Material product cup in nuclear fuel post-processing plant

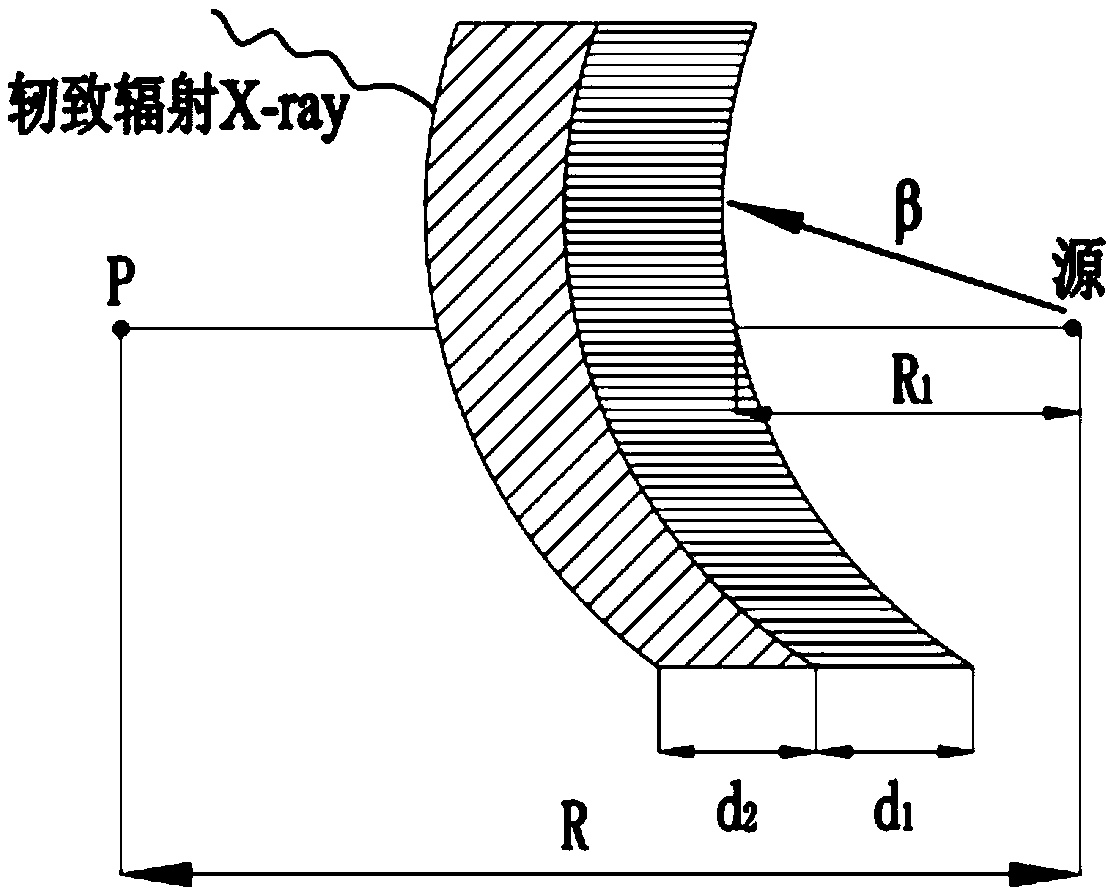

A nuclear fuel and material technology, applied in the direction of reactor fuel elements, nuclear engineering, nuclear power generation, etc., can solve the problems of insufficient shielding effect and high exposure dose to personnel, so as to improve the radiation shielding ability, make the exposure dose reasonable and feasible, and reduce the contribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

