Fuel tank with oil collection device

A technology of oil collecting device and fuel tank, which is applied in the direction of charging system, liquid fuel feeder, engine components, etc., can solve the problem of weak oil collecting and storage capacity, achieve stable liquid level, improve equipment operation safety, The effect of high volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation will be described below in conjunction with the accompanying drawings.

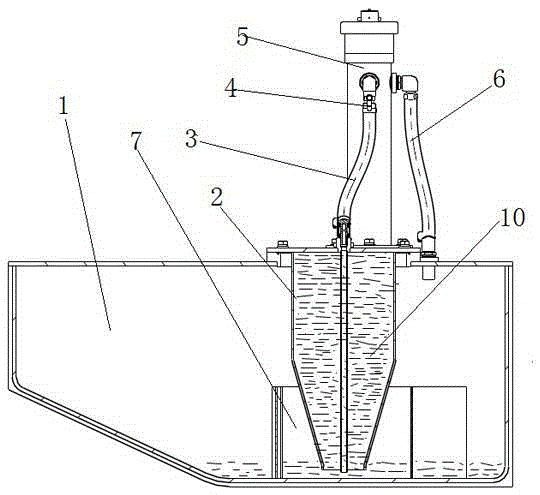

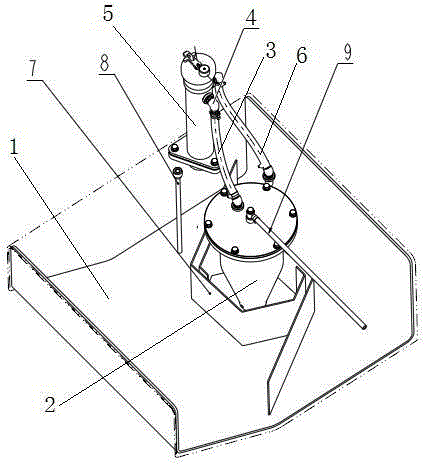

[0021] Such as figure 1 Shown, the fuel tank among the present invention comprises casing 1, is provided with oil collecting device 7 at casing bottom, and casing 1 is provided with the filling pipe 5 that refuels in casing, oil return pipe 8, oil collecting tank 2, An air return pipe 6 is also connected between the oil filling pipe 5 and the top of the casing 1 .

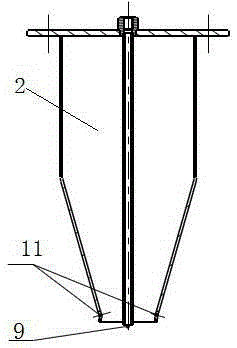

[0022] Such as Figure 6 As shown, the oil collecting device 7 comprises two shrouds 71, and the two shrouds 71 are welded on the bottom plate of the box and are perpendicular to the bottom plate. Combined to form an oil collection chamber, the coaming handle 73 of one of the coaming boards is directed obliquely backward, and the coaming board handle of the other coaming is pointed forward obliquely, and the coaming board handle of each curved The coaming hook of the bent plate forms an oil collection ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com