Sandwich-type inert gas shielding hot chamber

An inert gas, interlayer technology, applied in the field of interlayer inert gas protection hot cells, can solve problems such as no inert gas protection hot cells, and achieve the effects of reducing radioactive dose, reducing emissions, and avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

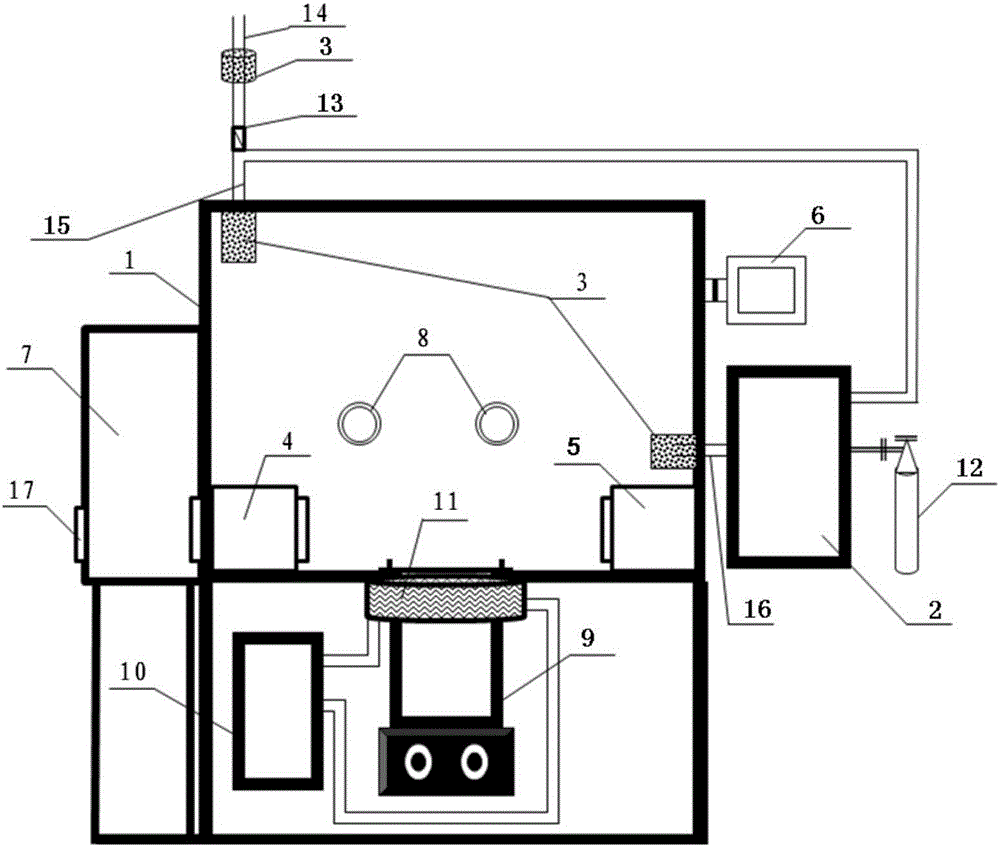

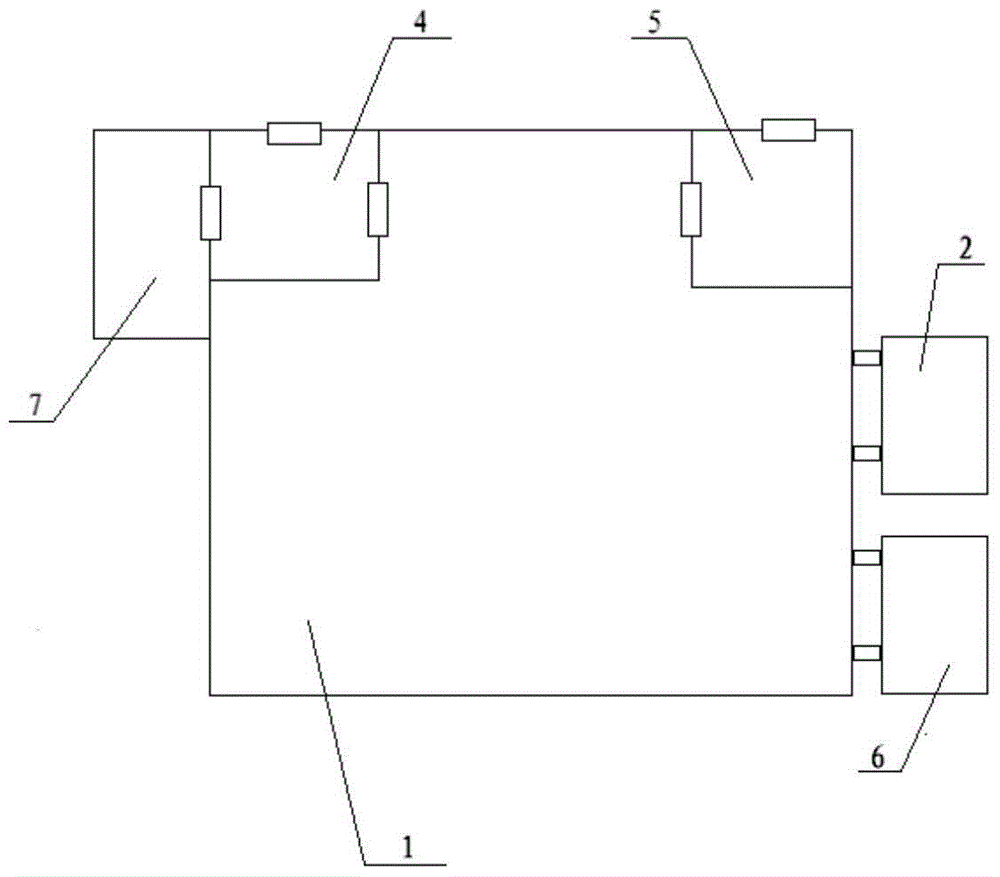

[0033] A sandwich type inert gas shielded thermal chamber, such as Figure 1 ~ Figure 3 As shown, the hot cell mainly includes a hot cell main body 1, a gas circulation purification device 2, an aerosol filter device 3, an automatic pressure control system, and a material entry and exit device, wherein the gas circulation purification device 2 and the automatic pressure control system operation panel 6 are located in the heat chamber. Outside the chamber main body 1, the material inlet and outlet device is in sealing connection with the hot chamber main body 1; the inert gas is argon.

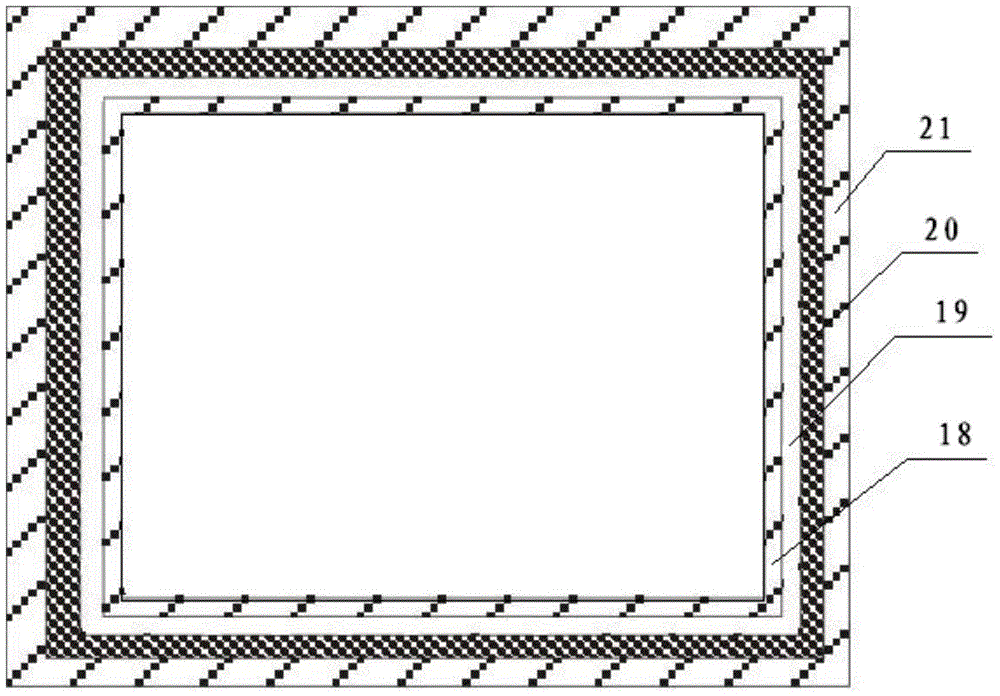

[0034] The hot cell main body 1 is a sandwich structure, which includes an inert gas sealed casing 18, a shockproof sealed casing 20, a neutron and / or gamma ray shielded casing 21 from the inside to the outside, wherein the inert gas sealed casing 18 There is a gap 19 of 1-20mm between the anti-seismic sealing shell 20, and a negative pressure is drawn on the gap 19, and the negative pressure v...

Embodiment 2

[0047] The difference from Embodiment 1 is that there is a gap of 3 mm between the inert gas sealed casing 18 and the shockproof sealed casing 20 . Two pairs of manipulators are arranged on the front of the main body 1 of the heat chamber. The pressure inside the inert gas sealed casing is -200Pa, and the pressure in the gap provided between the inert gas sealed casing 18 and the shockproof sealed casing 20 is -500Pa.

Embodiment 3

[0049] The difference from Embodiment 1 is that there is a gap of 5 mm between the inert gas sealed casing 18 and the shockproof sealed casing 20 . The pressure inside the inert gas sealed casing 18 is -300Pa, and the pressure in the gap provided between the inert gas sealed casing 18 and the shockproof sealed casing 20 is -500Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com