Tunnel type biomass pyrolysis gasification incinerator

A pyrolysis gasification and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high operating costs, uneven drying of transmission equipment, etc., to avoid tunnel accumulation and improve pyrolysis gasification efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

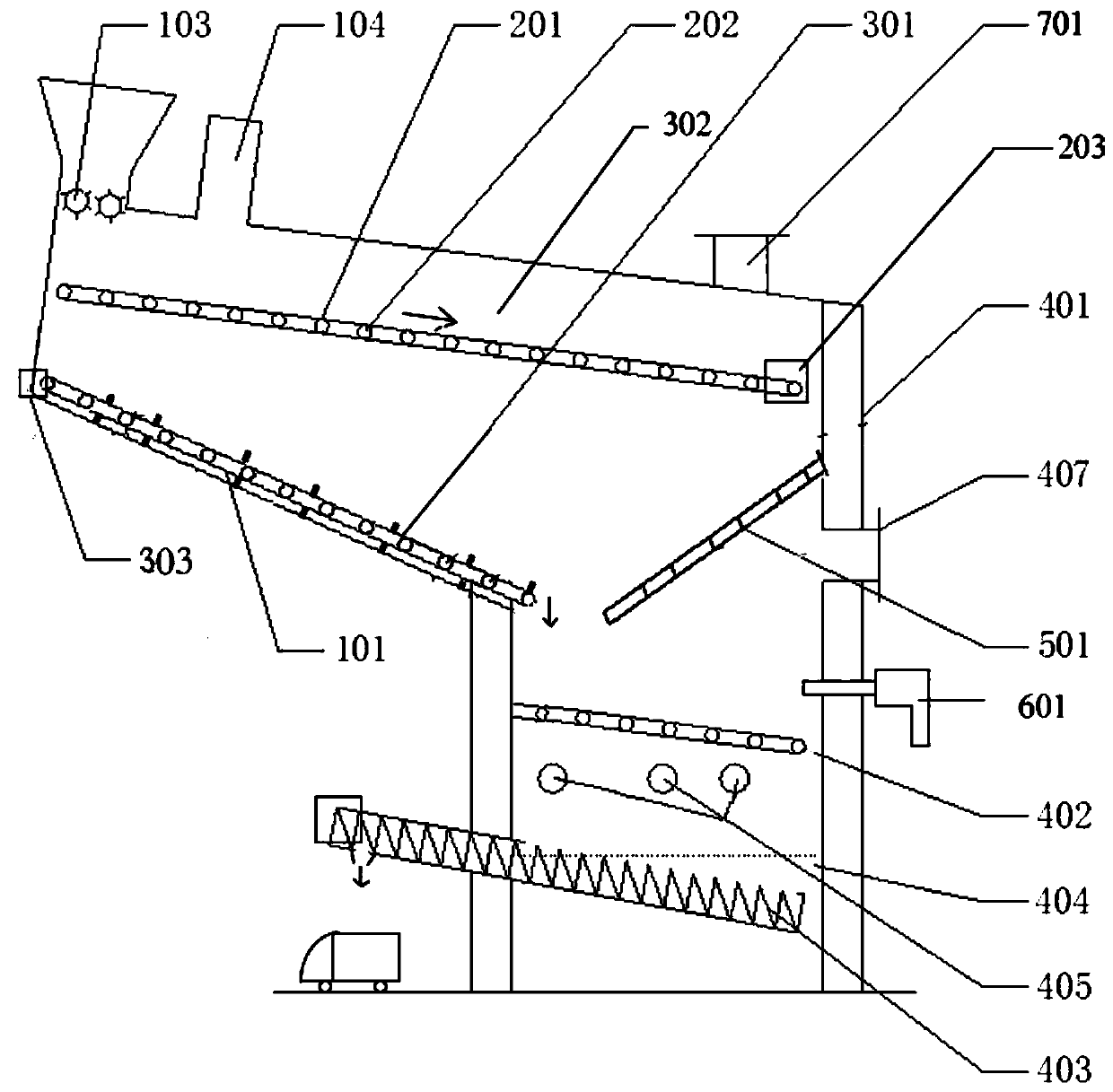

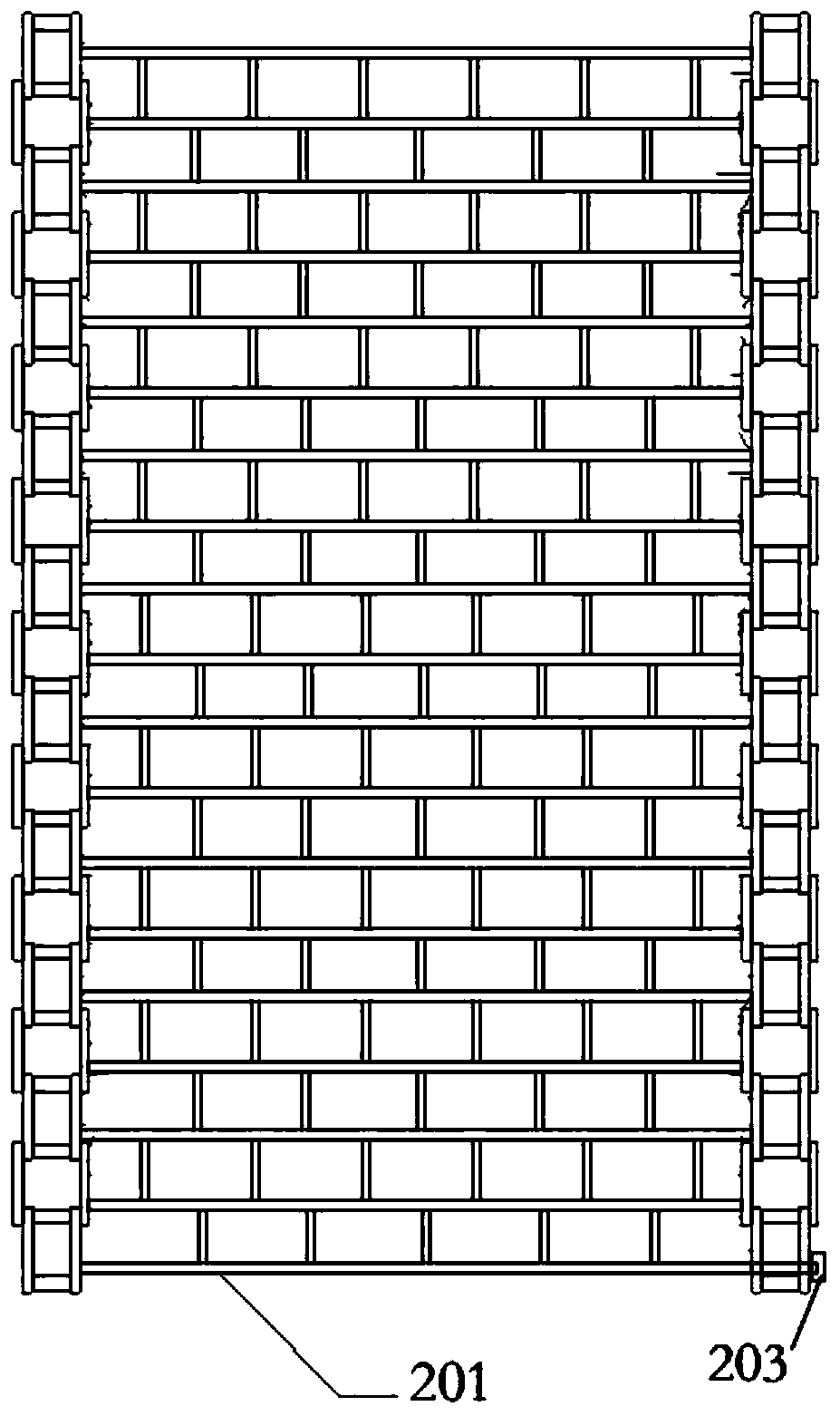