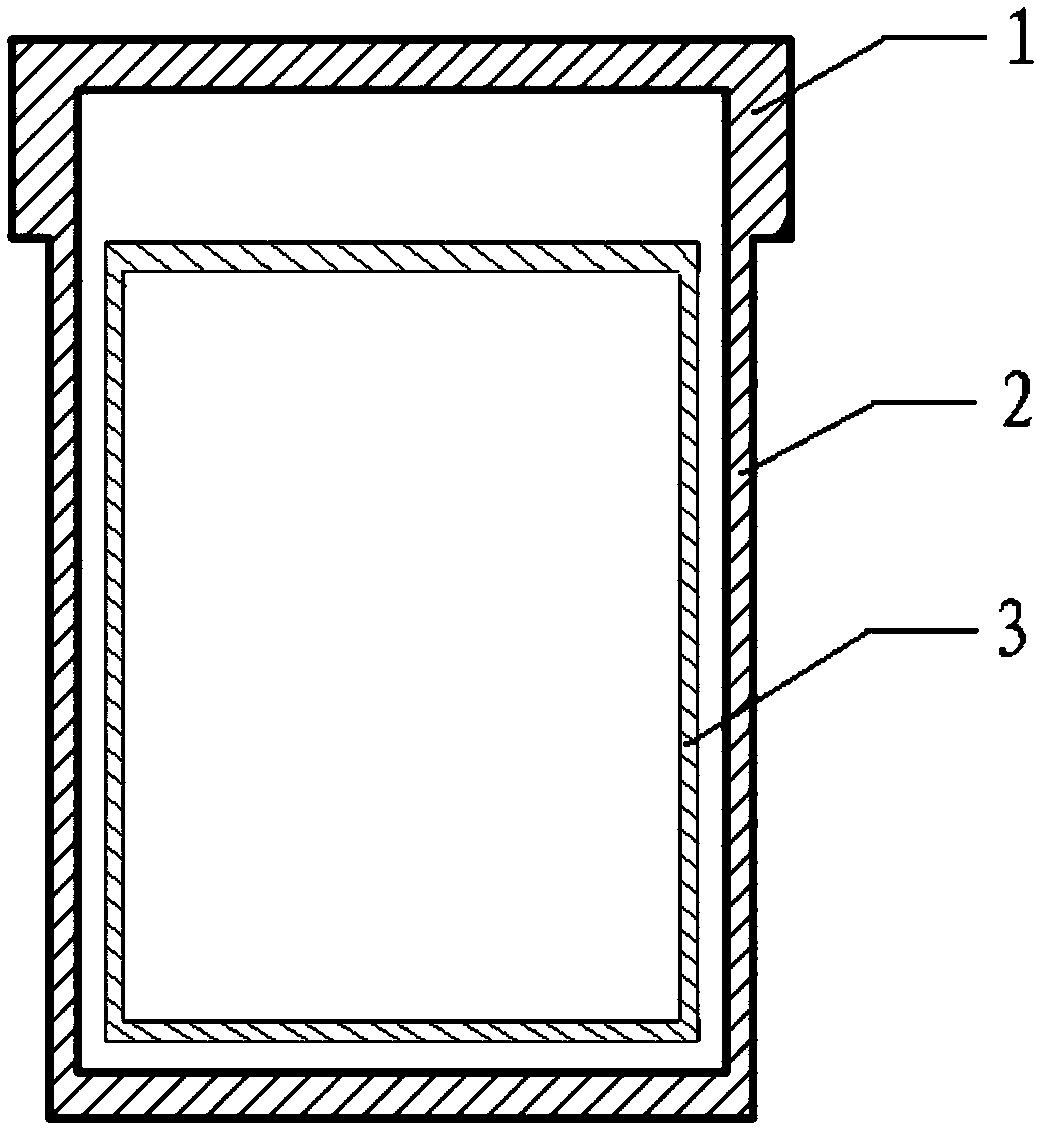

[0034] Such as figure 2 As shown, a kind of nuclear fuel reprocessing plant material product cup (referred to as the product cup) provided by the present invention is used to store radioactive materials extracted by the nuclear fuel reprocessing plant. After preliminary radiation shielding calculation analysis and reference to the current typical material product cup design , the product cup provided by the present invention adopts inner and outer double-layer cup structure design, and is made up of components such as outer cup body 1, outer cup cover 2, inner cup body 3, inner cup cover (not marked in the accompanying drawings).

[0035] Wherein, the outer cup body 1 is the outer layer of the product cup, and the top opening of the outer cup body 1 can be sealed by the outer cup cover 2 . The inner cup body 3 is located inside the outer cup body 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com