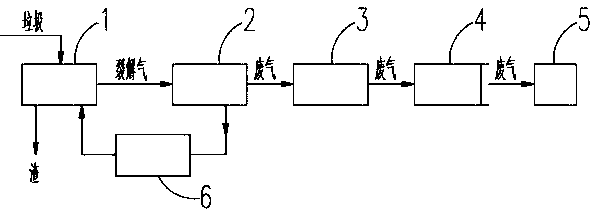

A waste pyrolysis gasification system

A technology of pyrolysis gasification and garbage, which is applied in the field of garbage pyrolysis gasification system, can solve problems such as unsatisfactory combustion effect, uncontinuous operation of the device, insufficient pyrolysis gasification, etc., to meet the needs of garbage treatment and shorten construction Cycle, the effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

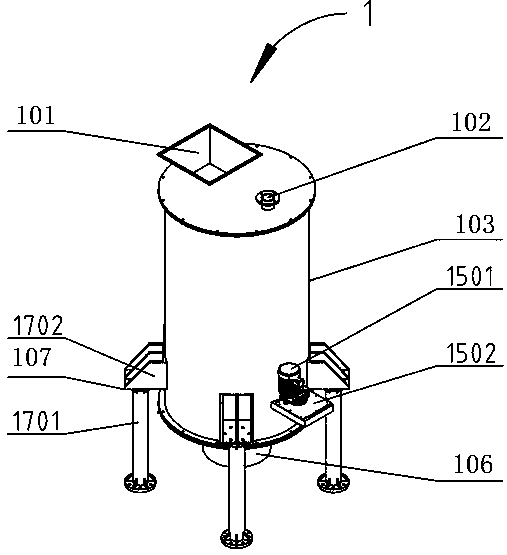

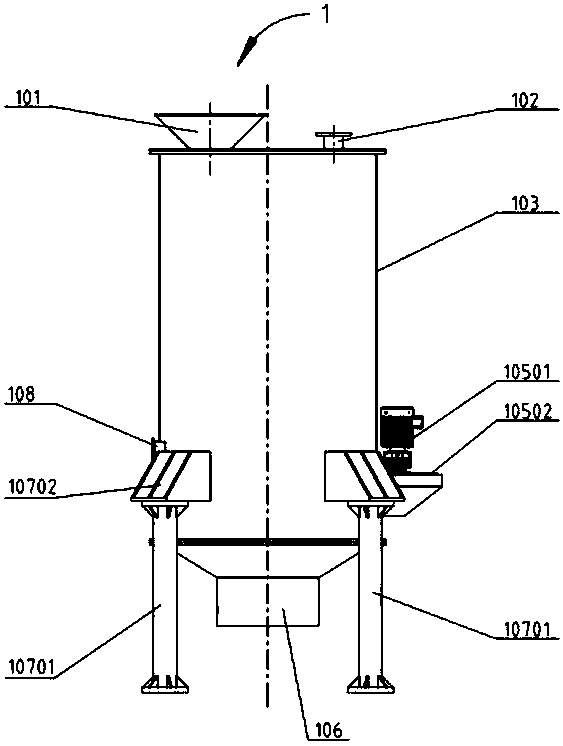

[0041] On the basis of the foregoing embodiments, in this embodiment, the pyrolysis gasifier 1 includes a feed inlet 101, a cracked gas outlet 102, a pyrolysis gasifier furnace body 103, a rotary grate 104, and the grate drives Device 105, slag outlet 106, furnace support structure 107, manhole 108 and pyrolysis gasifier burner 109; feed inlet 101 and cracked gas outlet 102 are located at the upper end of pyrolysis gasifier furnace body 103, and the rotary grate 104 is located at the bottom of the pyrolysis gasification furnace body 103, and the grate driving device 105 is located at the lower side outside the pyrolysis gasification furnace body 103; the slag outlet 106 is arranged at the bottom of the pyrolysis gasification furnace body 103, The bottom of the pyrolysis gasification furnace body 103 is connected to the furnace body support structure 107; the manhole 108 is located on the lower side outside the pyrolysis gasification furnace body 103 and is not on the same side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com