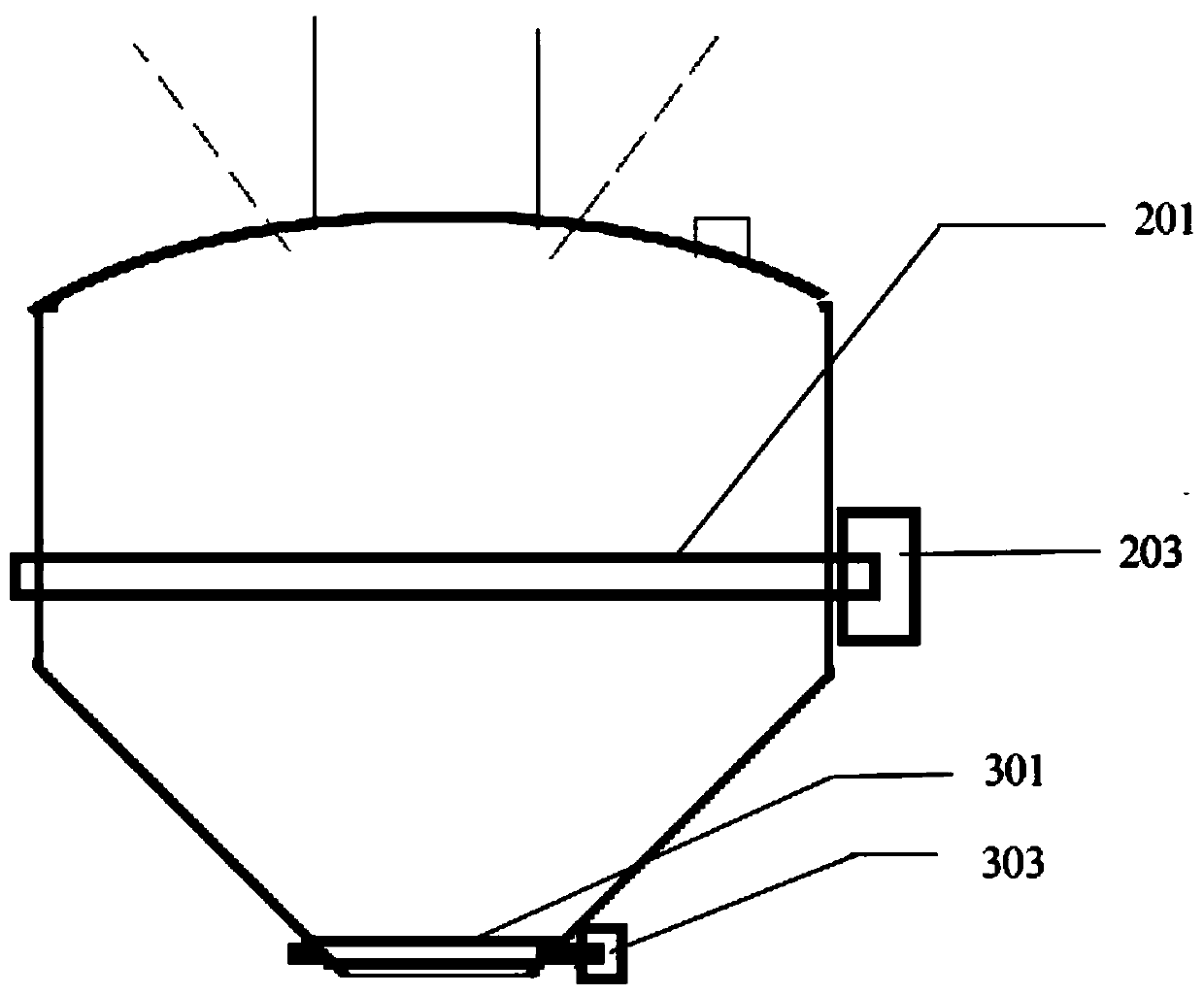

[0035] Please also refer to figure 1 as well as figure 2 , this embodiment discloses a tunnel-type biomass pyrolysis gasification incinerator, including a pyrolysis channel 101 , a chain metal conveyor belt 201 , a slag scraper 301 and an incinerator 401 . The pyrolysis channel 101 is provided with a feed port and a discharge port, and the pyrolysis channel 101 is arranged obliquely. low end. The chain metal conveyor belt 201 is arranged in the pyrolysis channel 101, and the guide wheel 202 is arranged along the length direction of the pyrolysis channel 101. The chain metal conveyor belt 201 is sleeved on the guide wheel 202, and is laid The material bearing surface is formed above the direction, and the surface of the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com