Patents

Literature

67 results about "Nuclear reprocessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear reprocessing is the chemical separation of fission products and unused uranium from spent nuclear fuel. Originally, reprocessing was used solely to extract plutonium for producing nuclear weapons. With commercialization of nuclear power, the reprocessed plutonium was recycled back into MOX nuclear fuel for thermal reactors. The reprocessed uranium, also known as the spent fuel material, can in principle also be re-used as fuel, but that is only economical when uranium supply is low and prices are high. A breeder reactor is not restricted to using recycled plutonium and uranium. It can employ all the actinides, closing the nuclear fuel cycle and potentially multiplying the energy extracted from natural uranium by about 60 times.

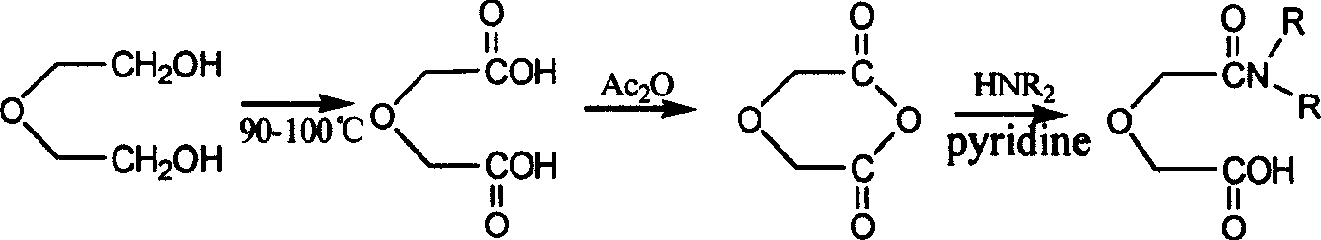

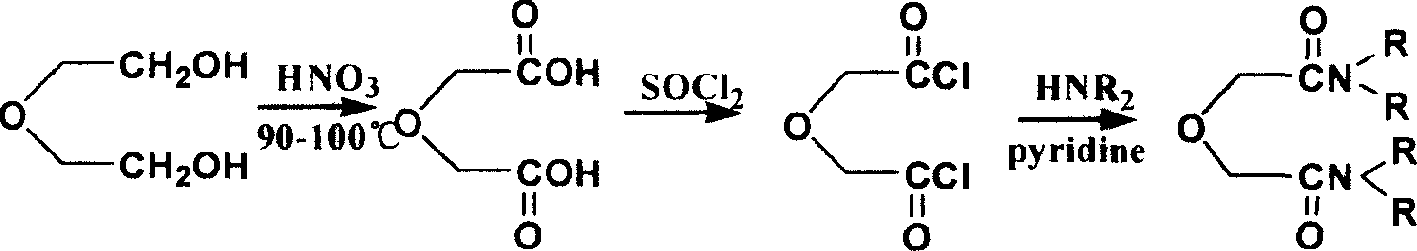

Synthesis of water soluble oxamonoamide

InactiveCN1613846AGood water solubilitySimple processOrganic compound preparationCarboxylic acid amides preparationSolubilitySolvent

Synthesis of water soluble half amide oxide is carried out by taking 1,4-dioxane as solvent at low-temperature, diethylene acid anhydride reacting with dimethylamine, diethylamine, and dipropylamine under pyridine, the products concentrating, chlorhydric acid acidifying, crystallizing precipitating, and annealing purifying in water or alcohol and diethyl ether mixed solvent. Its advantages include good water solubility, high output, and simple process.

Owner:TSINGHUA UNIV

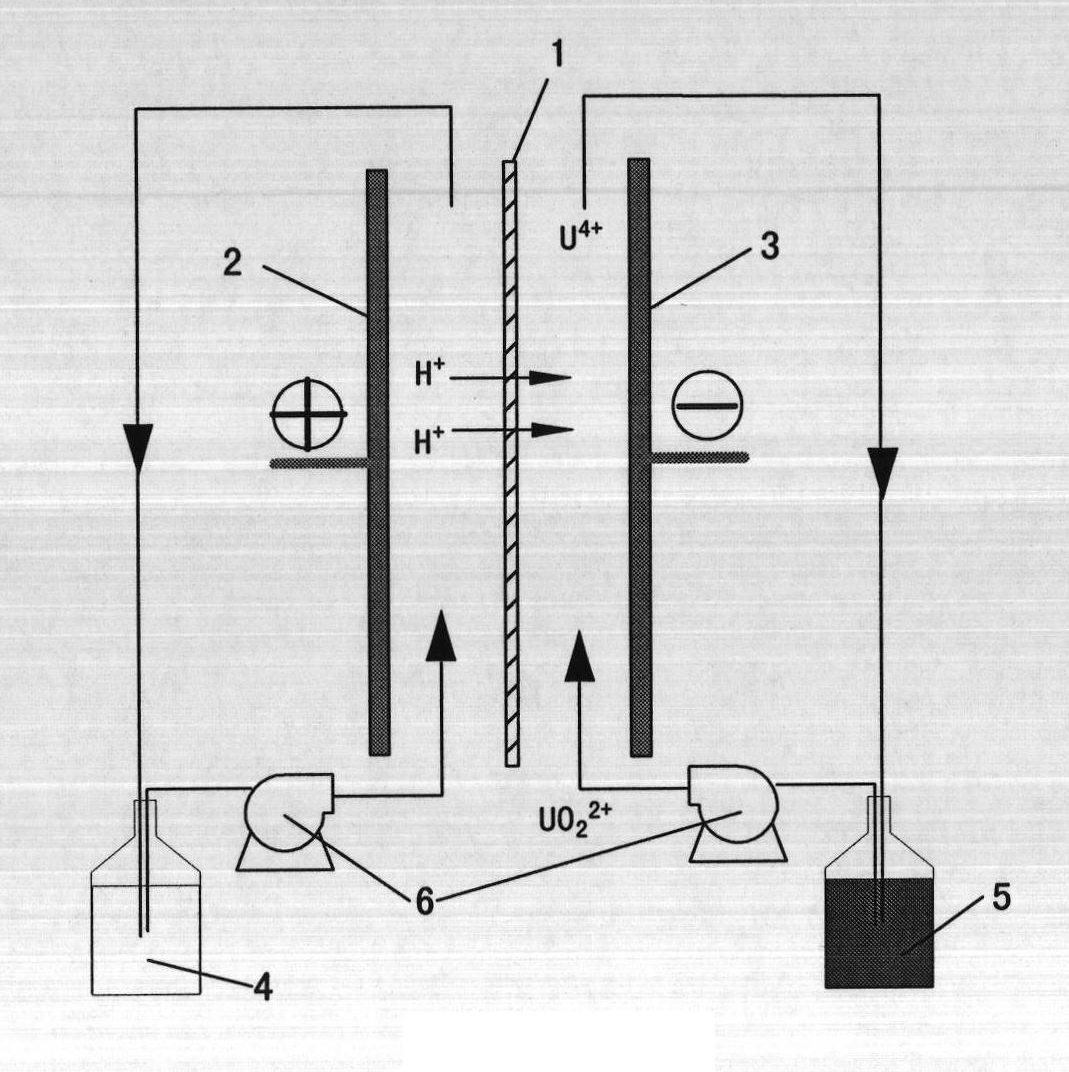

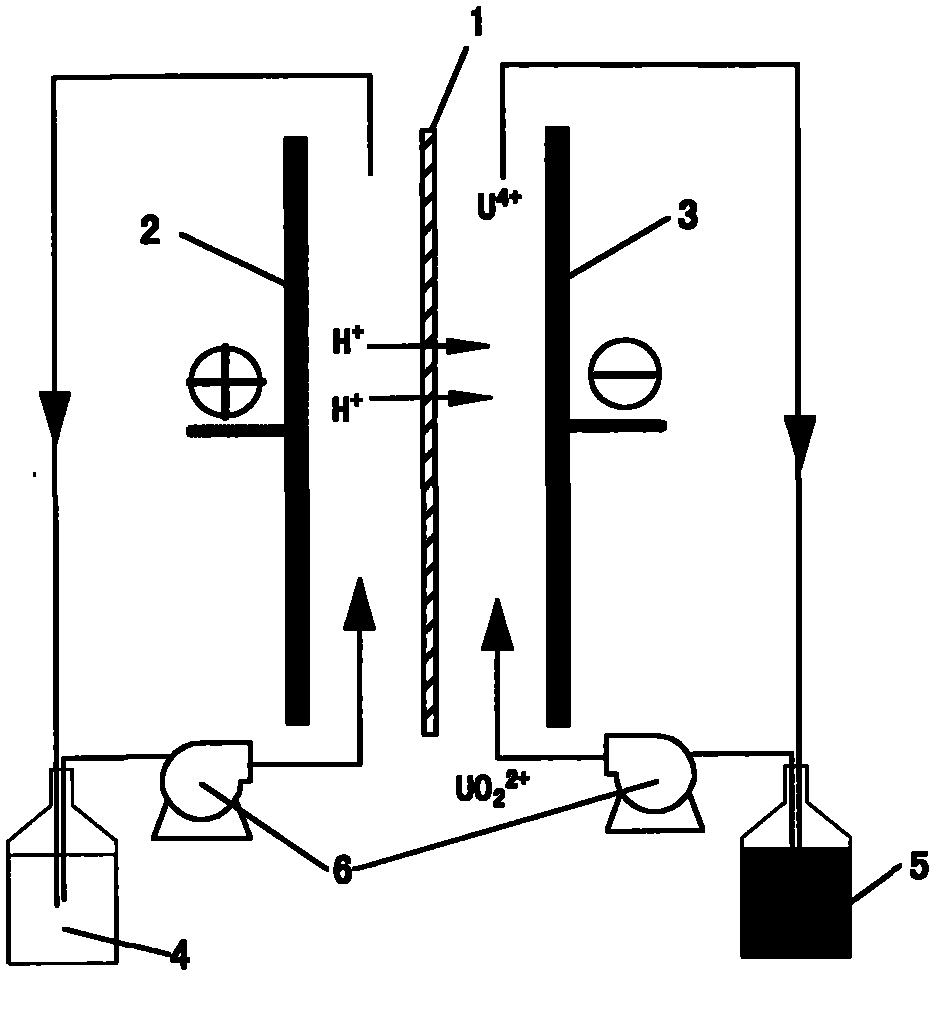

Method for preparing uranous solution

InactiveCN102249331AIncrease concentrationSimple and fast operationUranium compoundsUranylReducing agent

The invention discloses a method for preparing uranous solution, which comprises the following steps of: adding an organic reducing agent and a catalyst into acidic solution of uranyl ions, and reacting under the action of the catalyst to reduce the uranyl ions into uranous ions. The method for preparing the uranous solution used in the nuclear fuel reprocessing industry is high in uranium conversion rate, easy and convenient to operate, mild in reaction conditions and high in prepared uranous concentration.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

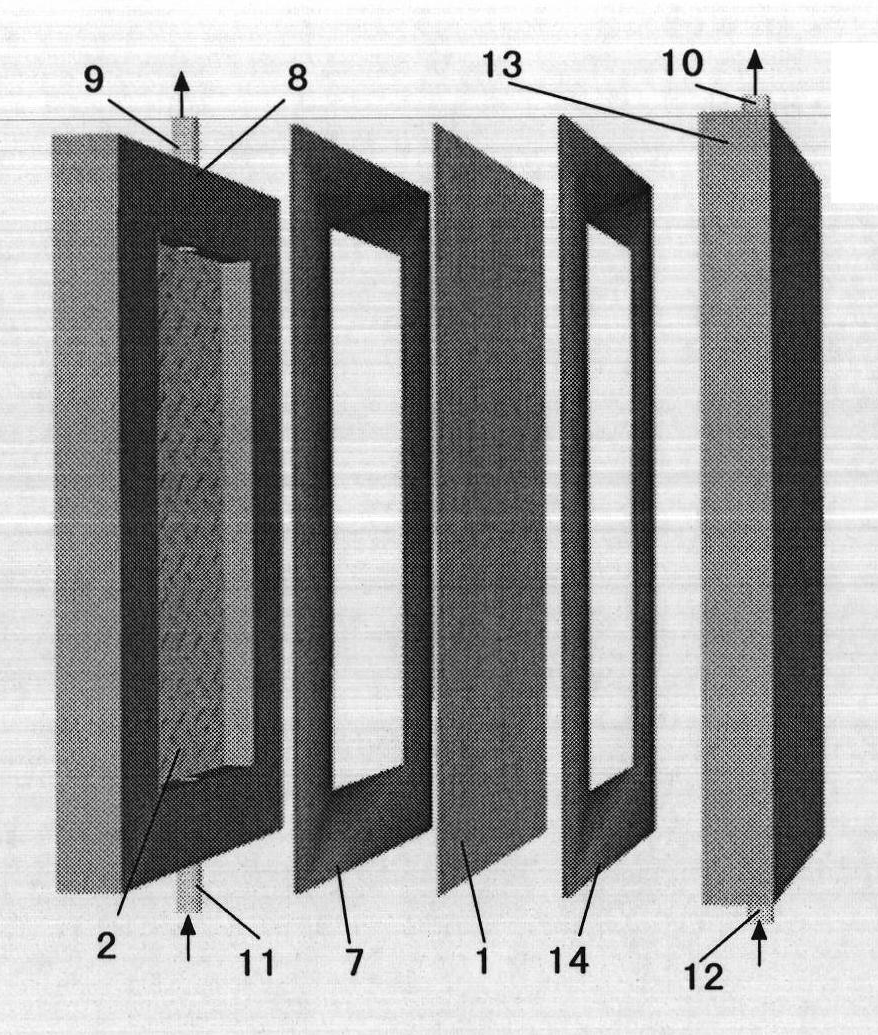

Device and method for preparing tetravalent uranium by dynamic membrane electrolysis

ActiveCN102534644APrevent re-oxidationReduce thicknessCellsElectrode shape/formsPeristaltic pumpIridium

The invention belongs to the field of nuclear fuel reprocessing, and in particular relates to a device and a method for preparing tetravalent uranium by dynamic membrane electrolysis. The device consists of a cation exchange membrane, an anode, a cathode, anolyte, catholyte, a peristaltic pump, a gasket a, an electrode frame a, an anolyte outlet, a catholyte outlet, an anolyte inlet, a catholyte inlet, an electrode frame b and a gasket b, wherein the electrode frame a, the gasket a, the cation exchange membrane, the gasket b and the electrode frame b are arranged on the device from left to right and superposed layer upon layer to form a sealed space; each of the gasket a and the gasket b has a quadrilateral structure; the anode is a titanium-coated ruthenium iridium mesh; the cathode is a titanium mesh; the distance between the cathode and the anode is 6 to 15mm; and the cation exchange membrane is a perfluorosulfonated cation exchange membrane. By the device and the method for preparing the tetravalent uranium by dynamic membrane electrolysis, the content of the tetravalent uranium in a product is ensured, and the tetravalent uranium can be stably and quickly prepared; and the device has a simple structure.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for back-extracting and separating radioactive element from organic phase by using water soluble oxaamide

InactiveCN1477649AReduce lossesPromote decompositionNuclear energy generationIsotope separationLanthanideWater soluble

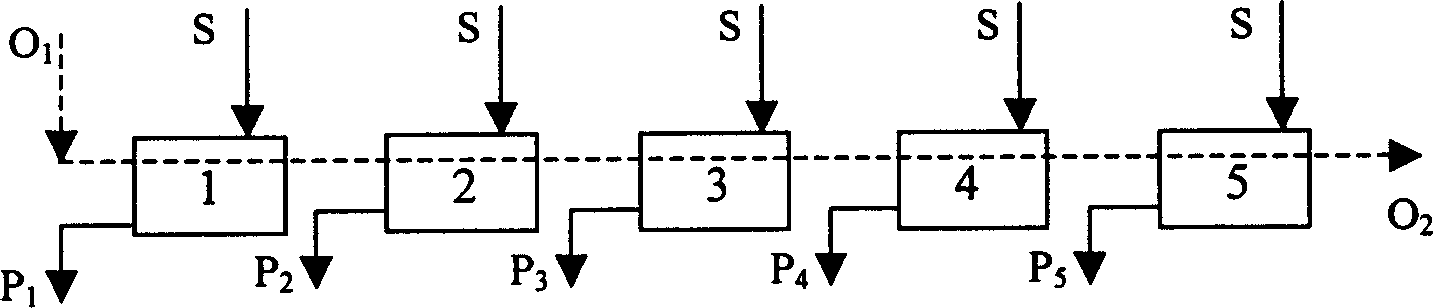

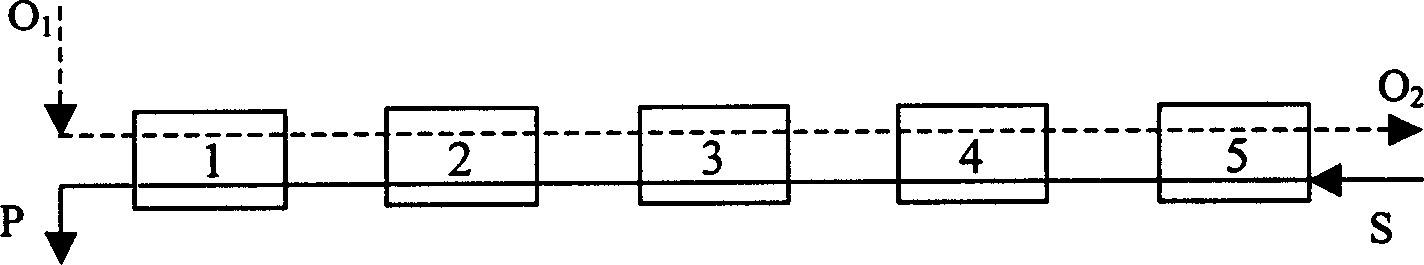

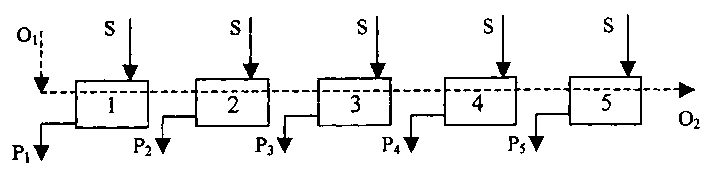

The present invention uses alkyl-3-oxyalutaramine aqueous solution whose substituted alkyl carbon chain length is less than 3 carbons as back extractant, and utilizes the multistage cross current back extraction and / or continuous counter-current back-extraction process to separate and extract superuranium element and lanthanide from organic phase of tributyl phosphate and trialkyloxyphosphine in which the actinoid and lanthanide are extracted.

Owner:TSINGHUA UNIV

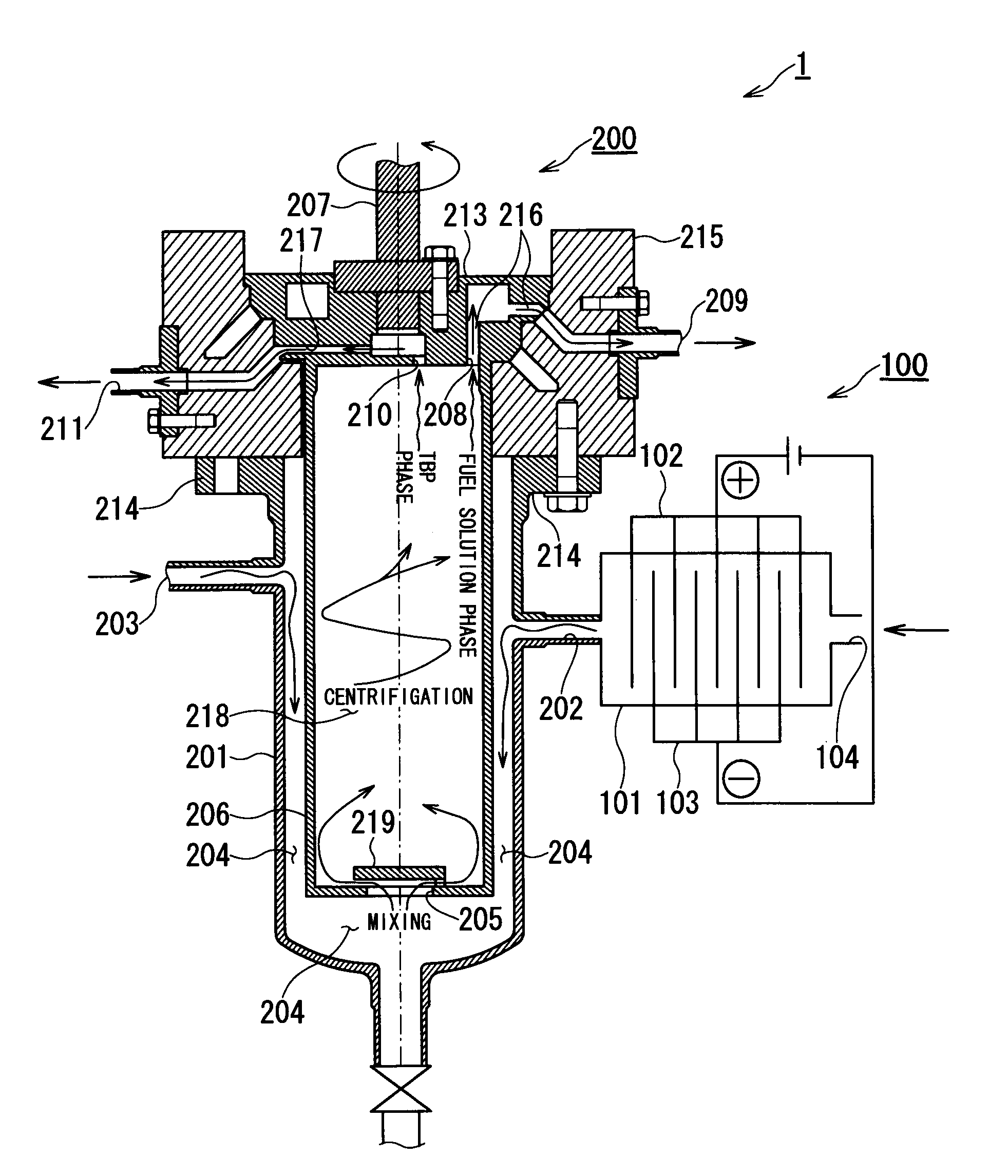

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS20100038249A1Isolation difficultRecovery difficultPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

