BP price-adjusting, degassing and acid-adjusting integrated device and method in Purex process

A technology for acid regulation and process, applied in Purex process BP price regulation, acid regulation integrated device, degassing field, can solve the problems of excessive consumption of nitrogen oxides, poor economy, complicated operation, etc., to reduce consumption and save The effect of post-processing cost and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

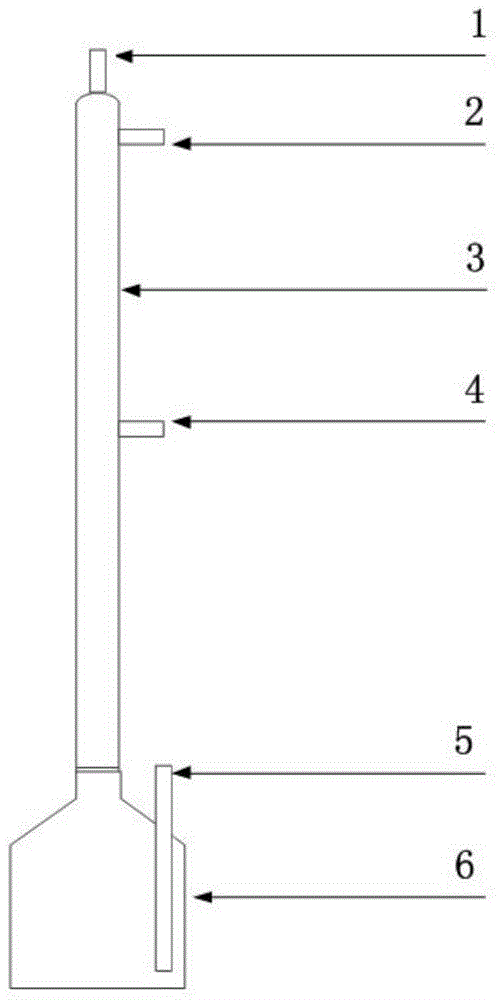

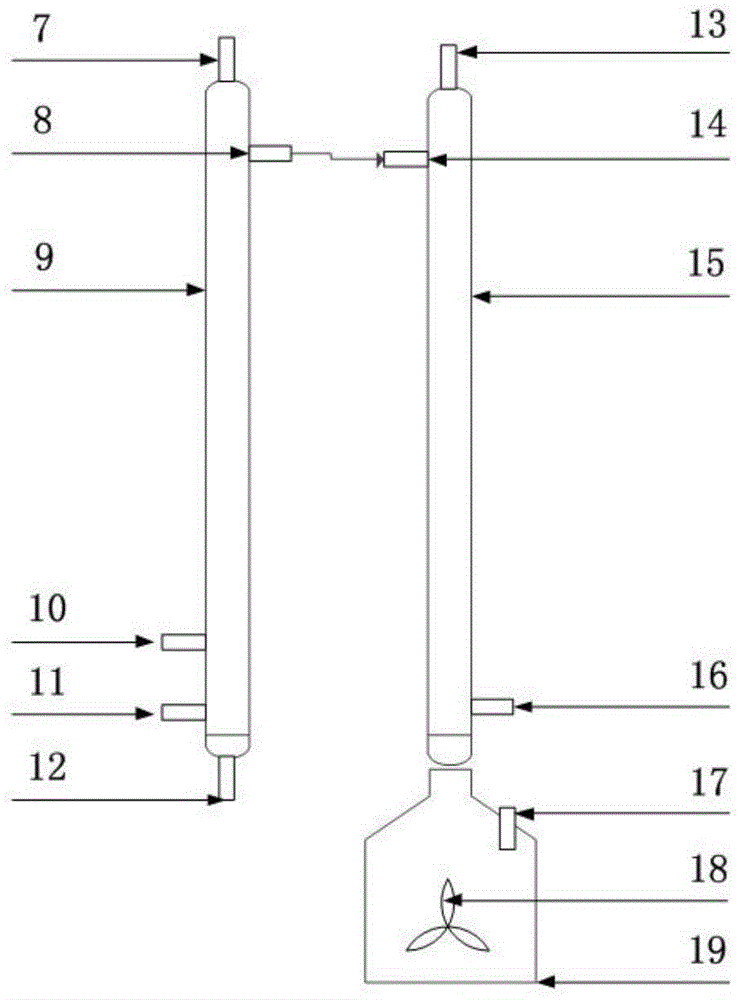

Method used

Image

Examples

Embodiment 1

[0022] Using the Purex process BP price adjustment, degassing, and acid adjustment integrated device and method of the present invention to treat a certain 1BP feed liquid, the reducing agent in the 1BP feed liquid is dimethyl hydroxylamine-methyl Hydrazine salt-free reducing agent, the specific steps are as follows:

[0023] (1) Through the BP feed liquid inlet, NO 2 The feed port and the feed pipeline are continuously fed with BP feed liquid and NO 2 , air, let NO 2 The oxidation-reduction reaction occurs in countercurrent contact with the reducing agent, and the NO produced by the reaction is quickly absorbed by the O in the air. 2 Oxidation to NO 2 , continue to undergo oxidation-reduction reaction with the reducing agent, so as to realize the price adjustment of Pu, and the excess nitrogen oxides are transported to the exhaust gas treatment system through the exhaust gas outlet;

[0024] (2) After completing the price adjustment of Pu, stop feeding NO 2 , continue to...

Embodiment 2

[0028] Using the Purex process BP price adjustment, degassing, and acid adjustment integrated device and method of the present invention to process a certain 2BP feed liquid, the specific steps are as follows:

[0029] (1) Through the BP feed liquid inlet, NO 2 The feed port and the feed pipeline are continuously fed with BP feed liquid and NO 2 , air, let NO 2 The oxidation-reduction reaction occurs in countercurrent contact with the reducing agent, and the NO produced by the reaction is quickly absorbed by the O in the air. 2 Oxidation to NO 2 , continue to undergo oxidation-reduction reaction with the reducing agent, so as to realize the price adjustment of Pu, and the excess nitrogen oxides are transported to the exhaust gas treatment system through the exhaust gas outlet;

[0030] (2) After completing the price adjustment of Pu, stop feeding NO 2 , continue to pass air into the feed liquid through the feed pipe to remove excess nitrous acid in the feed liquid, convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com