Suction cooling device for production of polyester and nylon composite filaments

A technology of polyester-nylon composite yarn and cooling device, which is applied to household refrigeration devices, cooling fluid circulation devices, coolers, etc., can solve the problems of inability to vacuum the composite yarn, environmental protection, poor cooling effect, etc., so as to improve the cooling effect. , The effect of uniform cooling and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

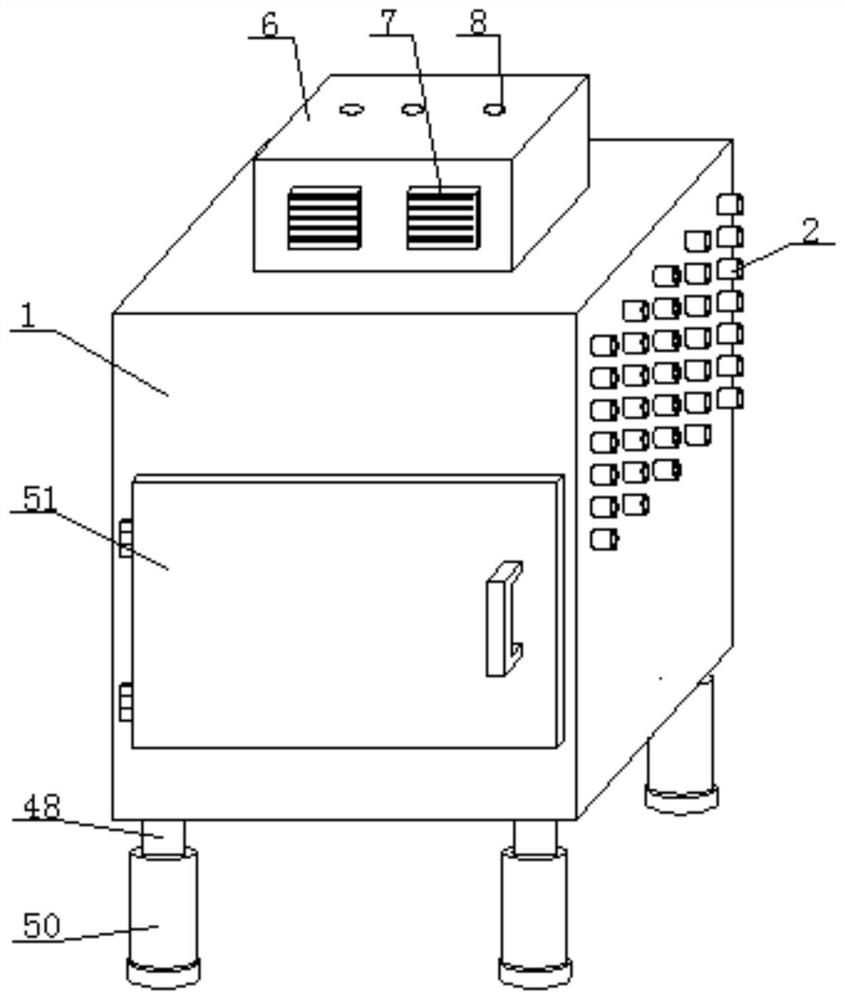

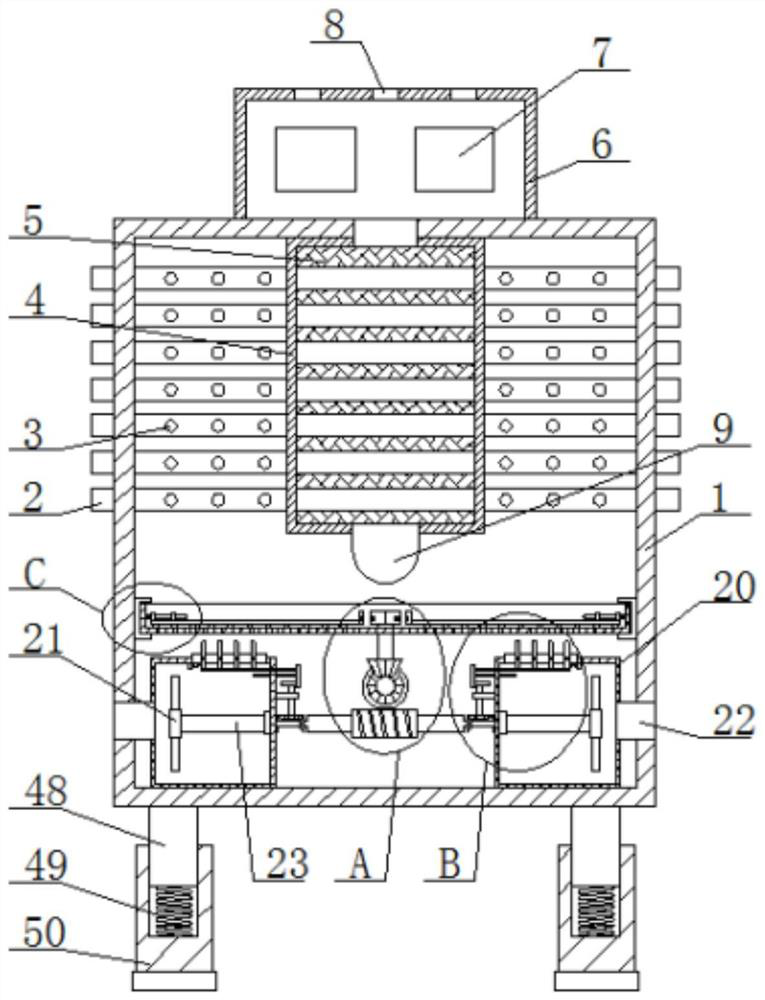

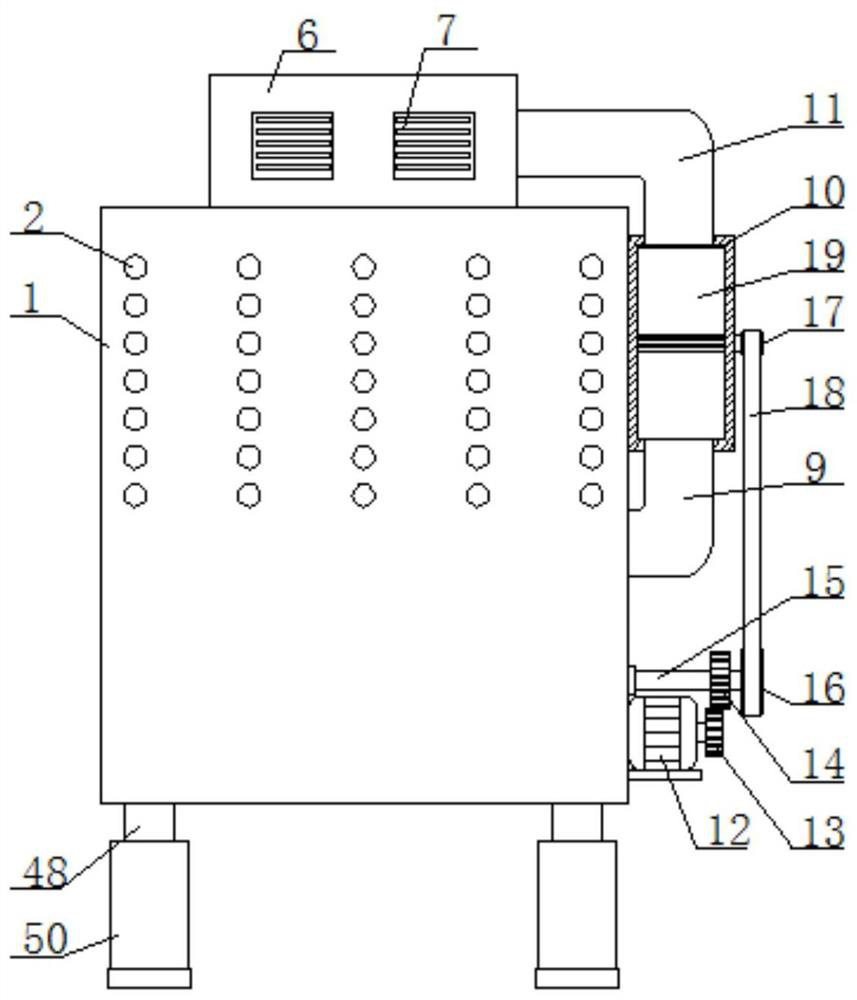

[0031] refer to Figure 1-7, a suction cooling device for the production of polyester-nylon composite yarn, comprising a refrigeration cabinet 1, a case cover 51 is installed on the front of the refrigeration cabinet 1, a plurality of guide wire pipes 2 are arranged in the refrigeration cabinet 1, and a Cooling box 4, a plurality of wire guide tubes 2 are located in the cooling box 4, the cooling box 4 is filled with insulation cotton 5, the insulation cotton 5 is wrapped on the outside of the wire guide tube 2, and the outside of the wire guide tube 2 is provided with a plurality of air holes 3. A plurality of air holes 3 are located on the outside of the cooling box 4. The top of the cooling box 4 is connected to a refrigeration mechanism. The outside of the refrigeration cabinet 1 is connected to a suction cylinder 10. A propeller 19 is installed in the suction cylinder 10, and the suction cylinder The bottom of 10 communicates with the bottom of the cooling box 4 with a su...

Embodiment 2

[0047] refer to Figure 1-7 , a suction cooling device for the production of polyester-nylon composite yarn, comprising a refrigeration cabinet 1, a case cover 51 is installed on the front of the refrigeration cabinet 1, a plurality of guide wire pipes 2 are arranged in the refrigeration cabinet 1, and a Cooling box 4, a plurality of wire guide tubes 2 are located in the cooling box 4, the cooling box 4 is filled with insulation cotton 5, the insulation cotton 5 is wrapped on the outside of the wire guide tube 2, and the outside of the wire guide tube 2 is provided with a plurality of air holes 3. A plurality of air holes 3 are located on the outside of the cooling box 4. The top of the cooling box 4 is connected to a refrigeration mechanism. The outside of the refrigeration cabinet 1 is connected to a suction cylinder 10. A propeller 19 is installed in the suction cylinder 10, and the suction cylinder The bottom of 10 communicates with the bottom of the cooling box 4 with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com