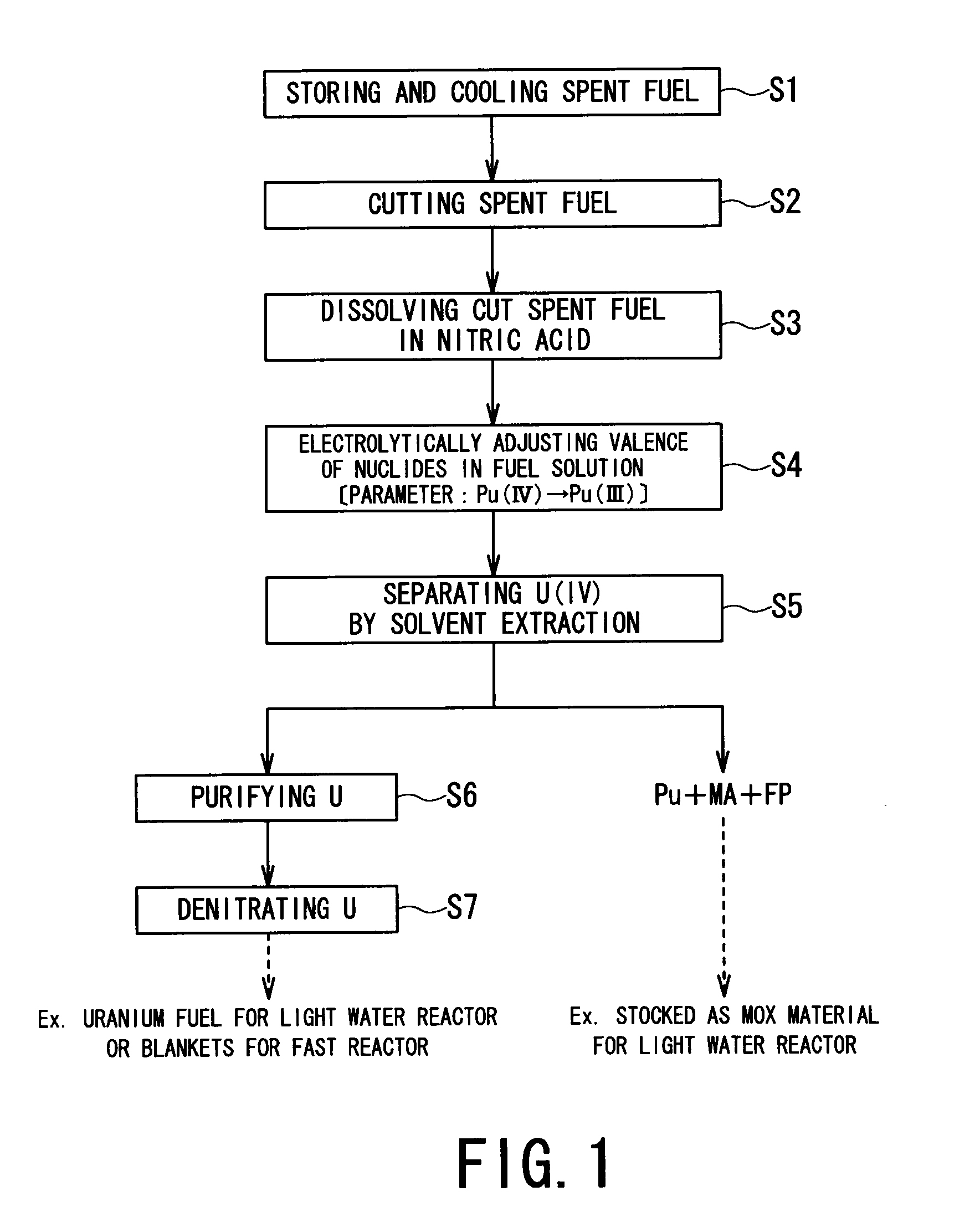

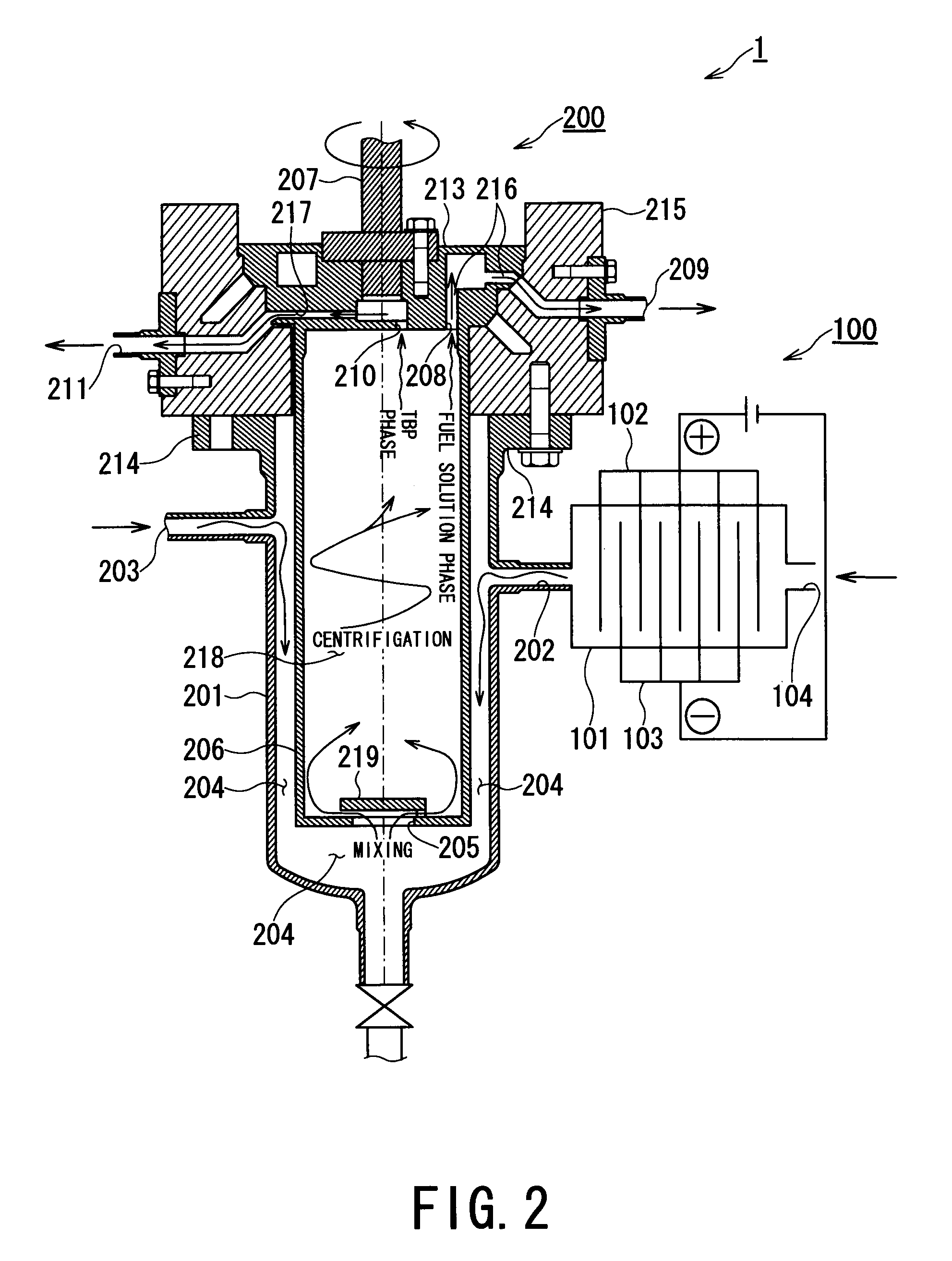

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

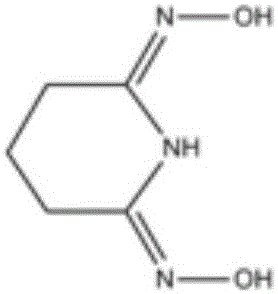

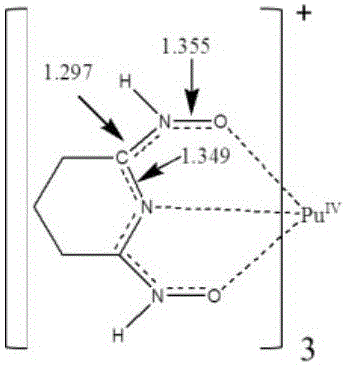

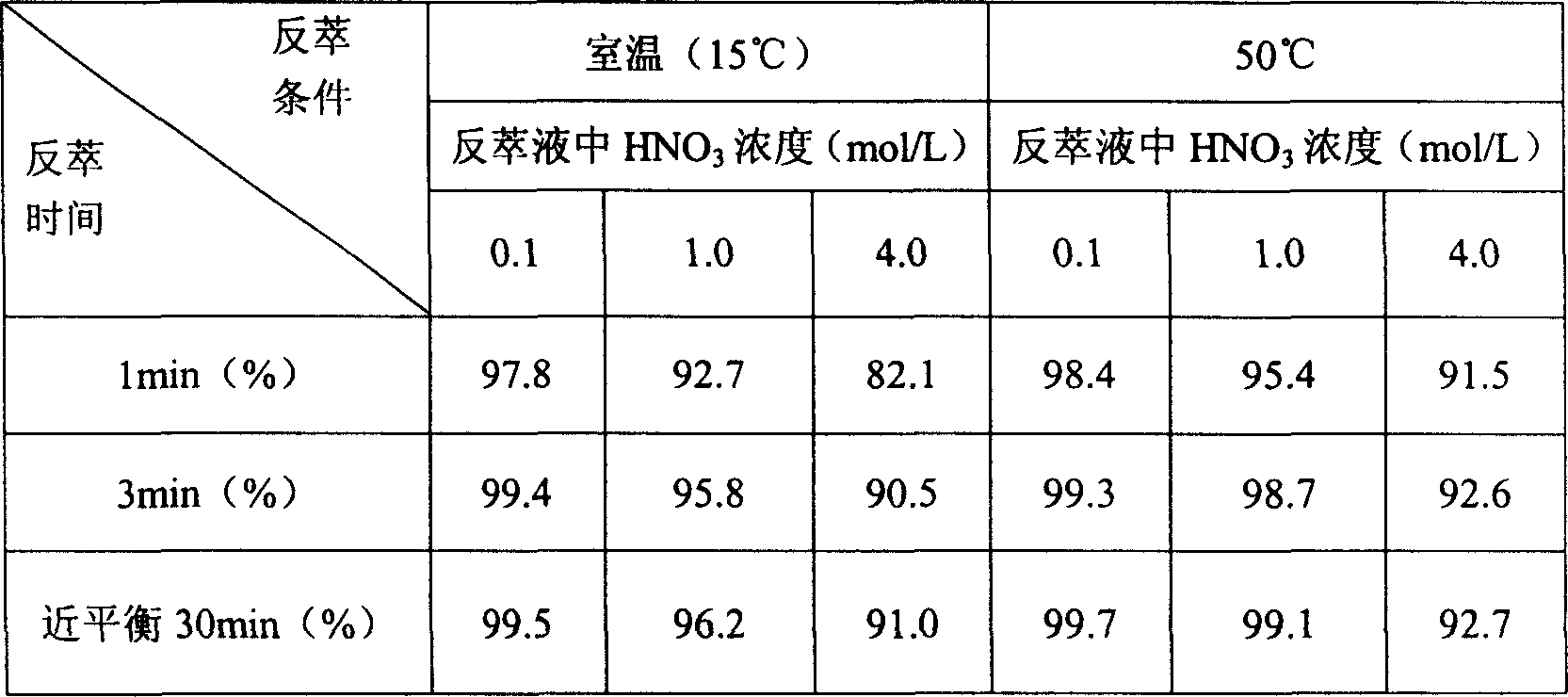

Plutonium purification and concentration method utilizing dioxime imide as reduction and reextraction agent

The invention belongs to the speciality of nuclear fuel reprocessing, and discloses a plutonium purification and concentration method utilizing dioxime imide as a reduction and reextraction agent. The method comprises the two steps of extraction and reextraction. In the step of extraction, Pu(IV) and U(VI) in a salpeter solution are extracted to enter an organic phase 30%TBP-kerosene solution, so that uranium and plutonium are separated from other components. In the step of reextraction, dioxime imide is utilized as the reduction and reextraction agent, the salpeter solution containing dioxime imide is utilized as a water phase to quickly reduce Pu(IV) in an organic phase into Pu(III) to enter the water phase, and therefore plutonium purification and concentration are achieved, wherein the volume ratio of the organic phase to the water phase is 10:1-1:1. The method has the beneficial effects that the single-stage two-phase contact time is short, the amount of generated radioactive liquid waste is small, and solvent radiolysis damage is small.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

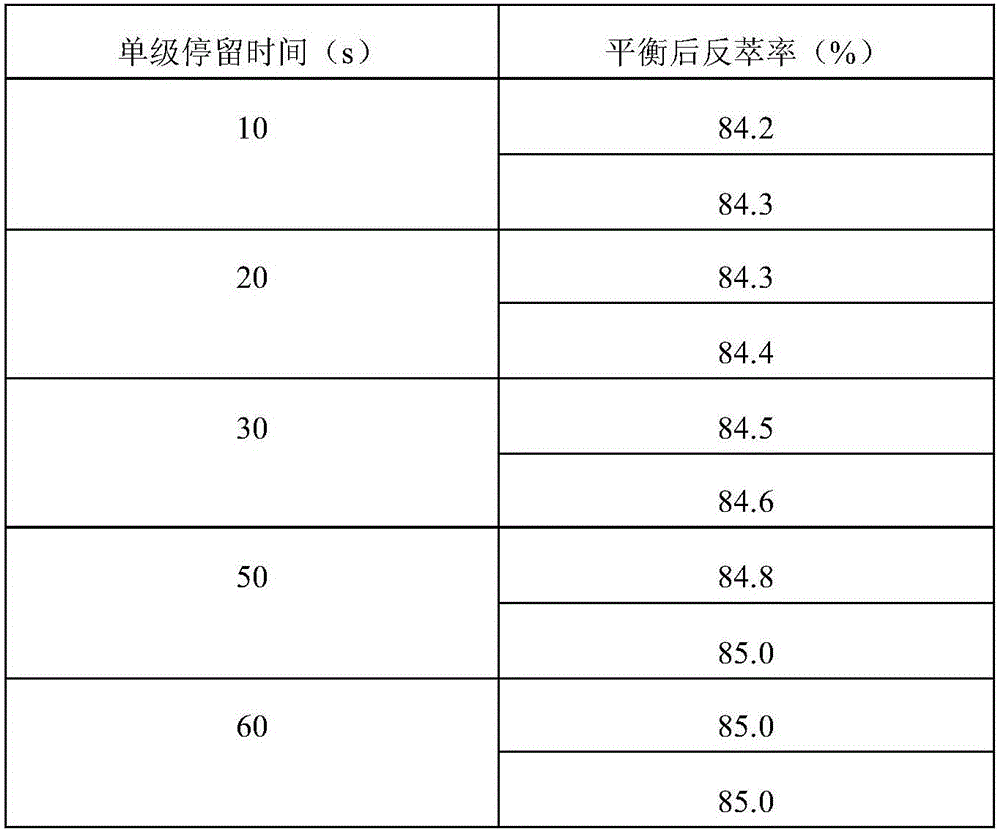

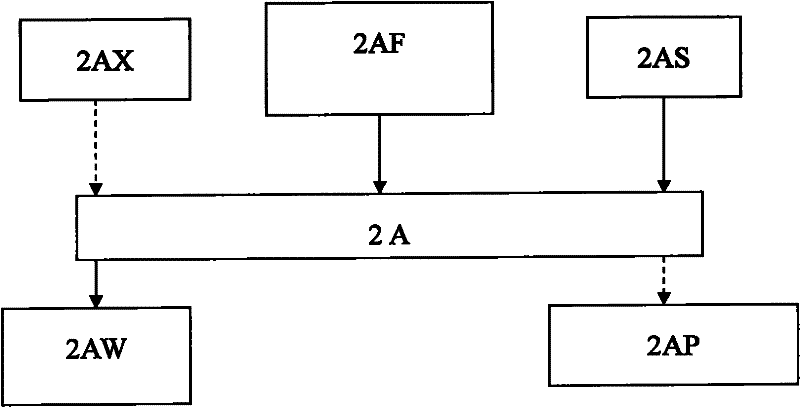

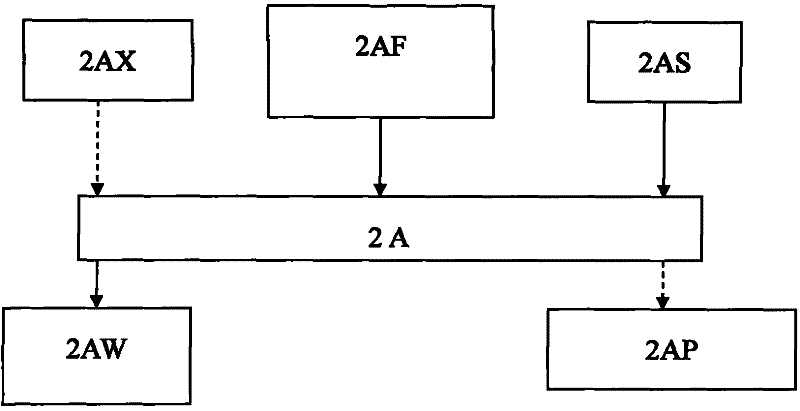

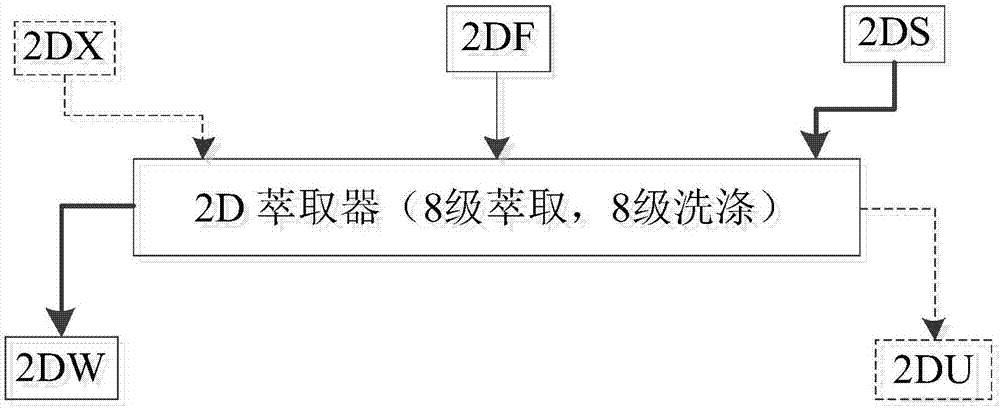

Method for improving 2A process plutonium concentration multiple in Purex flow

The invention belongs to the technical field of nuclear fuel reprocessing, and in particular relates to a method for improving 2A process plutonium concentration multiple in a Purex flow. By the method, the 2AF feed acidity is improved to be 3.8-5mol / L, and a flow ratio of 2AF to 2AX to 2AS is (7-8):1:(0.4-0.5). By the method, the plutonium concentration of the 2AP can be more than 10g / L.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Uranium purification method for simultaneously removing neptunium and plutonium in nuclear fuel Purex post-treatment process

ActiveCN107130121AReduce extractionGood removal effectNuclear energy generationRecycling and recovery technologiesPurification methodsEvaporation

The invention belongs to the technical field of nuclear fuel post-treatment, and relates to a uranium purification method for simultaneously removing neptunium and plutonium in the nuclear fuel Purex post-treatment process. The uranium purification method sequentially comprises the following steps that firstly, evaporation and concentration pretreatment is conducted, a uranium rough product from the Purex post-treatment procedure uranium plutonium codecontamination separating cycle is subjected to evaporation and concentration pretreatment, accordingly, Np(IV) in the uranium rough product is adjusted to Np (V) and Np (VI); secondly, a reducing agent is adopted for reducing, a concentrated solution obtained in the first step is cooled to the room temperature, then the reducing agent is added, then Pu (IV) and Pu (VI) in the concentrated solution are reduced into Pu (III), and Np (VI) is reduced into Np (V); and thirdly, organic solvent extraction is conducted, the acidity of the solution obtained in the second step is adjusted, extraction is conducted in an extractor with an organic solvent containing tributyl phosphate in a multi-level manner, wherein the organic solvent containing the tributyl phosphate is divided into multiple parts to be added at different extraction levels. By utilization of the uranium purification method, the Np and the Pu can be removed at the same time through one uranium purification cycle, and qualified uranium products are obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

