Virtual reality system and method for nuclear fuel reprocessing plant head end

A technology of virtual reality and nuclear fuel, applied in the field of virtual reality, can solve the problems of multi-energy consumption, huge space occupation, lack of information feedback, etc., and achieve the effects of strong immersion, small space occupation and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

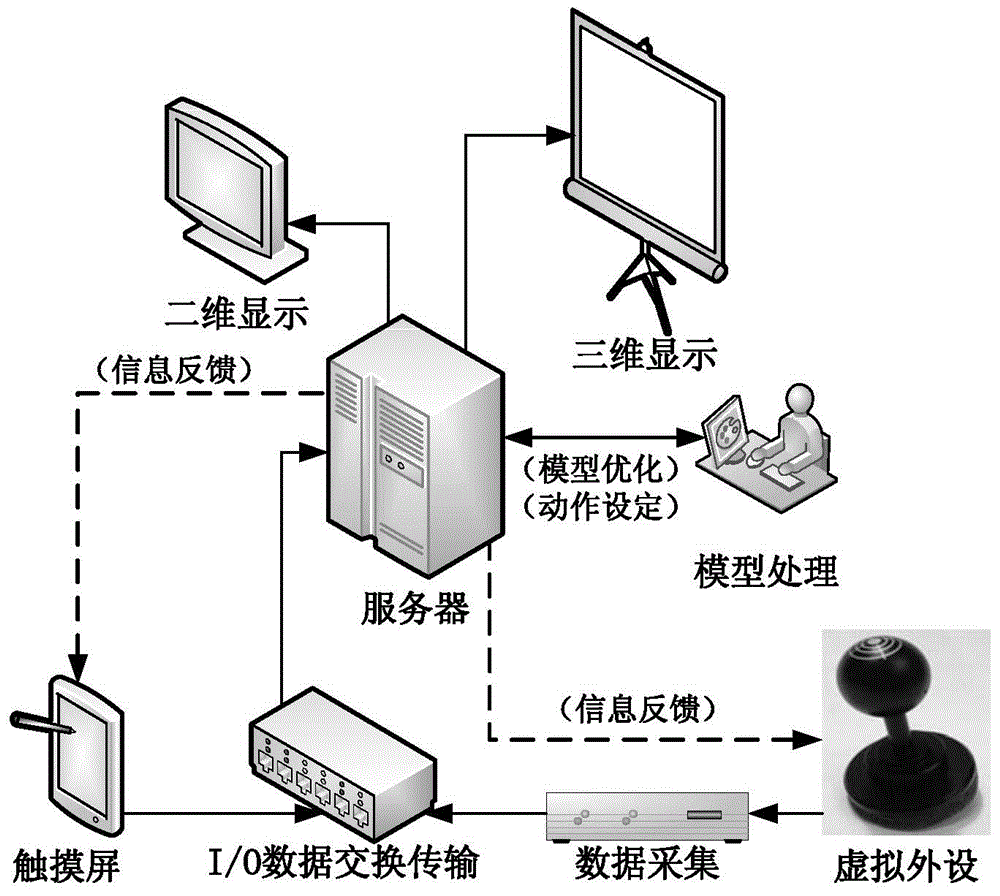

[0029] Such as figure 1 As shown, the basic composition of a head-end virtual reality system of a nuclear fuel reprocessing plant mainly includes a two-dimensional display unit, a three-dimensional display unit, a server, a model processing unit, a touch screen, an I / O data exchange transmission unit, a data acquisition unit and a virtual exterior Assume.

[0030] Among them, the two-dimensional display unit adopts an ordinary liquid crystal display screen, and by installing the camera at a fixed position on the three-dimensional model, the display effect of the virtual hot-room camera is achieved; the three-dimensional display unit adopts the method of rear projection in a black box, which reduces the space occupied by the system. The server is the main device for data storage and processing, which receives virtual control instructions and transmits and displays the corresponding data on the two-dimensional display unit and the three-dimensional display unit. The model proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com