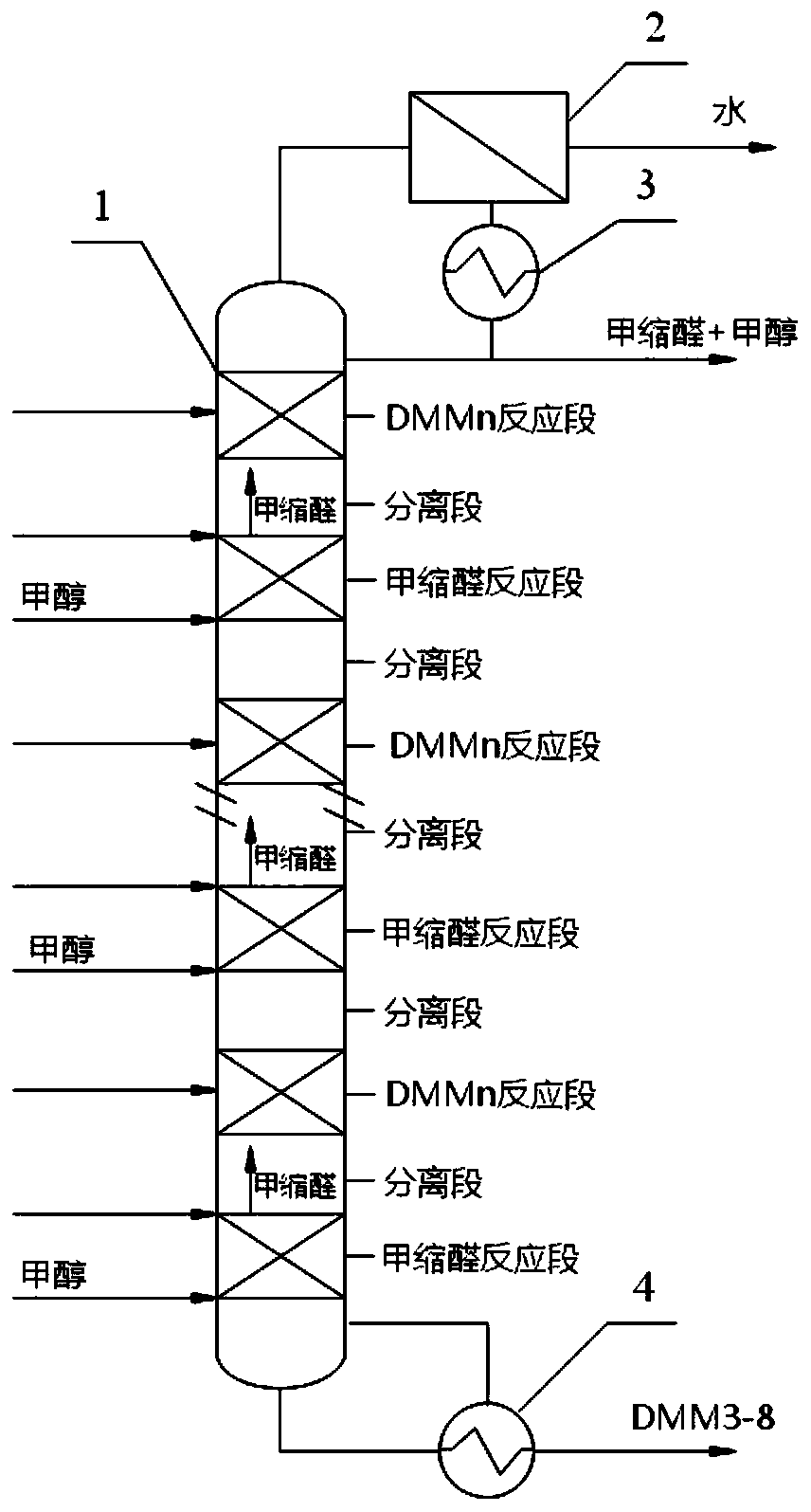

Multi-stage reactive distillation synthesis technique and device of PODEn (polyoxymethylene dimethyl ethers)

A polymethoxydimethyl ether, multi-stage reaction technology, applied in chemical instruments and methods, chemical industry, sustainable manufacturing/processing, etc., can solve the problem that the yield cannot be greatly improved, the overall process economy is low, and the circulating flow problems such as large flow rate, to achieve the effect of improving the reaction yield and selectivity, shortening the separation process, and reducing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The top operating pressure of the multi-stage reactive distillation tower is an absolute pressure of 1.5 atm, and the mass ratio of formaldehyde and methanol in the formaldehyde aqueous solution of the reactant feed in the methylal reaction section is 0.46, and the catalyst is an acidic resin catalyst, and the usage amount of the catalyst is 300kg / m3 , The mass ratio of the formaldehyde in the reactant feed formaldehyde solution on the polyoxymethylene dimethyl ether reaction section and the methanol feedstock on the formaldehyde reaction section is 4.5, and the catalyst is an acidic resin catalyst, and the usage amount of the catalyst is 350kg / m3,, The reflux ratio at the top of the tower is 9; the catalytic packing of the methylal reaction section is 1 m / layer, a total of 4 layers, and the catalytic packing of the polyoxymethylene dimethyl ether reaction section is 1.5 m / layer, a total of 4 layers, two stages The separation section packing between the reaction sections...

Embodiment 2

[0031] The operating pressure at the top of the multi-stage reactive distillation tower is 5 atm absolute pressure, the mass ratio of formaldehyde to methanol in the formaldehyde solution fed to the methylal reaction section is 0.6, the catalyst is an acidic molecular sieve catalyst, and the amount of catalyst used is 100kg / m 3 , The mass ratio of the formaldehyde in the reactant feed formaldehyde solution in the polyoxymethylene dimethyl ether reaction section and the methanol feedstock on the formaldehyde reaction section is 1.5, and the catalyst is an acidic molecular sieve catalyst, and the usage amount of the catalyst is 120kg / m 3 , the top reflux ratio is 2; the catalytic packing of the methylal reaction section is 0.2 m / layer, a total of 8 layers, the catalytic packing of the polyoxymethylene dimethyl ether reaction section is 0.3 m / layer, a total of 8 layers, two sections The separation section packing between the reaction sections is 0.5 meters, the rectification sec...

Embodiment 3

[0034] The operating pressure at the top of the multi-stage reactive distillation tower is an absolute pressure of 1.8 atm, the mass ratio of formaldehyde and methanol in the formaldehyde solution of the reactant feed formaldehyde solution on the methylal reaction section is 0.5, the catalyst is an acidic resin catalyst, and the usage amount of the catalyst is 250kg / m 3 , the mass ratio of the formaldehyde in the reactant feed formaldehyde solution on the polyoxymethylene dimethyl ether reaction section and the methanol feedstock on the formaldehyde reaction section is 4, the catalyst is an acidic resin catalyst, and the usage amount of the catalyst is 280kg / m3, the tower The top-to-reflux ratio is 6; the catalytic trays in the methylal reaction section are 12 pieces / layer, a total of 3 layers, and the catalytic packing in the polyoxymethylene dimethyl ether reaction section is 15 pieces / layer, a total of 3 layers, two sections There are 10 trays in the separation section betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com