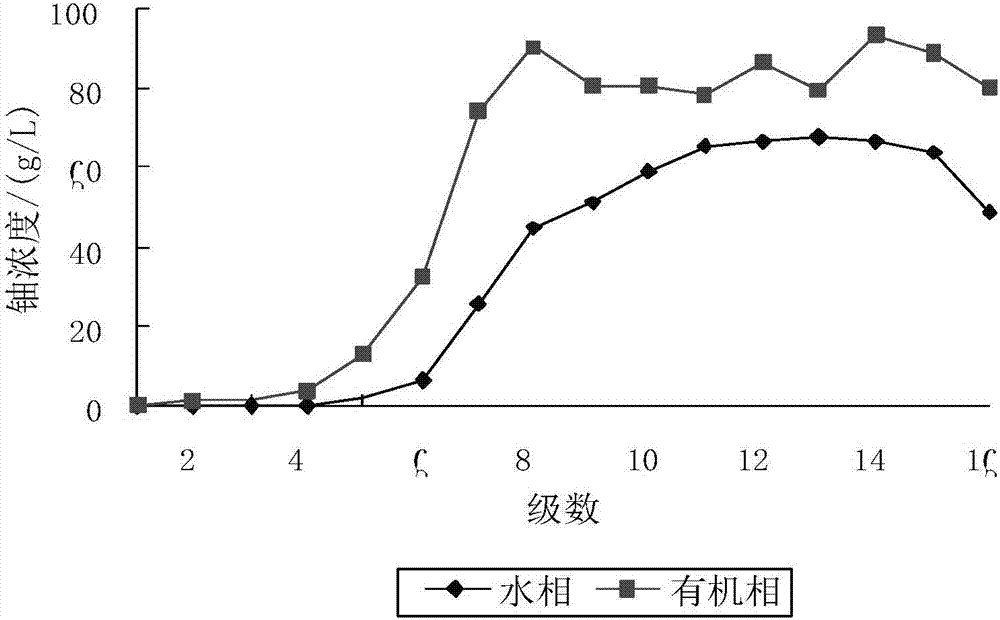

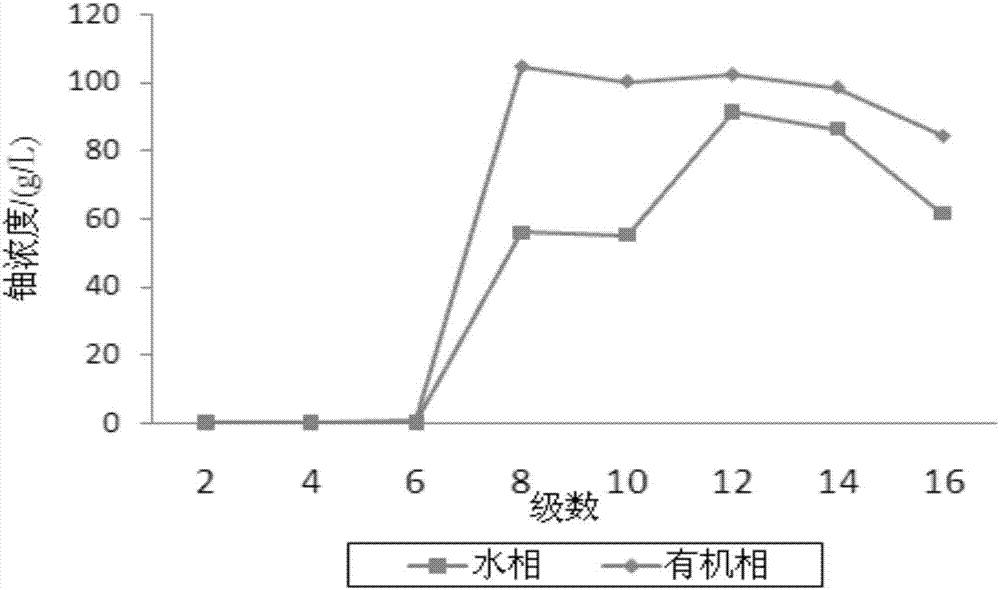

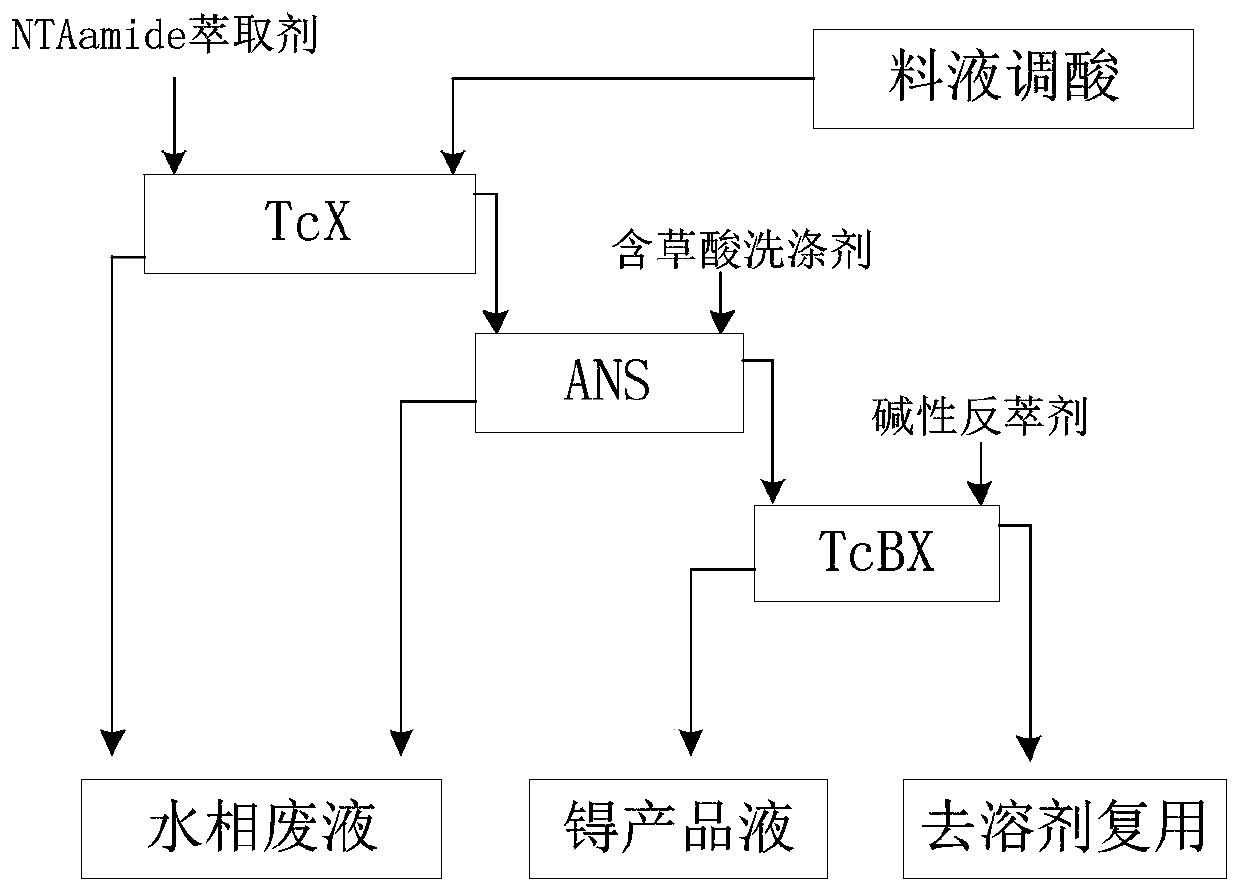

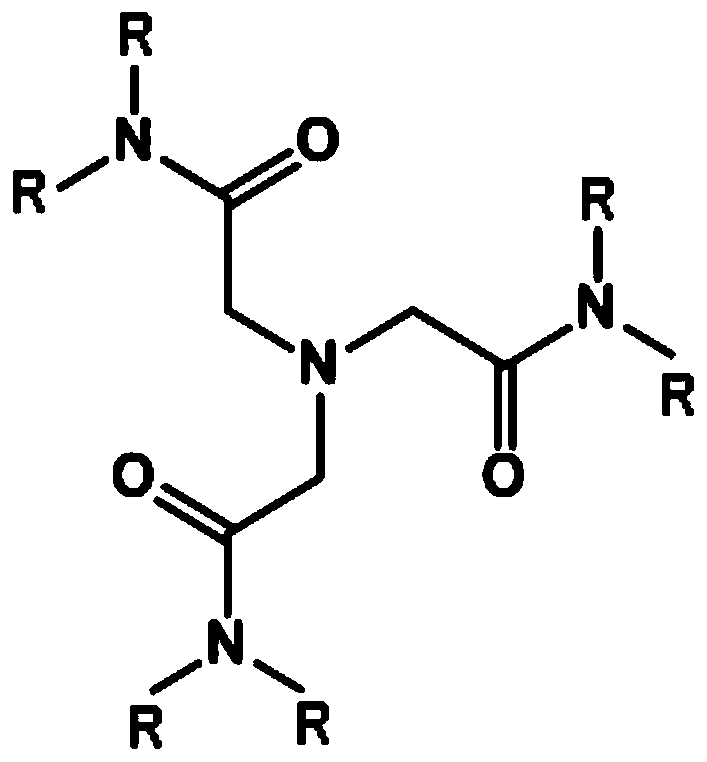

Method for extracting technetium from nuclear fuel post-treatment waste liquid

ActiveCN110144471AImplement extractionAchieve purificationProcess efficiency improvementLiquid wasteOxalate

The invention provides a method for extracting technetium from a nuclear fuel post-treatment waste liquid. The method comprises the following steps of (1), adjusting nitric acid concentration of nitric acid waste liquid containing high technetium acid radical to 2 mol / L; (2), extracting the high-technetium acid radical ions in the waste liquid, and separating to obtain an organic phase; (3), washing the organic phase obtained in the step (2) by adopting an oxalic acid-containing nitric acid solution; and (4), reversely extracting technetium in the organic phase by using an alkaline aqueous solution to obtain a technetium product solution. According to the method, extraction and purification of technetium in the nuclear fuel post-treatment nitric acid waste liquid are effectively realized;the method for extracting technetium is simple to operate, and can be applied to a traditional PUREX flow post-treatment plant, the concentration and the concentration of nitric acid of technetium inthe treated object can be higher, the composition of the waste liquid can be relatively complicated, and the generation amount of a radioactive waste in the treatment process is smaller.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY +1

Modified mesoporous silica adsorbent and preparation method and application thereof

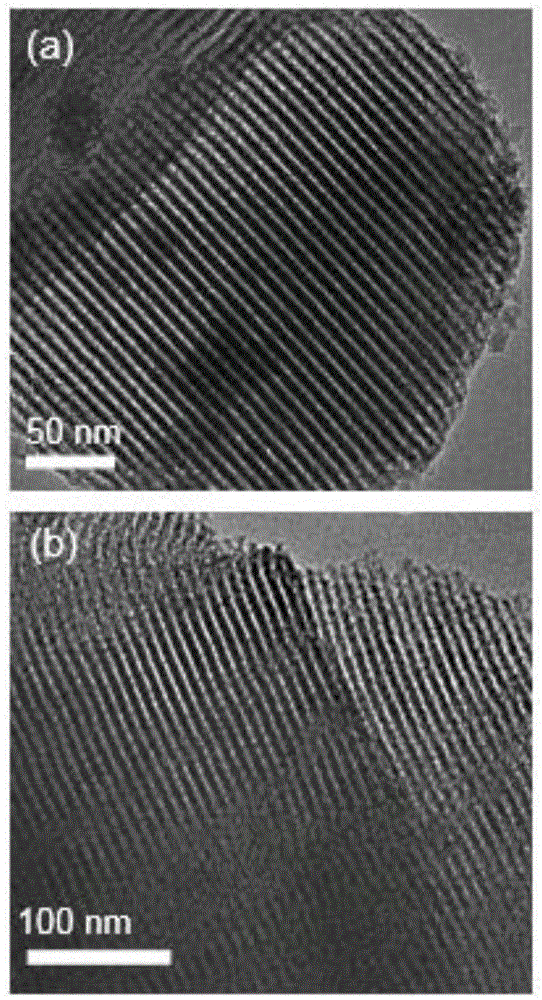

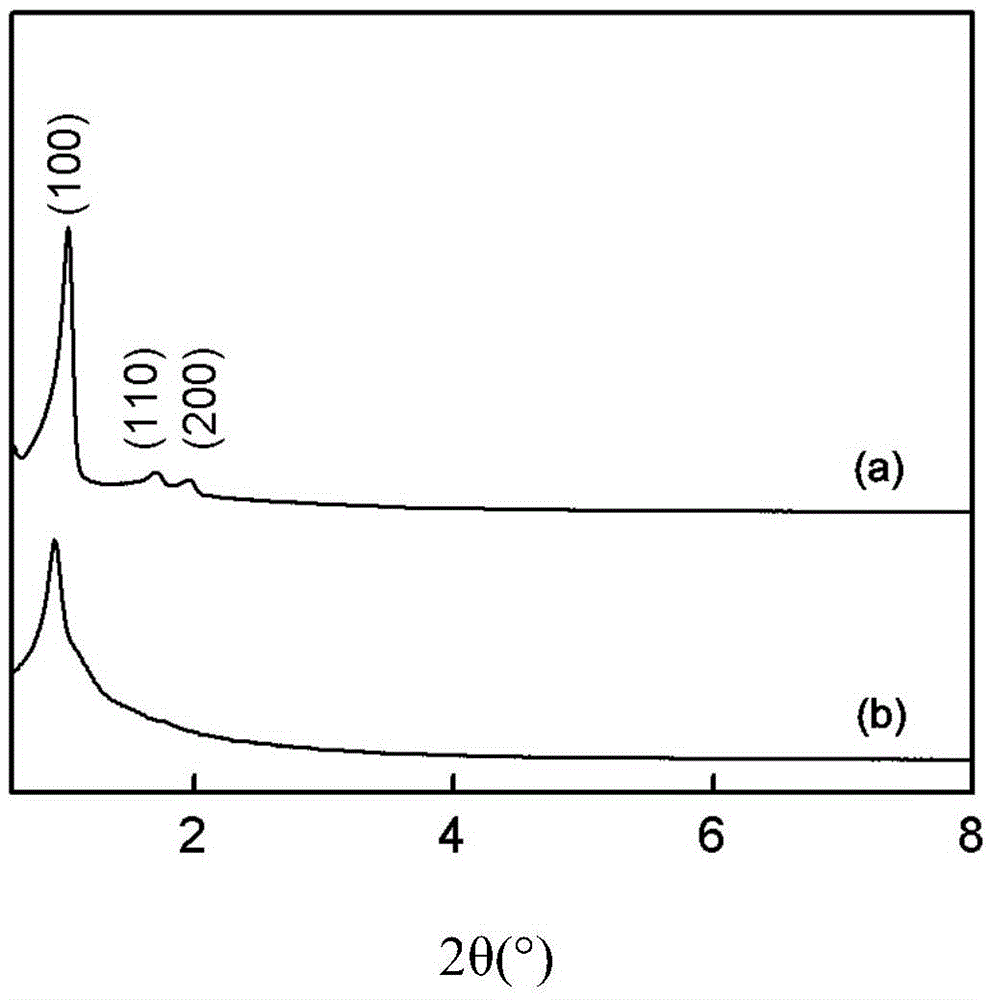

ActiveCN105617979ALarge specific surface areaImprove hydrophilicityOther chemical processesProcess efficiency improvementSorbentMesoporous silica

The invention relates to a modified mesoporous silica adsorbent and a preparation method and application thereof. Under the catalysis of potassium carbonate and potassium iodide, aza-macrocyclic ligand is modified onto the surface of chlorine group functional mesoporous silica through nucleophilic substitution, and the adsorbent is prepared; palladium recycling and enrichment under different nitric acid concentrations are achieved through the adsorbent, and the selective recovery performance of palladium in highly-active effluent simulated feed liquid is evaluated. According to the modified mesoporous silica adsorbent, mesoporous nanomaterials are combined with the supermolecule recognition performance of the aza-macrocyclic ligand, the problems that selectivity is poor, operation is complex, the raw material cost is high and the stability is poor in the traditional treatment technology for palladium in highly-active effluent are solved, and the adsorbent has the advantages of being good in selectivity, large in adsorption capacity, high in adsorption speed and easy to recycle for palladium within the wide nitric acid concentration range, and has the great practical significance in the aspects of nuclear fuel reprocessing and hydrometallurgy.

Owner:TSINGHUA UNIV

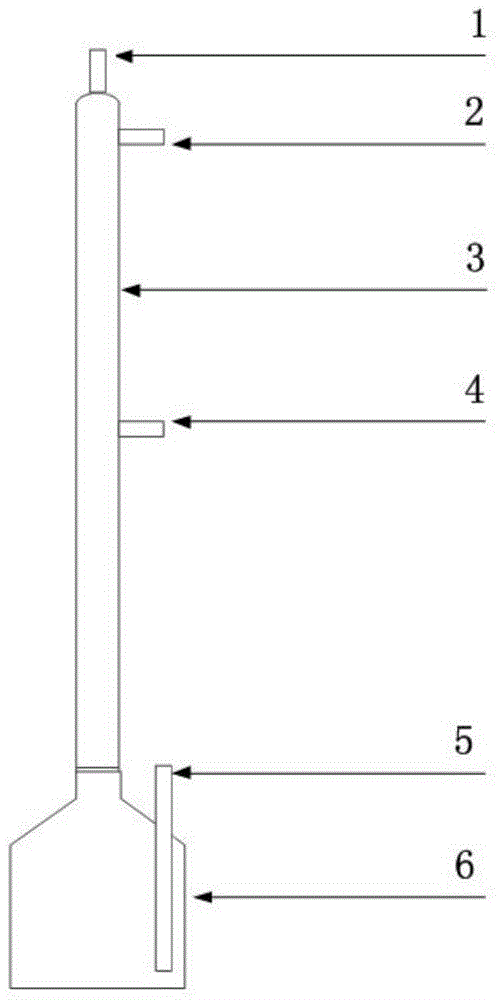

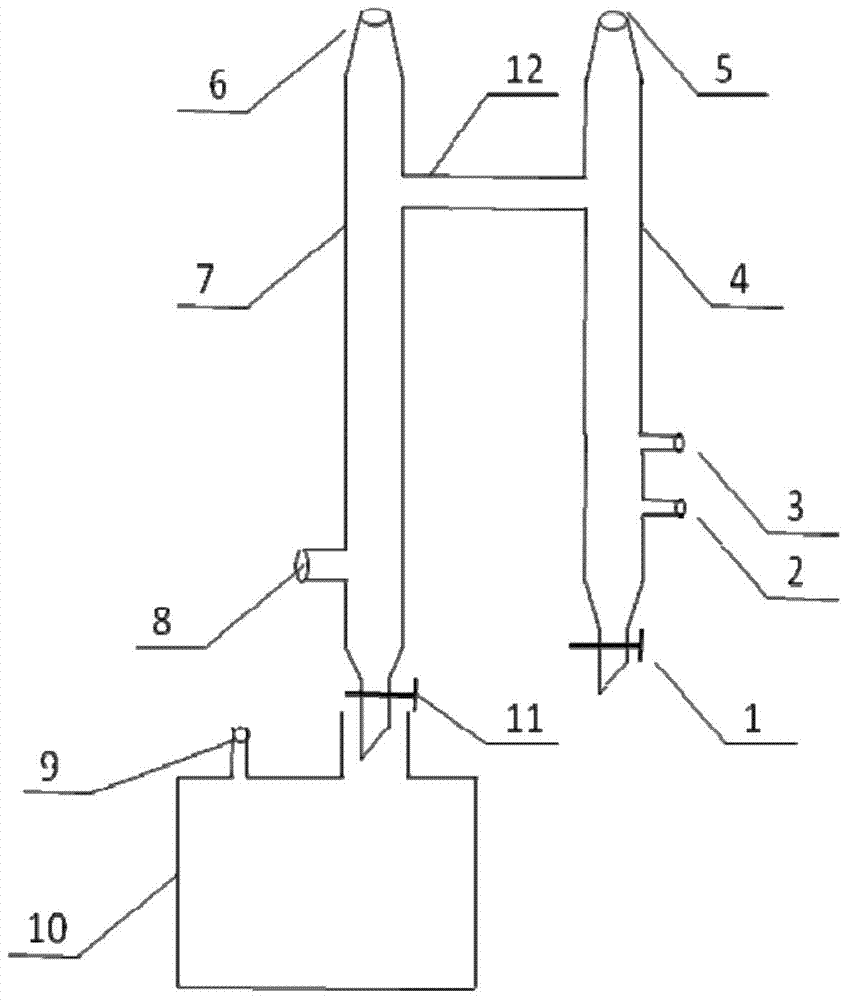

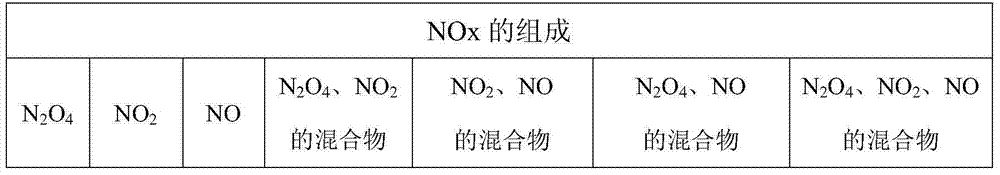

Oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV)

ActiveCN104328291AIncrease profitReduced disposal burdenRadioactive decontaminationRadiation resistantNitric oxide

The invention belongs to the technical field of nuclear fuel reprocessing and discloses an oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV). The equipment mainly comprises an oxidizing tower, a feed liquid receiving tank and a NOX storage tank, wherein a feed liquid outlet is formed at the upper end of the oxidizing tower, a Pu (III) feed liquid inlet and a NOX feed inlet are formed at the lower end, and the feed liquid outlets at the upper parts of the feed liquid receiving tank and the oxidizing tower are connected by virtue of a pipeline; the main body of the oxidizing tower and packing in the tower are both radiation-resistant and nitric acid corrosion-resistant materials; a heating device is arranged on the outer tower wall of the oxidizing tower; the Pu (III) feed liquid enters the oxidizing tower from the Pu (III) feed liquid inlet at the lower part of the oxidizing tower; NOX gas provided by the NOX storage tank enters into the oxidizing tower from the NOX feed inlet at the lower part of the oxidizing tower separately or together with carrier gas; the valence-adjusted feed liquid enters the feed liquid receiving tank from the feed liquid outlet at the upper part of the oxidizing tower. The equipment is large in processing scale, high in NOx utilization ratio, safe and stable in valence-adjusting process and low in processing burden of nitric oxide tail gas.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

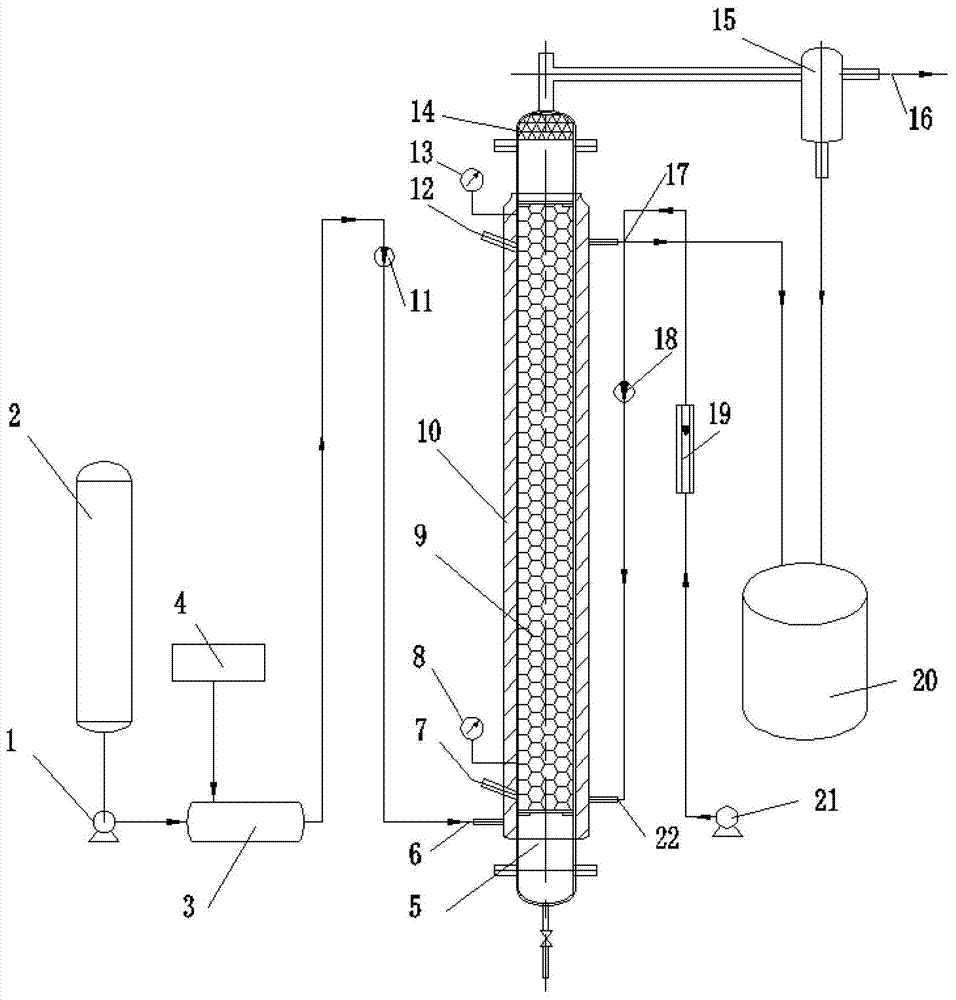

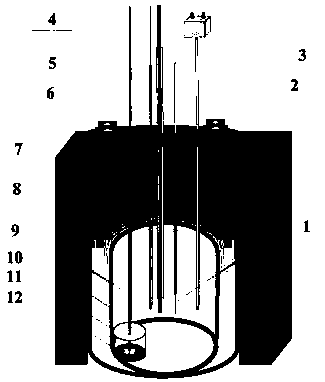

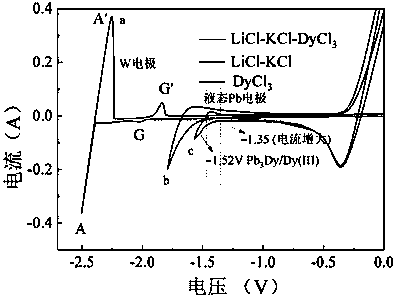

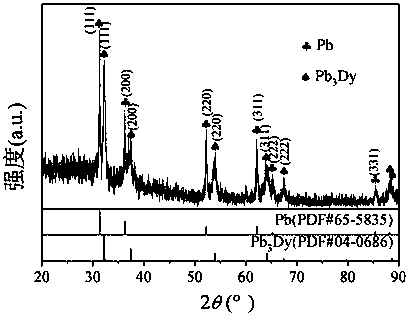

Method for electrolytically extracting rare earth through liquid cathode molten salt and preparing lead rare earth alloy

ActiveCN110195243AHigh extraction rateSolve the problem of reciprocating cycle idle currentElectrodesLithium chlorideElectrolysis

The invention discloses a method for electrolytically extracting rare earth through liquid cathode molten salt and preparing lead rare earth alloy, and belongs to the technical field of nuclear fuel reprocessing. According to the technical scheme, lithium chloride, potassium chloride, and rare earth chloride are put into an alumina crucible, a mixture is subjected to temperature rise and is meltedto molten salt, a small crucible containing a lead ingot is put into the alumina crucible, and heat preservation is carried out; a cathode, a reference electrode and an auxiliary electrode are inserted into the molten salt to be connected with an electrochemical workstation; electrochemical workstation cyclic voltamogram and timing potential are used for measuring rare-earth reduction peak potential and alloy forming current; according to the reduction peak potential of the rare earth on the liquid-state lead electrode and the forming current of the lead rare earth alloy, constant potential electrolysis and constant current electrolysis are carried out for extracting the rare earth; the small crucible is cooled under the argon protection, an electrolysate is taken out, ethyl alcohol and deionized water are used for flushing, low-temperature drying is carried out, and the lead rare earth alloy is obtained. Compared with a method for extruding the rare earth through a solid electrode and obtaining the lead rare earth alloy, the method is short in flow process, and high in extraction rate, and the rare earth extraction rate is up to 97.2%.

