Gas-liquid separator suitable for air conditioning system with multi-compressor parallel connection

A gas-liquid separator and air-conditioning system technology, applied in the direction of refrigerators, refrigeration and liquefaction, refrigeration components, etc., can solve the problems of difficult return of lubricating oil, slow air flow in the pipe, damage to the compressor, etc., and achieve stable liquid level and suction The effect of the same air pressure and basic suction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

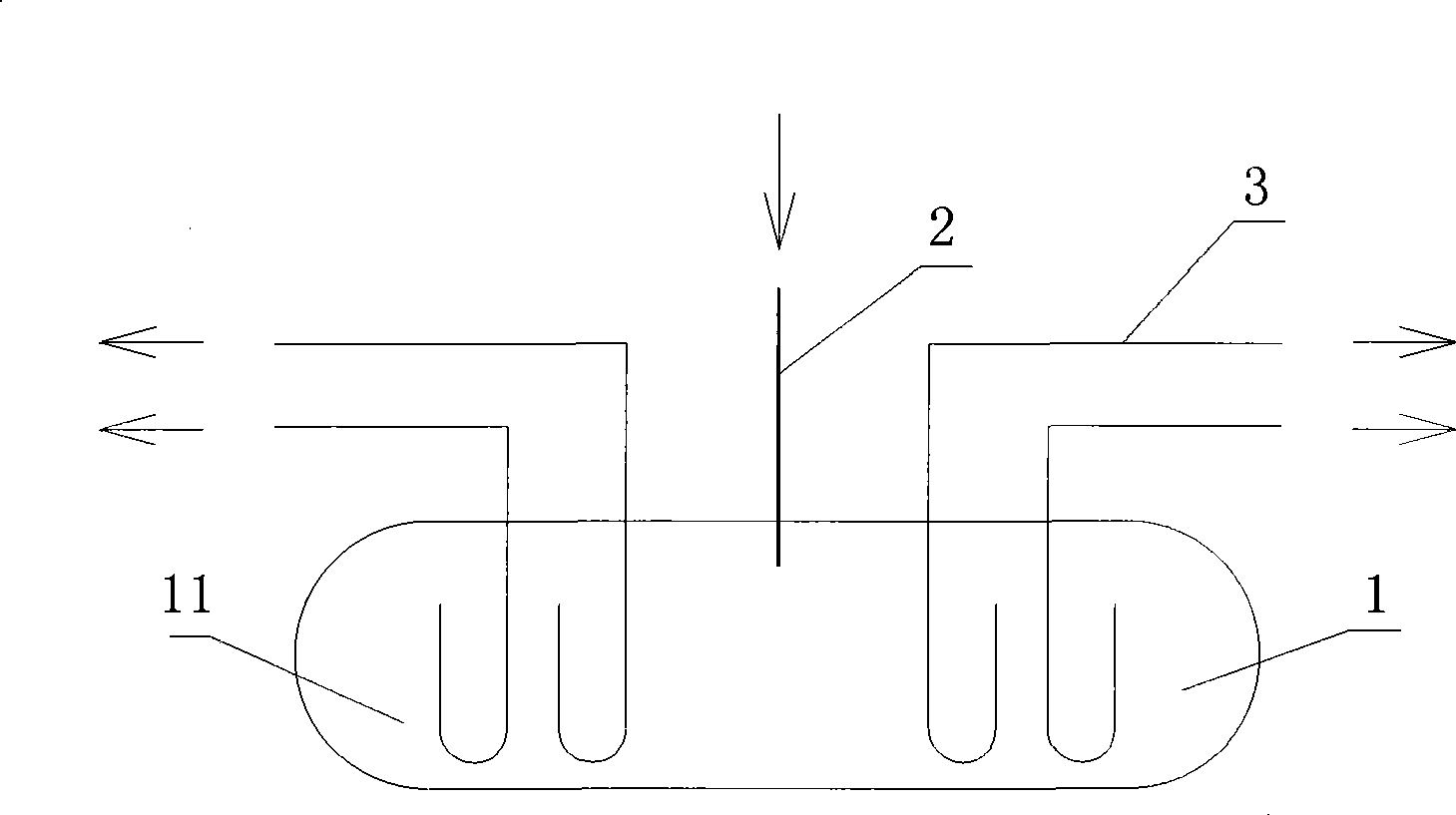

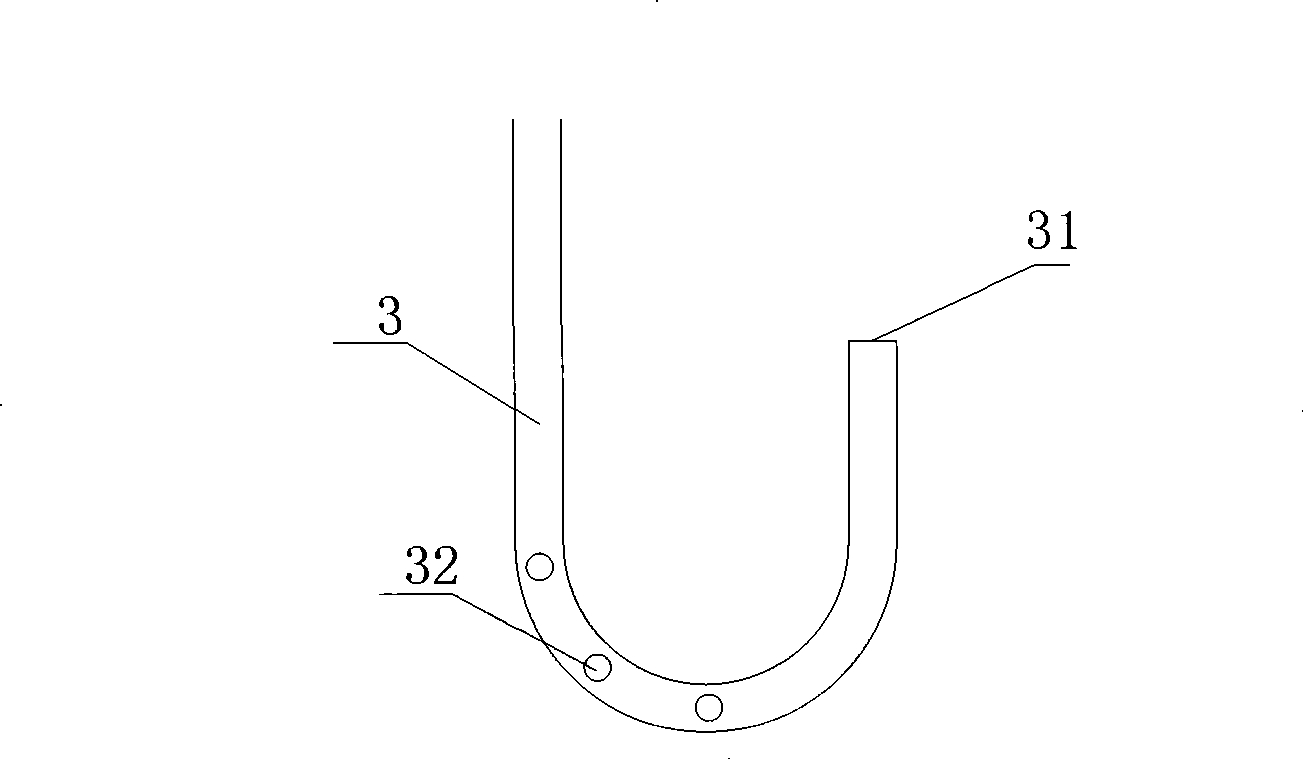

[0012] see figure 1 and figure 2 , the present invention includes a shell 1 of the gas-liquid separator and a refrigerant inlet pipe 2 connected to the upper end of the shell 1 and four suction pipes 3 . The refrigerant inlet pipe 2 is a main pipe communicating with the inner chamber 11 of the housing 1 . The multi-channel refrigerant flowing out from each evaporator / condenser 4 flows into the inner cavity 11 of the housing 1 through the refrigerant inlet pipe 2 . The suction pipes 3 are a plurality of U-shaped pipes placed at the bottom of the inner chamber 11 of the housing 1 , and the U-shaped section at the lower end of each suction pipe 3 is provided with a plurality of oil suction holes 32 .

