Pyrolysis gasification garbage treatment system and garbage treatment system

A waste treatment system and pyrolysis gasification technology, applied in the field of pyrolysis gasification waste treatment system and waste treatment system, can solve the problems of high energy, low waste pyrolysis and gasification efficiency, gas environment pollution, etc. The effect of high degasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

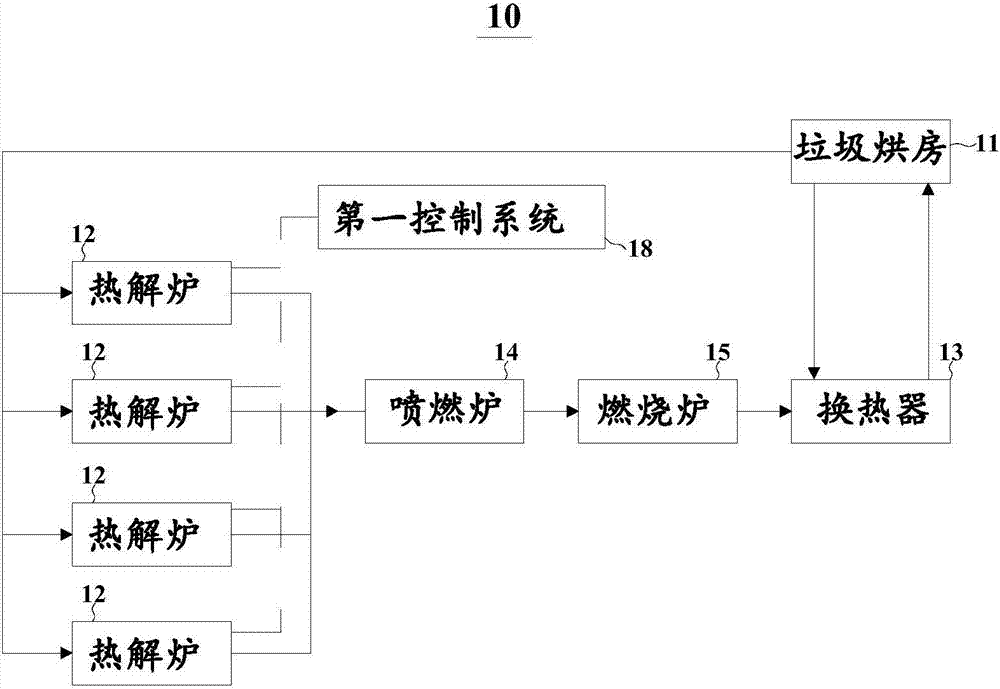

[0046] This embodiment provides a pyrolysis and gasification garbage treatment system 10, through which the pyrolysis and gasification garbage treatment system 10 can effectively perform pyrolysis and gasification with low energy consumption, so that the gas discharged from combustion does not pollute the environment.

[0047] Please refer to figure 1 , figure 1 A schematic diagram of the pyrolysis gasification waste treatment system 10 provided in this embodiment is shown.

[0048] The pyrolysis gasification waste treatment system 10 includes a waste drying room 11 , at least two pyrolysis furnaces 12 , a secondary combustion chamber, a heat exchanger 13 and a first control system 18 .

[0049] Among them, the garbage drying room 11 is used for drying garbage, and the pyrolysis furnace 12 has a feeding part and a combustible gas discharge part. And the combustion outlet, the combustion inlet is communicated with the combustible gas discharge parts of at least two pyrolysis ...