Owner:EAST CHINA UNIV OF TECH

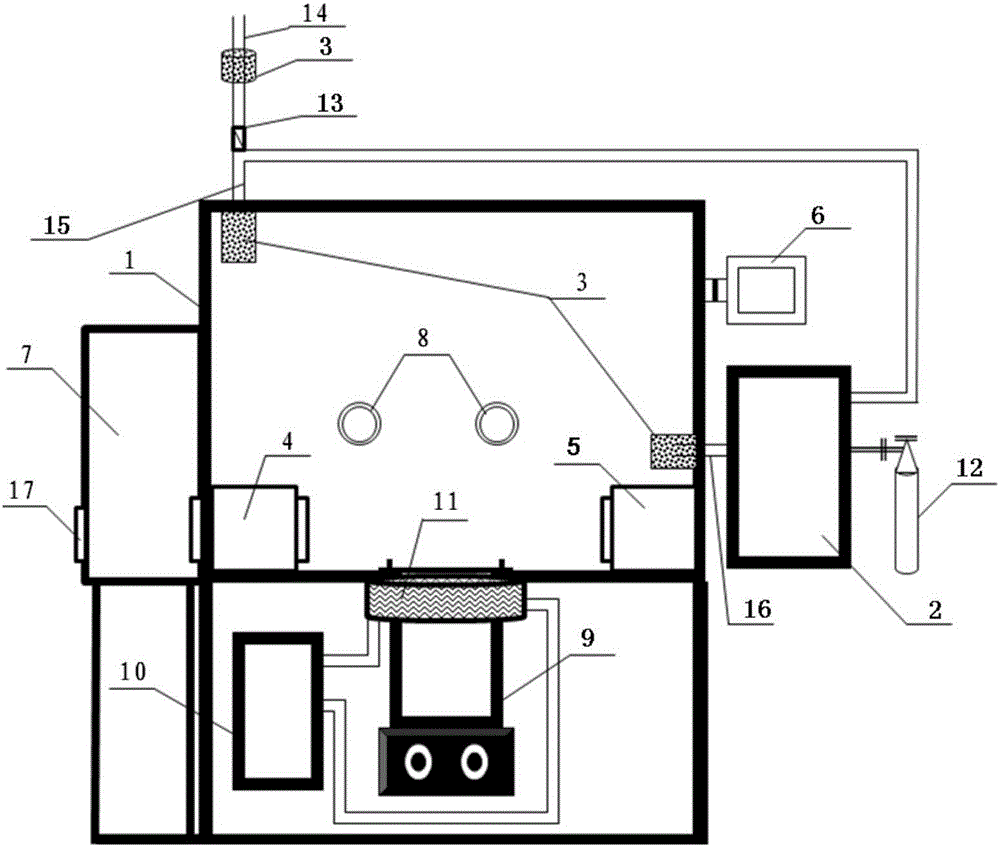

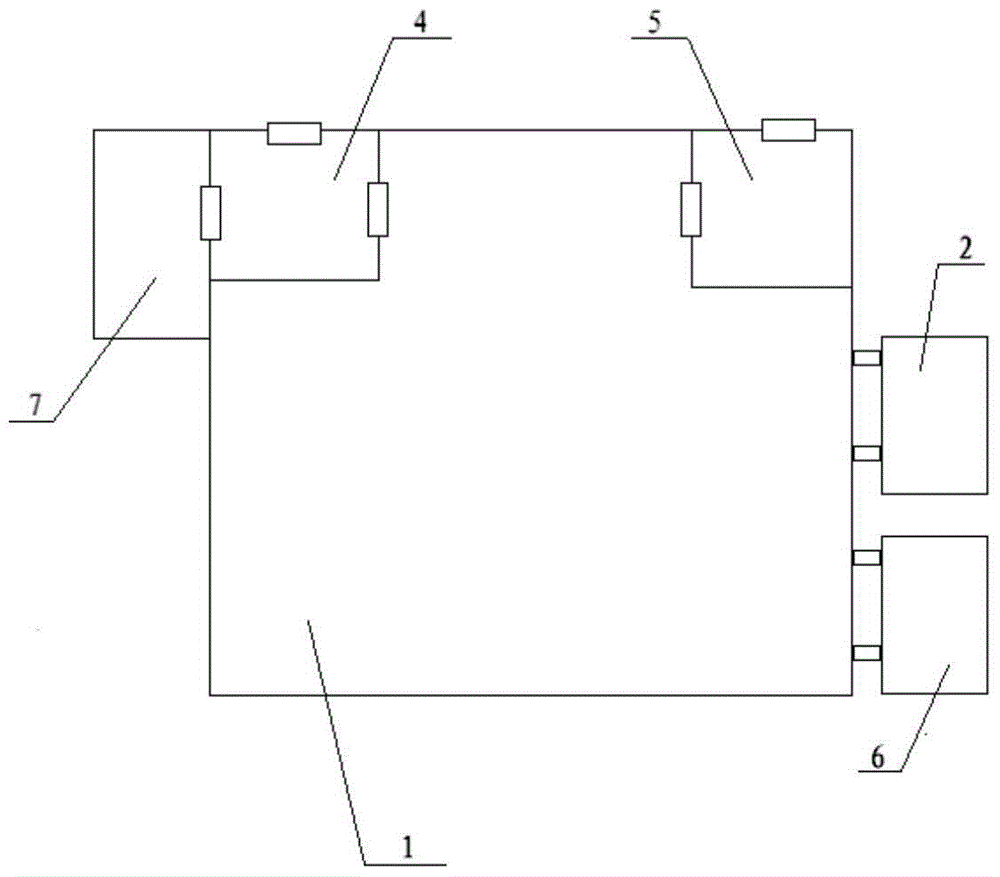

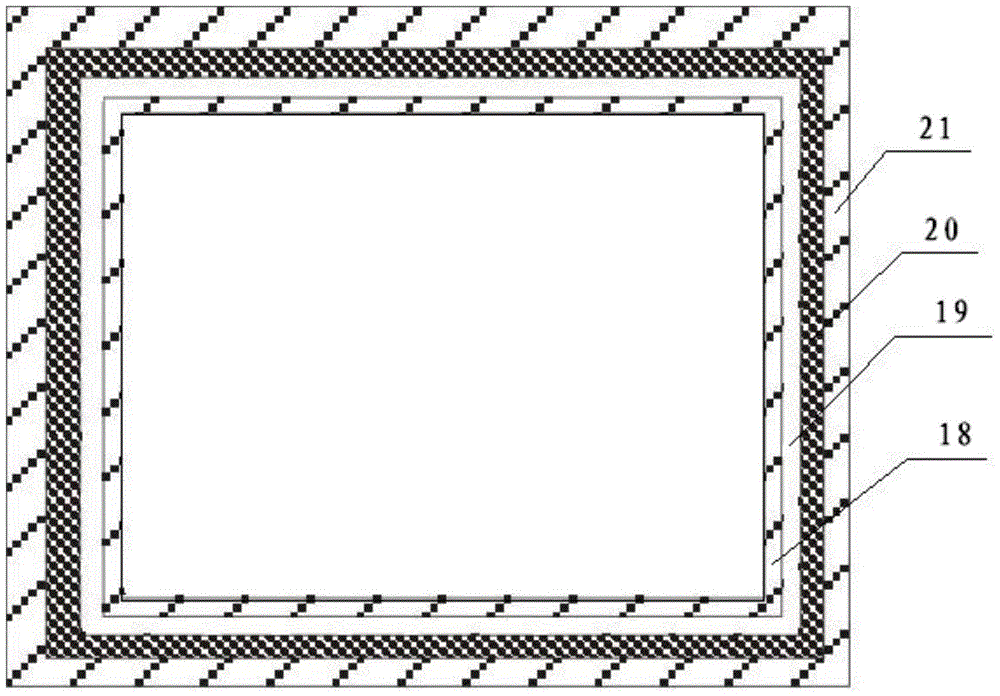

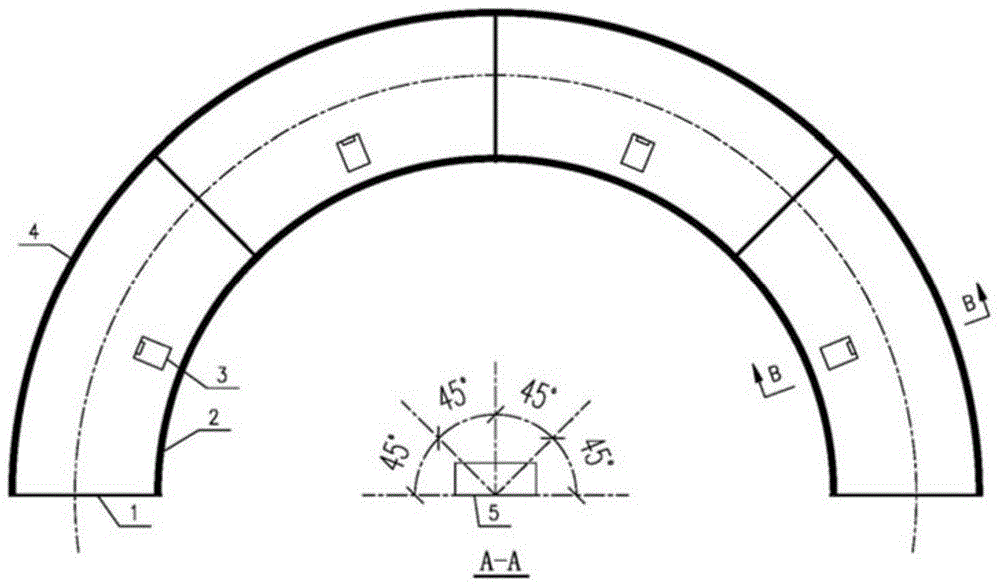

Sandwich-type inert gas shielding hot chamber

ActiveCN105719712AMeet high temperature meltingFulfil requirementsNuclear energy generationReactor fuel elementsControl systemGamma ray

The invention belongs to the technical field of nuclear fuel reprocessing and nuclear chemical engineering, and discloses a sandwich-type inert gas shielding hot chamber.The hot chamber mainly comprises a hot chamber body, a gas circulating and purifying device, an aerosol filtering device, an automatic pressure control system and a material feeding and discharging device, wherein the gas circulating and purifying device and an automatic pressure control system operation panel are located outside the hot chamber body.The hot chamber body mainly comprises an inert gas sealing shell, an anti-seismic sealing shell and a neutron and / or gamma ray shielding shell, wherein a gap is formed between the inert gas sealing shell and the anti-seismic sealing shell, the inert gas sealing shell is filled with high-purity inert gas, and an inert gas inner circulation inlet and an inert gas inner circulation outlet are formed in the diagonal corners of the inert gas sealing shell.The gas circulating and purifying device comprises a fan and a purifying column.The hot chamber has the advantages that insert gas can be controlled, radioactive aerosol can be efficiently filtered, and the requirements for low water and low oxygen can be met.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Synthesis method for water-soluble bisamide oxide

InactiveCN1687015AHigh yieldEasy to purifyOrganic compound preparationCarboxylic acid amides preparationFiltrationAminolysis

The method for synthesizing water-soluble oxabisamide uses diethylene glycol as raw material, makes said raw material undergo the processes of oxidation and chloridization to obtain diethylene aryl chloride, then makes it react with dialkylamine to obtain bisamide, in the presence of pyridine uses 1,4-dioxane as solvent, and makes diethylene acyl chloride respectively react with dimethylamine or diethylamine or dipropylamine under the condition of low temperature, and makes the obtained product undergo the processes of filtration and aminolysis to make the product separated and purify so as to obtain oxabisamide compound.

Owner:TSINGHUA UNIV

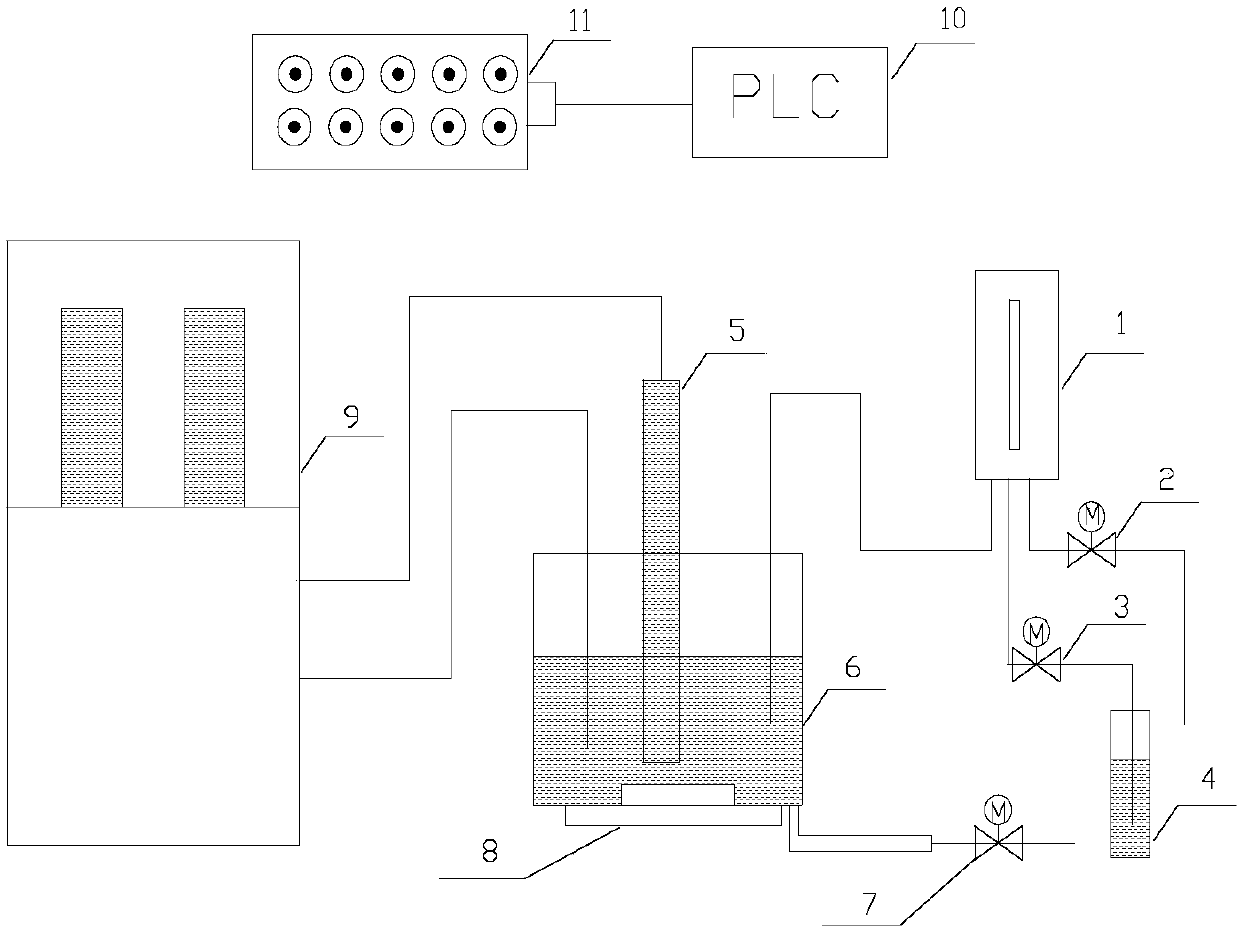

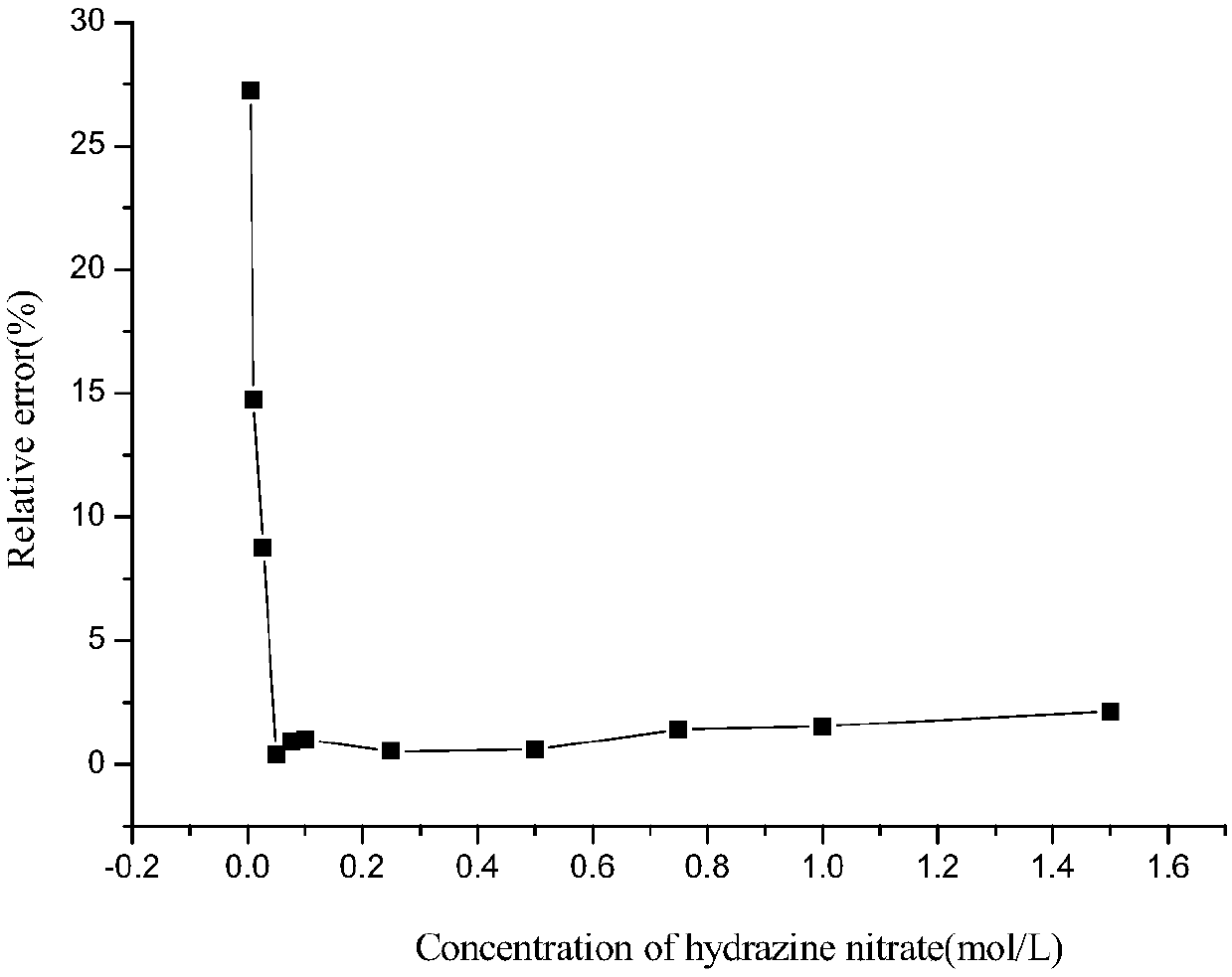

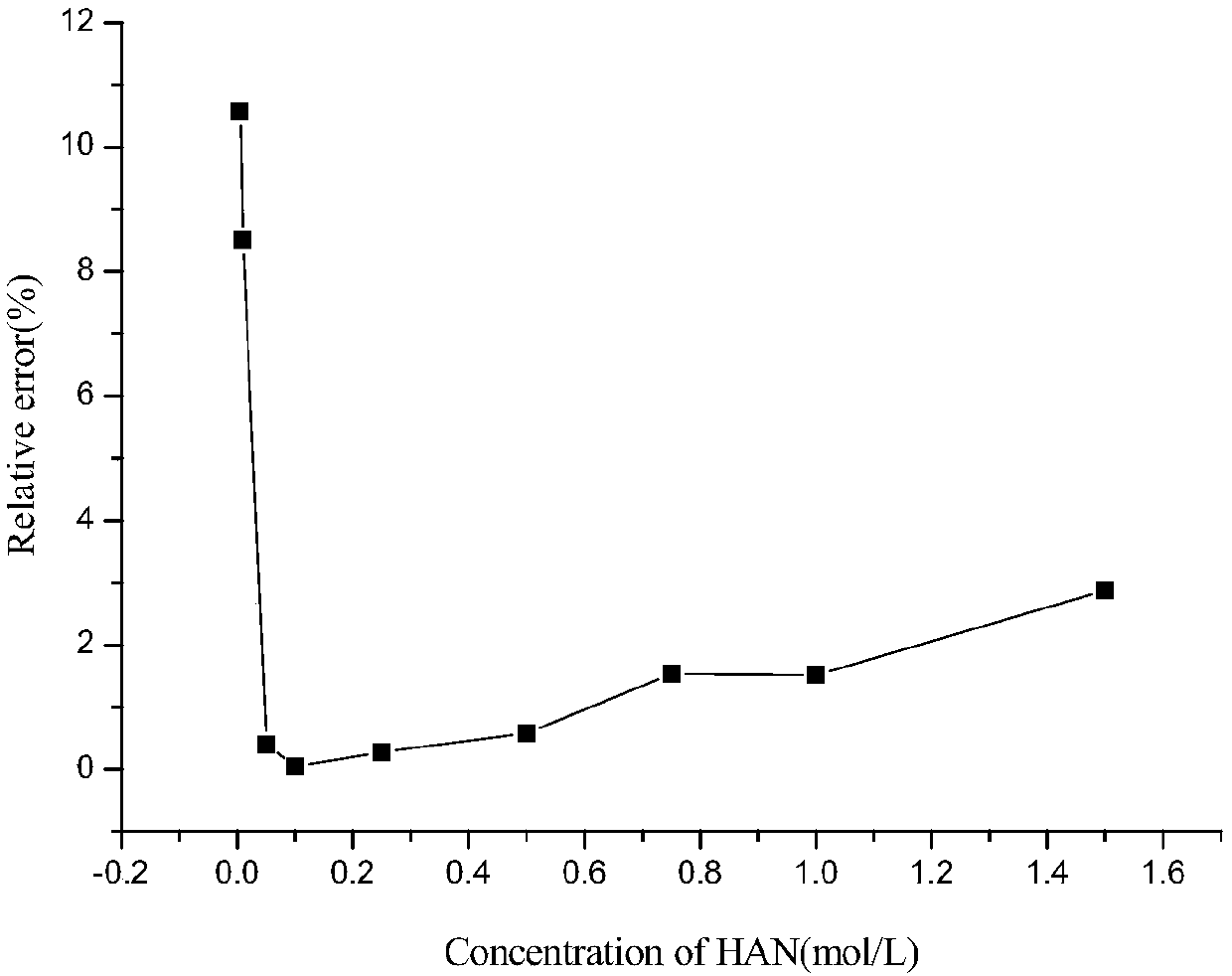

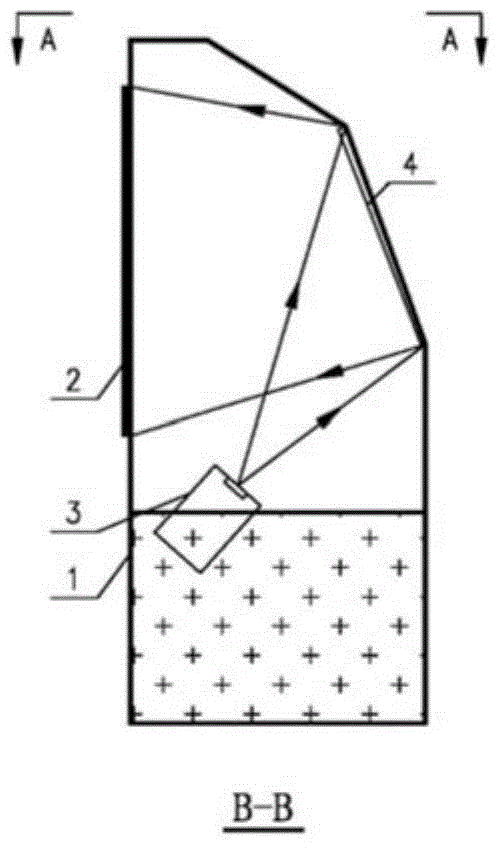

Online monitoring system for detecting hydrazine nitrate and hydroxylamine nitrate simultaneously

