Diesel engine external-cycle oil tank structure

A diesel engine and external circulation technology, which is applied to mechanical equipment, engine components, machines/engines, etc., to achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

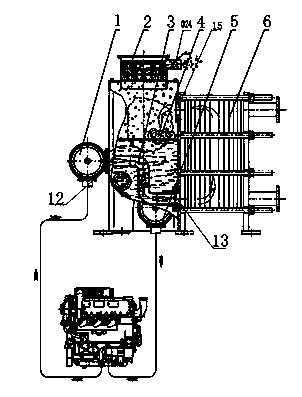

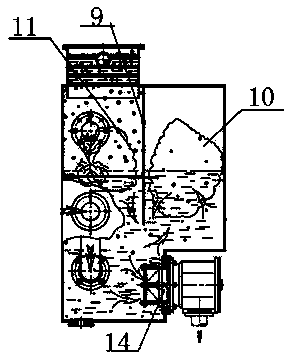

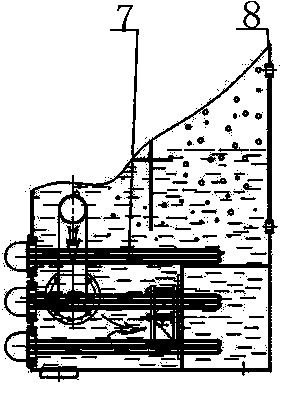

[0018] As shown in the figure, a diesel engine external circulation oil tank structure, which includes an oil-gas separator assembly 2, an oil return cannula 3 inside the oil tank, a defoaming partition 4, a lubricating oil heat exchanger 6, and a longitudinal partition 9 of the oil tank, the oil tank The middle part is divided into a front oil storage unit 10 and a rear oil storage unit 11 by a fuel tank longitudinal partition 9, and the fuel tank longitudinal partition 9 is aligned and welded with the upper edge of the fuel tank; The plate 4 and the diesel engine oil inlet 14, the defoaming partition 4 divides the rear oil storage unit 11 into two parts, the upper cavity and the lower cavity, and the oil return cannula 3 inside the fuel tank is arranged under the defoaming partition 4 and connected with the rear oil storage The oil return port 12 of the unit 11 communicates with the oil outlet 13, and the oil outlet 13 communicates with the upper cavity of the rear oil st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com