Uranium purification method for simultaneously removing neptunium and plutonium in nuclear fuel Purex post-treatment process

A purification method and nuclear fuel technology, applied in the purification of uranium from plutonium, and the removal of neptunium at the same time, can solve the problems that cannot be realized and the concentration requirements are harsh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Evaporation concentration test of simulated 1CU feed liquid

[0041] Will contain 60g / L uranium, 2.6×10 -2 The simulated 1CU feed solution of g / L Np(IV) and 0.1mol / L nitric acid was evaporated and concentrated at 100°C under normal pressure, and the evaporation process took a total of 2 hours. After evaporation and concentration, the uranium concentration in the 1CU concentrated solution is 350g / L, the total Np concentration is 0.150g / L, and the Np(IV) concentration is 2.83×10 -3 g / L, that is, more than 98% of Np(IV) in 1CU feed solution was oxidized to a high valence state, and the effect of evaporative concentration pretreatment on Np valence state was satisfactory.

Embodiment 2

[0042] Embodiment 2: Comparative test of hydroxylamine stripping and hydroxylamine reduction

[0043] The single-stage back-extraction method was used to investigate the effect of hydroxylamine back-extraction trace Pu(IV), and the results are shown in Table 1. In the experiment, the uranium concentration in the organic phase was 90g / L, the plutonium concentration was 34.5μg / L, and the nitric acid concentration was 0.1mol / L; . The single-stage back-extraction experiment was carried out with extraction tubes at room temperature, and the phase ratio during back-extraction was 6:1, shaken by hand for 2 minutes, and centrifuged to separate the phases. The experimental results show that the stripping rate of Pu(IV) in the organic phase is about 90% only relying on hydroxylamine to reduce the trace amount of Pu(IV) in the organic phase, and the stripping rate of plutonium does not increase significantly with the increase of stripping times. Relying only on hydroxylamine-hydrazine ...

