A two-stage pyrolysis gasification system for solid waste

A solid waste, pyrolysis gasification technology, applied in gasification process, granular/powdered fuel gasification, combustible gas production, etc., can solve the problem of power generation and gas supply not running normally, hindering biomass pyrolysis gasification Technology popularization and application, low tar content and other issues, to increase stability and operational flexibility, improve pyrolysis gasification efficiency, and benefit desulfurization and dechlorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

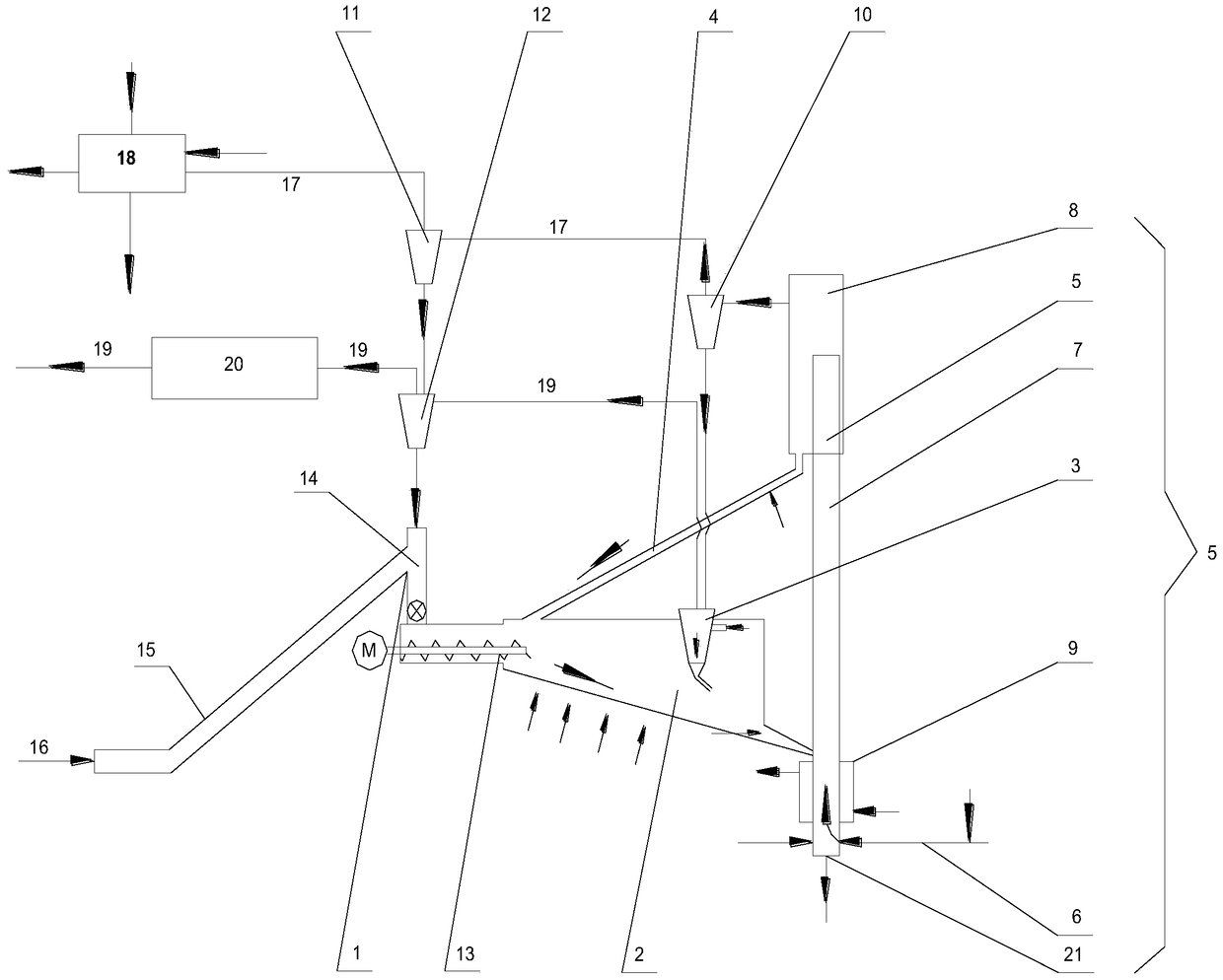

[0028] See figure 1 As shown, the solid waste two-stage pyrolysis gasification system of the present invention has a solid waste material feeding system 1, a pyrolyzer 2, a circulating fluidized bed oxidation gasifier system 5, and an oxidation gasifier cyclone separation device and cyclone separation reactor, wherein the solid waste feed system 1 is connected to the pyrolyzer 2; the output port of the pyrolyzer 2 is connected to the circulating fluidized bed oxidation gasifier system 5 through a pipeline; the circulating fluidized bed The output end of the oxidation gasifier system 5 is connected to the input end of the oxidation gasifier cyclone separator, the output end of the oxidation gasifier cyclone separator is connected to the cyclone separation reactor, and the cyclone separation reactor is connected to the pyrolyzer 2 connected connection.

