Two-section type pyrolysis-gasification revolving bed for biomass and pyrolysis gasification method

A technology of pyrolysis gasification and rotating bed, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc. It can solve the problems of destroying the gas flow of the fluidized bed, reducing the heat transfer efficiency, and unstable operation of the fluidized bed, etc. Achieve the effects of improving efficiency and gasification gas quality, avoiding biomass bridging, improving yield and pyrolysis gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

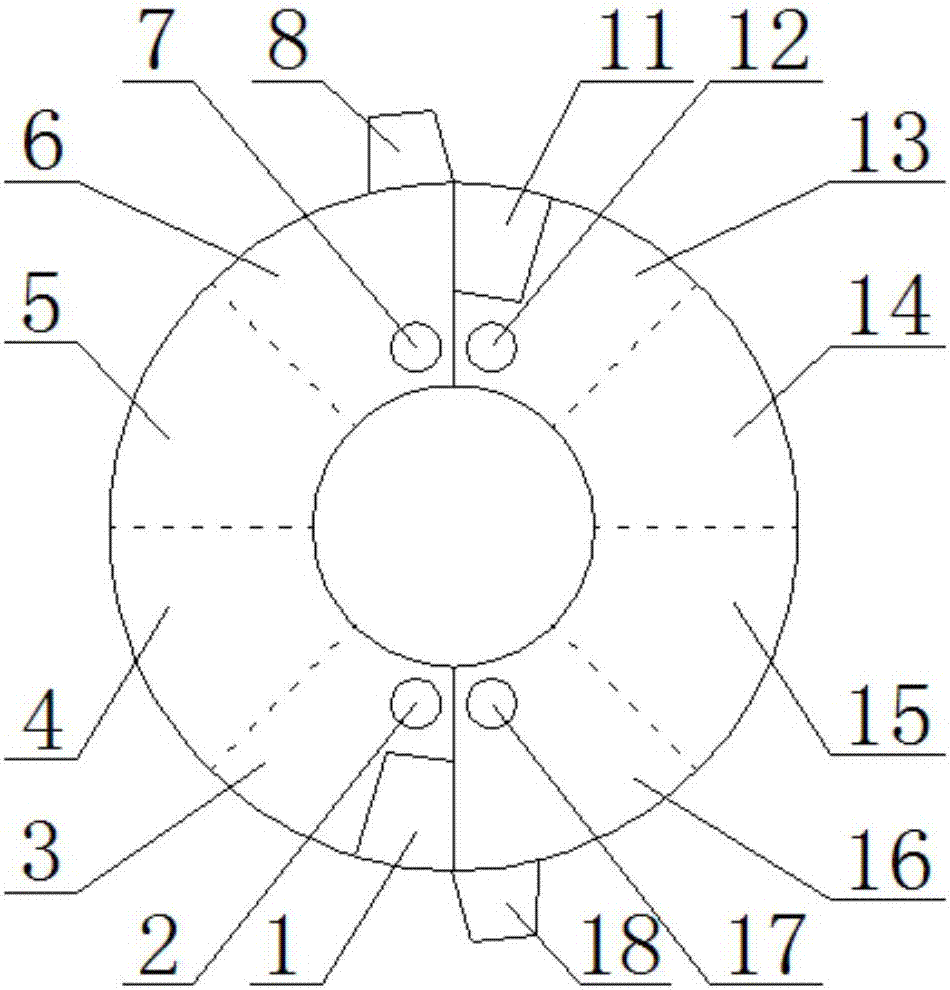

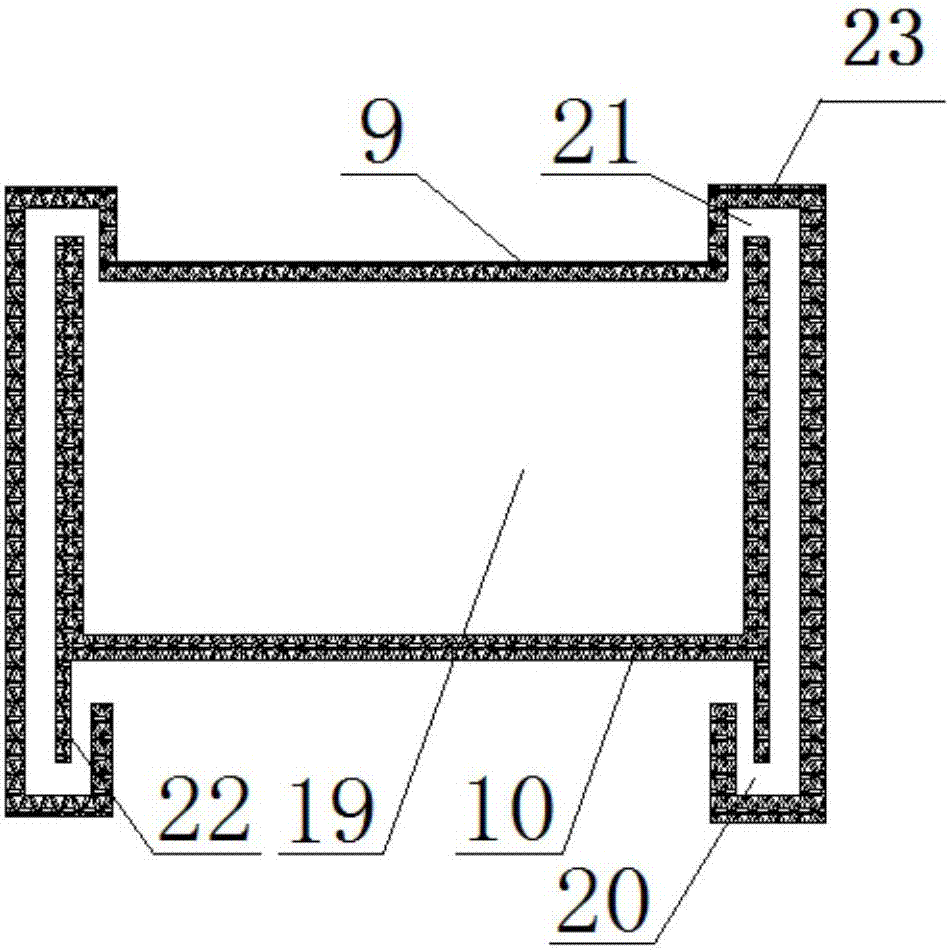

[0030] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

[0031] The purpose of the technical solution of the present invention is to improve the productivity of the biomass pyrolysis gasifier and the quality of the pyrolysis gas, so as to facilitate the continuous feeding and operation on the disc. The design idea of the present invention is to combine the pyrolysis downstream type and countercurrent type, that is, the feed port is adjacent to the feed port, the air inlet is adjacent to the air inlet, and the gasification gas outlet is adjacent to the gasification gas outlet. , multi-stage biomass pyrolysis can be carried out at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com