Process method and device for recycling nitric acid from uranium-bearing wastewater

A process method and technology of nitric acid, applied in the directions of nitric acid, nitrogen oxides/oxyacids, fractionation, etc., can solve problems such as explosion of red oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

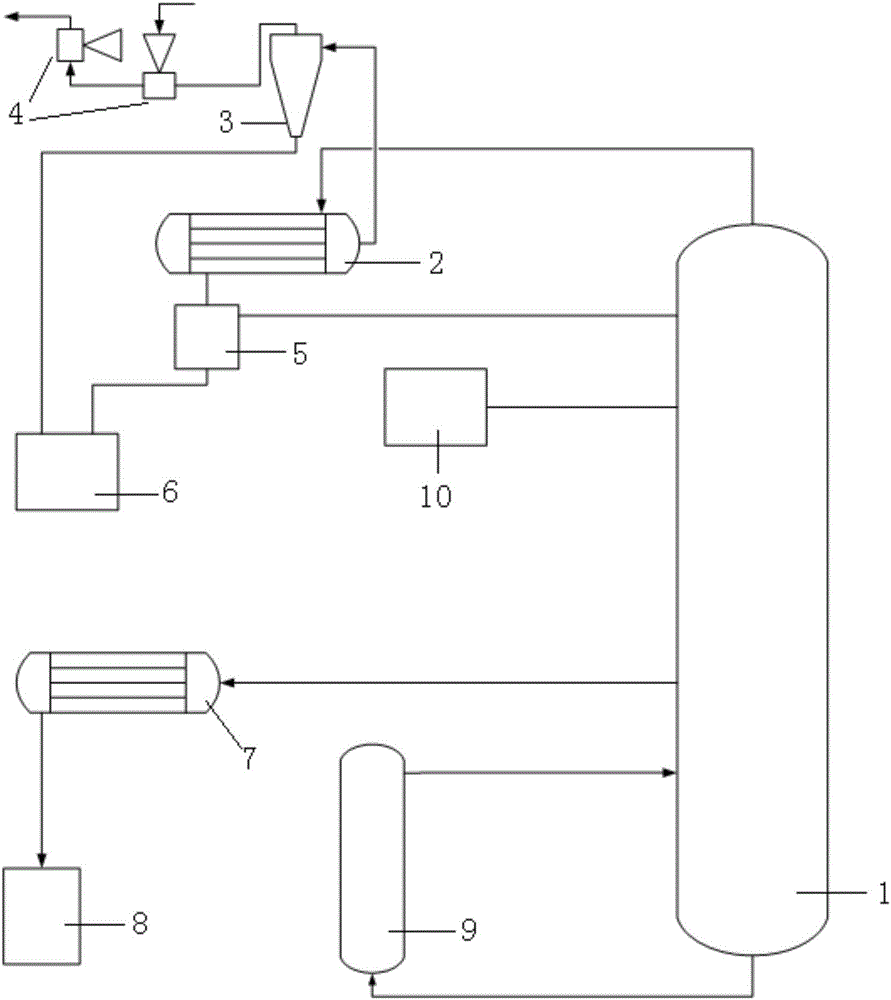

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] According to the technical scheme of nitric acid recovery in uranium-containing waste liquid, combined with the physical and chemical properties of nitric acid aqueous solution, the technical route of nitric acid recovery in uranium-containing waste liquid and the devices embodied are as follows: figure 1 shown.

[0045] A process for recovering nitric acid in uranium-containing waste liquid of the present invention comprises the following steps;

[0046] (1) The concentration of nitric acid produced in the uranium purification production is 1.0mol / L-2mol / L, and the uranium-containing acidic waste liquid with a uranium concentration of 0.01-0.10g / L enters the header tank,

[0047] A side feed port is set up at a horizontal height of 12000mm from the horizontal plane of the rectification tower;

[0048] The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com