ActiveCN109856221ASimplify the analysis processHigh measurement accuracyMaterial analysis by electric/magnetic meansHydroxylamineMonitoring system

The invention relates to an online monitoring system for detecting hydrazine nitrate and hydroxylamine nitrate simultaneously, and belongs to the technical field of nuclear fuel post-treatment. The online monitoring system comprises a solution extraction system, a potential titration system and a system control center, and uses a standard sodium hydroxide solution to determine the hydrazine nitrate and hydroxylamine nitrate simultaneously, and when a detection result is beyond the detection range of (0.05-0.5)mol / L, the system samples the liquid to be tested in a multiplication or dilution way. Thus, the relative measurement error for concentration determination of hydrazine nitrate and hydroxylamine nitrate is lower than 1%, operation is simple, and the average consumption time of a sample is 60-100s. Compared with a present determination method, the system is characterized by high precision, short time, and simultaneous detection for the contents of hydrazine nitrate and hydroxylamine nitrate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

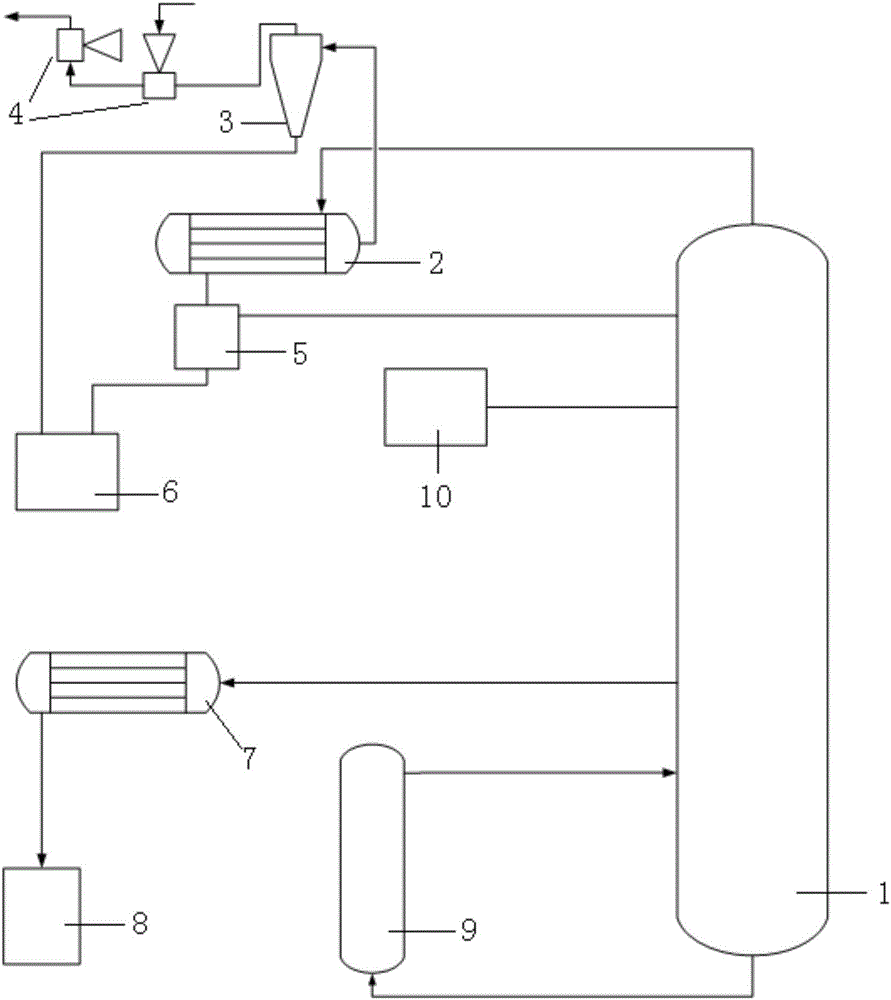

BP price-adjusting, degassing and acid-adjusting integrated device and method in Purex process

InactiveCN104789782AReduce consumptionEasy to handleNuclear energy generationRecycling and recovery technologiesProcess engineeringEngineering

The invention relates to a nuclear fuel reprocessing method in order to solve the problems that more devices are adopted, actual operation is complex, excessive nitric oxide is consumed, the economy is low and the like when a U / Pu separation section of the Purex process adopts nitric oxide for price adjustment, and provides a BP price-adjusting, degassing and acid-adjusting integrated device and method in a Purex process. The device comprises a filler column and a feed liquid receiving tank, wherein a BP feed liquid inlet and an NO2 feed port are formed in the filler column, a tail gas outlet is formed in the top, and a feed pipe extending to the feed liquid receiving tank is arranged on the feed liquid receiving tank. The method comprises steps of Pu price adjustment, nitrous acid removal and acid adjustment. According to the BP price-adjusting, degassing and acid-adjusting integrated device in the Purex process, nitric oxide price adjustment equipment is successfully simplified, the overall design of the adopted technological process is remarkably optimized, the nitric oxide consumption and the tail gas treatment quantity are remarkably reduced, the economy is remarkably improved, and a large quantity of costs is saved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

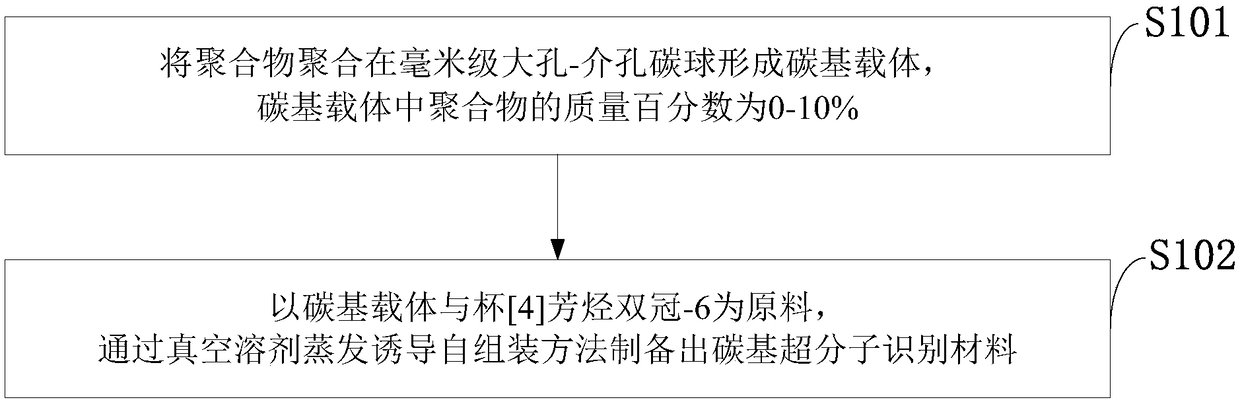

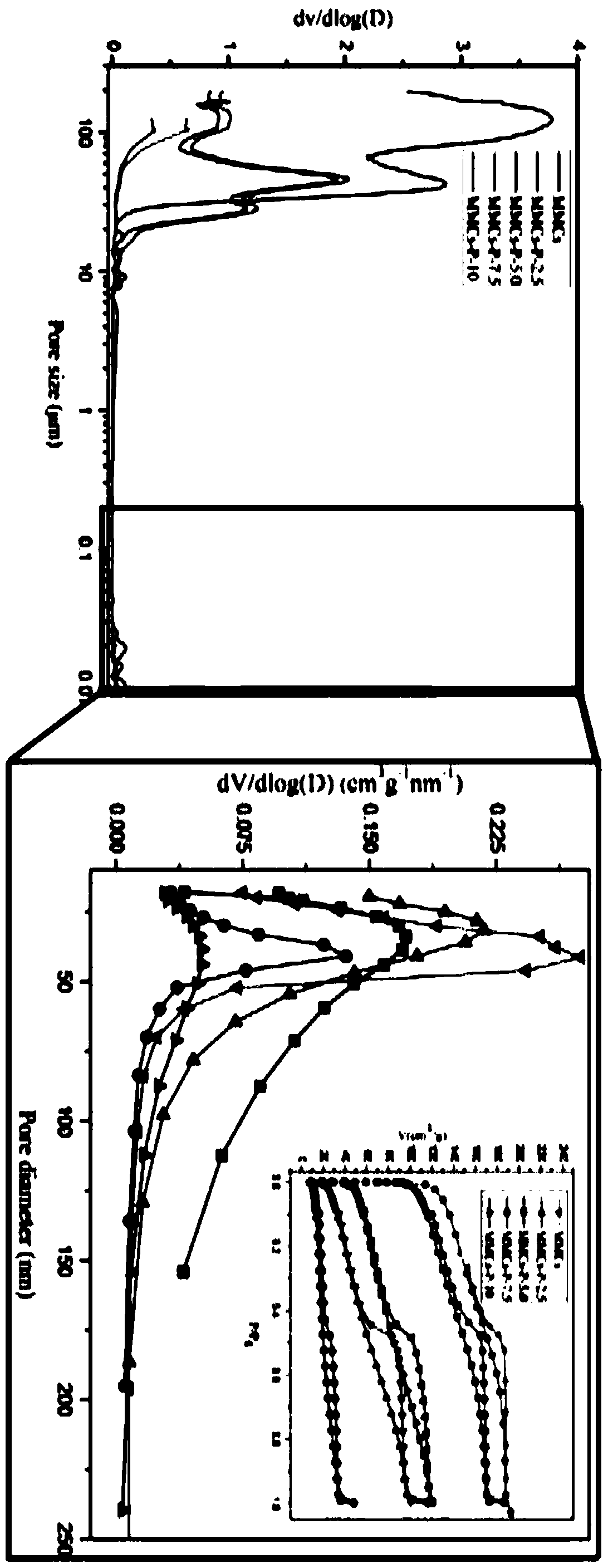

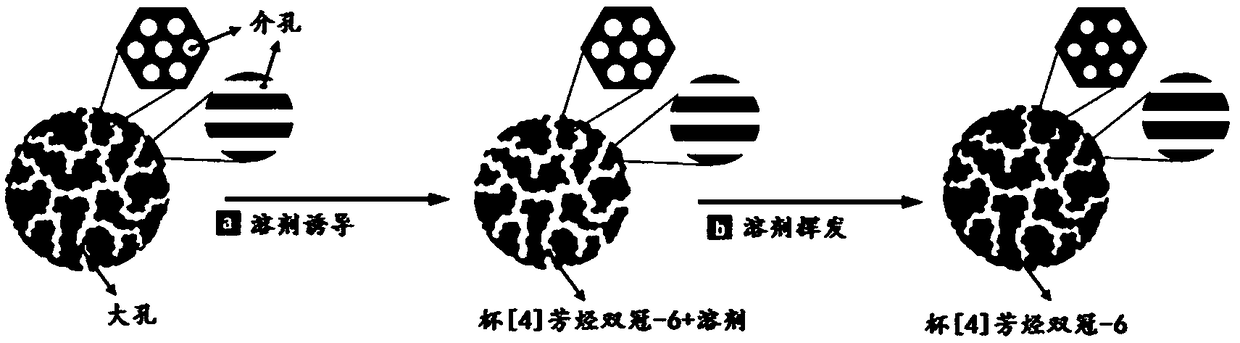

Carbon-based supramolecular recognition material and preparation method thereof and application of carbon-based supramolecular recognition material in adsorption and separation of Cs

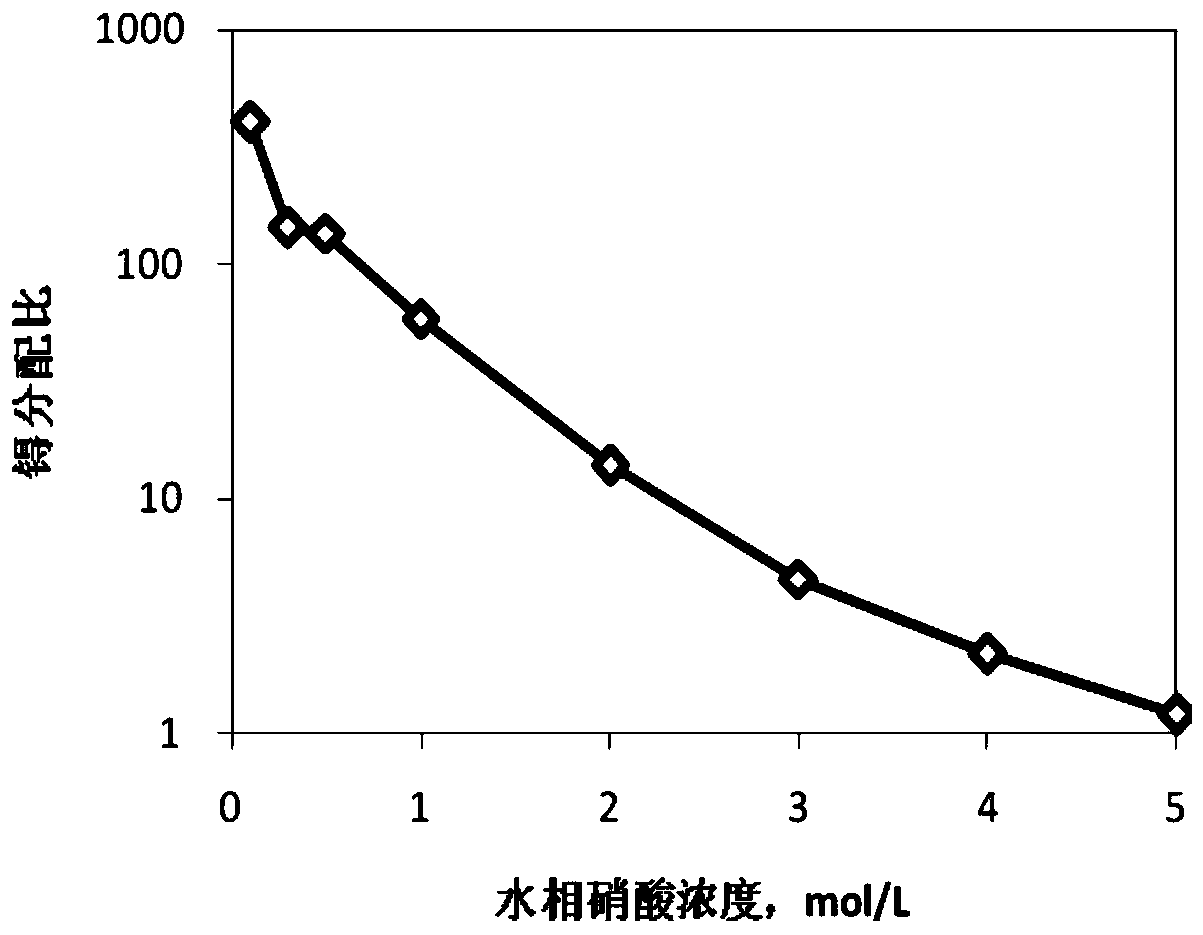

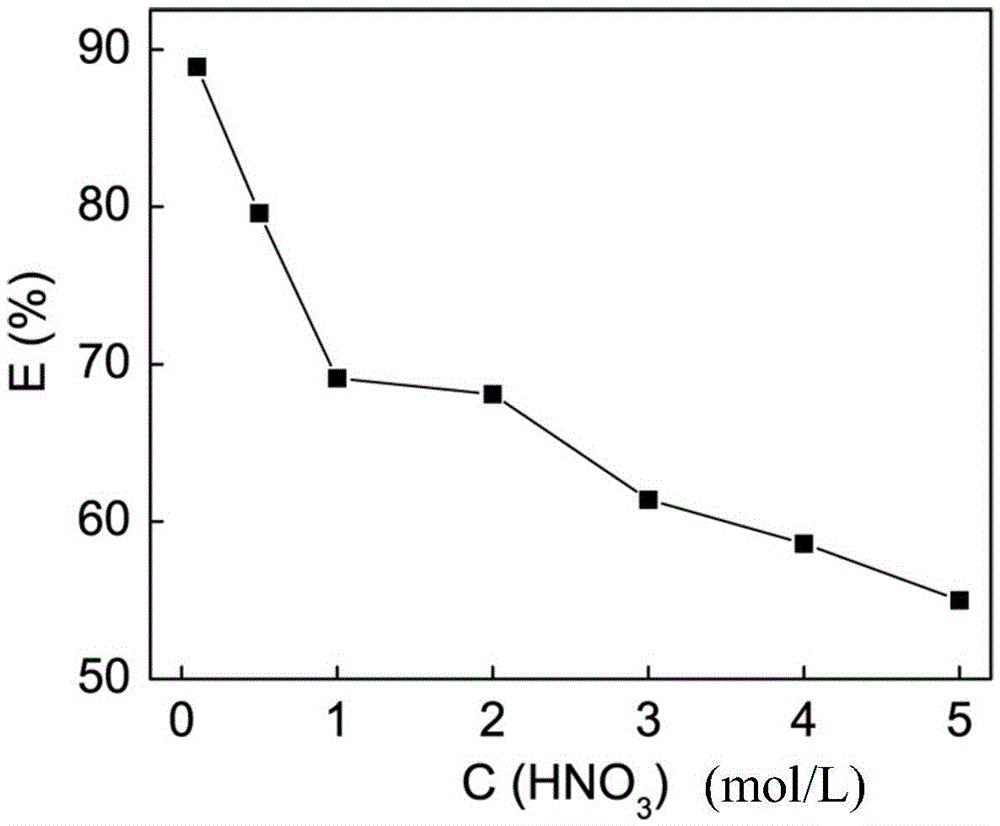

PendingCN108620042AThe synthesis method is simpleHigh partition coefficientOther chemical processesAlkali metal oxides/hydroxidesStrong acidsStructural formula

The invention belongs to the technical field of nuclear fuel post-treatment and discloses a carbon-based supramolecular recognition material and a preparation method thereof and application of the carbon-based supramolecular recognition material in adsorption and separation of Cs. A polymer is polymerized to millimeter-level macroporous-mesoporous carbon spheres to form a carbon-based carrier; thepolymer in a carbon-based carrier has mass percentage of 0-10%; the carbon-based carrier and calix[4]-arene-biscrown-6 are used as raw materials subjected to vacuum solvent evaporation induced self-assembly to prepare the carbon-based supramolecular recognition material; the mass of the carbon-based carrier in the carbon-based supramolecular recognition material is 0.5-40 times that of calix[4]-arene-biscrown-6; the calix[4]-arene-biscrown-6 has a structural formula shown as in (1). The carbon-based supramolecular recognition material disclosed herein has the structure well retained in a strong acid solution, has excellent adsorption selectivity for cesium ions, and is applicable to high-selectivity adsorption separation of cesium from strong-acidity high-emission waste liquid.

