Intermediate cooling medium flow passage and compressor comprising same

An intermediate channel and compressor technology, which is applied in the field of compressors, can solve problems such as pressure pulsation at the step, affecting the suction stability of the high-pressure cylinder, and increasing the intermediate process of the refrigerant, so as to reduce pressure loss and reduce energy consumption. The effect of reducing and increasing the suction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a novel refrigerant intermediate channel and compressor with simple structure. More particularly, the present invention mainly improves the intermediate passage of the refrigerant, so that the energy consumption of the compressor is reduced. Preferred specific embodiments of the present invention will be described in detail below.

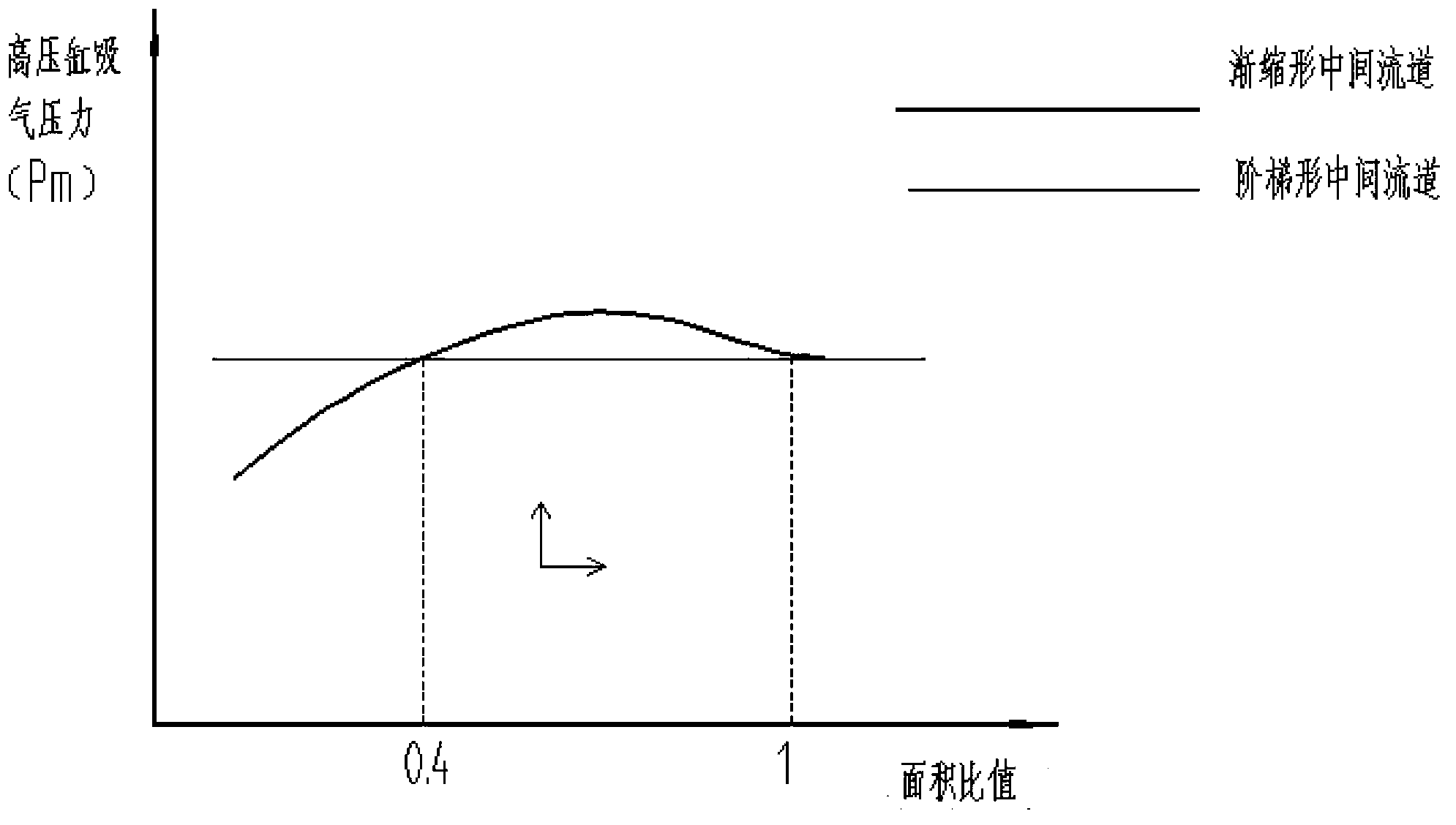

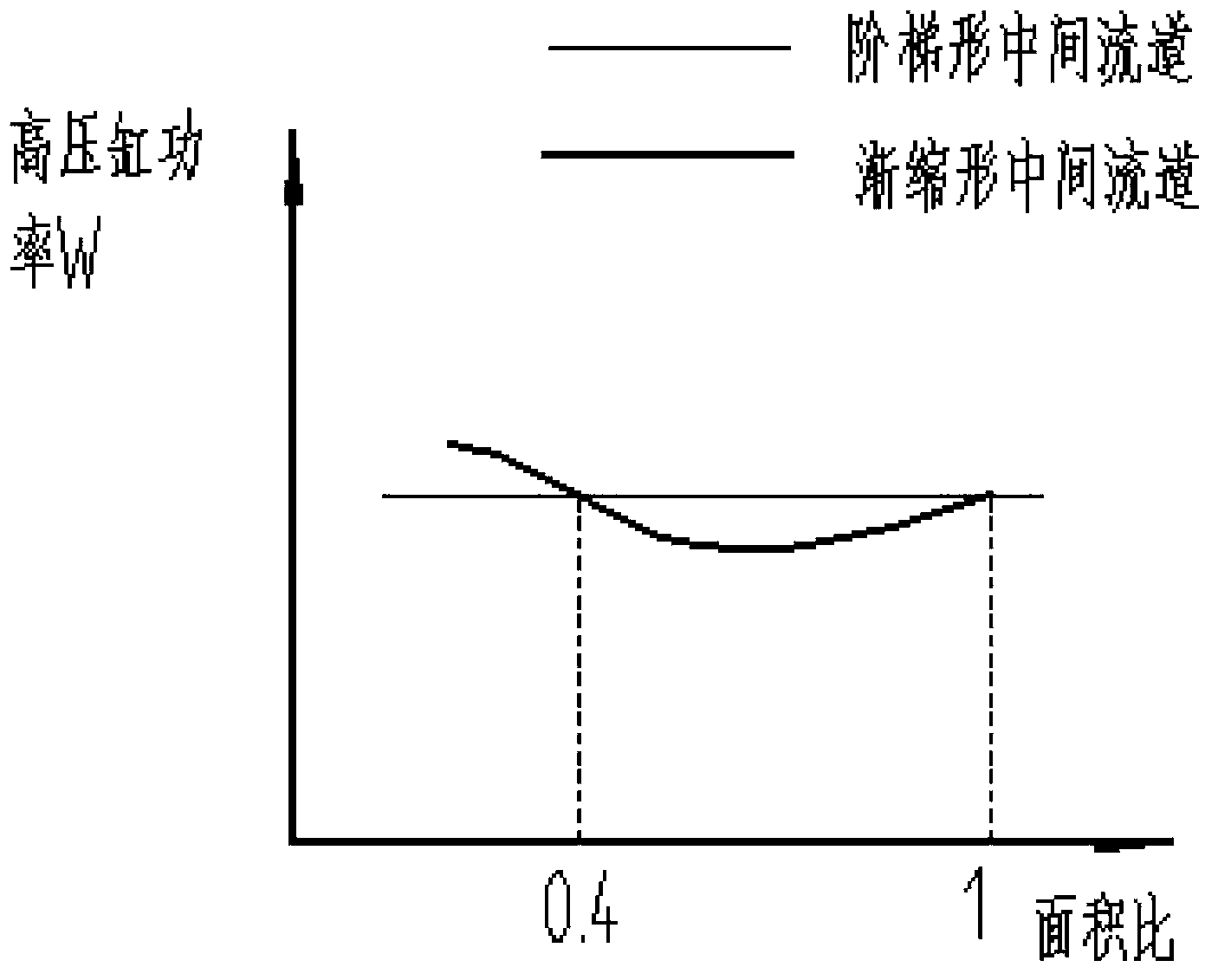

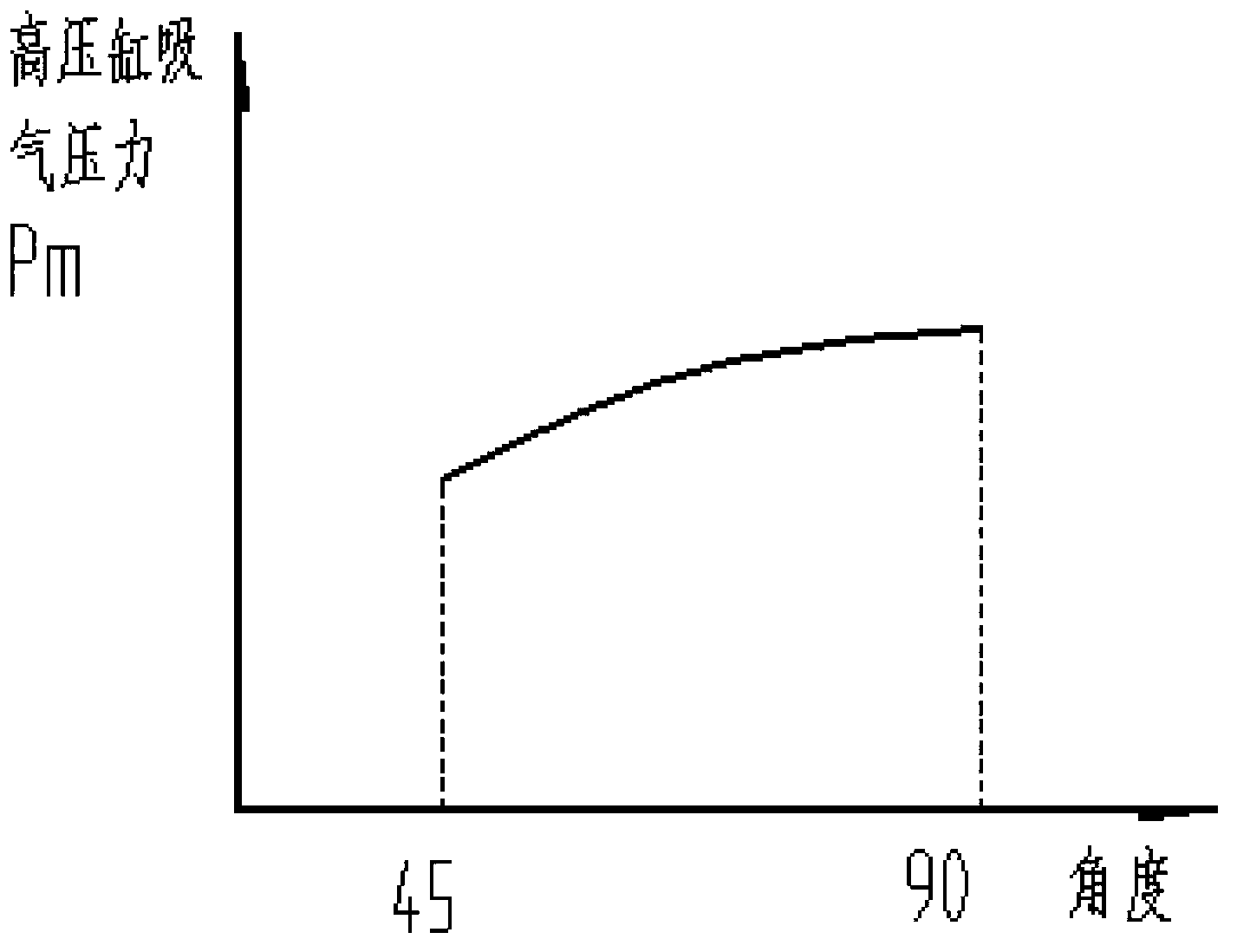

[0029] Disclosed is a refrigerant intermediate flow channel of a compressor. The entire refrigerant intermediate flow channel is a pipe with a gradual cross section, and the inner wall of the refrigerant intermediate flow channel is smooth. That is to say, the refrigerant intermediate flow channel of the present invention is different from the stepped refrigerant intermediate flow channel in the prior art. The channel as a whole is a pipe with a gradual change in cross-section, and the inner diameter or area of the pipe changes gradually. Generally speaking, as the length of the refrigerant process increases, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com