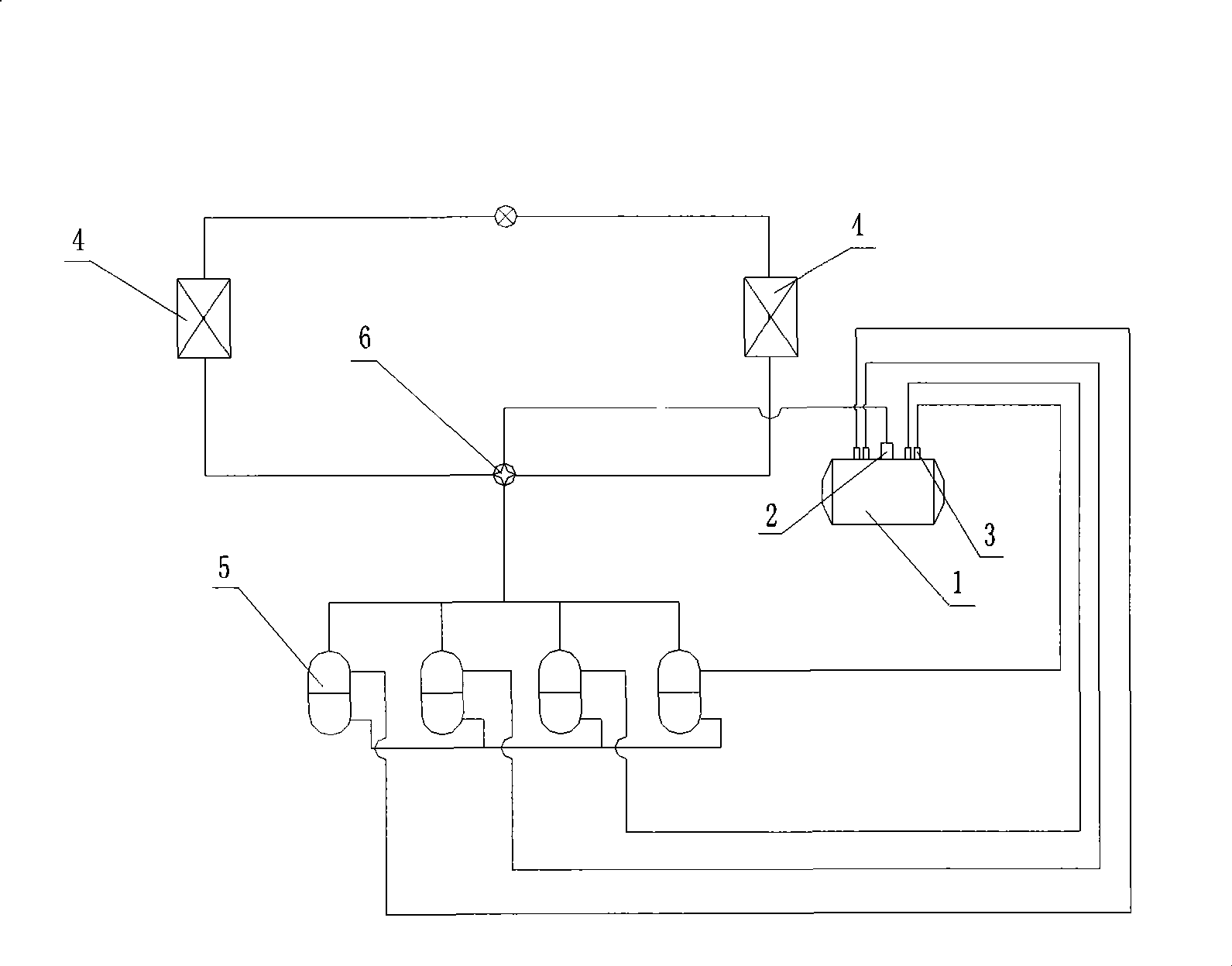

[0013] see image 3 , when the present invention is used, the refrigerant flowing out from each evaporator / condenser 4 flows into the refrigerant inlet pipe 2 through the four-way valve 6, and enters the inner chamber 11 of the gas-liquid separator shell 1. A large amount of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com