Embodiment 3

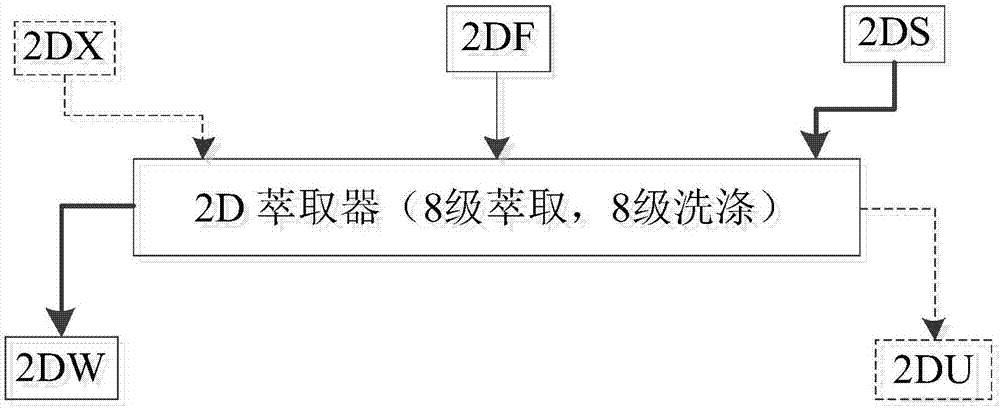

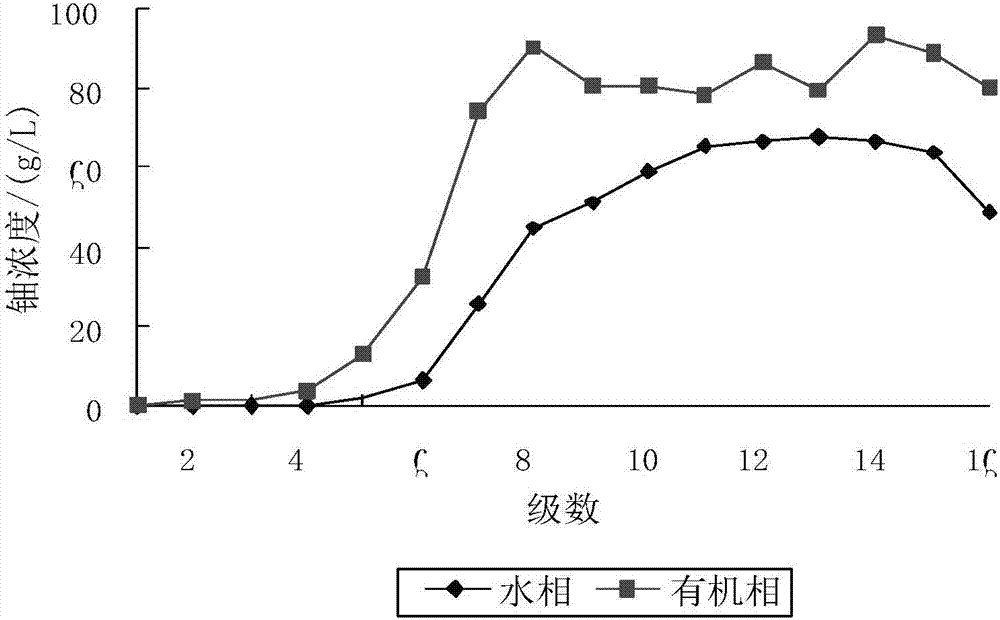

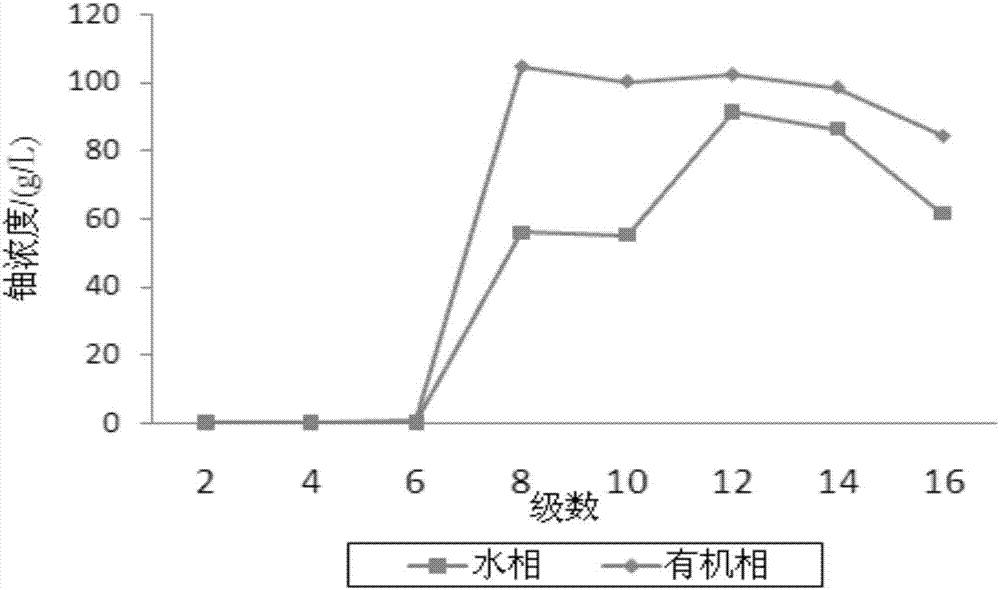

[0049] Example 3: Test of the Effect of Feed Uranium Concentration on the Saturation of Organic Phase Uranium in the Extractor

[0050] Through process experiments, the distribution of uranium concentration in each stage is compared when 1CU feed liquid is evaporated or not (that is, the concentration of feed uranium is different), so as to compare the influence of feed uranium concentration on the uranium saturation of the organic phase in the extractor. Schematic diagram of uranium purification process figure 1 As shown, the experimental parameters are shown in Table 3, and the experimental results are shown in figure 2 , 3 shown. Through comparison, it can be found that even in the set dilute uranium feed process, 2DU (2DU is the organic phase with uranium extracted, 2DW is the nitric acid waste liquid containing residual reducing agent and trace uranium, neptunium and plutonium) has a higher concentration of uranium at the outlet (diluted uranium The measured value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com