Embodiment 2

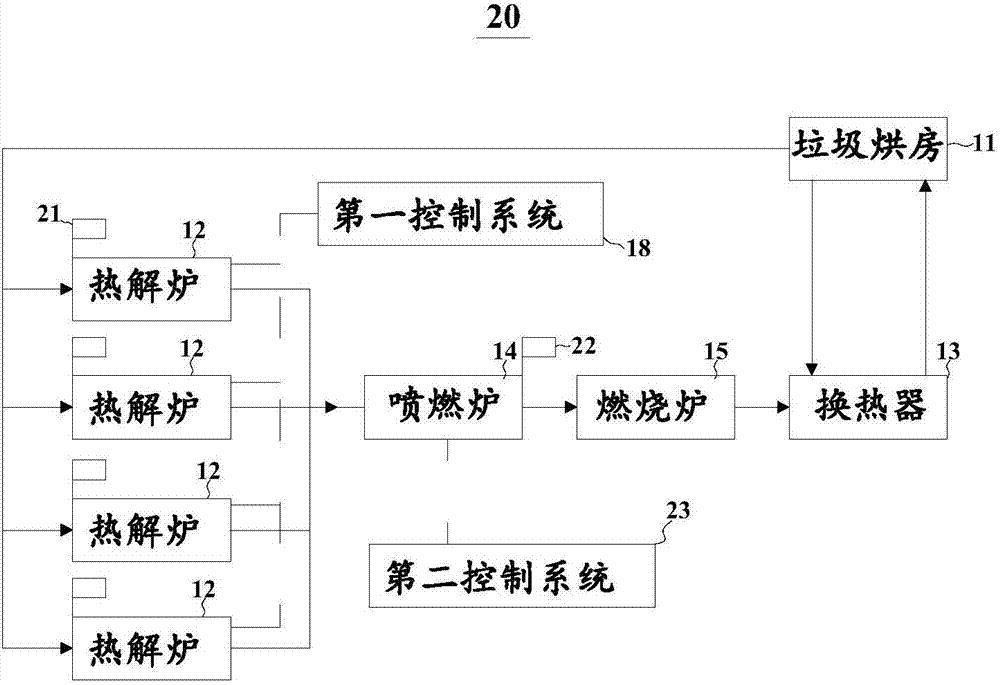

[0058] This embodiment provides a pyrolysis gasification waste treatment system 20, which is based on the pyrolysis gasification waste treatment system 10, please refer to figure 2 , figure 2 A schematic diagram of the pyrolysis gasification waste treatment system 20 in this embodiment is shown.

[0059] The pyrolysis gasification waste treatment system 20 also includes a second temperature sensor 22, a second control system 23 and the first temperature sensor 21 having the same number as the pyrolysis furnace 12, and a plurality of first temperature sensors 21 are respectively arranged in the pyrolysis In the furnace 12 , the first temperature sensors 21 respectively sense the furnace temperature of the corresponding pyrolysis furnace 12 .

[0060] When the first control system 18 receives a signal that the temperature sensed by the first temperature sensor 21 does not reach the first preset temperature, it controls the combustion air nozzle in the pyrolysis furnace 12 to ...

Embodiment 3

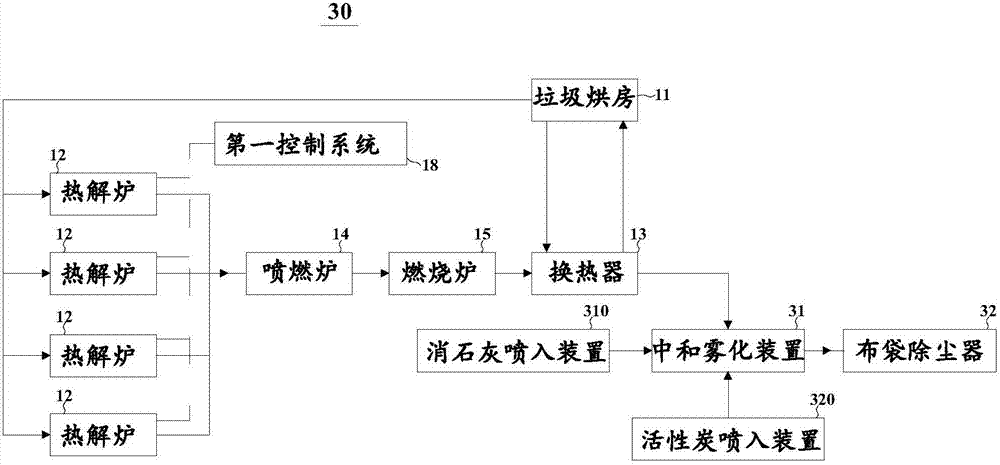

[0064] Please refer to image 3 , image 3 A schematic diagram of the pyrolysis gasification waste treatment system 30 provided in this embodiment is shown.

[0065] Based on the pyrolysis and gasification garbage treatment system 10, the pyrolysis and gasification garbage treatment system 30 also includes a neutralization atomization device 31 and a bag filter 32, so as to treat the gas discharged from the combustion furnace 15 and further reduce the pollution to the atmosphere .

[0066] The neutralization and atomization device 31 is connected to the gas outlet of the heat exchanger 13, and the neutralization and atomization device 31 is used to treat the harmful gas discharged from the secondary combustion chamber, specifically, through the neutralization and atomization device 31, the smoke passes through the mist The rapid cooling and neutralization of chemical water can effectively prevent the regeneration of dioxins, and make the flue gas go through preliminary deaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com