Owner:EAST CHINA UNIV OF TECH

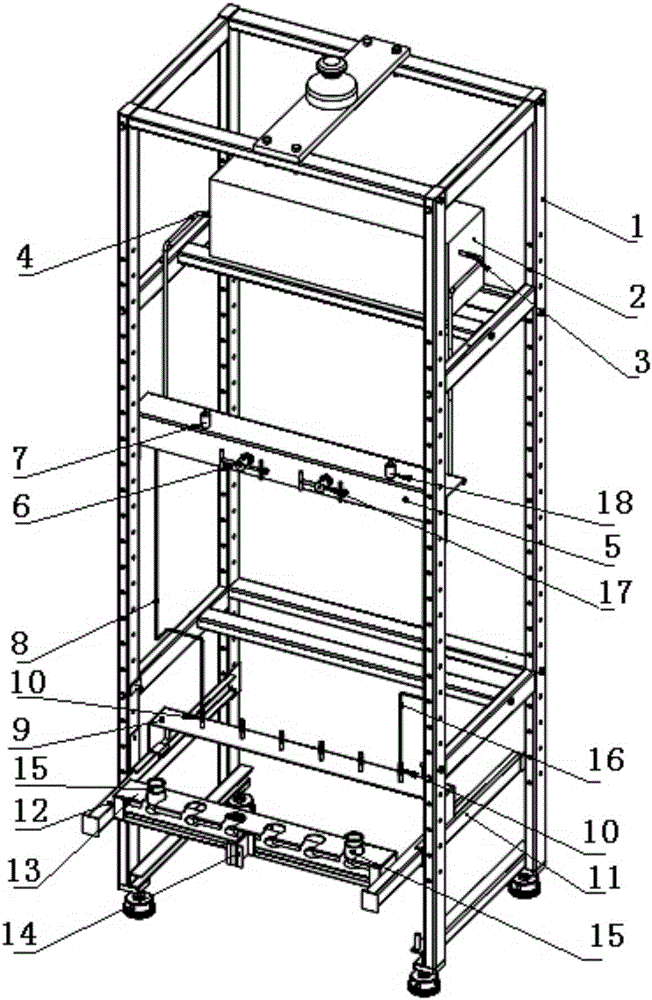

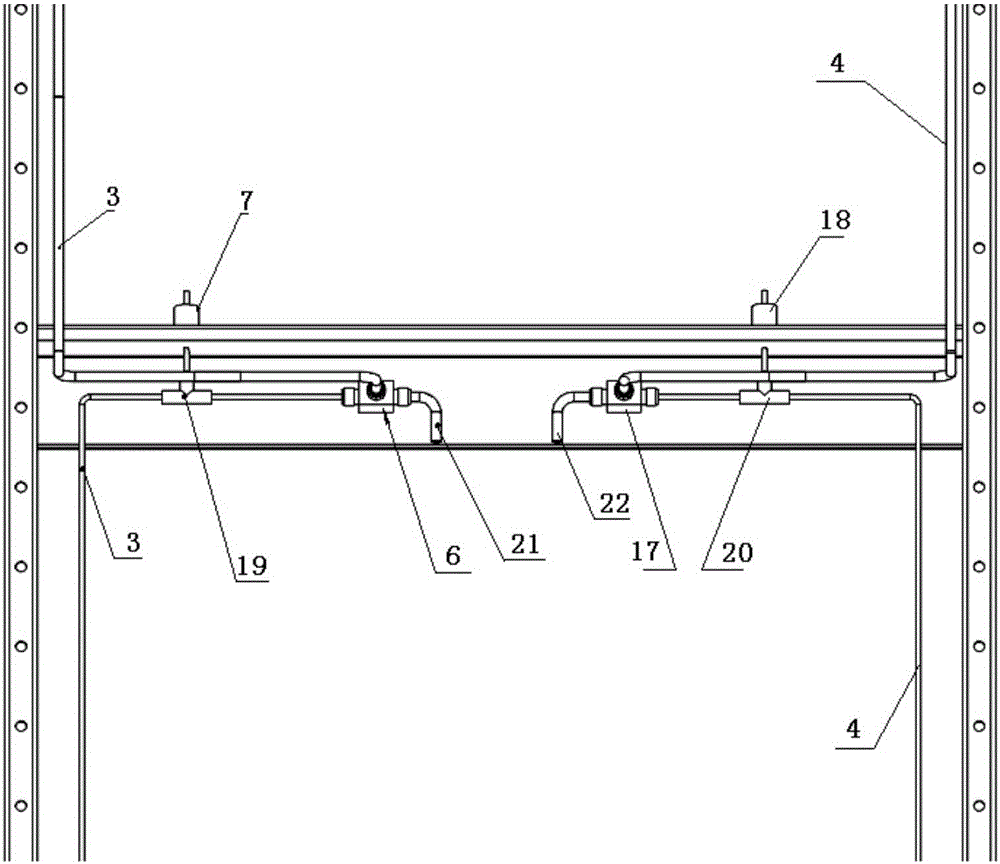

Instantaneous sampling apparatus for radioactive bench test

InactiveCN105910853ASave spaceDoes not affect hoistingWithdrawing sample devicesAfter treatmentLiquid state

The invention belongs to the technical field of liquid-phase sampling in a hot cell extraction process in the field of nuclear fuel after-treatment and discloses an instantaneous sampling apparatus for a radioactive bench test. The apparatus is arranged on the bottom of a radioactive bench and includes a sampling pipeline, a first three-way valve, a second three-way valve, an exhaust pipe, a sampling bottle bracket, a fixing sleeve tube, a fixing sleeve tube supporter and a sampling bottle bracket handle. The sampling bottle bracket has a drawable structure and is provided with a sampling bottle trough and the sampling bottle bracket handle. The fixing sleeve tube supporter is arranged above the sampling bottle bracket. The fixing sleeve tube is welded to the fixing sleeve tube supporter. The fixing sleeve tube is arranged on a corresponding position above the sampling bottle trough and can be matched with and connected to the sampling pipeline. The sampling pipeline includes an organic phase sampling tube and a water phase sampling tube. The sampling apparatus has simple structure and is easy to operate, saves space on the bench, enables the bench to be hoisted conveniently, and can effectively avoids retention and overflow of a sample liquid.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

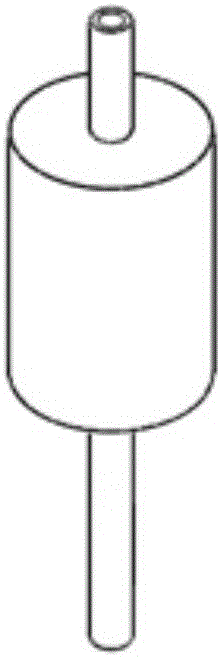

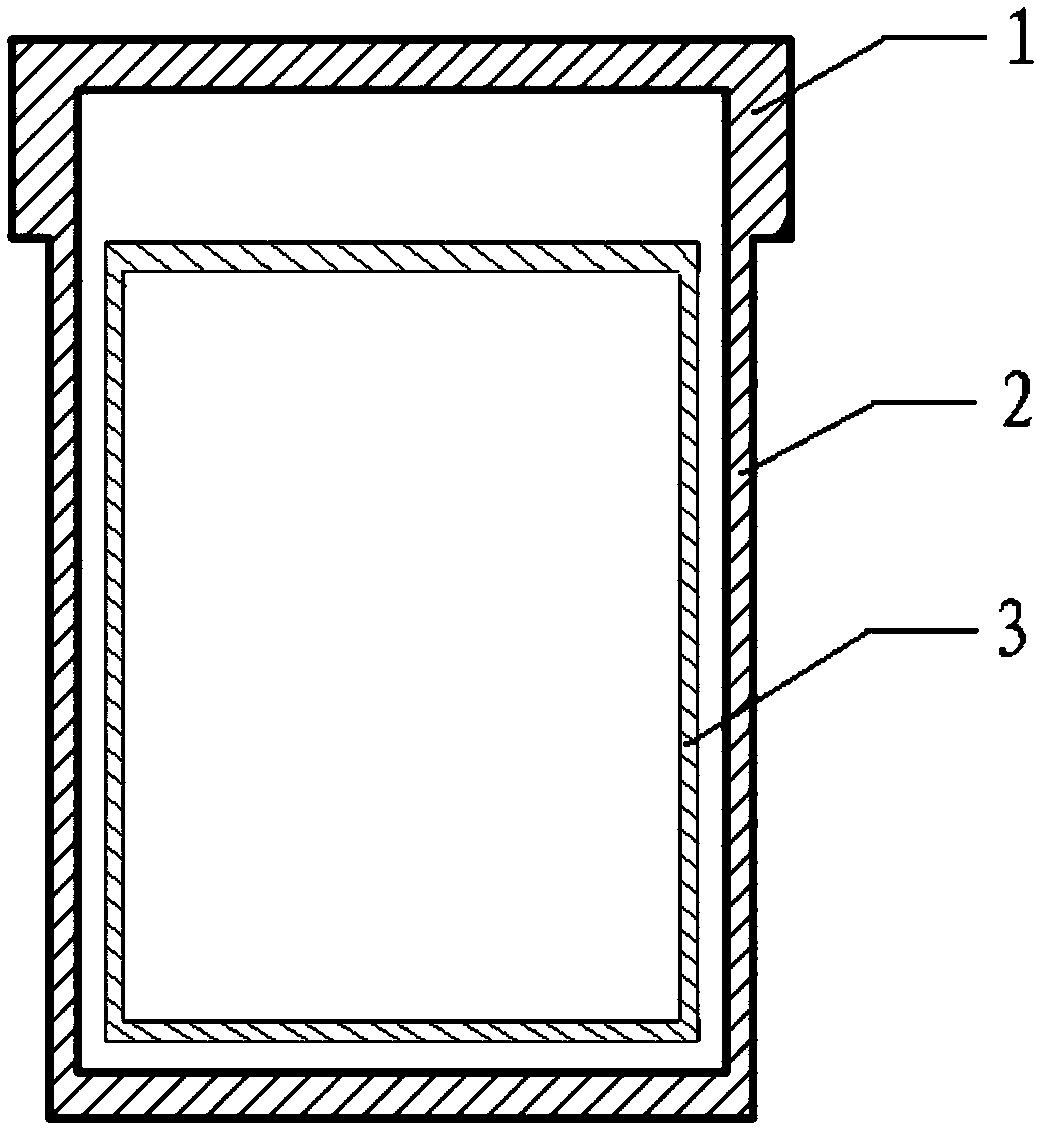

Material product cup in nuclear fuel post-processing plant

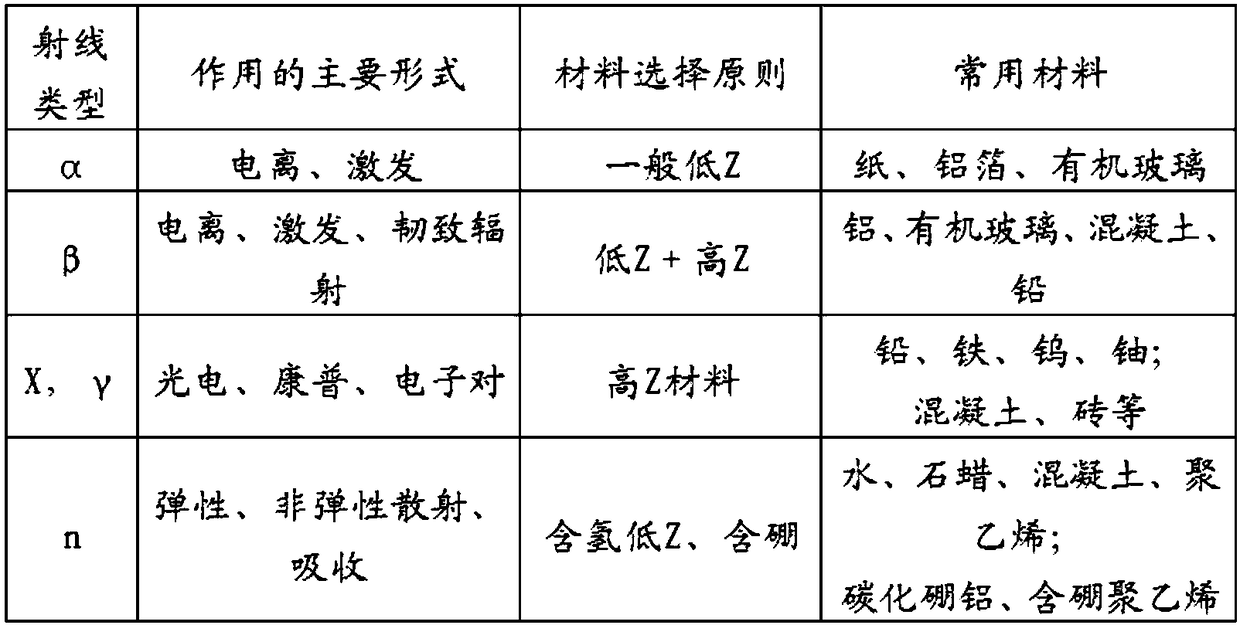

ActiveCN108648842AImprove sealingDoes not affect storage functionNuclear energy generationRecycling and recovery technologiesDose rateAlpha particle

The invention belongs to the technical field of radiation shielding design of radioactive materials in a nuclear fuel post-processing plant, and particularly relates to a material product cup in the nuclear fuel post-processing plant for storing radioactive materials extracted by the nuclear fuel post-processing plant. The material product cup includes an outer cup body (1) which is arranged at the outer layer and can be sealed by an outer cup cover (2) and an inner cup body (3) which is arranged inside the outer cup body (1) and can be sealed by an inner cup cover, wherein the inner cup body(3) is used for storing the radioactive materials, alpha particles, beta particles and other charged particles generated by the radioactive materials in the inner cup body (3) can be shielded completely through the sealed outer cup body (1) and the sealed inner cup body (3), and heat generated by the radioactive materials can be transferred. A variety of radioactive rays radiated by the radioactive materials can be shielded through the product cup, the irradiation dose of bremsstrahlung photons to workers can be reduced, the contact dose rate of the surface of the product cup can be reduced by15-40%, and the operation cost of the nuclear fuel post-processing plant is reduced.

Owner:CHINA NUCLEAR POWER ENG CO LTD

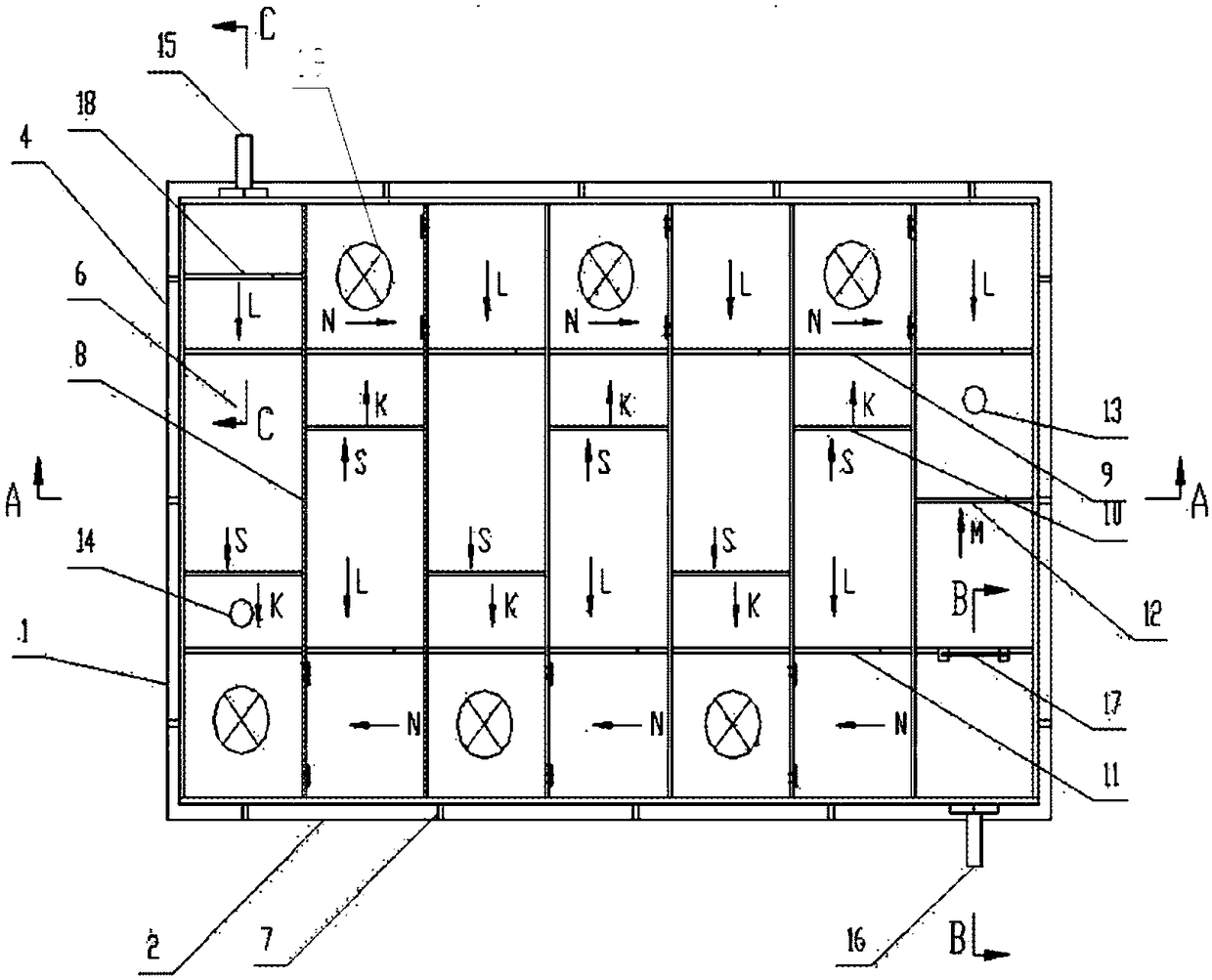

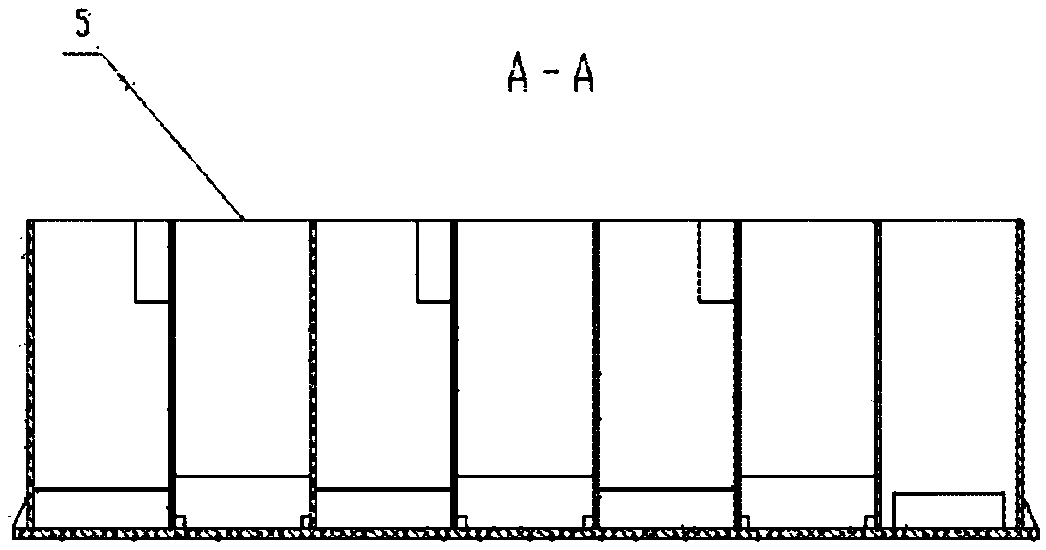

Novel nuclear fuel reprocessing big-flow-ratio mixing and clarifying tank

PendingCN109273128ALiquid level stabilityInterface stabilityRadioactive decontaminationFlow ratioNuclear fuel

The invention relates to a novel nuclear fuel reprocessing big-flow-ratio mixing and clarifying tank which comprises an aqueous-phase outlet stage and a mixing and clarifying stage in sequential connection. The aqueous-phase outlet stage is provided with an aqueous-phase outlet and an organic-phase inlet, and the aqueous-phase outlet is provided with a height-adjustable heavy-phase weir to ensurereasonable and stable interface height and reduce organic-phase entrainment loss; the mixing and clarifying stage is provided with a mixing chamber and a clarifying chamber, a crossed stirring deviceis arranged in the mixing chamber which is not provided with a hidden chamber, an upper phase port, a lower phase port and a backflow port are arranged, and unique phase port structure enables part oforganic phase or aqueous phase to flow back, so that mass transfer needs are met while stable running is ensured; the clarifying chamber is divided into three clarifying areas, so that effective clarifying is ensured while continuous mass transfer effect is realized. The tank has the advantages that mixing and clarifying are realized through staged treatment, and the tank can run stably for a long time in the big-flow-ratio process and is stable in liquid level and interface at each stage, moderate in interface, little in phase entrainment, excellent in hydraulic performance and mass transferperformance and high in stage efficiency reaching process requirements.

Owner:CHINA NUCLEAR POWER ENG CO LTD

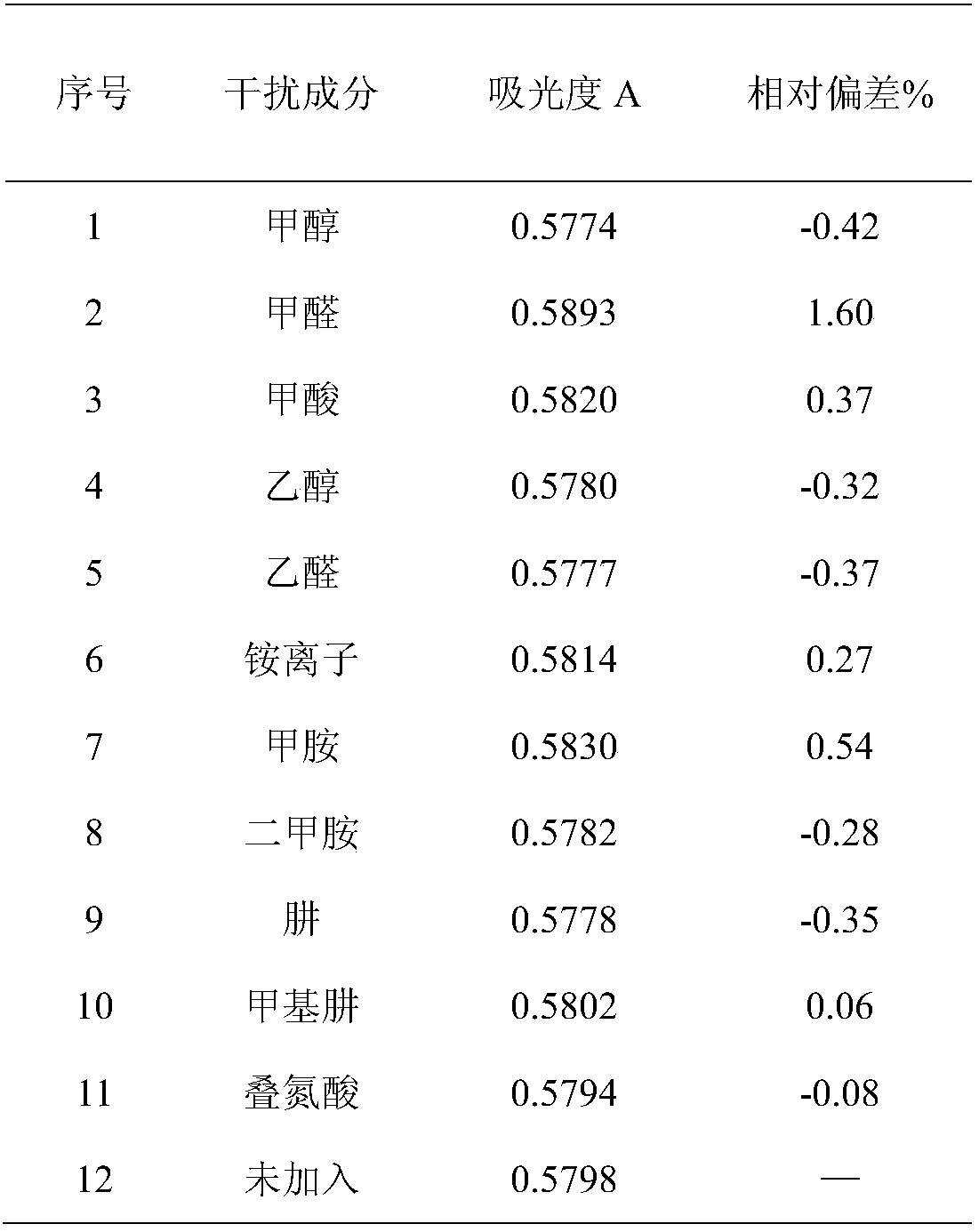

Analyzing method of hydroxysemicarbazide in nuclear fuel post-treatment process

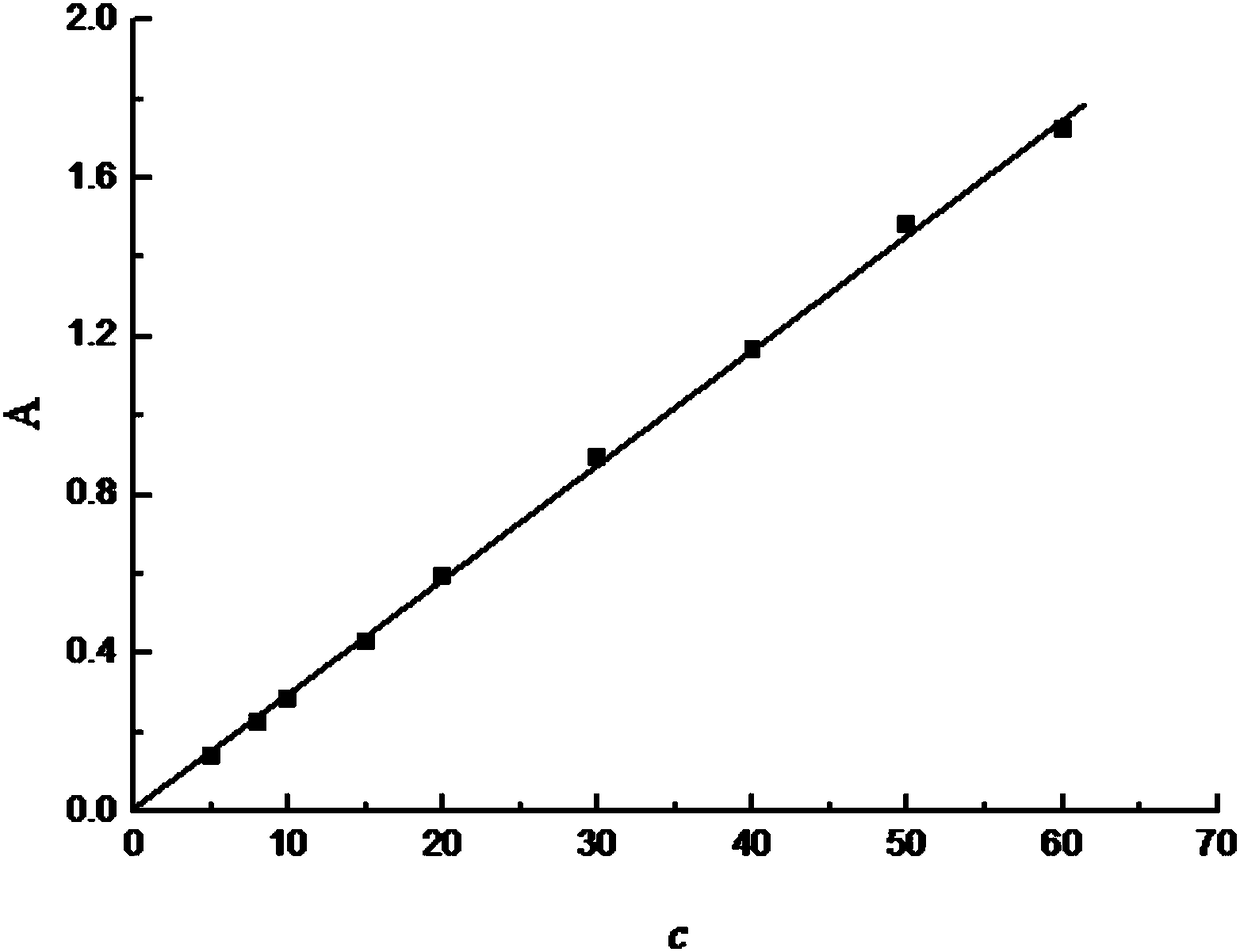

PendingCN108519374ASolve problems that are difficult to apply to nuclear fuel reprocessing processesMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsAbsorbanceVolumetric flask

The invention provides an analyzing method of hydroxysemicarbazide in a nuclear fuel post-treatment process. The method includes the following steps: (1) preparing a series of standard aqueous solutions, preparing multiple volumetric flasks for holding a color developing agent and a buffer solution, preparing a first blank sample and a series of standard samples, measuring the absorbance value ofeach standard sample at a same feature absorption peak by using an ultraviolet-visible spectrophotometer by taking the first blank sample as a reference, and making a standard curve of absorbance varying with the concentration of the hydroxysemicarbazide; and (2) taking a to-be-measured sample, removing plutonium, preparing multiple volumetric flasks for holding the color developing agent and thebuffer solution, preparing a second blank sample and a to-be-measured sample, measuring a corresponding absorbance value by using the ultraviolet-visible spectrophotometer by taking the second blank sample as a reference, and substituting the corresponding absorbance value into the standard curve to calculate the concentration of the hydroxysemicarbazide in the sample.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

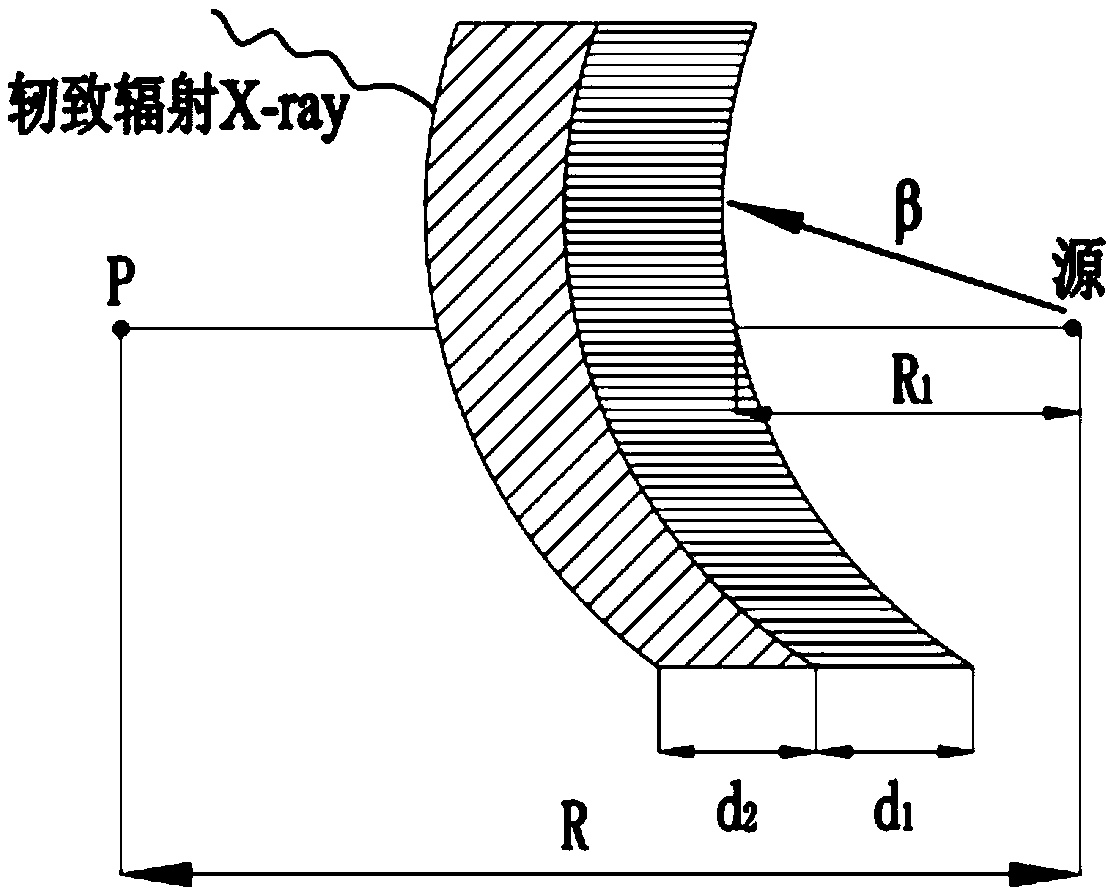

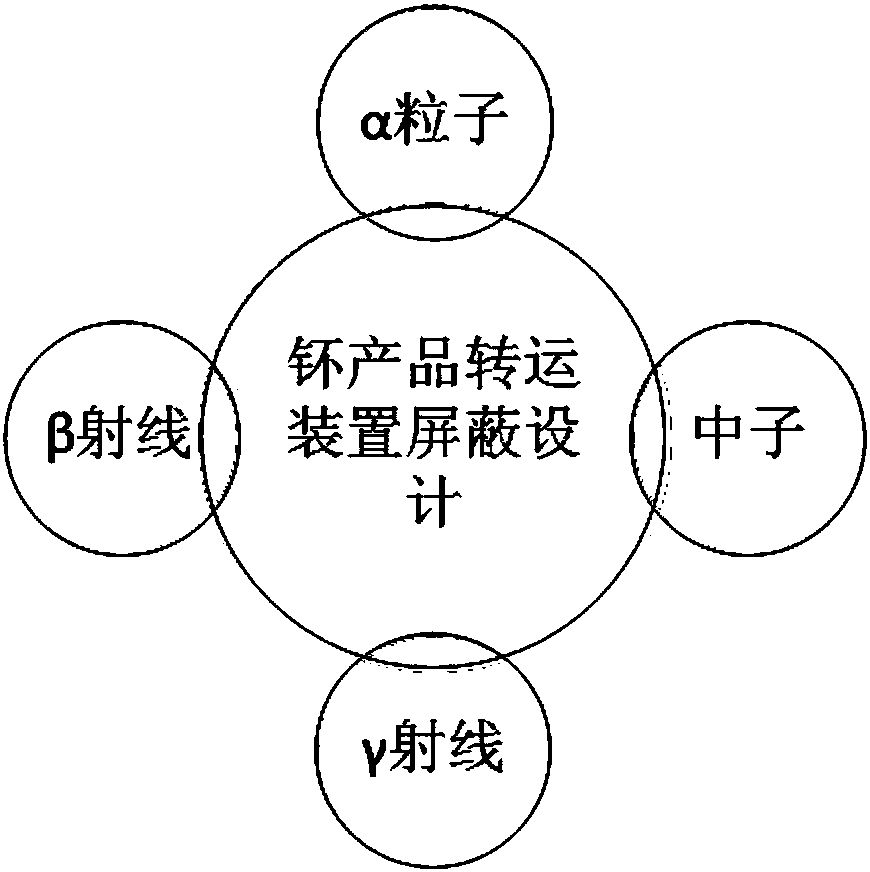

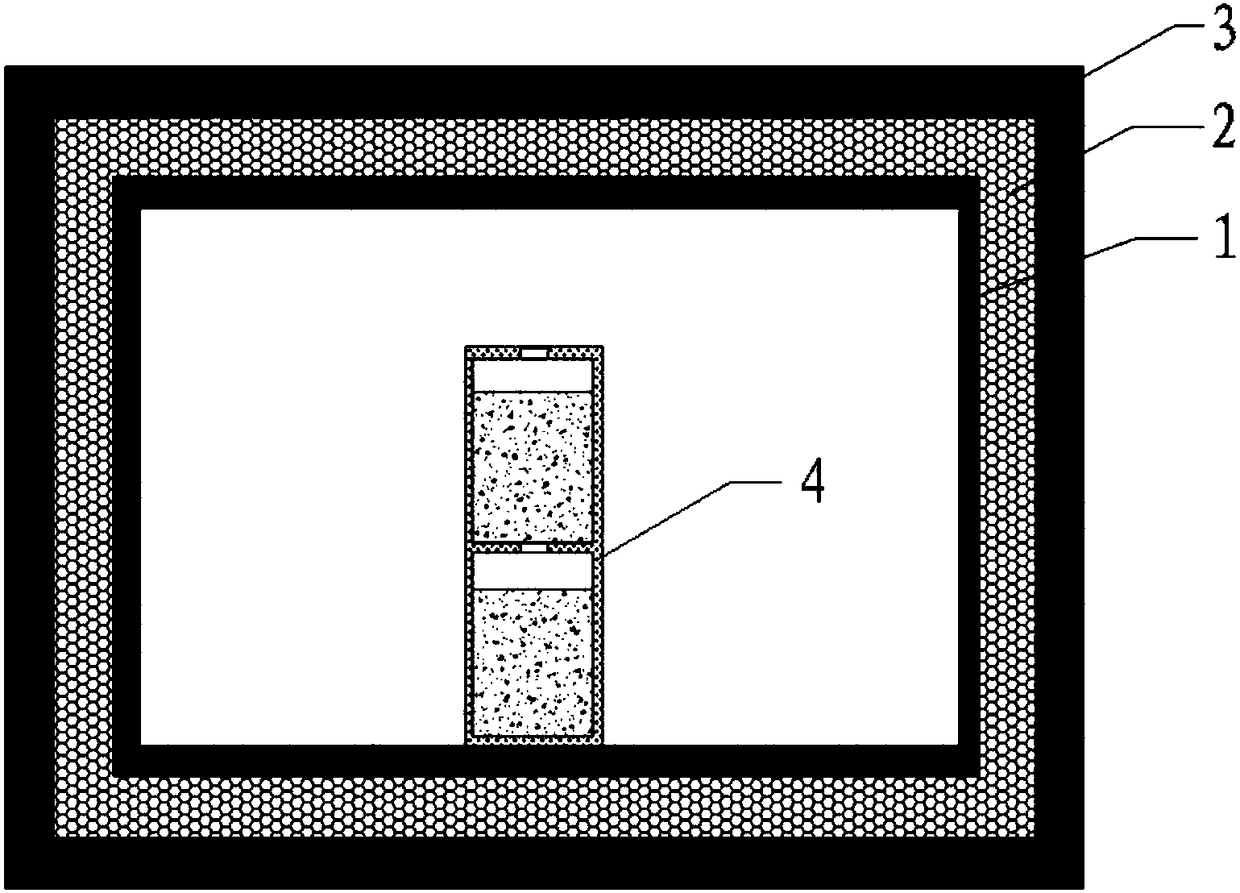

Nuclear fuel reprocessing plant plutonium product transfer device

InactiveCN108417284AImproved Radiation Shielding PerformanceLower raysShieldingAlpha particleGamma ray

The invention belongs to the technical field of nuclear fuel reprocessing plant radioactive material radiation shielding design, and particularly relates to a nuclear fuel reprocessing plant plutoniumproduct transfer device. The device is used for containing plutonium product cups containing plutonium products in a sealed mode. A shielding layer comprises a first stainless steel shielding layer,a neutron shielding layer and a second stainless steel shielding layer which are sequentially arranged from inside to outside. The first stainless steel shielding layer is used for shielding alpha particles and part of beta rays and gamma rays emitted by the plutonium product cups. The neutron shielding layer is used for shielding neutrons emitted by the plutonium products. The second stainless steel shielding layer is used for shielding the gamma rays and bremsstrahlung photons and secondary photons generated after passing of the neutron shielding layer. By means of the device, neutron rays and the gamma rays can be greatly reduced, the neutron and photon radiation risk generated in the transferring process of the plutonium product cups is greatly reduced, and meanwhile the alpha particles and the beta rays can be completely shielded and the stability of the device is considered.

Owner:CHINA NUCLEAR POWER ENG CO LTD

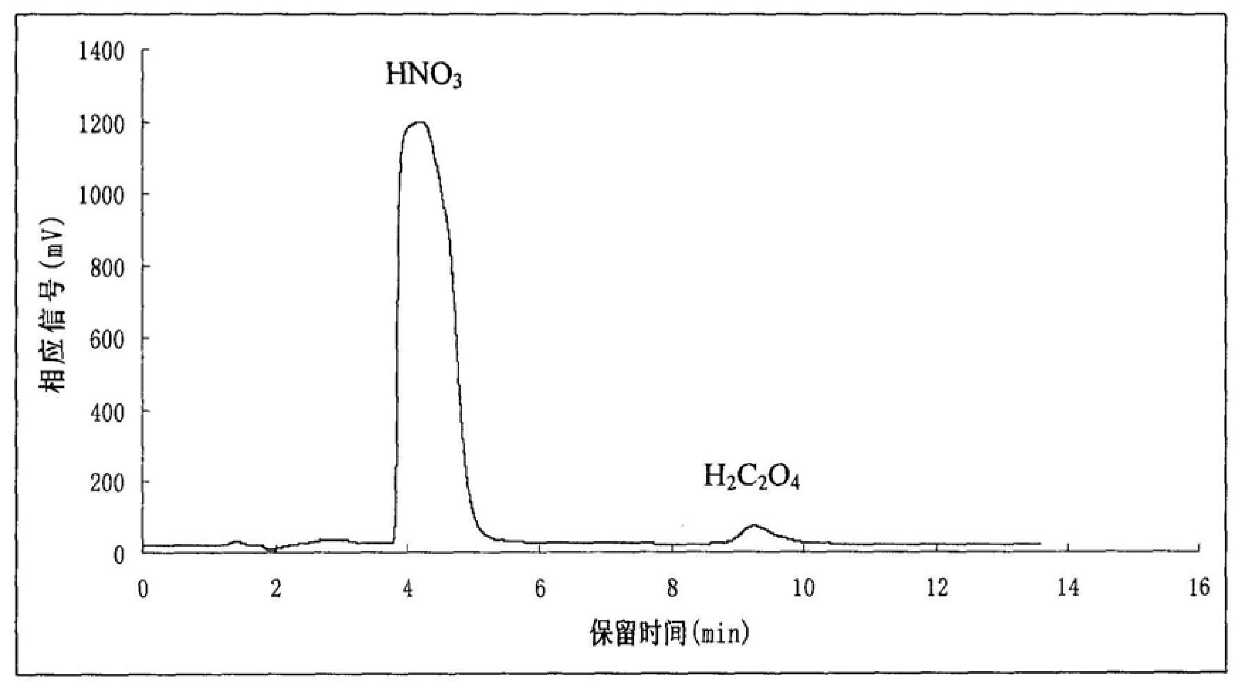

Ion Chromatography Analysis Method of Trace Oxalic Acid in High Concentration Nitric Acid Solution

ActiveCN106342219BAccurate analysisImprove protectionComponent separationHigh concentrationIon chromatography

The invention belongs to the technical field of post-processing of nuclear fuel, and in particular relates to an ion chromatography analysis method for trace amounts of oxalic acid in a high-concentration nitric acid solution. Instrument detection and analysis, wherein, before the above-mentioned washing step, solid NaHCO3 is used to pretreat the destroyed plutonium (IV) oxalate precipitation mother liquor, so that the pH value is 6 to 8; the composition of the eluent system is: Na2CO3, NaHCO3 and H3BO3, wherein the concentration of Na2CO3 is 2-10mmol / L, the concentration of NaHCO3 is 2-10mmol / L, and the concentration of H3BO3 is 2-10mmol / L. The ion chromatography analysis method can accurately analyze trace amounts of oxalic acid in high-concentration nitric acid solution.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Process method and device for recycling nitric acid from uranium-bearing wastewater

ActiveCN106621434AAchieve recyclingReduce manufacturing costDistillation regulation/controlFractional distillationEnvironmental resistanceWastewater

The invention belongs to the technical field of nitric acid recycling processes, in particular to a process method and device for recycling nitric acid from uranium-bearing wastewater in uranium purifying-transforming and nuclear fuel posttreatment industry. According to the process method for recycling the nitric acid by rectifying under a reduced pressure, the nitric acid and water in the uranium-bearing wastewater are recycled, so that waste of the nitric acid is avoided, the volume of the wastewater is reduced greatly, and the risks of excessive corrosion of equipment and explosion caused by red oil are lowered, thereby fulfilling the aims of lowering uranium purifying production cost, protecting the environment, reducing emission and improving operation security.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

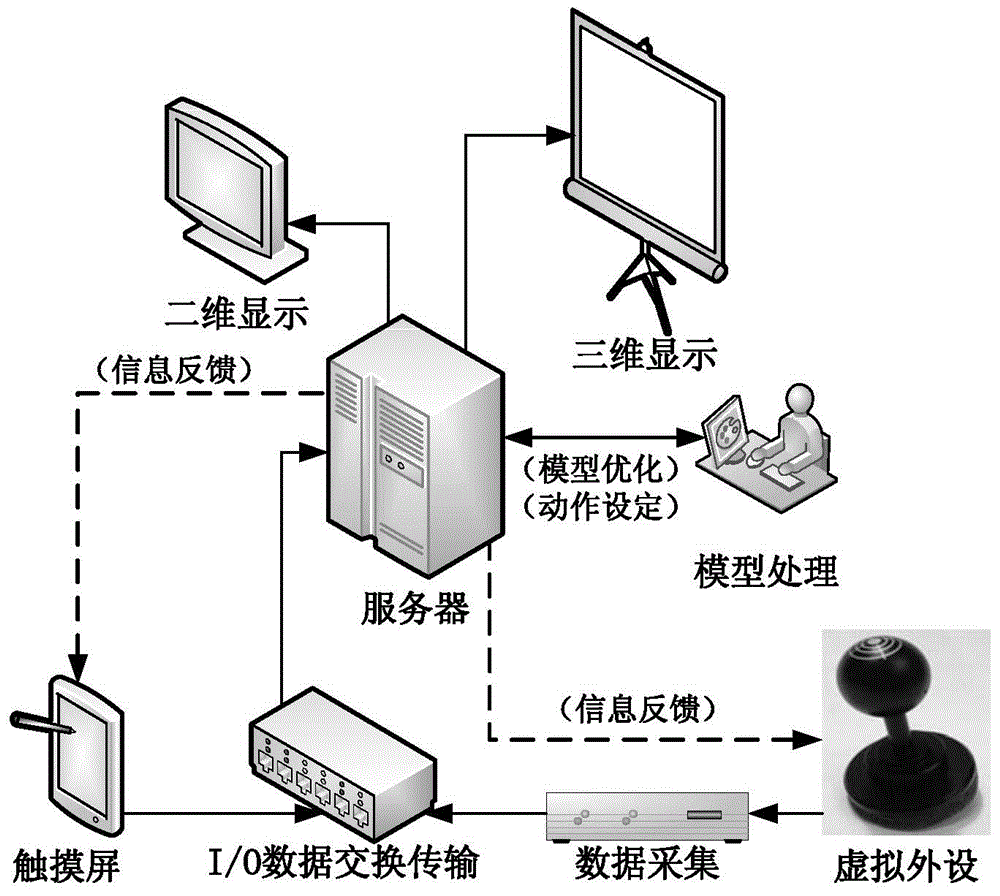

Virtual reality system and method for nuclear fuel reprocessing plant head end

ActiveCN104537910AStrong sense of immersionIn line with real working conditionsCosmonautic condition simulationsSteroscopic systemsFuel reprocessingStaff training

The invention belongs to virtual reality technology, and particularly relates to a virtual reality system and method which can economically and truly simulate mechanical operation environment of a nuclear fuel reprocessing plant head end. The system comprises a server, a model processing unit, a data acquisition unit, an I / O data exchange transmission unit, display units, a touch screen and a virtual peripheral; the operation control instructions of the touch screen and the virtual peripheral are transmitted to the model processing unit through the data acquisition unit and the I / O data exchange transmission unit, the model processing unit carries out model optimization and action setting, and transmit and display the processed model data which are processed again through the server in the display units; the display units comprise a two-dimensional display unit and a three-dimensional display unit, and the display method of two and three dimensional integration has strong immersion and more accords with the real work condition. The virtual reality system and method for the nuclear fuel reprocessing plant head end has the advantages of being smart, convenient and fast, good in economy, small in space usage, and capable of being widely applied to the fields such as the facility design optimization, the equipment research and development and the staff training of the nuclear fuel reprocessing plant head end.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Device and method for continuously generating iodine vapor

ActiveCN110544544APrevent overflowEvenly heatedNuclear energy generationNuclear monitoringEngineeringNuclear fuel

