreatment feed liquid, processing capacity is 100L / h, and wherein feed liquid consists of: nitric acid concentration: 2.4mol / L, U (VI) concentration: 2g / h L, Fe(III) concentration: 10g / L, the content of nitrous acid after removal by removal tower 2 is 0.09mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com