Novel nuclear fuel reprocessing big-flow-ratio mixing and clarifying tank

A mixed-clarification tank and mixed-clarification technology, which is used in nuclear engineering, radioactive purification, etc., can solve the problems of unsuitable large flow ratio, small contact, limited stirring capacity, etc., and achieves excellent hydraulic performance and mass transfer performance, and moderate interface. , the effect of less phase entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

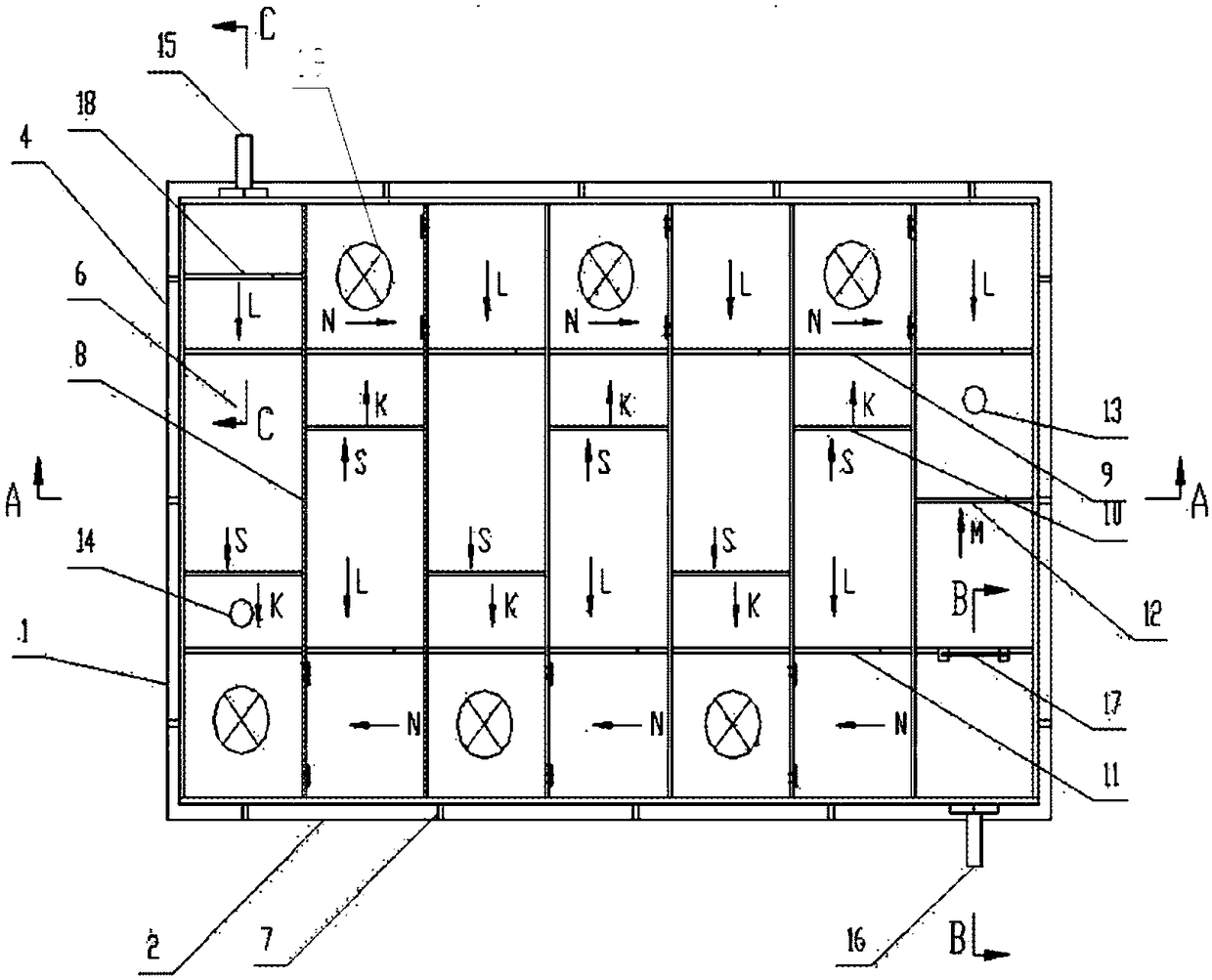

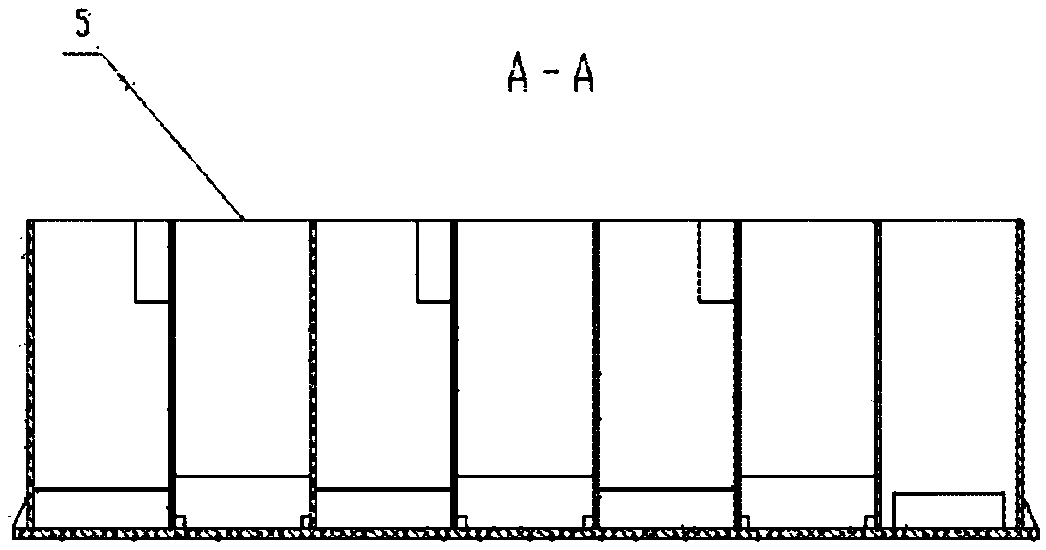

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0028] like figure 1 and figure 2 As shown in the figure, the present invention provides a new type of nuclear fuel reprocessing large flow ratio mixing and clarifying tank, which is a box-type structure as a whole. Plate 5, bottom plate 6 and reinforcing plate 7 are composed. Specifically, it includes the water phase outlet stage and each mixed clarification stage connected in sequence; each stage is separated by a stage partition board 8 (a stage partition board is set between the adjacent water phase outlet stage and the mixed clarification stage; a stage partition board is set between the adjacent two stages Stage spacer; the structure of stage spacer is as follows Figure 9 The water phase outlet stage is provided with an aqueous phase outlet and an organic phase inlet; the last stage of the mixing and clarification is an organic phase outlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com