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

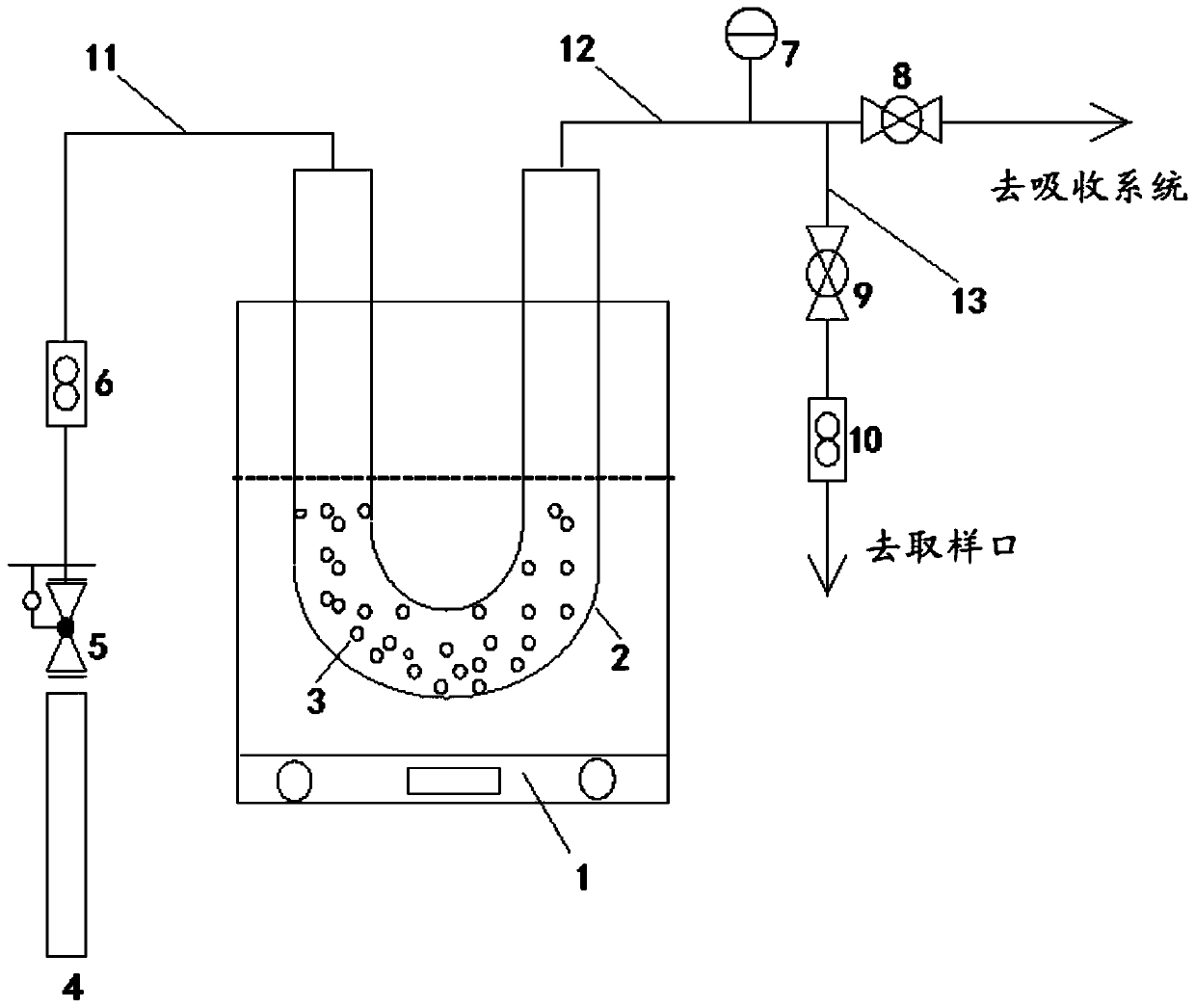

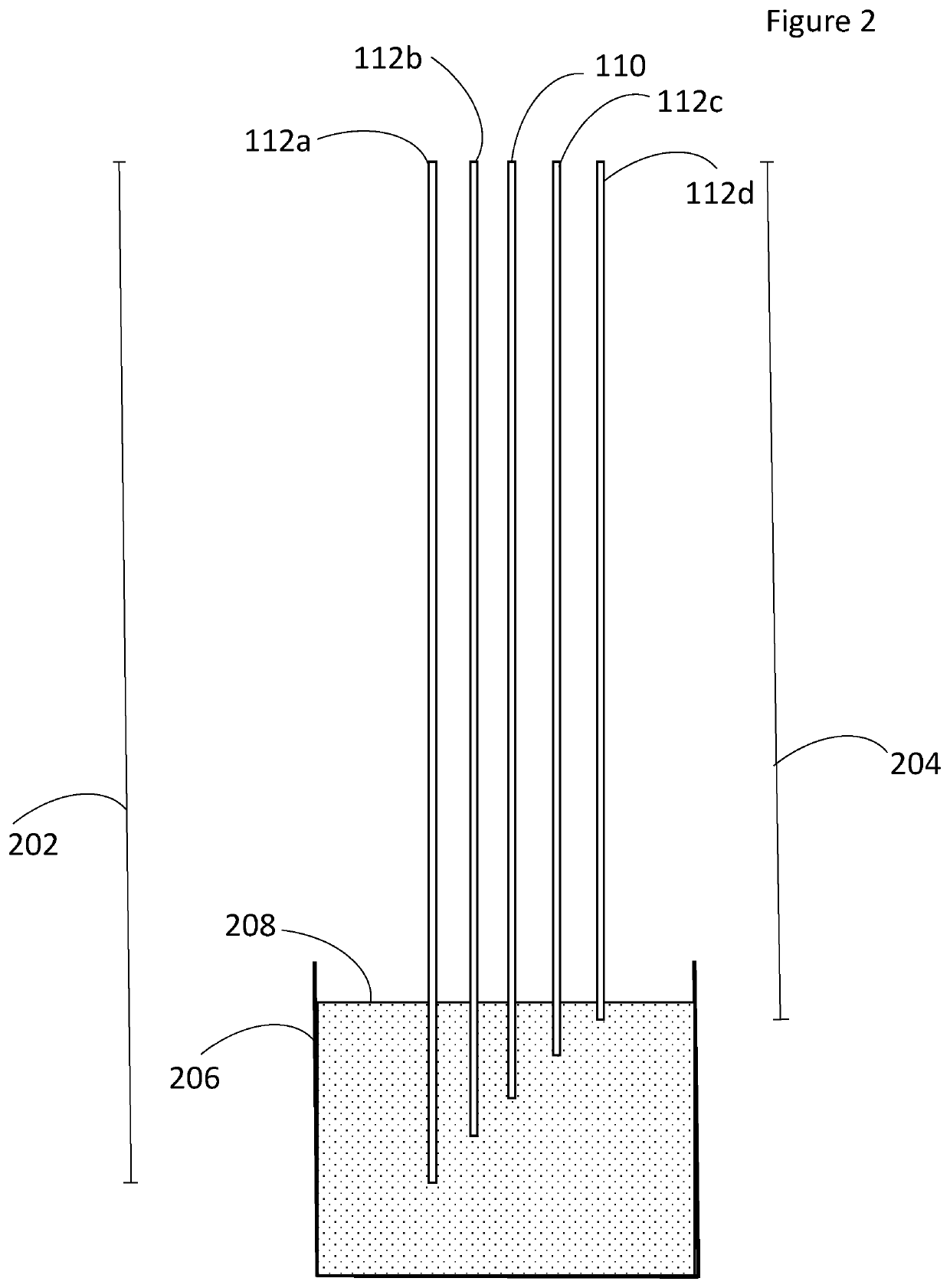

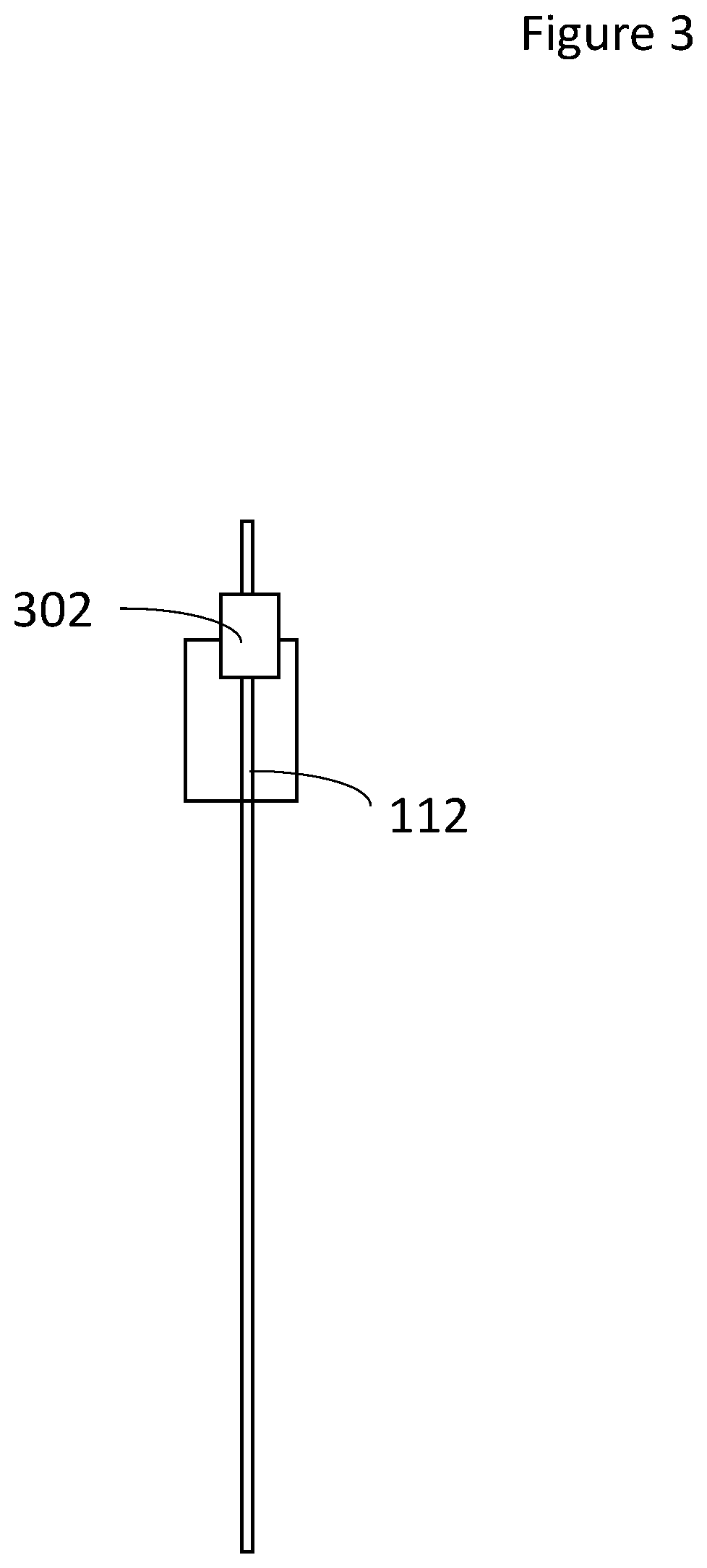

Multielectrode sensor for concentration and depth measurements in molten salt

ActiveUS10955375B2Shorten the timeReduce frequencyMaterial electrochemical variablesEngineeringPotentiostat

A multi electrode sensor that provides in-situ, real time measurements for molten salts and other process fluids such as real-time concentration and salt level measurements for nuclear systems such as molten salt reactors, nuclear reprocessing facilities utilizing molten salts and concentrated solar power systems. The sensor has multiple electrodes with unique lengths which are connected to a potentiostat. Measurements are taken when the electrodes are immersed in the process fluid.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Method for separating uranium from plutonium in Parex procedure

InactiveCN1229814CSimplify process conditionsIncrease separation speedNuclear energy generationRecycling and recovery technologiesReducing agentNuclear fuel

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

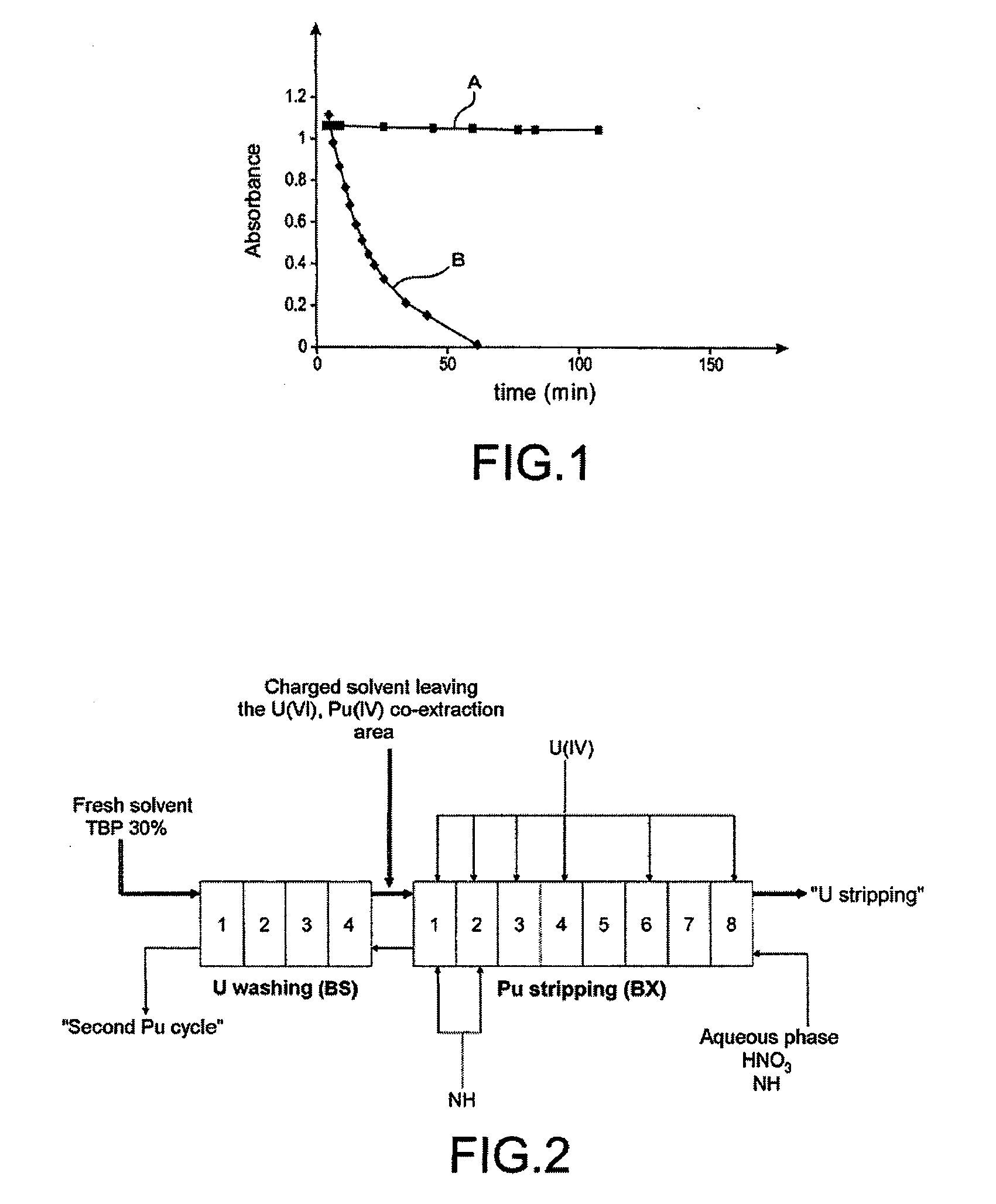

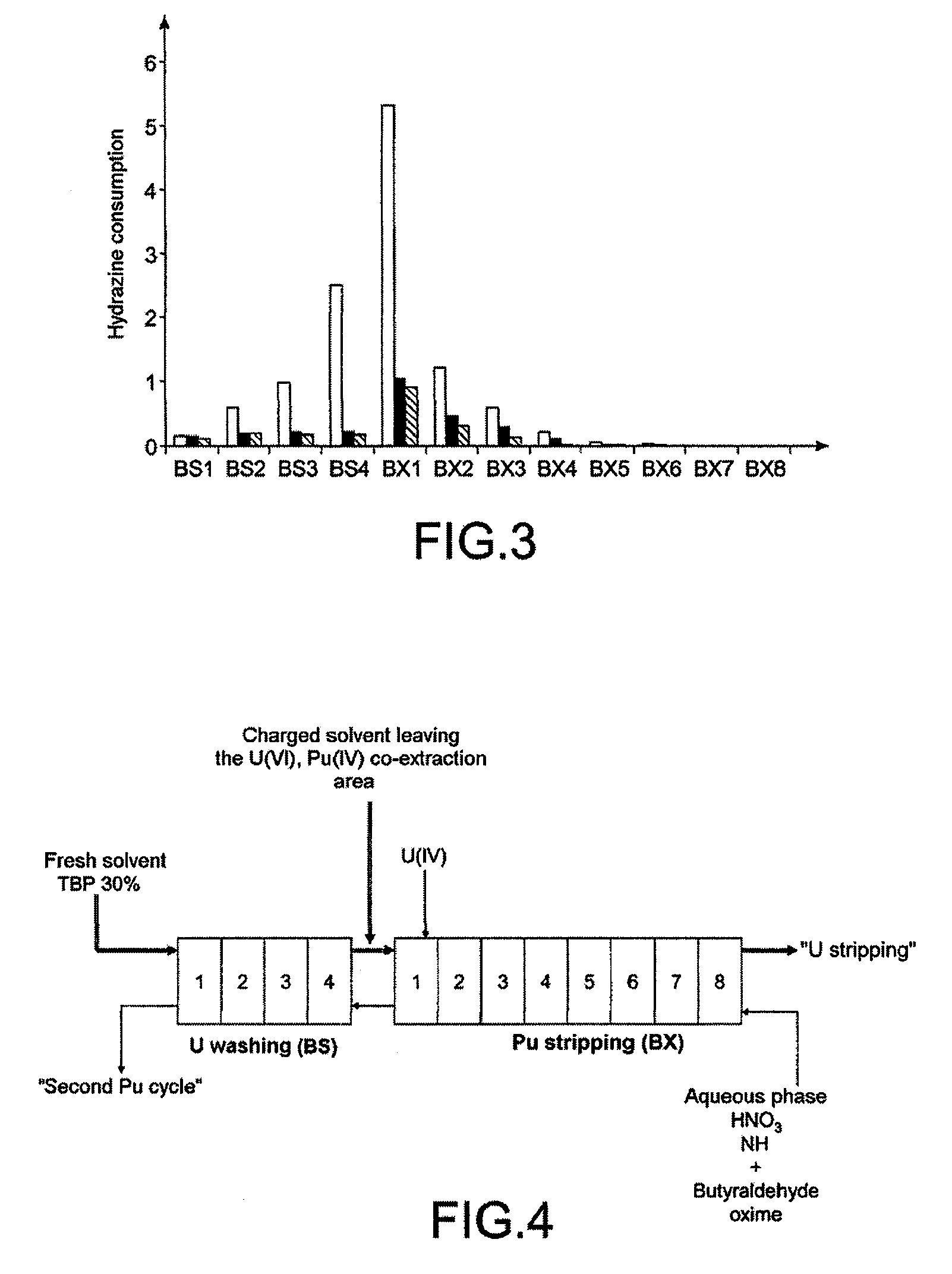

Use of Butyraldehyde Oxime as an Anti-Nitrous Agent in an Operation for the Reductive Stripping of Plutonium

InactiveUS20100310438A1Reduce in quantityEasy to operateSolvent extractionTransuranic element compoundsNitriteOxidation state

The invention relates to the use of butyraldehyde oxime as an anti-nitrous agent in a plutonium stripping operation based on a reduction of this element from oxidation state (IV) to oxidation state (III).Applications: any nuclear fuel reprocessing process in which employing a compound that has the twofold property of being extractable into an organic phase and of being capable of destroying the nitrous acid therein may be useful, and especially any process including one or more operations for the reductive stripping of plutonium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

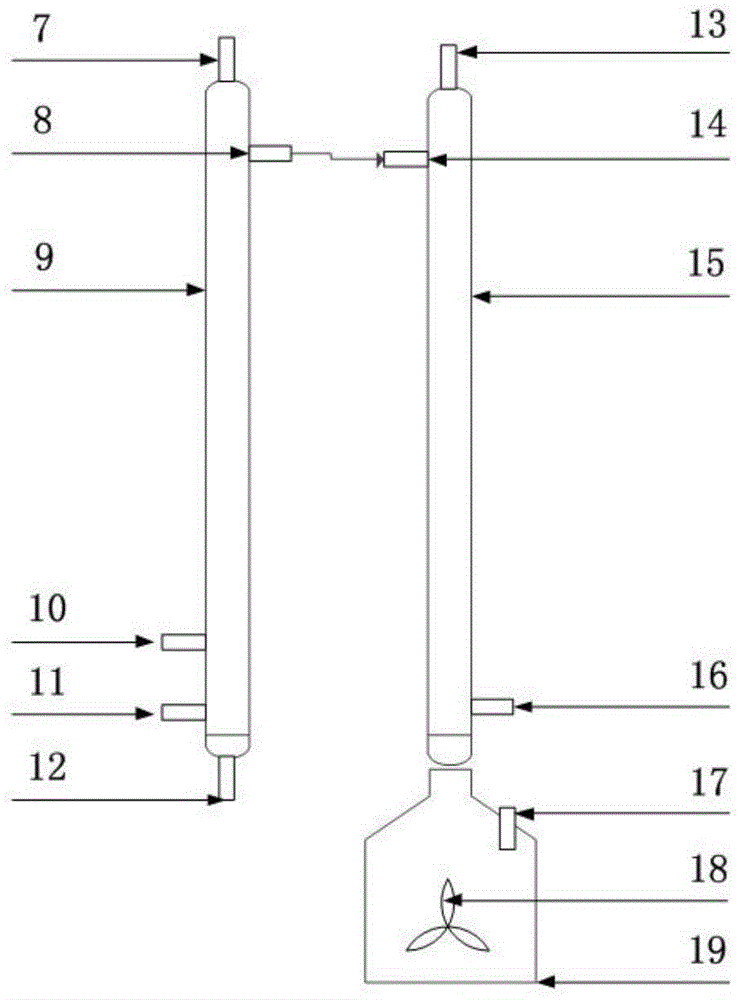

Method and device for oxidative adjustment of plutonium valence with NOx

The invention belongs to the technical field of post treatment of nuclear fuels, and discloses a method and device for oxidative adjustment of plutonium valence with NOx. According to the method, NOx and oxygen-containing gas are used as oxidants to destroy a reducing agent in Pu (III) liquid and oxidize Pu (III) into PU (IV); the device comprises a Pu (III) oxidation column and a nitrous acid dispelling column, wherein the upper part of the Pu (III) oxidation column is connected with the nitrous acid dispelling column through a liquid delivery pipe; the device is characterized in that a first exhaust discharge port and a second exhaust discharge port are formed in the top ends of the Pu (III) oxidation column and the nitrous acid dispelling column respectively, and an oxidant inlet and a Pu (III) liquid inlet are formed in the lower part of the Pu (III) oxidation column. The method and the device have the advantages of improving the utilization rate of NOx, stabilizing the pressure in the Pu (III) oxidation column and lightening the treatment burden of nitrogen oxide exhaust.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com