[0029] The oxidation gasifier cyclone separator includes the oxidation gasifier primary cyclone separator 10 and the oxidation ...

Embodiment 2

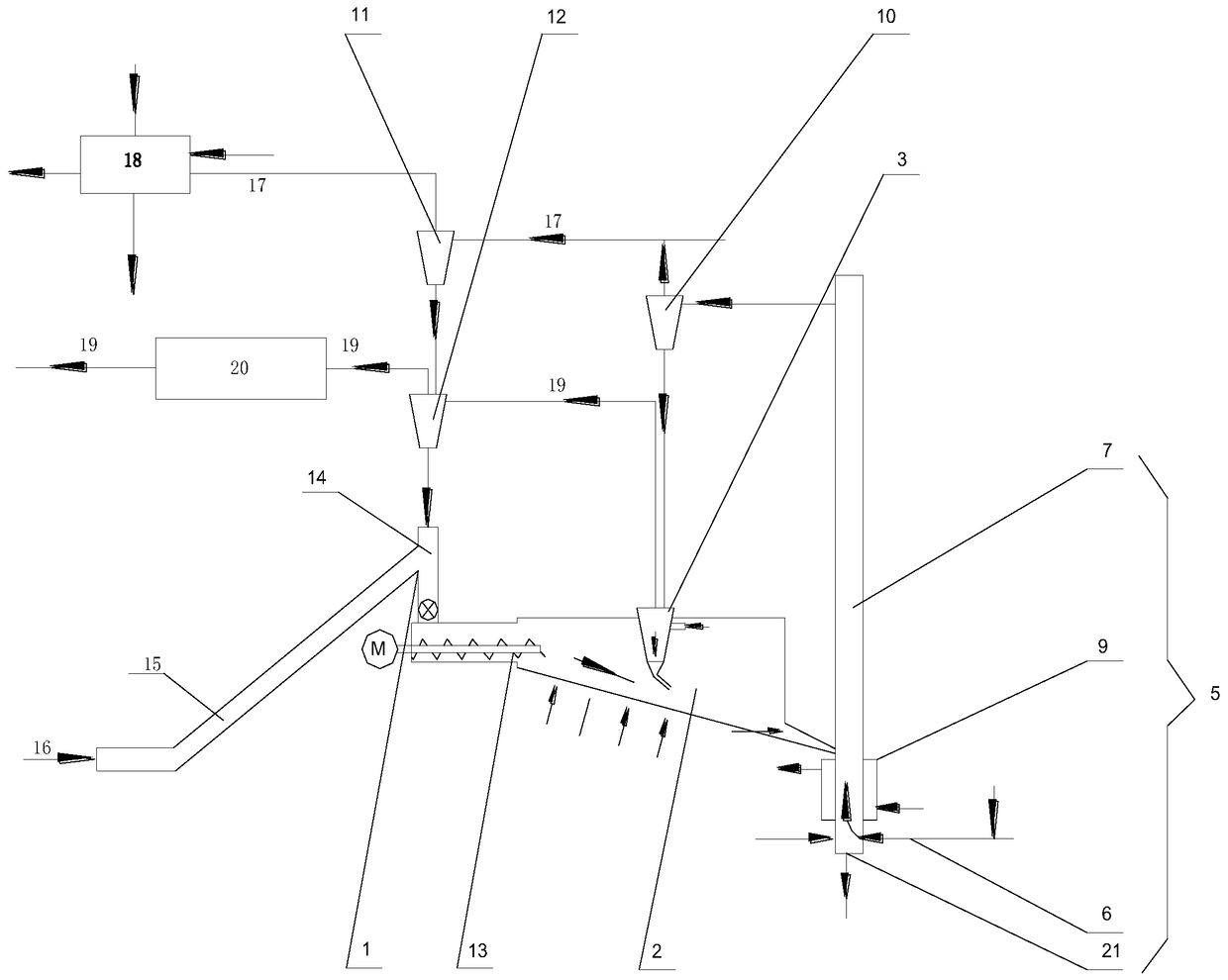

[0037] See figure 2 As shown, the difference from Embodiment 1 is that the circulating fluidized bed oxidation gasifier system 5 uses a single-tube reactor with the same diameter, which sequentially includes a riser 7, an air intake system 6 at the bottom, and a slag The outlet 21 and the steam generator 9 arranged outside the tube wall of the circulating fluidized bed oxidation gasifier system 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com